General Model Simulation of the Mexican Poultry Value Chain

Luis Antonio Calderón

1

and Pablo Nuño

2

1

Huatusco Institute of Technology, Veracruz, Mexico

2

Interdisciplinary Graduate Programs and Research Center, UPAEP University, Puebla, Mexico

Abstract: The use of simulation contributes to better analysis and understanding of the interactions between the major

variables of the Mexican poultry value chain. This general model of the value chain poultry considers

biological processes such as growth and reproduction, as well as economic factors and food costs operating

at different stages of industrial poultry farming. The program was designed for poultry producers in general

and for the Mexican poultry industry as an aid in the evaluation of different economic scenarios for the

production of chicken meat. Although this model is based on the Mexican poultry industry, this can be used

where operating conditions are presented here assumed. The integrated simulation model can perform

poultry simulations to establish correlations between various parameters of production and their output

under standard operating conditions at farms and stands. It can provide answers to parameters such as

growth and viability, the number and weight of birds at feedlots, the number of births and the total

production cost per kilogram. The model provides a holistic description of the production system and its

outputs, reflecting the random variation in the stalls and booths between birds, which is important to

represent the production risk. Thus, simulations of poultry value chain through this model can provide

answers to what would result if changes were made to specific production parameters.

1 INTRODUCTION

In Mexico, poultry can be classified as the livestock

industry with more historical background, before the

arrival of the Spaniards to the Americas, raising

poultry was practiced mainly in turkeys. With the

arrival of settlers, breeds and varieties of birds were

introduced to the conquered territories that were

adapted to the operating conditions of Mexico.

Production began on a small scale. It should be

noted that at the time of the colony, it was allowed

to employees of poultry farms to maintain self-

sufficiency, which is considered the origin of the

current system of backyard poultry or rural,

practiced in large parts of the country. The

predominant pattern of production and trade until the

early 50's consisted of medium and small farms

supplying urban areas, a system that was interrupted

by the outbreak of the Newcastle disease in México.

Following this event, the authorities in coordination

with producers developed an intensive poultry

development program, which marked the foundation

for the current poultry endeavor. It may be noted

that from the second part of the early 80's, technical

production has replaced both semi-technical

production and backyard that was practiced in areas

close to expanding urban areas. Currently, the

poultry sector is a branch of farming that has

reached a technological level of efficiency and

productivity, which is comparable to that of

developed countries, adjusting quickly to the levels

demanded by the population. In the past 10 years,

the poultry industry has experienced a phenomenon

of expansion that has led this segment to be the

second place in the consumption of meat produced

in México, and the lowest price meat alternative in

the country.

2 METHODS AND MODEL

DESIGN

It can be assumed for the purpose of the simulation

model, (Calderón Ph.D. Dissertation), that the

system of interest consists of a set of lots of birds

that pass through the stages of breeding and egg

production, to later produce batches of eggs entering

the stage of incubation. Once this is completed, a

new batch of birds is sent to the broiler process. A

lot of (13700 males and 4725 females) birds is

considered to be the transaction flowing through the

model for the purposes of this model, which must

complete their breeding cycles, egg production,

incubation and growth on the farm stands. Likewise,

637

Calderón L. and Nuño P..

General Model Simulation of the Mexican Poultry Value Chain.

DOI: 10.5220/0005118906370643

In Proceedings of the 4th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2014),

pages 637-643

ISBN: 978-989-758-038-3

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

lots of fertile eggs should complete its cycle in

incubation machines. Each process facilities, stalls

and setters have a finite capacity to determine the

number of transactions (lots) that are able to

accommodate for each of these elements within the

system, and in turn, each lot is composed of a

number of specific units at the corresponding stage

(birds or eggs). Each stage requires a specific time to

complete the cycle before moving on to the next

process. These cycles must be coordinated and

balanced, so that there is an adequate flow of

transactions in the system. The explanation of the

process just presented, forms the basis of the

conceptual model of the system under study. It is

noteworthy that the conceptual model can be used

for any poultry value chain under the assumptions

and conditions presented here. Figure 1 shows the

conceptual model approach to simulate the poultry

value chain.

Source: Own elaboration

Figure 1: Conceptual model.

For this study, the operation manuals and

performance objectives by Ross Bird (2001), form

the basis for the progeny of breeding birds as well as

for broiler. Such data also establishes the empirical

distributions of times of chick placement of birds,

the mortality of females and males at different

stages, the average weight of birds at the beginning

of the cycle, and its uniformity in breeding flocks,

posture and broilers. To estimate the probability

density functions, we associated empirical data

relevant to the above input, using the results of

operations for one year of a Mexican Poultry

Company operating under the conditions assumed in

this research work.

2.1 Conceptual Model Validation

Conceptual model validation is defined as

determining the theories and assumptions underlying

the conceptual model correctly, and that

representation of the problem in the model is

"reasonable" for the purpose required. The

verification of the model ensures the correct

implementation of the conceptual model and of the

computer program. Operational validation of the

simulation model is achieved if the model output

behavior closely resembles the real system having

sufficient accuracy for the intended purpose. The

validity of the data is to ensure that the data needed

for building, evaluating, testing and conducting

experiments using the model in solving the problem

are adequate and correct (Sargent, 2004). By using

earlier approaches to model the stages of breeding,

egg production, and broiler hatching we may

conduct trials in order to compare with available

historical results of poultry operations at each stage.

This is done in order to validate the theories and

underlying assumptions in the conceptual model, as

well as to validate the representation of the model

structure, its logic and to verify that the

mathematical causal relationships are “reasonable”

responding to the objective of the model. In order to

verify the simulation program in SIMNET II, we

performed several simulation runs having the model

already validated and under different conditions and

scenarios. The resulting values are compared against

the historical data available to determine whether the

computer program implementation is correct. The

behavior of the system model can be explored by

examining the output of various sets of experimental

conditions of interest. To support the verification

and complementing the above, the simulation

language SIMNETII provides a powerful TRACE

command to verify the logical flow of transactions

through the stages of the simulation model,

observing the consistency of input and output

relations, verifying also the internal consistency of

the model. Behavioral output is plotted for different

experimental conditions. The number of

experiments is determined according to the accuracy

required for the purpose for the model. Expert

opinion complements the determination of the

accuracy by providing feedback to contemplate

adjustments in the structure of the program code.

The purpose of this is to improve the representation

of the overall integrated model and the operation of

the submodels to reflect a better approximation to

the real system under study. In order to obtain

reliable results, the first step is a proper analysis of

the steady state of the system. This is achieved by

considering the stability of the response variables

with respect to the next process. We consider being

BREEDING

EGG

PRODUCTION

INCUBATIO

N

BROILER

1daychicken

Thereisa

ratioof13%

ofmalesover

females.

20weeks

later,egg

production

starts.

Average

production:

167eggs/bird

fromweek21

to25.10of

theseeggs

Average

hatching:

138

eggs/Bird.

18.5days

incubating.

2.5daysin

49days

cycle

OnAverage

thereisa7%

mortalityin

theentire

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

638

at steady state if the current variability does not

affect the next process performance. Once this is

achieved, the selection of the number of runs is

determined based on the accuracy required for the

specific problem at hand. The length of each cycle

time in this case is several weeks, which leads to

evaluate horizons of operation cycles for at least one

year or more. The analysis of results considers the

overall operation of the integrated model but

focusing on the growing stage since it generates the

final value to the consumer.

3 EXPERIMENTATION

An experiment was carried out to determine if one or

more independent variables affects one or more

dependent variables and the reasons behind. From

experience and evidence of key causal relationship,

it was decided to manipulate the independent

variables but keeping track of the variation of the

dependent variable. This manipulation is

synonymous to the assignment of different values to

the independent variables (Hernández et al., 2003).

In this paper we have defined the critical

research variables (dependent variables) based on

the key strategic indicators of operation of the

poultry value chain under study, which include:

• The production of fertile eggs in the laying stage

• The density of birds in breeding stages, posture and

Broilers

• The final mortality in the breeding stage, posture

and

broilers

• The conversion of feed into meat in broilers

• The rate of productivity in the growing stage

• Production of kilograms of meat in broilers

• The cost of production in the breeding stage,

posture, hatching and broiler production.

Independent variables investigated are:

•

Initial number of breeding birds, egg production

and broilers

• Mortality in the 1st week of the broiler cycle

• Fertility rate, egg hatching at the incubation stage

• Food costs in the production broiler

• Direct and indirect costs of breeding, posture,

hatching and broiler stages.

The Model construction is based on established

performance standards for the Ross 308 breed type,

both for breeding and broiler birds. Ross 308 broiler

chickens have genetic characteristics for rapid

growth, efficient feed conversion and viability.

These broilers have strong legs and powerful

cardiovascular system. They are designed for high

meat production. Performance of birds can be

influenced significantly by many factors including

flock management, quality of feed, health and

climate conditions (Ross, 2001).

Six experiments were performed using the model.

The first one evaluates the amount of birds that

begin breeding at this stage to establish the

appropriate range of birds that provide the best

balance between increased productivity and lower

costs in the value chain. The second experiment

assesses the square meters required in the bird flocks

to provide a better first approximation of the range

of outcomes as a result of greater comfort and space

for the birds without increasing operating costs. The

third experiment focuses on mortality in the first

week of the cycle of broilers, which is critical in

poultry production. The fourth experiment evaluates

the range of values of key input variables that are

directly related to the birth of poultry production that

feed the growing stage. The fifth experiment

evaluates the operating range of values of the costs

of the feeding cycle with the least possible impact on

cost. Finally, the sixth experiment analyzes the range

of values for direct and indirect costs of operation

for all stages of the poultry value chain. The

followings variables are estimated by the simulation

model, which vary according to the case in study:

fertilized eggs production, density of birds in flocks,

dead birds at the end of each cycle, feed conversion

into meat, productivity rate, kilograms of meat

production, and complete cycle costs. Since then the

experiments mentioned above are illustrative. There

is a wide range of applications that can be tested

with the simulation model. For example, we can

perform simulations where changes could be

considered simultaneously, like an increase in the

number of birds at the beginning, with an increase or

decrease in the available area in the breeding flocks;

or separate experiments to find out the model

response to shifts of certain factors.

3.1 First Experiment: Number of Birds

at the Beginning of the Breeding

Stage

It is important to know the behavior of the breeding

and production stages. The number of birds at the

start is critical, in order to take the necessary actions

to prevent or reduce negative consequences such as

high mortality, excessive costs and low production.

It is assumed that increasing the number of birds at

the beginning of breeding in flocks, also increases

the number of fertile eggs in the laying stage, the

density of the flocks, and as a side effect to some

GeneralModelSimulationoftheMexicanPoultryValueChain

639

extent rising mortality. The magnitude of these

increases can be estimated quantitatively by the

simulation model. In the following tests, it is

assumed that the capacity of the flocks is fixed, with

a standard value of 1800 m2 for both breeding and

egg production flocks. The simulation considers 9

flocks in the process of breeding and 16 flocks in the

egg production stage. It may consider any other

capacity of the bird houses, since is only necessary

to reflect these values in the simulation model set for

initial conditions. It is also assumed that the major

constraint of the breeding farms and egg production

is the available space for bird growth. This also

includes the associated costs of having more space.

To reflect the increase in the birds at the beginning

of breeding and egg production, the number of

flocks (male and female quantities) can be modified

in the attribute value of the corresponding

transactions, in order to evaluate what the system

can process at a real operating poultry company. The

results are the mean and confidence intervals for

fifteen observations using the simulation model and

under the prevailing conditions at a Mexican Poultry

Company that is taken as the basis of this research.

The summary of results for these tests is shown in

Table 1.

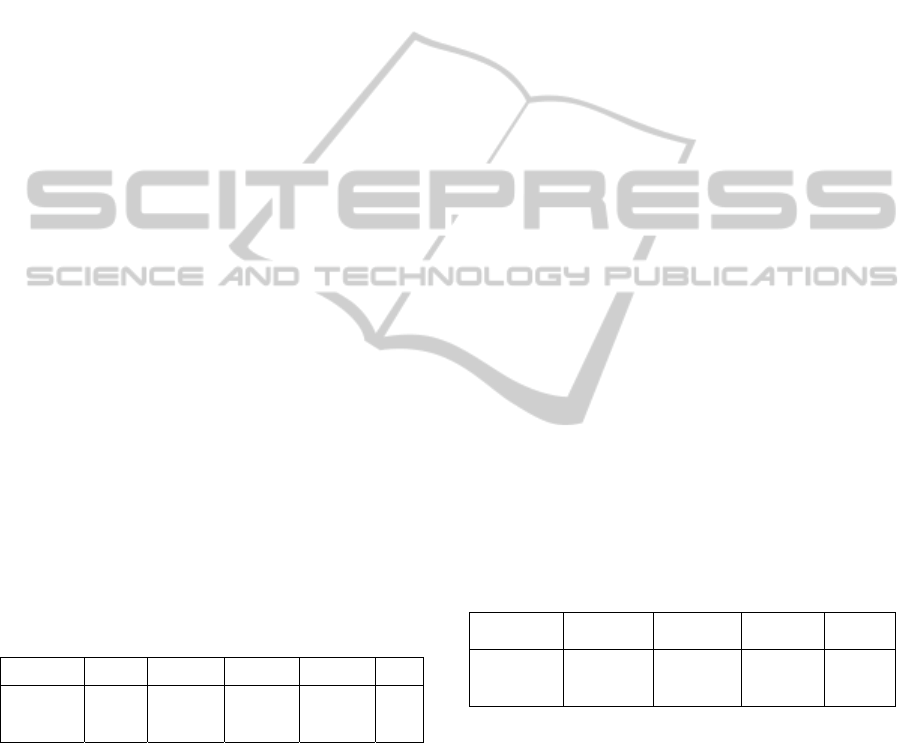

Table: 1: First Experiment.

Experiment

Density

(Birds/m2)

Fertile egg

production

Final

Mortality

Costs

No. of starting

Birds

6

6

7

19225

20629

22032

4234/1623

4544/1748

4855/1868

60/76.2

60/76.2

59.8/76

We performed 15 simulation runs in order to obtain

representative observations of the behavior of the

poultry value chain. Three levels for the number of

birds at the start were considered. The first level

(six) is based on the standard operation of a poultry

company in Mexico and increases at other levels are

taken into account according to any increases that

may exceed the current demand for the facilities

which were used as based values. By increasing the

number of birds at the start, increases the number of

fertile egg production, but as a logical consequence,

note that with an increase of the density of birds in

the flocks, produces a negative effect on the comfort

of birds, therefore reducing the space available for

breeding, which increases the number of dead birds

at the end of the cycle. On the other hand,

production costs decrease in terms of kilograms of

meat at this stage. It is noteworthy, that the main

purpose of this stage is raising healthy males and

females to produce as many fertile eggs as possible.

Therefore, what we seek is the balance between total

costs and the optimal production of fertile eggs.

Although this experiment only considered variables

or indicators of interest at the strategic breeding

stage, is of great importance because the output

stage are breeding birds (female and male healthy

enough for reproduction at sexual maturity). It is the

entrance to the position stage, and if the birds do not

arrive in optimal conditions, appropriate results may

not be obtained in these first two links of the value

chain. This will result in the underutilization of

poultry at the company. Accordingly, as a first

approximation to the final conclusions, we could say

that a controlled increase in birds at the start of the

stage of breeding under the conditions and

assumptions of this study, may lead to increase the

production of fertile eggs at a lower cost in the

production stage.

3.2 Second Experiment: Available

Area

The infrastructure of poultry varies from region to

region depending on the space and capital available

for each farmer. A common goal is to streamline any

poultry infrastructure to maximize its production

capacity. The dimensions of the stalls for breeding

and position are generally the same; this paper

builds on an area of 1800 m2. For broiler houses an

area of 2016 m2 was considered. Simulations assess

changes that could arise if there is more or less

space. Table 2 assesses the density for breeding

flocks, egg production and broilers in a smaller area,

and higher than the standard. Similarly, evaluating

the impact on mortality at the end of the cycle, and

for the case of the broiler stage, effects are observed

in the final kilograms production of chicken meat.

That is the main objective in the value chain for

poultry. The importance of space for the birds is a

direct function of comfort in the flocks where they

grow. Having the appropriate space and climatic

conditions, the desired production standards can be

achieved.

Table 2: Second Experiment.

Experiment

Density

(Birds/m2)

Final Mortality

Kg. Production

(Kg/1000)

Available

Area (m2)

Female

7/12/5

Male 3/4/2

Broiler

12/14/10

4234/4242/4227

1623/1630/1615

607/608/507

26556/26557/26556

12737

79500/79589/79669

The bird comfort directly affects the rates of poultry

mortality at any stage and represents a critical point

of attention in monitoring operations in poultry

production. It can be inferred form Table 2, that a

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

640

larger production area with a low ratio of birds per

square meter, decreases the amount of mortality in

birds and consequently increases the production of

kilograms of meat in the final stage of broiler. As

mentioned earlier, these experiments as well as the

other ones are the results of basic operating

characteristics of a Mexican poultry company. The

generic simulation model developed has no limits

for these variables for future exploratory research

experiments.

3.3 Third Experiment: Broilers

Mortality at First Week

In the broiler growing stage, the first week is critical

for best bird’s performance. This situation arises

depending on the good or bad operating conditions

and health of birds in the first week which affect

considerably the end of the cycle and production

goals. The purpose is to get the best yields of poultry

operations along the entire value chain. A high

mortality rate in broiler farms or houses during the

first week will affect the operation of the booth

throughout the cycle and the conversion of the birds

and their productivity. The simulation model is used

to evaluate the effects of an increase in the mortality

rates during the first week of broiler chicken. It is

assumed that the standard mortality rate in the first

week of broiler´s cycle is between 0.2% and 0.3%

(based on observations taken from a poultry

company in Mexico). On the other hand, we

explored two different mortality rate ranges, from

1.0% to 1.1%, and also from 1.4 to 1.5%. These

interval values are specified in the initial parameters

conditions of the simulation model. The summary

results are shown in Table 3.

Table 3: Third Experiment.

Experiment

End

Mortality

Conversion

Productivity

Rate

Kg.

Production

Costs

First

Week

Mortality

608

769

830

1.65

1.66

1.67

377

371

369

79600

78765

78445

4.73

4.75

4.75

The simulation model shows that there are large

negative impacts as we increase the mortality rate in

the strategic indicators of the value chain. Increased

mortality results in poor conversion of birds, which

negatively affects the resulting productivity index of

the flock, and therefore the production of chicken

meat in kilograms, affecting costs. In the previous

simulation, the adverse effects are contemplated for

the first week only, assuming no problems the rest of

the cycle. For research purposes, it is possible to

explore both cases.

3.4 Fourth Experiment: Appropriate

Percentage of Births

A wide variety of experiments can be performed

with the simulation model with variables of interest

in the poultry chain, such as fertility rate, percent of

egg hatching, percent of defects, and the incubation

capacity represented by the number of hatching

machines. This will assess the main effects that are

directly related to the number of resulting births,

which will become healthy birds to enter the

growing stage. For this research, simulation

experiments were performed using fixed percentage

amounts, however the simulation model can handle

ranges of values in frequency distributions. It is

assumed that the standard values for fertility percent

of eggs produced in the laying stage is 92%. The

percent of eggs hatching handled in the incubation

stage is 92%. The percent of defects present in the

egg entering the incubator is 8% and there are 20

machines available for incubation. The Capacity of

these machines is 30240 eggs, which is the number

of eggs hatch by each machine. For the case of the

number of hatching machines, the simulation

experiments considered de minimum installed

capacity that is needed to process the number of

eggs produced in the previous stage position, under

current operating conditions. The critical variables

of interest or strategic indicators that were evaluated

due to the expected impact were fertile egg

production expressed in volume, the productivity

rate, production of meat in kilograms and the cost in

the early stages of laying, hatching and broiler

chicken.

Table 4: Fourth Experiment.

Experiment

Fertile egg

production

Productivity

rate

Kilograms

Production

Costs

Births

19226

18616

19819

377

378

377

79600

79585

79596

1.80

2.75

4.74

An increase in the fertility egg production not

necessarily increases the number of kilograms

production, and the cost per kilogram of meat

increases in the growing stage. It is noteworthy that

the numerical combination of selected variables has

a wide area of opportunity for experimentation. The

main purpose of this experiment is to evaluate the

main cause and effect relationships. Although this

experiment only shows part of the wide variety of

possible strategic indicators at the stage of

incubation, is of great importance since the outcome

of the incubation stage will be the input of the

broiler´s cycle, stage at which the birds should arrive

GeneralModelSimulationoftheMexicanPoultryValueChain

641

in optimal conditions. A first conclusion from this

experiment is that a high percentage of fertility is

necessary to achieve a solid production of meat in

kilograms, along with a smaller percentage of

defects in the next stage.

3.5 Fifth Experiment: Operating

Range of Feeding Costs

The common objective when discussing these costs

is to find the point where the marginal gain is the

greatest. Any poultry infrastructure to be

competitive needs to maximize their production

while reducing operating costs. In the present study,

the effects of feed costs are evaluated in the broiler

chicken, since they represent 70% of the total cost of

chicken production. The base value is a production

cost of 2.8 pesos per kg. feed given to birds in the

first week, 3.1 pesos per kg. feed during the second

and third week, 2.5 pesos per kg. feed supplied in

the fourth and fifth week of the cycle, and finally 2.8

pesos per kg. feed for the remaining weeks. Table 5

presents the results, evaluating higher and lower

values than the standard, showing the impact on the

final cost of chicken production. The effects

observed in the final production of meat kilograms

are directly proportional to the total cost of the

feeding cycle. The importance of cost control is vital

because it makes the difference between competitive

poultry companies.

Table 5: Fifth Experiment.

Experiment

Costs ( $ x Meat Kilogram)

Scenario 1:

Standard

Scenario 2:

Quality grains

Scenario 3:

Reprocessing

Broiler’s Feed

Costs

4.73

5.16

4.31

This experiment evaluates the scope or range of

competitive fluctuating costs, looking at pessimistic

and optimistic scenarios in the production and cost

of feed for birds. Table 5 shows that an increase in

feed costs increases the total production cost of meat

kilograms in the final broiler´s cycle stage. This

experiment as well as the other five are for

exploratory purposes, but are the guidelines for

future research experiments.

3.6 Sixth Experiment: Direct and

Indirect Costs

As the poultry full-cycle ends, the full picture of the

costs incurred in each of the stages of the poultry

value chain is obtained. In order to take action to

avoid or reduce costs, both direct and indirect, the

simulation model can be used to analyze the

scenarios, to obtain a first approximation of what

areas or activities should be monitored to prevent an

increase in operating costs. The scenarios considered

in this experiment are based on amounts present in a

poultry company in Mexico. In the following tests,

we included direct and indirect costs of breeding

stages, egg production, and broiler hatching. Direct

costs include: feed, gas, electricity, vaccines, straw,

cleaning, disinfection and direct labor. Indirect costs

include indirect labor, depreciation, maintenance,

and laboratory analysis. As mentioned above, the

simulation considers 9 flocks in the breeding stage,

16 flocks in the laying stage, 20 and 60 incubation

broiler houses. Of course, you may consider any

amount of poultry facilities. The ultimate goal of this

experiment is to take the first steps toward an

administrative structure that results in higher profits

for any poultry enterprise. In this experiment, as in

the previous ones, the results come from the average

of fifteen observations of the simulation model. The

summary of cumulative results for each scenario is

shown in Table 6. We considered three levels of

costs; the first level is based on the standard

operation of a poultry company in Mexico, the other

levels being an increment and a decrement from the

standard that might occur in a normal operation of a

poultry enterprise at a Mexican poultry company in

the state of Veracruz.

Table 6: Sixth Experiment.

Experiment Costs ( $ x Meat Kilogram)

Scenario 1:

Standard

Scenario 2:

Higher quality

Scenario 3:

Cost efficient

Direct and

Indirect

Costs

Breeding 76.27

59.99

Egg prod. 1.82

Incubation 2.77

Broiler 4.73

78.26

61.16

2.05

3.45

5.43

76.22

59.08

1.36

2.16

4.53

Observe in this experiment, the relationship of

fluctuations in costs. Subsequent tests with the

model can complement experiments to simulate the

behavior of the total operating costs, as a function of

critical variables of poultry operations. Production

costs of meat kilograms are critical and a

fundamental part of the poultry sector, determining

the gains or losses for companies at this point in

time. A successful industrial poultry operation

contemplates the right balance between costs and

optimal production. There is a wide variety of

analysis on costs across the entire value poultry

chain that can be addressed using the simulation

model. It can be used as the basis for evaluating the

use of poultry resources available at Mexican

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

642

companies, with the aim of increasing their

competitiveness.

4 SUMMARY

The simulation experiments presented above showed

that there are many areas of opportunity at each of

the poultry stages. Strategic indicators were taken

from the poultry value chain to assess their impact

and to establish initial cause-effect relationships that

could improve the overall results of operations in the

flocks and poultry farms for the production of

chicken meat. The final objective is to meet the

needs of consumers, and to increase the

competitiveness of the poultry sector to conquer new

markets.

For the first strategic indicator, the production of

fertile eggs, it is observed based on the input

variables, that the number of birds that begin at the

stage of breeding, the fertility rates, egg hatching

and the percentage of defects are major factors that

influence a high yield. The evaluation of the density

of birds in the stands, allowed us to evaluate the bird

comfort in their living space which has a direct

relationship with the number of birds at the start of

the simulation, and the square meters available for

birds in production. The main objective is to find

the right balance between these two variables for the

optimization of the poultry chain. The third strategic

indicator is mortality, which is set according to the

assumptions of the system under study. The input

variables directly affecting this indicator are: the

number of birds at the start, the available area for

breeding flocks, egg production, and broiler chicken.

For broiler chicken an important factor of great

weight is the evolution of birds in the first week of

the cycle, which directly affects the performance of

broiler houses at the end of the production of

chicken meat. The conversion is a strategic indicator

directly related to the growing stage, which is

affected by the mortality that occurs early in the

cycle. This indicator is also closely related to the

welfare of birds in the flocks, which requires control

and care of various factors, such as the climate and

the health of birds. For the purposes of this research,

the number of variables and indicators are the most

representative of a poultry operation. However,

there is a wide spectrum of research to be addressed

in subsequent projects. Finally, for the cost of

production of chicken meat kilograms, the mortality

behavior in the first week of the broiler’s cycle is the

main factor that directly affects the direct and

indirect feed costs of poultry operations.

5 CONCLUSIONS

Simulation is a good tool to get started and provide a

basis for holistic solutions. The simulation model

developed focuses on the core part of the supply

chain to evaluate strategic poultry production

opportunities areas for taking decisions to improve

the system-wide integrated poultry from producers

to consumers. The poultry industry faces challenges

with the opening of global markets. The simulation

model provides an effective mathematical support to

improve the growth of Mexican poultry companies

and their production operations at all levels.

REFERENCES

Aviagen, (2001), Objetivos de Rendimientos de

Reproductoras Ross 308, USA: Aviagen Incorporated,

pp. 2-10.

Calderón, L (2008), Ph.D. Disssertation: Simulation model

of the value chain in the Mexican poultry industry.

Hernández Sampieri, Fernández Collado, y Baptista Lucio

(2003), Metodología de la Investigación, México:

Editorial McGraw-Hill.

RISTIC, M., (2004), Meat quality of organically produced

broilers, Rev. World Poultry, Vol. 20 No. 8 2004, pp.

30-31.

ROBBINS, S. (1994)., Administración: Teoría y Práctica,

México: Editorial Prentice Hall Hispanoamericana 4ta

Edición.

Sargent, R., (2004), Validation and Verification of

Simulation Models, 2004 Winter Simulation

Conference, pp. 17-26.

SOLARES, A. M. G., (2004), El ALCA y su

trascendencia para la avicultura: Visión

Latinoamericana, Rev. Avicultura Profesional, Vol.

22, No. 7/8 2004, pp. 28-29.

TAHA, H. A., (1992), Simulation with SIMNET II, 2da

Ed., SimTec Inc. Fayetteville, AR, USA.

TAHA, H. A., (2003), Operations Research an

Introduction, USA:7 Ed. Prentice Hall, pp. 645-673.

UNA, (2005), Monografía de la Industria Avícola

Mexicana 2005, http://www.una.org.mx, Unión

Nacional de Avicultores, 2005.

URRUTIA, S. (1999), El Broiler del año 2001, Revista

Avicultura Profesional, 15 Ed., pp. 23-28.

GeneralModelSimulationoftheMexicanPoultryValueChain

643