Defect Prediction over Software Life Cycle in Automotive Domain

State of the Art and Road Map for Future

Rakesh Rana

1

, Miroslaw Staron

1

, Jörgen Hansson

1

and Martin Nilsson

2

1

Computer Science & Engineering, Chalmers, University of Gothenburg, Gothenburg, Sweden

2

Volvo Car Group, Gothenburg, Sweden

Keywords: Defect Prediction, Software Life Cycle, Automotive Software, Test Resource Allocation, Release

Readiness.

Abstract: Software today provides an important and vital role in providing the functionality and user experience in

automotive domain. With ever increasing size and complexity of software together with high demands on

quality and dependability, managing software development process effectively is an important challenge.

Methods of software defect predictions provide useful information for optimal resource allocation and

release planning; they also help track and model software and system reliability. In this paper we present an

overview of defect prediction methods and their applicability in different software lifecycle phases in the

automotive domain. Based on the overview and current trends we identify that close monitoring of in-

service performance of software based systems will provide useful feedback to software development teams

and allow them to develop more robust and user friendly systems.

1 INTRODUCTION

Software is now an important part of automotive

products, over 2000 software functions running on

up to 70 Electronic Control Units (ECUs) provide a

range of functionality and services in modern cars

(Broy, 2006). With premium segment cars today

carrying about 100 million lines of code, which is

more than fighter jets and airliners (Charette, 2009).

Automotive software development projects at full

EE (Electronics & Electrical System) level usually

are large and span several months. Given the size,

complexity, demands on quality and dependability,

managing such projects efficiently and tracking the

software evolution and quality over the project

lifecycle is important.

Defects in software provide observable

indicators to track the quality of software

project/product under development. Different

methods for analysis of software defect data have

been developed and evaluated, these methods have

also been used to provide a range of benefits such as

allowing early planning and allocation of resouces to

meet the desried goals of projects. The different

methods of software defect analysis and predictions

have different characterstics. They need different

types of input data, are only appropriate to be

applied at specific granularity levels and for certain

applications. In this paper we summarize the state of

the art methods for software defect predicitons. We

place these methods where these are applicable on

the automotive software development life . The

methods are mapped to their appropriate level of

granularity and application type. We also contend

for the position that with technology enabling

collection and analysis of in-operations data

efficently will enable software designers and

developers to use this information to design more

robust and user friendly features and functions.

2 BACKGROUND

2.1 Automotive Software Development

Life Cycle

Most automotive Original Equipment Manufacturers

(OEMs) follow Model Driven Development (MDD).

And since car/platform projects are often large and

spread over several months, they are executed in

number of iterations. Software development in this

domain has been illustrated as variants of iterative

development based on spiral process model (Boehm

377

Rana R., Staron M., Hansson J. and Nilsson M..

Defect Prediction over Software Life Cycle in Automotive Domain - State of the Art and Road Map for Future.

DOI: 10.5220/0005099203770382

In Proceedings of the 9th International Conference on Software Engineering and Applications (ICSOFT-EA-2014), pages 377-382

ISBN: 978-989-758-036-9

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

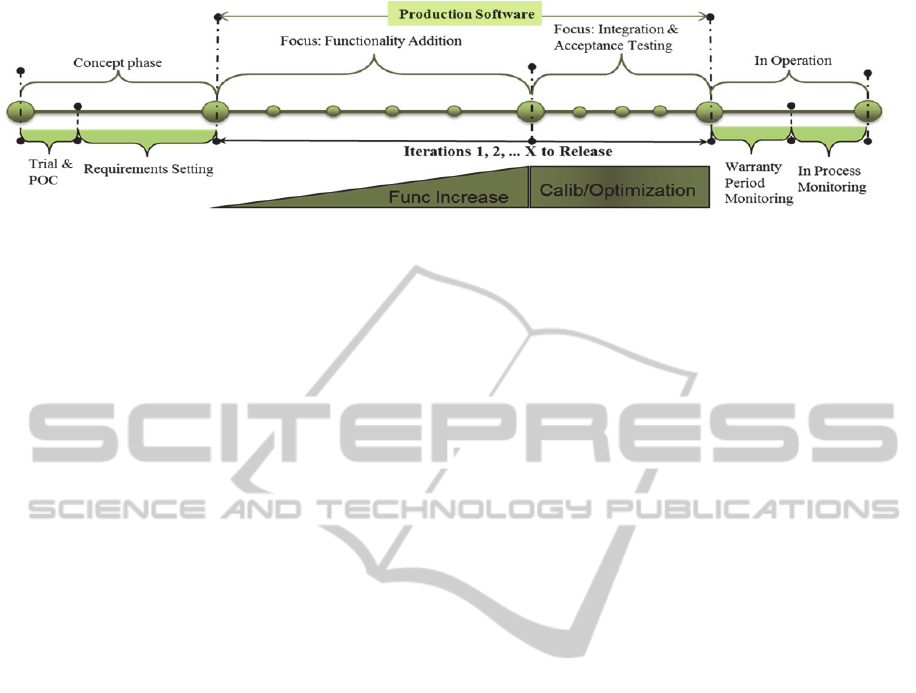

Figure 1: Time Line of Automotive Software Development Life Cycle.

1988) and approaches based on V-model (Dieterle,

2005; ISO 2011).

The full EE (Electronics & Electrical System)

development constitutes the complete development

of software and hardware (Electronic Control Units).

Different stages of software development process in

the automotive domain (illustrated by Figure 1) are:

1. Concept Phase: Where a new functionality is

designed and tested on prototypes and Proof of

Concept (POC) is demonstrated.

2. Production Software: The main requirements (on

vehicle level) are set for the upgrade and new

functions approved for market introduction.

Software and hardware intended to be included

in production automobiles is developed in

iterative manner following V-model or spiral

development process.

The first part of developing production

software is dominated by the addition of the new

functionality. Unit, integration and function

testing are also part of each iteration. In the

second part, also carried out in number of

iterations – the focus is shifted to integration and

acceptance testing.

3. In Operation: Once the new vehicle model is

released into the market, the performance of

software and hardware is monitored (through

diagnostics) during its operation.

2.2 Methods for Software Defect

Predictions (SDP)

Early estimations of software defects can be used

effectively to do better resource planning and

allocations. It can also help to track the progress of

given software project and improve release planning.

A number of methods have been used for

predicting software defects. These methods differ

from one another based on the type of input

required; the amount of data needed, prediction

made and sensitivity to give stable predictions

varies. Based on their characteristics, the models can

be categorized as:

Causal Models,

Using Expert Opinions,

Analogy Based Predictions,

Models based on Code and Change Metrics,

Software Reliability Growth Models

(SRGMs), etc.

2.3 Related Work

Expert opinions were used and their performance

compared to other data based models in a study by

Staron and Meding (Staron and Meding, 2008).

Long term predictive power of SRGMs within the

automotive domain was studied in authors earlier

works (Rana, Staron, Mellegård, et al. 2013; Rana,

Staron, Berger, et al., 2013), demonstrating their

usefulness in making defect and reliability

predictions.

Number of software metrics based on code

characteristics such as size, complexity etc., has

been successfully used to classify defect prone

software modules or estimate software defect

densities. Khoshgoftaar and Allen (Khoshgoftaar

and Allen, 1999) used logistic regression for

classifying modules as fault-prone, while Menzies,

Greenwald and Frank (Menzies, Greenwald, and

Frank 2007) used static code attributes to make

defect prone forecasts. Methods that use code and

change metrics as inputs and use machine learning

methods for classification and forecasting have also

been studied by Iker Gondra (Gondra, 2008) and

(Ceylan, Kutlubay, and Bener 2006).

Fenton and Neil (N. E. Fenton and Neil, 1999)

critique the use of statistical based software defect

prediction models for their lack of causal link

modelling and proposes use of Bayesian Belief

Networks (BBNs). Bayesian Nets have been used to

show their applicability for defect forecasting at very

early stages of software projects (N. Fenton et al.,

2008).

ICSOFT-EA2014-9thInternationalConferenceonSoftwareEngineeringandApplications

378

Our study complements earlier studies in defect

predictions by illustrating when different methods of

SDP are most appropriate over a software

development life cycle.

3 DEFECTS PREDICITON OVER

AUTOMOTIVE SOFTWARE

LIFE CYCLE

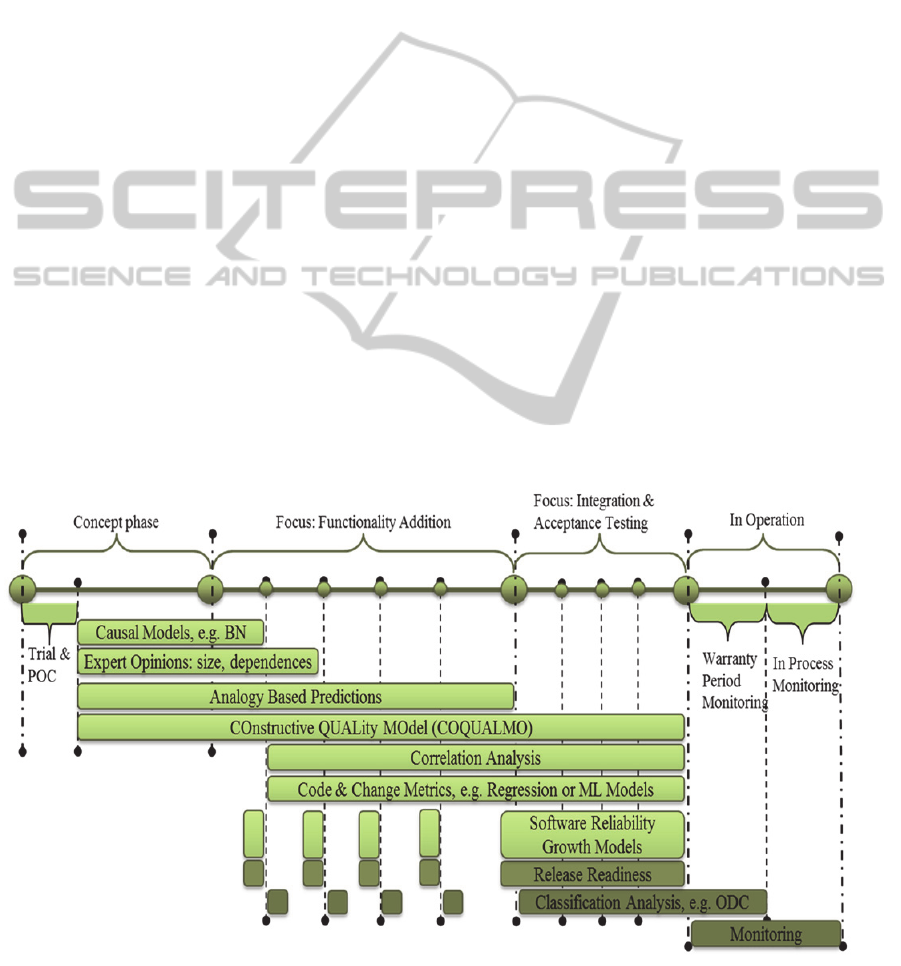

Applicability of various methods for software defect

predictions over the life cycle phases of automotive

software development is represented in Figure 2 and

the characteristics of each method are summarized in

Table 1. At earliest (concept) phase models that can

be applied (given the availability of data about

requirements, designs and implementation) are:

Causal Models

Using Expert Opinions

Analogy Based Predictions

COnstructive QUALity MOdel (COQUALMO)

Models applied at this (concept) phase usually

also use information from similar historical projects.

Experts in the company draw on their experience to

make such forecasts, while data based models

require the data to be supplied as inputs. The larger

the amount of information available on similar

historical projects, the higher is the likelihood for

these models to make accurate and stable

predictions.

Other SDP methods require data from the

development/testing phase. Examples of such

methods are:

Correlation Analysis

Methods based on Code & Change Metrics

Software Reliability Growth Models (SRGM)

Correlation analysis models uses number of

defects discovered in given iteration (and possibly

more attributes) to predict number of defects for

following iterations or defect count at project level.

Methods based on code and change metrics require

access to source code/functional models to measure

characteristics such as size, complexity,

dependencies etc., which are then used to make the

defect proneness classification or forecasting of

defect counts/densities. Thus methods based on code

and change metrics can only be applied when access

to source code/functional models is available. After

end of iteration 1, such data is usually available and

can be used for making such forecasts. In some

cases which is often the situation in automotive

software development, access to source code may be

an issue when software is sourced through a sub-

supplier. Further since the software development in

automotive domain pre-dominantly uses MDD,

functional/behavioural model metrics alternatives to

code metrics may need to be used where their

applicability and performance is currently not well

investigated/documented.

Figure 2: Methods for software defect predictions, applicability over SW life cycle in automotive domain.

DefectPredictionoverSoftwareLifeCycleinAutomotiveDomain-StateoftheArtandRoadMapforFuture

379

SRGMs on the other hand do not need access to

source code/model metrics data; these are black-box

techniques that only use defect inflow data during

development/testing to model the reliability of

software systems. While these models can be

applied when the software is under

development/testing – they need substantial data

points (defect inflow) to make stable predictions.

Analysing defects data over software life cycle

Another characteristic of defect analysis methods is

at what level they can be applied. Based on the type

of method and input data needed different models

provide optimal results at different granularity

levels. They can also be used for variety of different

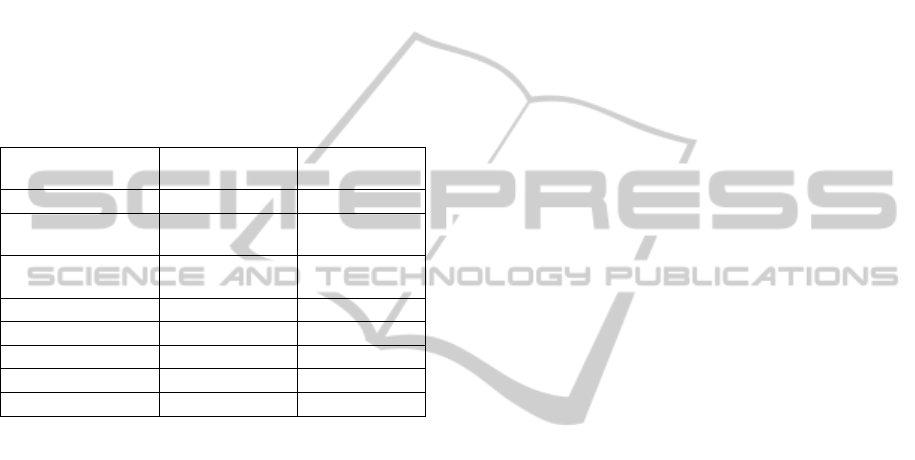

purposes. Table 2 summarizes the levels and

appropriate applications for each model type. The

granularity level at which analysis can be done are:

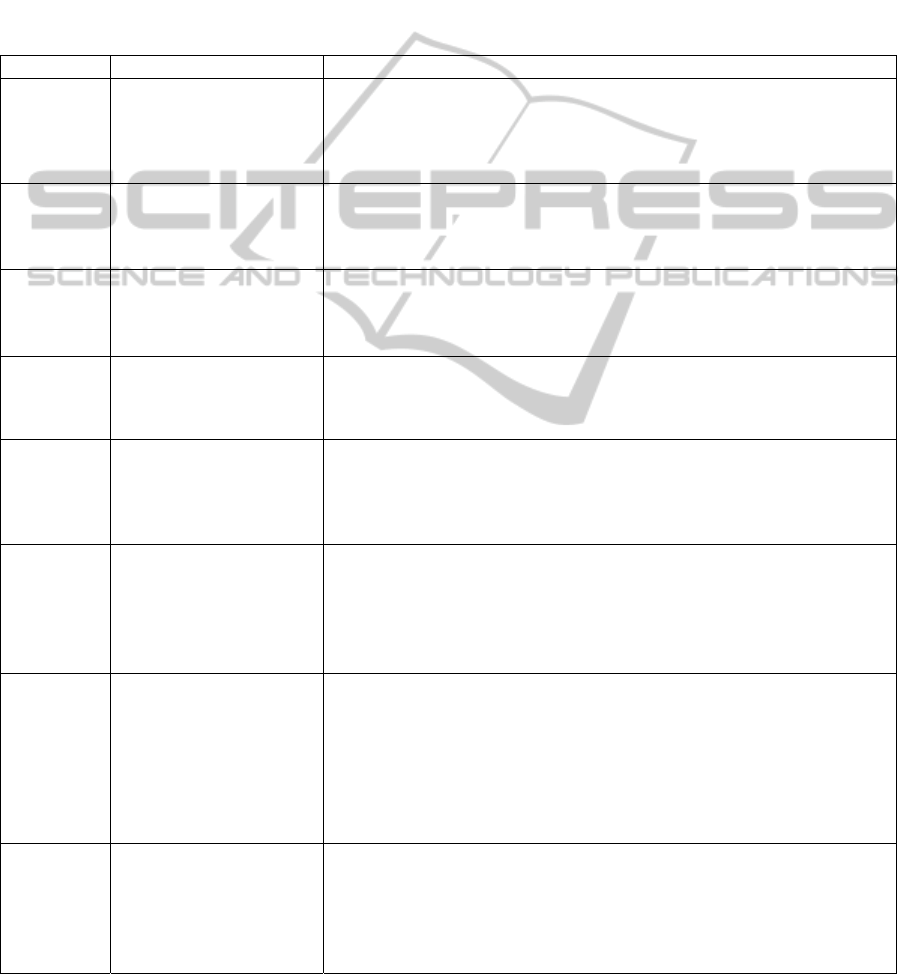

Table 1: Software defect prediction models, characteristics and applicability over Automotive SW life cycle.

Method

Input Data Required

Advantages and Limitations

Causal

Models

Inputs about estimated

size, complexity,

qualitative inputs on

planned testing and

quality requirements.

Causal models biggest advantage is that they can be applied very early in

the development process.

Possible to analyse what-if scenarios to estimate output quality or level of

testing needed to meet desired quality goals.

Expert

Opinions

Domain experience

(software development,

testing and quality

assessment).

This is the quickest and most easy way to get the predictions (if experts are

available).

Uncertainty of predictions is high and forecasts may be subjected to

individual biases.

Analogy

Based

Predictions

Project characteristics and

observations from large

number of historical

projects.

Quick and easy to use, the current project is compared to previous project

with most similar characteristics.

Evolution of software process, development tool chain may lead to

inapplicability or large prediction errors.

COnstructiv

e QUALity

MOdel

Software size estimates,

product, personal and

project attributes; defect

removal level.

Can be used to predict cost, schedule or the residual defect density of the

software under development.

Needs large effort to calibrate the model.

Correlation

Analysis

Number of defects found

in given iteration; size and

test effort estimates can

also be used in extended

models.

This method needs little data input which is available after each iteration.

The method provides easy to use rules that can be quickly applied.

The model can also be used to identify modules that show higher/lower

levels of defect density and thus allow early interventions.

Regression

Models

Software code (or model)

metrics as measure of

different characteristics of

software code/model;

Another input can be the

change metrics.

Uses actual code/models characteristic metrics which means estimates are

made based on data from actual software under development.

Can only be applied when code/models are already implemented and

access to the source code/model is available.

The regression model relationship between input characteristics and output

can be difficult to interpret – do not map causal relationship.

Machine

Learning

based

models

Software code (or model)

metrics as measure of

different characteristics of

software code/model;

Another input can be the

change metrics.

Similar to regression models, these can be used for either classification

(defective/not defective) or to estimate defect count/densities.

Over time as more data is made available, the models improvise on their

predictive accuracy by adjusting their value of parameters (learning by

experience).

While some models as Decision Trees are easy to understand others may

act like a black box (for example Artificial Neural Networks) where their

internal working is not explicit.

Software

Reliability

Growth

Models

Defect inflow data of

software under

development (life cycle

model) or software under

testing.

Can use defect inflow data to make defect predictions or forecast the

reliability of software based system.

Reliability growth models are also useful to assess the maturity/release

readiness of software close to its release

These models need substantial data points to make precise and stable

predictions.

ICSOFT-EA2014-9thInternationalConferenceonSoftwareEngineeringandApplications

380

Product Level (PL),

System Level (SL),

Sub-System level (SSL),

Functional Unit level (FU),

MOdule (MO), or at the

File Level (FL)

And the applications where analysis of software

defect data can be useful are:

Resource Planning and Allocations (RPA),

What-IF analysis (WIF),

Release Readiness Assessment (RR),

Root Cause Analysis (RCA), or for

Identification of Defect Prone units (IDP)

Table 2: Application level and useful purposes.

Model Application level

Application

area

Causal Models PL, SL, SSL RPA, WIF

Expert Opinions PL, SL, SSL, FU

RPA, RRA,

RCA, WIF

Analogy Based

Predictions

PL, SL, SSL, FU RPA, RRA

COQUALMO PL, SL, SSL, FU RPA

Correlation Analysis SSL, FU, MO, FL RRA, IDP, WIF

Regression Models SSL, FU, MO, FL RRA, IDP, WIF

ML based models SSL, FU, MO, FL RRA, IDP, WIF

SRGMs PL, SL RPA, RR, RCA

4 ROADMAP FOR INCREASING

EFFICIENCY IN COMBINING

DEFECT PREDICTION

METHODS WITH FIELD DATA

In the software domain, the post release monitoring

have been fairly limited as software is not regarded

same as hardware (software do not degrade or break

down with age). Another major reason for lack of

monitoring of software in-operation performance in

the past has been the un-availability of necessary

skills at the service end to retrieve the data and

easily feed it back to OEMs for analysis.

But with the advancements of new technology

such as high speed data transfer, cloud storage and

highly automated computer based diagnostics

equipment’s available across most of the service

points - offers unprecedented opportunity to collect

and retrieve the data from the in-operations phase.

This feedback information can further enhance the

capabilities to design and develop even better,

higher quality and safe automotive software.

We contend that the current technologies make it

possible for OEMs to collect and analyse in-

operations performance of software based systems

very much like it has been the case for hardware

components in the past. And much like how such

monitoring helped design better hardware

components, increase their life and reliability –

monitoring the in-operations data of software

systems performance will help design more robust,

reliable and user friendly software functions in the

future.

For example, following and analysing detailed

performance metrics of software based system

during their life-time operations will:

Provide in-operations performance metrics of

software based systems.

The qualitative and quantitative robustness

and reliability measures from in-operations

data will provide input (feedback) for experts

and causal models on which software

characteristics lead to most reliable

performance.

The current evaluation of performance of code

& change metrics SDP models is based on

their performance compared to defects found

during development and testing. Using in-

operations performance data and using code &

change metrics data from their source code

will help identify “best practices” for the

software designers and developers to avoid

actions that may lead to sub-optimal

performance during operations.

Insights from the in-operation phase are

already used by certain OEMs for effective

optimization/calibration. For example

functional units such as powertrain use in-

operations data to calibrate engines for

achieving optimal balance between power and

efficiency.

Active monitoring and analysis of in-

operations performance (of software based

systems) will help isolate any potential

performance related issues and offer quick

updates whenever needed. This will further

enhance the overall dependability of

automotive products.

Further in future where in-operation

monitoring and feedback cycle is shortened

would also enable OEMs to identify user

satisfaction and usefulness of different

features within their cars. This will allow for

design and development of more user friendly

features that will benefits the end customers.

DefectPredictionoverSoftwareLifeCycleinAutomotiveDomain-StateoftheArtandRoadMapforFuture

381

5 CONCLUSIONS

The role and importance of software in automotive

domain is rapidly increasing. The size, complexity

and value software provides in modern automotive

products is ever increasing and expected to grow

further. With trends moving towards more software

enabled functions, autonomous vehicles and active

safety systems – ensuring dependability of software

based systems is highest priority.

Software development in automotive domain is a

long and complex process, various software defect

predictions models offer possibilities to predict

expected defects thus providing early estimations

that are useful for resource planning and allocations,

release planning and enabling close monitoring of

progress of given project.

In the paper we reviewed that different methods

for SDP need different forms of input data, they also

have different capabilities and limitations when it

comes to their ability to make accurate and stable

forecasts. Thus given at what phase of software

development life cycle we are in and what kind of

data is available, certain defect prediction models

may be more appropriate than others and thus should

be preferred.

We also show that unlike past, the present

technology enables close monitoring, collection and

analysis of detailed performance data of software

based system during in-operations phase. This data

now and in future will be much easy to collect, store,

retrieve and analyse. We contend that analysis of

such data will lead to development of more robust

software based systems that will further help to

enhance the reliability of automotive products and

aid in development of features that provide superior

overall user experience.

ACKNOWLEDGEMENTS

The research presented here is done under the

VISEE project which is funded by Vinnova and

Volvo Cars jointly under the FFI programme

(VISEE, Project No: DIARIENR: 2011-04438).

REFERENCES

1044-2009-IEEE Standard Classification for Software

Anomalies. 2010.

Boehm, Barry W. 1988. “A Spiral Model of Software

Development and Enhancement.” Computer 21

(5): 61–72.

Broy, Manfred. 2006. “Challenges in Automotive

Software Engineering.” In Proceedings of the

28th International Conference on Software

Engineering, 33–42.

Ceylan, Evren, F. Onur Kutlubay, and Ayse Basar Bener.

2006. “Software Defect Identification Using

Machine Learning Techniques.” In 32nd

EUROMICRO Conference on Software

Engineering and Advanced Applications,

SEAA’06., 240–47. IEEE.

Charette, Robert N. 2009. “This Car Runs on Code.” IEEE

Spectrum 46 (3): 3.

Dieterle, Werner. 2005. “Mechatronic Systems:

Automotive Applications and Modern Design

Methodologies.” Annual Reviews in Control 29

(2): 273–77.

Fenton, N.E., and M. Neil. 1999. “A Critique of Software

Defect Prediction Models.” IEEE Transactions

on Software Engineering 25 (5): 675–89.

doi:10.1109/32.815326.

Fenton, Norman, Martin Neil, William Marsh, Peter

Hearty, Łukasz Radliński, and Paul Krause.

2008. “On the Effectiveness of Early Life Cycle

Defect Prediction with Bayesian Nets.”

Empirical Software Engineering 13 (5): 499–

537. doi:10.1007/s10664-008-9072-x.

Gondra, Iker. 2008. “Applying Machine Learning to

Software Fault-Proneness Prediction.” Journal

of Systems and Software 81 (2): 186–95.

ISO. 2011. “International Standard-ISO 26262-Road

Vehicles-Functional Safety”. International

Organization for Standardization.

Khoshgoftaar, Taghi M., and Edward B. Allen. 1999.

“Logistic Regression Modeling of Software

Quality.” International Journal of Reliability,

Quality and Safety Engineering 6 (04): 303–17.

Menzies, Tim, Jeremy Greenwald, and Art Frank. 2007.

“Data Mining Static Code Attributes to Learn

Defect Predictors.” IEEE Transactions on

Software Engineering 33 (1): 2–13.

Rana, Rakesh, Miroslaw Staron, Christian Berger, Jörgen

Hansson, Martin Nilsson, and Fredrik Törner.

2013. “Evaluating Long-Term Predictive Power

of Standard Reliability Growth Models on

Automotive Systems.” In Pasadena, CA, USA.

Rana, Rakesh, Miroslaw Staron, Niklas Mellegård,

Christian Berger, Jörgen Hansson, Martin

Nilsson, and Fredrik Törner. 2013. “Evaluation

of Standard Reliability Growth Models in the

Context of Automotive Software Systems.” In

Product-Focused Software Process

Improvement, 324–29. Springer.

Staron, Miroslaw, and Wilhelm Meding. 2008. “Predicting

Weekly Defect Inflow in Large Software

Projects Based on Project Planning and Test

Status.” Information and Software Technology

50 (7): 782–96.

ICSOFT-EA2014-9thInternationalConferenceonSoftwareEngineeringandApplications

382