Cell Formation Problem: An Multithreading Tabu Search for Setup

Time Optimization for Limited Machine Magazines

A New Solution for a Classical Problem

Arthur T. Gómez, Felipe R. Ferrary, José V. Canto dos Santos and Leonardo Chiwiacowsky

Universidade do Vale do Rio dos Sinos – PIPCA, Av. Unisinos, 950, São Leopoldo – RS, Brazil

Keywords: Tabu Search, Machine Setup Time Optimization, Manufacturing Cell Formation.

Abstract: This paper aims to present a solution for the Manufacturing Cell Formation Problem through the use of a

multithreading Tabu Search that uses deterministic methods to effectively explore local optimum areas.

Manufacturing Cell Formation problem involves the process of analysing parts and groups them according

to their similarity. This paper aims maximize the production efficiency, by minimizing the machine setup

time in a limited magazine size through the reduction of tool changes by creating clusters of parts that share

machining tools and present an initial scheduling based on tool changes reduction. In order to valid the

proposed algorithm, the results obtained are compared against other Tabu Search solutions proposed in the

literature.

1 INTRODUCTION

The process of batching and automate

manufacturing processes is an essential process for

companies that want to make competitive products.

The Batch manufacturing is estimated to be the most

common form of production, constituting more than

50% of the total manufacturing activity in the US. In

addition, there is a growing need to make batch

manufacturing more efficient and productive

(Groover, 2001).

In the batching process, Group Technology (GT)

has an important role and offers relevant

contribution helping to increase the efficiency of

production operations and reducing the requirement

of facilities (Xu et al., 2014). As part of GT, the

Manufaturing Cell Formation problem aims to

define an efficient struture to group machines (James

et. al., 2007).

The Manufaturing Cell Formation problem is a

NP-Hard (Spiliopoulos and Sofianopoulou, 2008).

Thus, simple heuristics has the propensity to not

present satisfactory results. Therefore, several

methods making use of artificial intelligence

techniques are proposed to solve the problem. Being

the manufacturing cell formation a problem of

combinatorial optimization, metaheuristic like Ant

Colony (Li et al., 2011; Spiliopoulos and

Sofianopoulou, 2008), Genetic algorithms (Xiaodan

et al., 2007), Tabu Search (Gómez et al., 2011) are

commonly used to find a good solution. On this

paper the metaheuristic Tabu Search is used to solve

the problem.

Beyond that, another resource that currently

receives increasing focus on academic papers is the

parallel processing applied to these methods

(Fiechter, 1994; He et al., 2005). In such cases,

different processors can perform multiple

calculations simultaneously.

Another method gaining increased attention is

the hybridization of metaheuristics (Kaur and

Murugappan, 2008). The success of the hybrid

approach comes from the union factor of the

strategic advantages of each method in a single

metaheuristic; providing a better performance

compared to the pure method (Tsai et al., 2009).

In this paper, a variation of the classical

implementation of Tabu Search is proposed. Being

part of this modification, concepts of hybridization

and parallel programming are used to provide

solutions near promising regions.

This paper is divided into 5 sections. Section 2

presents concepts of the Manufaturing Cell

Formation problem as well as review from its

literature. Section 3 presents details about the Tabu

332

Gómez A., Ferrary F., Canto Dos Santos J. and Chiwiacowsky L..

Cell Formation Problem: An Multithreading Tabu Search for Setup Time Optimization for Limited Machine Magazines - A New Solution for a Classical

Problem.

DOI: 10.5220/0005063403320339

In Proceedings of the 11th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2014), pages 332-339

ISBN: 978-989-758-039-0

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

Search proposed to solve the problem, also further

details about the multithreading concept used on this

method are provided. Section 4 presents the methods

used for general testing, as well as the metric used to

compare the result againt other solution found in the

literature. Section 5 presents the conclusions.

2 MANUFACTURING CELL

FORMATION LITERATURE

REVIEW

The cellular formation for a manufacturing system is

an application of the Group Technology (GT) –

which is a tool to identify similar parts and group

them together regarding similarities between them

(Selim et al, 1998). The Cell Formation (CF) aims to

reduce the setup and flow times – minimizing the

inventory and manufacturing lead times

(Wemmerlov and Hyer, 1989; Wu et al., 2010).

CF is a binary matrix machines versus parts

which reorganizes rows and columns with the

intention to group parts (part families) and machines

(machine cell). The binary element in the Figure 1

represents the relationship between part and machine

indicating:

1 – the part p uses the resource (or machine)

m;

0 – the part p can’t use the resource m;

See the example below:

Machine Number

Part Number

1 2 3 4 5

1 0 1 0 1 1

2 1 0 1 0 0

3 0 1 0 1 0

4 1 0 1 0 0

Figure 1: Relationship between part and machine.

Then, apply the Cluster Identification Algorithm

(Kusiak and Chow, 1987) to find any relationship

between parts and machines – rearranging the cells

and resulting in two cellular formation for

manufacturing systems and two part families, as

described in the Figure 2.

FP-1 FP-2

1 3 2 4 5

CM-1

2 1 1

4 1 1

CM-2

1 1 1 1

3 1 1

Figure 2: Cells created by Kusiak Algorithm.

3 PROPOSED Tabu SEARCH

Firstly proposed in 1986, Tabu Search is a method

that can be used to solve different problems on

combinatorial optimization environment (Glover,

1986). According with Glover (1986), Tabu Search

may be viewed as a metaheuristic superimposed on

another heuristic. This method uses a list in order to

forbid movements (“tabu movement”) that drives to

solution areas already explored.

Sumanta Basu (2012) brings a brief and updated

literature review about the Tabu Search being used

as a problem resolution tool related to combinatorial

area. On this paper, the main methods used to

perform movements from one solution to another

movements used to generate the neighbourhood,

Tabu List size and type, search intensification and

diversification, aspiration criteria as well as a couple

of other relevant details pointed along the article.

The diffent methods overviewed by this article

are evaluated qualitatively (through the quality of

the solution) as well as quantitatively (by checking

the number of times this method is used in the

studied articles). The methods employed in the

proposed Multithreading Tabu search take in

account of the methods pointed as the most efficiant

and appropriate to the resolution of combinatorial

problems.

The solution quality is evaluated using by metric

named “effective clustering” (Kumar and

Chandrasekharan, 1990). This metric is represented

by the equation(1).

0

(1)

In the given equation, e represents the number of

1’s in the given matrix, e

v

represents the number of

voids (number o 0’s inside the clusters in the main

diagonal) e

0

is the number of exception (the number

of 1’s outside the main diagonal).

CellFormationProblem:AnMultithreadingTabuSearchforSetupTimeOptimizationforLimitedMachineMagazines-A

NewSolutionforaClassicalProblem

333

3.1 Initial Solution

As initial solution, cluster identification is used. This

algorithm is an iterative process that selects rows

and columns in a matrix in order to simultaneously

create Family Parts and Machine Clusters. Kusiak

and Chow (1987) have initially proposed an

algorithm that identifies the similarity between

manufacturing processes and creates separable

groups. This method uses a binary part-machine

incidence matrix A = [a

ij

] and decomposes A into

sub matrices A

1

, A

2

, A

n

. Each sub matrix can be

defined as a machine cell.

However, once this paper aims to control and

reduce the number of tool changes in a limited

magazine, it is necessary taking in account of the

machine magazine limit. For this reason, the

algorithm used on this paper to generate the initial

solution is a method proposed by Gómez (Gómez,

1996) because this method considers the similarity

of tools used in the manufaturing process, as well as

the machine magazine limit.

Despite this kind of method hardly returns the

optimal solution, it is frequently used because it

points to an optimum solution. Usually an exact

algorithm points to a local optimum solution instead

of a global one. However, this algorithm can in some

particular cases point to the optimal solution as well

as it can point to a near-optimal solution that can be

considered an acceptable result (Black, 2005).

3.2 Search Intensification

Proposed by (Croes, 1958) as a method to solve the

travelling salesman problem, the 2-opt is widely

used to modify a current solution and generate a new

neighborhood until the stop criteria requirements are

met (Lim, Yong, Ramli and Khalid, 2011). Also, it

is used as a local search method in many other

combinatorial problems (Kothari and Ghosh, 2013;

Hasegawa, Ikeguchi and Aihara, 1997).

The 2-opt movement occurs through the removal

of two non-adjacent parts or machines from a

cluster. After the removal of these components,

those parts or machines have their position

exchanged thus preventing the need of perform an

evaluation of a subgroup again. In addition to, 2-opt

movement is also used to exchange the families

orders, thus changing the current scheduling. This

proccess helps in reducing the number of tool

change between Family parts, consequently reducing

the setup time.

The intensification occurs due the non-

substantial change of only two parts or machines,

thus creating a solution near of the current solution.

Considering it is a simple movement, consequently

it has a low computational complexity – θ(n

2

) for 2-

opt algorithm (Croes, 1958). For this reason, this

method can be commonly find in Tabu Search

implementations. In this paper, the 2-opt movement

is used to generate 20 neighbours and potential

solution candidates.

Another mehod used in the implementation and

on search intensification is a column insertion

method. In this method, as initial step an part or

machine is randomly selected and then, this

component is removed from its cluster. In a next

step, the algoritm should find the best cluster to

insert this part or machine back (Semet and Taillard,

1993).

Suppose that the Families FP-1, FP-2 and FP-3

(Figure 3(a)) are clusters that represent the current

solution for a machine supports 4 tools and the part

4 that belongs to the Cluster FP-3 is removed.

Considering the, algorithm should find the best

Family to insert this part back aiming to minimize

the associated objective function as well as its

restrictions. On this particular example, once the part

4 shares resources with the FP-1 the part 4 must be

moves this cluster reducing the FP-3(Figure 3(b)). In

a second iteration the part 7 could be moved to FP-2

cutting the FP-3 off.

FP‐1 FP‐2 FP‐3

1 5 3 6 2 8 7

4

MachineNumber

CM‐1

1 1 1

2 1 1

CM‐2

3 1

4 1 1 1

CM‐3

5 1 1 1

6 11

Figure 3(a): Incidence matrix [aij] before insertion

movement.

FP‐1 FP‐2 FP‐3

1 5 3

4 6 2 8 7

MachineNumber

CM‐1

1 1 1

2 1 1

CM‐2

6 1 1

3 1

CM‐3

4 1 1 1

5 1 1 1

Figure 3(b): Incidence matrix [aij] after insertion

movement.

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

334

When comparing both proposed intensification

methods, it is possible to notice that both methods

are very similar. More than this, it is possible to

affirm that the insert column method is an improved

2-opt once in both cases a randon part or machine is

selected. However, on insert column algorithm,

when returning this part to a cluster an objective

function must be respected giving always the best

solution. Due the second method requires more

computational resources than the 2-opt method, it is

used to generate only 5 neighbours and potential

solution candidates.

3.3 Search Diversification

Different from the movements proposed in order to

intensify the search (usually have simpler and subtle

movements), in situations where it is necessary

diversify the search and then to reach a solution far

from the current solution then diversification

movements are used. The diversification movements

should perturb the neighbourhood increasing its

candidate solution range consequently reaching

solutions areas not explored before.

In the proposed model, the diversification

movements occur only after a pre-defined number of

iterations without improve of the current value of the

actual solution or the value of the objective

function. By default, this value is set as half of the

value proposed as stopping criteria (The stopping

criteria is defined as a finite number of iteration

without improvement the value of objective

function).

Once the iteration counter reaches half of the

stopping criteria, automatically diversification

movements are made perturbing the current

neighbourhood. In this paper the chosen stopping

criteria is 500 rounds without improvement,

consequently the diversification movements only

creates solution candidates after 250 iterations. Two

different methods are proposed in order to generate

solution candidates.

As previously cited in this paper, the Tabu

Search is a method that improves the results though

several iterations using a list of movements that

should not be repeated and uses these resources to

avoid becoming stuck in local optima area.

However, the performance and the time to obtain an

optimal or near-optimal solution are strongly

affected by the proposed initial solution (Liu, Xiong

and Liu, 2009).

Bearing in mind that the diversification

algorithm is only used after several rounds without

improvements, we can assume that it is pottentially

stucked in a local optimal. If so, the result hardly

will be improved. For this reason, the implemented

Tabu Search proposes the usage of the same

deterministic method previously used to generate the

initial solution again, generating a unique solution

candidate that points to a new optimal or suboptimal

region, region which can possibly be the global

optimal solution (Black, 2005).

It is known that the deterministic algoritm used

to find an initial solution has a higher complexity -

θ(2mn) (Kusiak, 1987) - than the standard algorithm

used during the search intensification like 2-opt

(θ(n

2

)). Nevertheless, with the advancement from

studies related to the parallel processing area in

addition to technological advancement of the

computer hardware, it becomes possible to use

algorithms with higher complexity instead of save

processing time in combinatorial problems. Thus, it

is proposed the use of the modified kusiak algoritm

in parallel to the Tabu Search algoritm to create a

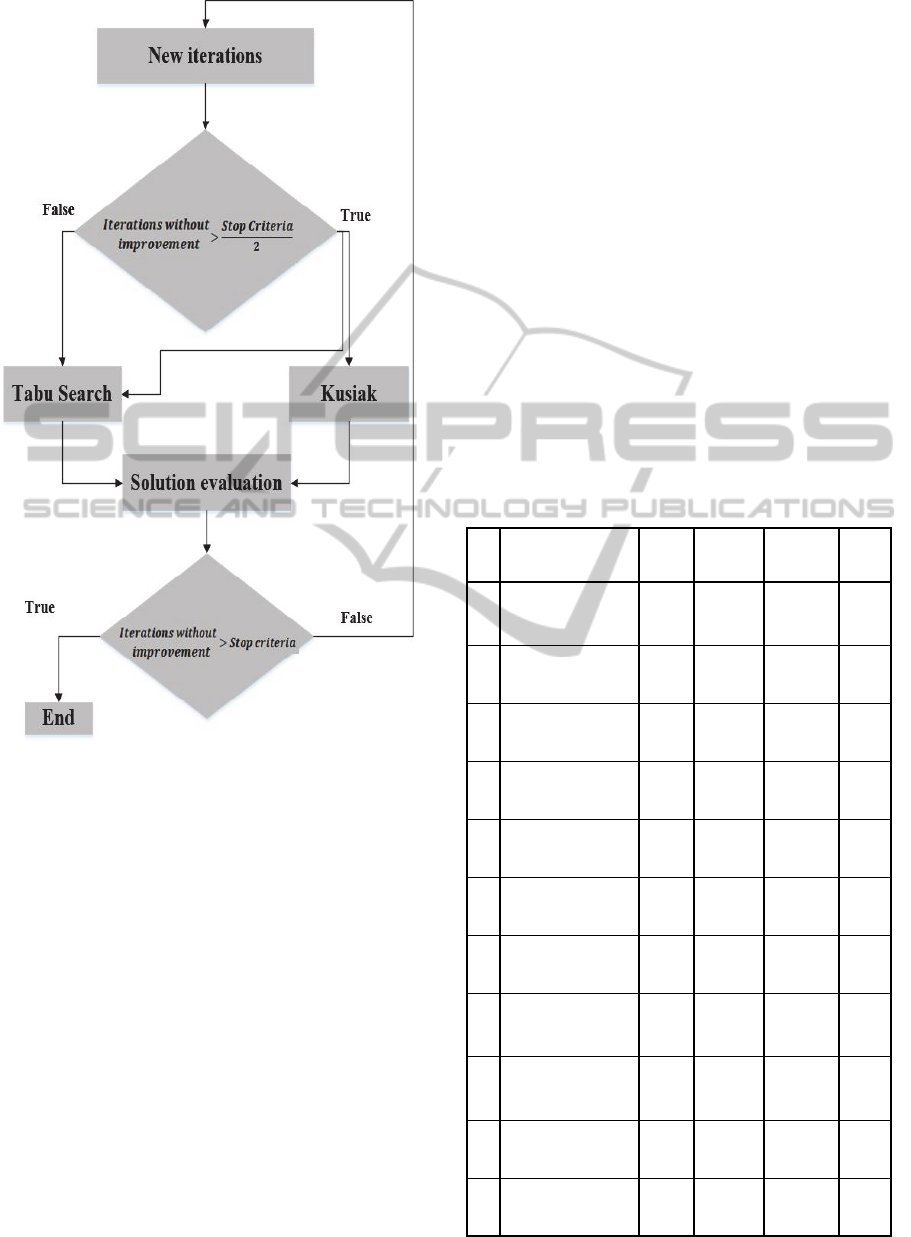

solution candidate. The Figure 4 shows the

architeture used to run the initial solution method in

parallel to the intensification and diversification

movements. Once it is a multithread processing

method, an iteration should not be finished until both

processes are completely done, otherwise there is a

risk of loose the synchronization between both.

The implemented alternative Kusiak method can

be defined as a deterministic algorithm, being non

deterministic only when selecting the initial part

represented by a row in the matrix. For this reason,

depending of the initial part selected, the same result

matrix can be obtained more than once. It occurs

every time the initial part previously selected is

selected again. For this reason, the implementation

of second Tabu List is proposed in order to prevent

that the same initial part be selected several times.

This secondary Tabu List is responsible for storing a

set of initial parts that were already used. This

special list size is proportional to the problem size

and has a size equivalent to 10% of the prblem size.

3.4 Tabu List

When generating a collection of solutions, it can be

observed that the new neighbourhood can present

only worse solutions in comparison with the best

solution found. The Tabu Search has resources that

can prevent the method to visit these worse solutions

again, as well as it has resources avoid becoming

stuck in a local optimal region (Sorlin and Solnon,

2005). A solution is added to the Tabu List every

time it was already visited.

CellFormationProblem:AnMultithreadingTabuSearchforSetupTimeOptimizationforLimitedMachineMagazines-A

NewSolutionforaClassicalProblem

335

Figure 4: Multithreading Tabu Search architecture.

The Tabu Search is a method with memory

structures. This memory structure is used in order to

store a finite collection of movementes made during

its processing. Therefore, a list is necessary to store

these movementes, being this list known as the Tabu

List (Glover, 1986). Bearing in mind that whether it

is an finite size list, each movement added to the

Tabu List must remain in this list for a limited and

pre-defined time. This limitation occurs through the

definition of the Tabu List Size (Basu, 2012).

The size of the Tabu List allows the user to

intensify or diversify the search. The Tabu List

memory types can be divided into three different

categories Short-term, Intermediate-term or Long-

term.

The Tabu List size can also be static, dynamic or

random (Tang and Hooks, 2005). According with

(Basu, 2012) survey, lists with static size are the

most common and its size usually varies from 0 to 4

like as proposed in (Crainic, Gendreau, Soriano and

Toulouse, 1993). On the other hand, there are

articles that also present static lists, however with a

larger list allowing more than 30 values (Lau, Sim

and Teo, 2003). In this paper as well as presented by

(Ting, Li and Lee, 2003; Greistorfer, 2003) the Tabu

List size is proportional the number of parts and

machines being analyzed, the chosen proportion on

this implementation is 25% of the problem size.

4 EXPERIMENTS AND RESULTS

In order to test the Tabu Search implementation, a

set of 11 problems extracted from the literature is

used. This set of problems was previously tested by

James et. al. (2007) and Gómez et. Al. (2011). The

best solutions found in both papers are compared

against the solutions obtained on this paper. The list

of test instances was extracted from James et. al.

(2007).

Table 1: Minimum, maximum and average efficiency.

ID Problem Source Min Max Average σ

1

King and

Nakornchai

(1982)

82,35 82,35 82,35 0,00

2

Waghodekar and

Sahu (1984)

70,00 80,00 74,08 2,44

3

Seifoddini

(1989)

79,59 79,59 79,59 0,00

4

Kusiak and Cho

(1992)

80,00 80,00 80,00 0,00

5

Kusiak and

Chow (1987)

58,62 60,71 58,97 0,75

6 Boctor (1991) 70,37 73,08 71,18 1,31

7

Seifoddini and

Wolfe (1986)

76,00 76,00 76,00 0,00

8

Chandrasekharan

and Rajagopalan

(1986a)

66,67 67,44 66,89 0,36

9

Chandrasekharan

and Rajagopalan

(1986b)

18,18 26,77 22,47 4,52

10

Mosier and

Taube (1985)

70,59 76,00 71,87 2,26

11

Chan and Milner

(1982)

92 92 92 0,00

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

336

Once the proposed Tabu Search uses

multithreading processing – a multi core processor

must be used to evaluate the processing time gain,

therefore the tests were made in a computer with an

Intel Core i5-3210M processor with 2.5Ghz and

6GB of RAM memory.

Each problem was submitted to 75 executions

considering a machine magazine limited to 4 tools.

In the Table 1 are shown the obtained: worse and

best efficiency result, average efficiency result and

its standard deviation. Like in James et. al. (2007)

the problems are organized by ID and problem

source.

An relevant point observed during the tests are

the low processing time. In most part of the cases,

the processing time have not exceed 2 seconds. The

lowest processing time is observed on problem 1 –

average processing time of 1 second and 200

milisenconds – and the biggest processing time is

observed on problem 8 taking 2 seconds and 79

miliseconds. This low processing time even using

the Kusiak algorithm to diversificate the search

proves that with the new hardware improvements,

methods with a higher complexity can be used in

metaheuristics without performance reduction.

The method proved it self powerful when

grouping machines that do not have to proccess

more parts than the magazine limit. Once we are

imposing a restriction, on this particular case

imposing a magazine limit of 4 tool. Consequently,

if a machine have to process more than 4 parts – it

tends to create a bottleneck because this part have to

be processed in more than one step. This situation is

observed on problem 9, this problem has several

parts that requires 5 tools on its production. For this

reason, it is expected to have a result above the

found on literature where this restriction is not

impose.

In other hand, in problems where 4 or less tools

are used during the process, like in problems 1, 2, 3,

4 and 5, the results are better or the same when

compared to the literature. Table 2 shows the results

in the literature in comparison to the obtained on this

paper. Proposed Tabu Search represents the results

found on this paper. Results better than the ones

found in literature are in bold.

Though the Table 2 it is possible to observe that

the solutions found to the problems 2, 4, 6, 7 and 10

are better than the solutions presented by the

literature. On problems 1, 3 and 11 the same result

was found. On problems 5, 8 and 9 the results found

in the literature are better than the ones found by the

proposed Tabu Search.

Table 2: Comparison between literature results and

proposed Tabu Search results.

ID

Best

Solution

in source

Problem

James et.

al. (2007)

Gómez et.

Al. (2011)

Proposed

Tabu Search

1 73,68 82,35 82,35

82,35

2 68 69,57 69,57

74,08

3 79,59 79,59 79,59 79,59

4 76,92 76,92 76,92

80,00

5 53,13 60,87 60,87 58,97

6 70,37 70,83 70,83

71,18

7 68,3 69,44 69,44

76,00

8 85,25 85,25 85,25 66,89

9 58,72 58,72 56,70 22,47

10 72,79 75 70,35 71,87

11 92 92 92 92

5 CONCLUSIONS

This paper aims to present a solution for the

Manufacturing Cell Formation Problem through the

use of a multithreading Tabu Search, that uses

deterministic methods to effctively explore loca

optimum areas. On this paper, the magazine is

considered with limited capacity. The magazine

capacity considered is four tools.

The method obtained better solutions when

compared against other solutions found in the

literature when using 4 or less tools on the

manufaturing proccess. proving to be a powerfull

method to create manufaturing cells for limited

number of tools or resources.

However, due the magazine limit restriction

added to the problem the better results are limited

only to parts that use 4 or less tools on its

processing. Thus, an independent method to deal

with this restriction could be implemented in order

CellFormationProblem:AnMultithreadingTabuSearchforSetupTimeOptimizationforLimitedMachineMagazines-A

NewSolutionforaClassicalProblem

337

to improve the result effiiency. Consequently

reducing the number of tool changes and setup time.

Future works will present other studies on the

problem addressed in this article.

REFERENCES

Basu, S., 2012. Tabu Search Implementation on Traveling

Salesman Problem and Its Variations: A Literature

Survey, American Journal of Operations Research.

Vol. 2 No. 2, pp. 163-173.

Black, P. E., 2005. Greedy algorithm, in Dictionary of

Algorithms and Data Structures [online], Vreda

Pieterse and Paul E. Black, eds.

Boctor, F. F., 1991. A linear formulation of the machine-

part cell formation problem. International Journal of

Production Research; 29(2):343–56.

Chan, H. M., Milner, D. A., 1982. Direct clustering

algorithm for group formation in cellular

manufacture. Journal of Manufacturing Systems;

1:65–75.

Chandrasekharan, M. P. , Rajagopalan, R., 1986. An ideal

seed non-hierarchical clustering algorithm for cellular

manufacturing. International Journal of Production

Research;24(2):451–64.

Chandrasekharan M. P., Rajagopalan R., 1986.

MODROC: an extension of rank order clustering for

group technology. International Journal of Production

Research; 24(5):1221–64.

Crainic, T. G., Gendreau, M., Soriano P., Toulouse, M.,

1993. A Tabu Search Procedure for Multicommodity

Location/Allocation with Balancing Requirements,

Annals of Operations Research, Vol. 41, pp. 359-383.

Croes, G. A., 1958. A method for solving traveling

salesman problems. Operations Res. 6. , pp., 791-812.

Fiechter, C. N., 1994. A parallel tabu search algorithm for

large traveling salesman problems, Discrete Applied

Mathematics, Volume 51, Issue 3.

Glover, F., 1986. Future paths for integer programming

and links to artificial intelligence. Computers and

Operations Research, 1, p. 533-549.

Gómez, A. T., 1996. Modelo para o sequenciamento de

partes e ferramentas em um sistema de manufatura

flexível com restrições às datas de vencimento e à

capacidade do magazine, PhD thesis, Instituto

Nacional de Pesquisas Espaciais, São José dos

Campos, São Paulo, Brasil.

Gómez, A. T., Linck, I., Galafassi, C., Wickert, T., 2011.

A Study for Manufacturing Cell Formation Approach

Considering Setup, 8th International Conference,

ICINCO 2011 Noordwijkerhout, The Netherlands, p.

43-48.

Greistorfer, P., 2003. A Tabu Scatter Search Metaheuristic

for the Arc Routing Problem, Computers and

Industrial Engineering, Vol. 44, No. 2.

Groover, M. P., 2001. Automation, Production Systems,

and Computer-Integrated Manufacturing. Upper

Saddle River, New Jersey: Prentice-Hall, USA.

Hasegawa, M., Ikeguchi, T., Aihara, K., 1997.

Combination of chaotic neurodynamics with the 2-opt

algorithm to solve traveling salesman problem.

Physical Review Letters, pp. 2344-2347.

He, Y., Qiu, Y., Liu, G., Lei, K., 2005. A parallel

adaptive tabu search approach for traveling salesman

problems, Natural Language Processing and

Knowledge Engineering.

James, T. L., Brown, E. C. and Keeling, K. B., 2007. A

hybrid grouping genetic algorithm for the cell

formation problem, Computers and Operations

Research, 34, 2059-2079.

Kaur, D., Murugappan, M. M., 2008. Performance

enhancement in solving traveling salesman problem

using hybrid genetic algorithm, in Proceedings of the

2008 annual meeting of the North American fuzzy

information processing society, New York, pp.1–6.

King, J. R., Nakornchai V., 1982. Machine-component

group formation in group technology: review and

extension. International Journal of Production

Research; 20(2):117–33.

Kothari, R., Ghosh, D., 2013. Tabu search for the single

row facility layout problem using exhaustive 2-opt and

insertion neighbourhoods, European Journal of

Operational Research, Volume 224, Issue 1, Pages 93-

100.

Kumar, K. R., Chandrasekharan, M. P., 1990. Grouping

efficacy: A quantitative criterion for goodness of block

diagonal forms of binary matrices in group

technology. International Journal of Production

Research, 28(2), 233–243.

Kusiak, A., Cho, M., 1992. Similarity coefficient

algorithm for solving the group technology problem,

International Journal of Production Research;

30(11):2633–46.

Kusiak, A., Chow, W. S., 1987. Efficient solving of the

group technology problem, Journal of Manufacturing

Systems, v. 6(2), p. 117–24.

Lau, H., Sim M., and Teo K., 2003. Vehicle Routing

Problem with Time Windows and a Limited Number of

Vehicles, European Journal of Operational Research,

Vol. 148, No. 3.

Li, X., Baki, M. F., Aneja, Y. P., 2011. Flow shop

scheduling to minimize the total completion time with

a permanently present operator: Models and ant

colony optimization metaheuristic, Computers &

Operations Research, Volume 38, Issue 1, Pages 152-

164.

Lim, Y. F., Hong, P. Y., Ramli, R., Khalid, R., 2011. An

improved tabu search for solving symmetric traveling

salesman problems, Humanities, Science and

Engineering (CHUSER), 2011 IEEE Colloquium on ,

vol., no., pp.851,854.

Liu, Y., Xiong, S., and Liu, H., 2009. Hybrid simulated

annealing algorithm based on adaptive cooling

schedule for TSP, Proceedings of GEC’09, Shanghai,

pp.895-898.

Mosier, C. T., Taube, L., 1985. The facets of group

technology and their impact on implementation.

OMEGA; 13(5):381–91.

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

338

Seifoddini, H., Wolfe, P. M., 1986. Application of the

similarity coefficient method in group technology. IIE

Transactions; 18(3):271–7.

Seifoddini, H., 1989. A note on the similarity coefficient

method and the problem of improper machine

assignment in group technology applications.

International Journal of Production Research;

27(7):1161–5.

Selim, M. S., Askin, R. G., Vakharia, A. J., 1998. Cell

formation in group technology: review evaluation and

directions for future research. Computers and

Industrial Engineering 34 (1), 3–20.

Semet, F., Taillard, E. D., 1993. Solving real-life vehicle

routing problems efficiently using Tabu Search,

Annals of Operations Research. Vol. 41, pp. 469-488.

Sorlin, S., Christine, S., 2005. Reactive Tabu Search for

Measuring Graph Similarity, Graph-Based

Representations in Pattern Recognition, pp. 172-182.

Spiliopoulos, K., Sofianopoulou , S., 2008. An efficient ant

colony optimization system for the manufacturing cells

formation problem, International Journal of Advanced

Manufacturing Technology, 36, 589-597.

Tang H., Hooks E., 2005. A Tabu Search Heuristic for the

Team Orienteering Problem, Computers & Operations

Research, Vol. 32, No. 6.

Ting, C., Li, S. and Lee, C., 2003. On the Harmonious

Mating Strategy through Tabu Search, Information

Sciences, Vol. 156, No. 3-4.

Tsai, C. W., Tseng, S. P., Chiang; M. C., Yang, C. S.,

2009. A Time-Efficient Method for Metaheuristics:

Using Tabu Search and Tabu GA as a Case, Hybrid

Intelligent Systems, 2009. HIS '09. Ninth International

Conference on, vol.2, no., pp.24-29.

Waghodekar, P. H., Sahu S., 1984. Machine-component

cell formation in group technology MACE.

International Journal of Production Research;22:937–

48.

Wemmerlöv, U., Hyer, N. L., 1989. Cellular

manufacturing in the U.S. industry: a survey of users,

International Journal of Production Research 27(9),

1511-1530.

Wu, T. H., Chung, S. H., Chang, C. C., 2010. A water

flow-like algorithm for manufacturing cell formation

problems. European Journal of Operational Research

205(2): 346-360.

Wu, X., Chu, C.H., Wang, Y., Yue, D., 2007. Genetic

algorithms for integrating cell formation with machine

layout and scheduling, Computers & Industrial

Engineering, 53, Issue 2, Pages 277-289.

Xu, Y. T., Zhang, Y., Huang, X., 2014. Single-machine

ready times scheduling with group technology and

proportional linear deterioration, Applied

Mathematical Modelling, Volume 38, Issue 1, pp. 384-

391.

CellFormationProblem:AnMultithreadingTabuSearchforSetupTimeOptimizationforLimitedMachineMagazines-A

NewSolutionforaClassicalProblem

339