3D Simulation of Industrial Large-scale Ceramics Furnace in SIMIO

Platform Environment

Georgios Tsaousoglou and Stamatis Manesis

Department of Electrical and Computer Engineering, University of Patras, Eratosthenous Str., Rio, Greece

Keywords: Industrial Production, 3D Modeling, Simulation, Production Management.

Abstract: This article presents a 3D simulation of an industrial large-scale furnace operating in the NGC (Northern

Greece Ceramics) ceramics industrial plant. The 3D modelling and simulation of the long industrial furnace

is based on the SIMIO software platform the capabilities of which are explored and tested in such a complex

production plant. After the understanding of the real system operational characteristics, its macroscopic

behaviour has been extracted and modelled; then a 3D model was created. Using the model, matters

concerning the production process optimization are explored, while also alternative production scenarios are

simulated, so that conclusions for the system’s behaviour at value variation of the functional parameters of

the real system can be extracted, without experimenting on the real process. In the four main sections of this

article, the following aspects are presented: the modeling approach of the furnace operation, the SIMIO

model of the furnace, its operation, examples of possible model applications and utility of the developed

model and further modeling of the whole production procedure preceding the furnace.

1 INTRODUCTION

Ceramic industry is considered to be among the

most ancient industries (Ameida et al., 2013). As the

production facilities and techniques are up-to-date

evolving, the production of bricks and tiles in the

modern era is supported almost entirely by industrial

large-scale production units. The major

reconstruction and the global adoption of the use of

ceramics in building architecture brought the

requirement for large-scale production as well as for

quality control, standardization, modernization of

methods, production cost reduction and innovation

(Bleininger, 1917) with one of the latest fields of

research being the production of ceramics from

waste materials (Jahangirian et al., 2010).

In a modern ceramics production unit, the entire

production process is automated. In normal

operation of the system no interference of human

hand is needed in any stage of the process, from mud

mixing, to shaping to drying (Lianyang Zhang,

2013), to baking. Human employment is oriented at

supervision, prevention and correction of errors,

planning and production organization etc. The

manual labor is replaced by integrated automated

systems formed by the cooperation of conveyors,

machinery processing, robotic arms, etc. The

production capacity of modern units totals more than

1000 tones of product per day. Industrial furnaces

are used, whose length is approximately 100 meters

while the maximum temperature of the interior, are

of the order of 1000 degrees Celsius.

1.1 The Profits of Simulation in the

Industrial Ceramics Furnace

Application

Simulation represents important elements of the real

system, thus has long been used to help designers,

engineers and investors, experience exposure to

circumstances both routine and unexpected and

explore the behavior of a system under certain

conditions. In the last decades a very large amount

of simulation techniques and applications have been

published (Terzia et al., 2004). The simulation

model can be used to investigate possible changes

and alternative choices in a low risk environment, as

opposed to the risk of experimenting with the actual

furnace plant, which could result not only in

inestimable cost but also in accidents of high danger.

Hence, ceramics production units are too expensive

or dangerous to make live tests. Simulation provides

a cheap, safe way to check the changes that may be

either a simple revision to the existing production

716

Tsaousoglou G. and Manesis S..

3D Simulation of Industrial Large-scale Ceramics Furnace in SIMIO Platform Environment.

DOI: 10.5220/0005046207160723

In Proceedings of the 11th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2014), pages 716-723

ISBN: 978-989-758-040-6

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

line, emulation of a new control system or

redesigning the entire production chain. The “best

guess” is usually a poor substitute for an objective

analysis, while now we can accurately predict

system behavior under different conditions and

reduce the risk of a bad decision.

Moreover, here the prediction of variability of

the process is important. A quick analysis cannot

capture the dynamic aspects of the system and issues

that can have a significant impact on system

performance. Through simulation we can be

provided with a better understanding of how

different parts interact and how they affect the

overall system performance.

Finally, with the modeled developed we are

given the capability of communicating ideas. We

can help partners, customers, employees or investors

to better understand the system. The modern 3D

modeling promotes communication and

understanding to a wide audience.

1.2 SIMIO Simulation Software

SIMIO is a SImulation Modeling framework based

on Intelligent Objects. It is a modeling tool that

combines the simplicity of objects with the

flexibility of procedures for the provision of a rapid

modeling without requiring programming (Oba et

al., 2014). It can be used to predict and improve the

performance of dynamic, complex systems (Pegden,

2014). The software prototypes and displays a three-

dimensional illustration of the behavior of the

system over time. Although simulation and

visualization tools have existed for many years,

SIMIO makes modeling extremely easy by

providing a new object-oriented approach. One can

select (http://www.simio.com/index.html) objects

from libraries and place graphics in the model.

Objects represent the physical components of the

system, such as tiles, conveyors, wagons etc. One

aspect that is often overlooked in the analysis of

systems performance is the role that randomness

plays in determining the behavior of the system. By

randomness we mean the idea that things that

happen in our system occur with some differences

from one another. Classic examples of randomness

are: the time between the arrival of a system entity

until the arrival of the next, the time between

failures of equipment or the time it takes to complete

an activity. If we want to understand and improve

our system we need to model accurately the

variations relevant to the randomness in the system.

In the model developed, the randomness factor was

implemented for the production line preceding the

furnace. The model of the furnace itself is

deterministic, as is the actual system due to control

techniques applied.

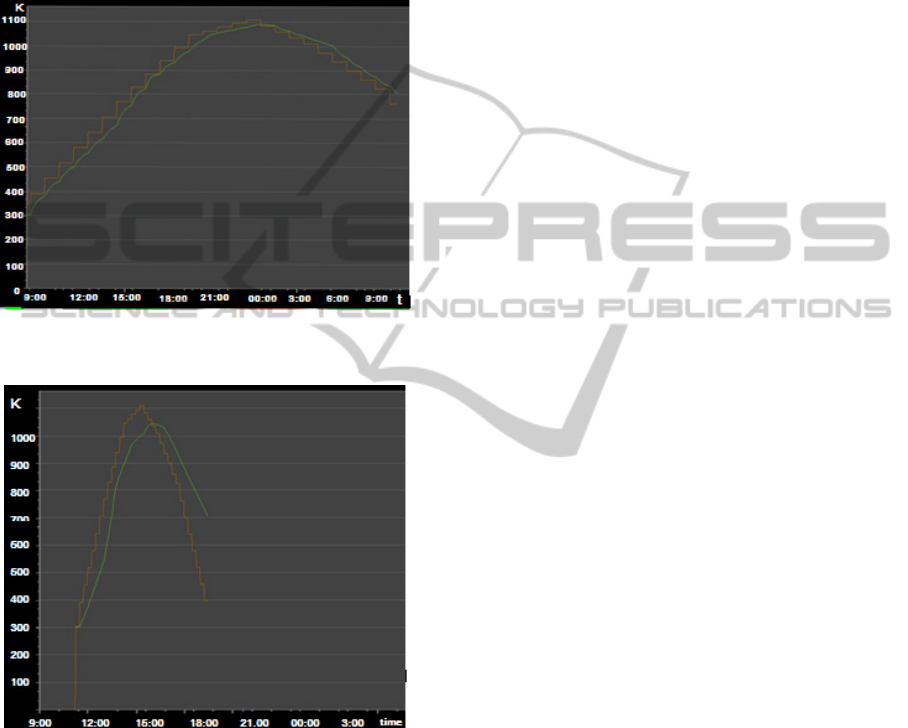

Consider a SIMIO model for a very simple

system in which entities arrive, processed by a

server, and then depart from the system. For this

simple example in which the system makes use of a

source, a server, a draw and a route from the library,

the SIMIO model is shown in Figure 1. The entities

entering the system from the source move to the

server where they are processed one by one and then

go to the draw where they leave the system.

The rate at which the source creates entities and

the processing time in the server are adjusted from

the user to the properties of the corresponding object

and the aforementioned factor of randomness can be

included (SIMIO LLC Documentation, 2011).

1.3 Overview of the Industrial, Large

Scale, Ceramics Furnace

The furnace, with which we deal, is of the

continuous, propulsion type. There are two gates,

one entrance and one exit and the tiles are baked

while moving inside the oven. In fact every time a

new wagon of tiles enters, all wagons move forward

to the next position, while the last wagon leaves the

oven. The oven has a length of 90 meters and 33

wagon positions. In normal operation, the input rate

of the heat is stable and the burners are rarely turned

off. Three distinct zones along the oven are formed.

First is the preheating zone starting from the first

wagon until the 7th. Second is the fire zone from the

8th until the 18th wagon and third is the cooling

zone from the 19th until the 33th wagon. The

thermal energy flow inside the furnace is subject to

extensive thermal analysis (Warren et al., 2000). In

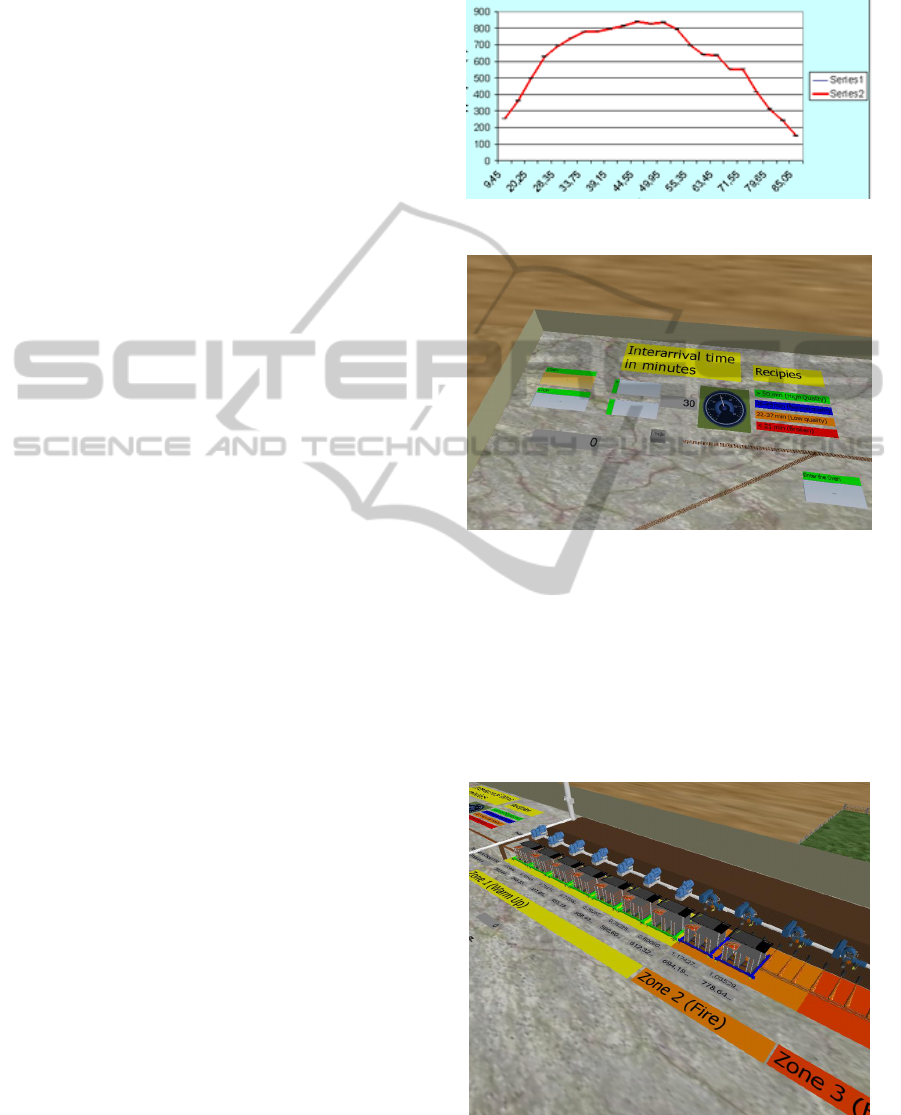

Figure 2, the temperature curve throughout the

length of the oven is presented.

Figure 1: Simple SIMIO model.

2 MODELING APPROACH OF

THE FURNACE OPERATION

Each wagon is modeled as an entity carrying the

3DSimulationofIndustrialLarge-scaleCeramicsFurnaceinSIMIOPlatformEnvironment

717

following properties which are variable with respect

to time:

• Temperature: Refers to the current temperature of

the tiles in the wagon

• Temperature Rate of change: Is the current rate at

which wagon temperature changes. Expressed in

degrees Kelvin per minute

• Ready or not: Boolean variable expressing whether

the tiles are baked (ready) or not.

• Quality: Expresses the current quality of the

wagon’s tiles based on the quality of baking

suffered. The more abruptly the temperature is

altered the worse the tiles quality turns out to be.

• Damaged or not: Boolean variable which expresses

whether the tiles are broken (due to abrupt

temperature change).

The most important of the above is the

“Temperature Rate of change”, according to which,

the rest of the properties are easily calculated. The

rate at which the tiles temperature changes at each

position depends on the temperature difference with

respect to the environment (furnace position

temperature) and a number of factors such as the

thermal conductivity of the material, the proportion

of heat absorbed by the walls of the furnace and of

the metals of the wagon etc. The industrial furnace

operation is thus described by a set of strongly non-

linear equations, making it extremely difficult to

implement them in a 3D model which needs to solve

them in a short simulation time. The shortness of the

simulation time is important here, so that the

illustrative part of the model is valid. Based on real

systems’ data and the industrial furnace model non-

linear equations, linear equations were built to

approach the macroscopic behavior of the system

and applied in order to estimate the “Temperature

Rate of change” in real time for each individual

wagon at its current position.

The user determines the rate at which wagons are

imported in the furnace (minutes before entering

new wagon). This is the same like determining how

long a wagon remains at each position. As output,

the user sees the current real time simulation values

of the above wagon’s properties, for each individual

wagon. Moreover sees the temperature at which the

wagons leave the furnace (exiting temperature) and

the total number of wagons produced.

3 THE SIMIO MODEL OF THE

FURNACE

We have now a first version of the model. At the

entrance of the furnace, wagons arrive at a rate set

by the user as shown in Figure 3.

Figure 2: Temperature throughout the length of the oven.

Figure 3: User defines the input rate.

The first wagon inserts at the first position, where it

stops and begins to alter its properties based on the

model equations and the parameters of the position

(environment temperature). When the second wagon

arrives, inserts at the first position, “pushing” the

first wagon to the second position, where its

properties continue altering, based now on the

parameters of the second furnace position.

Figure 4: Wagons processing through the furnace.

The process shown in Figure 4 continues until

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

718

the user presses the Stop button. When a wagon

arrives at the last position (33h), on the next wagon

arrival, it exits the furnace, its temperature is

recorded at the “output temperature by which the

wagons leaving the oven” and leaves the system.

Figure 5: Indication of outputs.

The model illustrates all the outputs that the user

needs to see as shown in Figure 5.

1) Current temperature in each wagon

2) Current Temperature Rate of change for each

wagon

3) Maximum temperature rate suffered by each

wagon

4) For each wagon if it is ready or not

5) The current quality of tiles of each wagon. This

is depicted by the color of the base of the wagon.

Interpreted as:

Green: High quality

Blue: average quality

Orange: Poor quality

Red: broken tiles (Figure 6)

Figure 6: Wagons turn red when tiles are broken.

Figure 7: Wagons turn green when ready.

When the temperature of the tiles of a wagon

exceeds a certain value, they are considered baked

(ready) and the roof of the wagon turns green as

shown in Figure 7.

Each wagon, in addition to the above indications,

also carries two displays on the roof. A thermometer

which shows the current temperature and a diagram

showing the temperature of the particular wagon as a

function of time, from the time entered in the

furnace until the current time.

This chart gives us a very useful illustration of

temperature, from which one can understand the

response and operation of the model. The red line

shows the furnace temperature from place to place,

such as seen by the wagon. Step increased, as the

wagon moves from one position to the next. As

shown, the curve of the temperature along the

furnace, extracted by the model during the

simulation, verifies the actual oven temperature

curve (Figure 2).

The green line shows the temperature of the tiles.

This generally tends to approach the red line.

Whether it reaches it or not, depends on the time

given to it, i.e. how much time a wagon is left to stay

in each position. As we can see in Figures 8 and 9,

clearly depends on the rate at which wagons are

imported in the oven. Two examples are given.

In Figure 8 the wagon tiles’ temperature

approaches the furnace temperature quite accurately,

which is logical as they are baked for quite a long

time.

The curves in Figure 9 result steeper, which

means high rates of temperature change of the tiles,

i.e. tiles of low quality or cracked. Also, it must be

noticed that the green curve does not manage to

reach the red.

3DSimulationofIndustrialLarge-scaleCeramicsFurnaceinSIMIOPlatformEnvironment

719

Practically, this means that we spent much

energy to maintain the oven temperature high,

without this being exploited for the baking of the

tiles since they do not stay long enough in the oven

to smoothly absorb this heat. Characteristic of this

waste is the temperature at which the wagons leave

the furnace (exiting temperature), as will be made

clear in the next section.

Figure 8: Wagon temperature diagram for low import rate

(one wagon every 60 minutes).

Figure 9: Wagon temperature for high import rate (one

wagon every 15 minutes).

4 EXAMPLES OF POSSIBLE

MODEL APPLICATIONS AND

UTILITY OF THE DEVELOPED

MODEL

We want to study the behavior of the model and the

results for different values of operating parameters.

The aim is to draw conclusions about the real system

and with the experiments made on the model. Thus,

to the extent that the model corresponds to the real

system, we acquire knowledge about the behavior of

the system in different operation modes. That would

be impossible to achieve with experimentation on

the actual production line, since the cost would be

too high.

With the experience drawn by experiments, we

can now make decisions concerning the production

strategy, making strategic choices and not random.

Experimentation could be done by running the

model separately for each case. But SIMIO provides

us with a powerful simulation tool, which gives us

the ability to run experiments. The designer designs

the experiment by choosing parameters which are

subject to value variation and setting the values of

these for each "scenario". Then selects those outputs,

which’s the behavior wants to study. The different

scenarios are running really fast and the software

shows the results. An example of such an

“experiment” is following.

4.1 Experiment: Study of the Import

Frequency of Wagons in the Oven

As varying-value parameter we select the import rate

of wagons in the oven (minutes per wagon) chosen

by the operator. We want, in correspondence with it,

to study the temperature at which wagons exit the

furnace.

The outlet temperature is a very important

parameter in the operation of the oven. It is a

characteristic parameter which indicates whether we

apply proper heat management of the oven and

proper management of the fuel. A high value of this

temperature is undesirable, mainly for two reasons.

First, tiles of high outlet temperature are sensitive to

cracks during further processes and secondly show

us that there has been waste of fuel. This is partly

because the excess heat, stored in the tiles, is

released in the environment and not exploited for

use in heating the tiles currently being in the stages

of fire, preheating or drying. Also, the fuel spent to

maintain the furnace temperature at high levels is

not utilized properly, because the tiles do not have

time to absorb the heat, thus resulting being baked

forcibly and heat is released to the environment

through the cooling tower, which in normal

conditions is not used at all.

We will consider four cases for value variation of

import rate: entering wagon every 19, 24, 42 and 52

minutes respectively. The results of the experiment

are summarized in Table 1.

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

720

4.2 Use of the Results for Improvement

of the Production Strategy

From the results we can estimate which is the cost

(high temperature output) if we want to produce

quickly (increase production). Hence, if there is a

need for rapid production (e.g. short-notice order)

we can determine the cost of meeting the demand, so

that the pricing of the product can be made

accordingly.

Table 1: Tiles exiting temperature to varying values of

Import Rate.

Import Rate (min) Exiting Temperature (K)

19 659.5

24 619.5

42 538.2

52 512.8

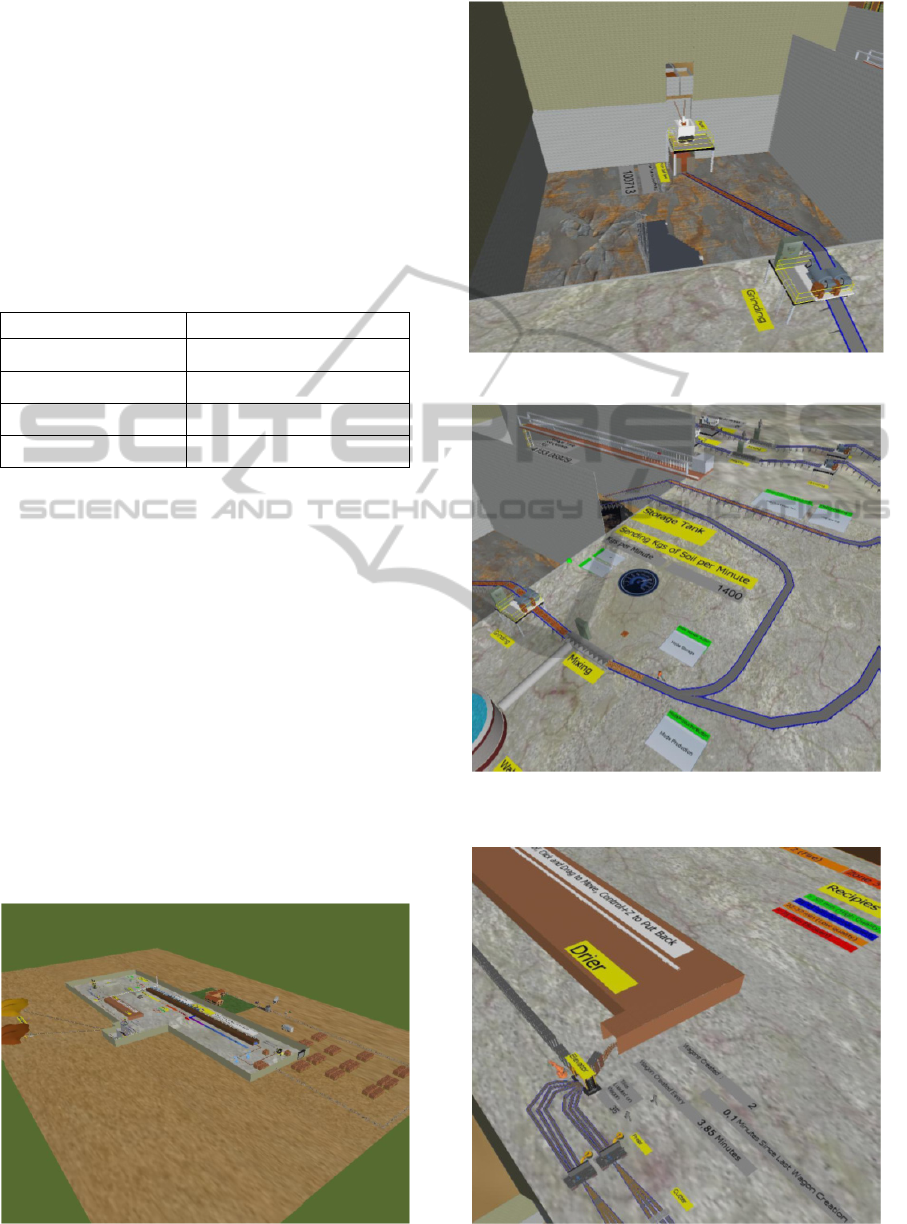

5 FURTHER MODEL

EXTENSION AND

APPLICATION

The whole production line (preceding the furnace)

was modeled. The stages in which the soil is

smoothed, mixed, stored, molded, cut, dried and

loaded on the wagons are incorporated in the model

and some samples are presented in Figures 10-13.

With the whole production line modeled, the user

can select with how many kgs per minute of soil he

wants to supply the production line. The choice of

the user is very important for the operation of the

whole model since as we will see, so is the rate at

which wagons enter the oven. That is, the user's

Figure 10: Panoramic view of the model.

Figure 11: Grinding stage.

Figure 12: User defines kgs per min of soil sent to the

production line.

Figure 13: Wagons of tiles inserted in the Drier.

3DSimulationofIndustrialLarge-scaleCeramicsFurnaceinSIMIOPlatformEnvironment

721

choice must be consistent with the production goals

to be served. An experiment this option affects the

rate at which wagons are prepared, thus designed

upon the variation of the parameter value “kgs per

minute” (of soil sent to the production line) explores

the impact of the user’s possible choices while in

this experiment the randomness factor is being

incorporated in our model, representing the

deviation in the value of the aforementioned

parameter, “kgs per minute”.

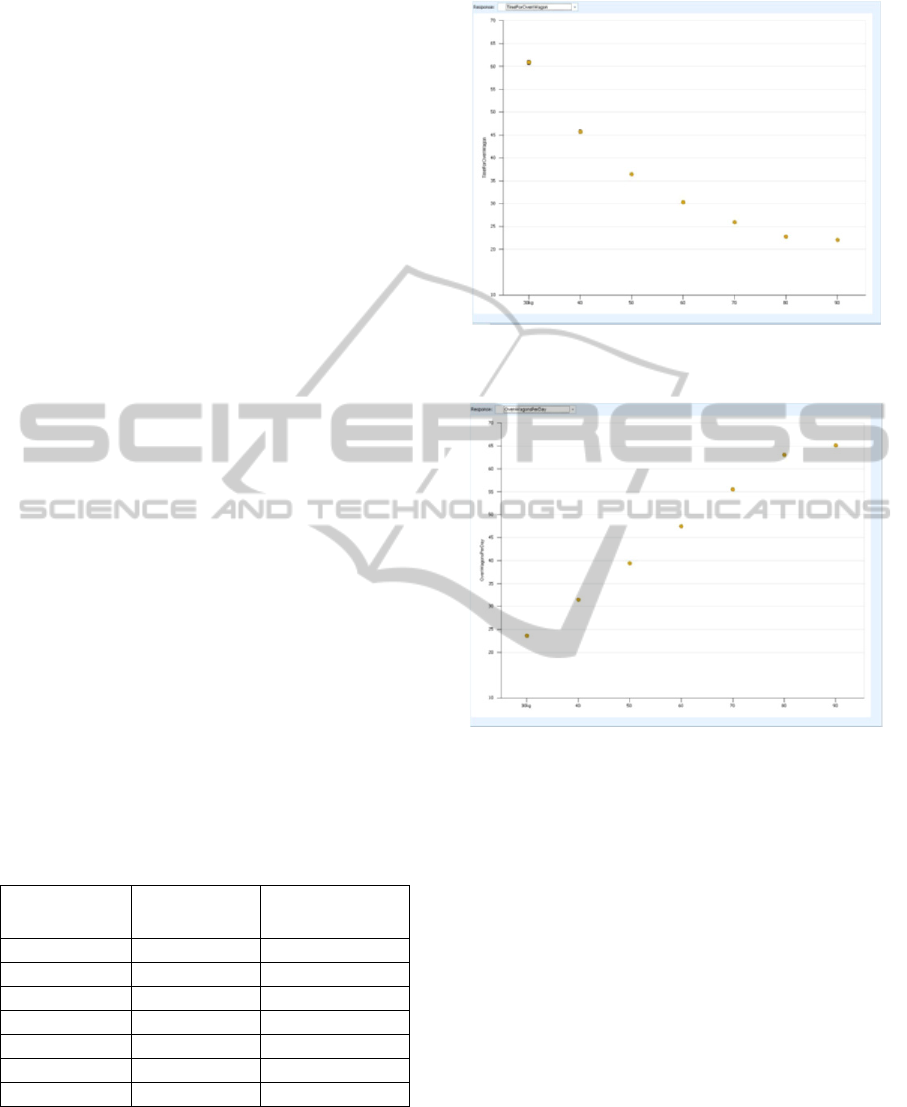

5.1 Experiment: Study of the Wagon

Production Rate

As varying parameter is set the rate at which soil is

provided to the production line (kgs per minute). We

want to study the time it takes to prepare a wagon

and the number of wagons prepared in 24 hours with

respect to this parameter.

We will study seven cases for the value of the

soil supply rate from 30 to 90 (in step 10) kgs of soil

per minute. A deviation is also incorporated. More

precisely, the rates of supply are 7 different

distributions (normal) with centers of the above

values and a standard deviation of 10. The results of

the experiment are summarized in Table 2, (average

values of distributions). The two responses of the

experiment are represented graphically in Figures 14

and 15. The supply of soil is represented on the

horizontal axis in kgs per minute.

Furthermore, by combining the results of the two

experiments, we can answer the question: "If you

have to produce X wagons in Y days, how much soil

must be provided to the line?"

Table 2: Time for Wagon preparation and Wagons

produced in 24 hours, according to the soil supply of the

line (model experiment results).

Soil Supply

(kgs per min)

Time for

Wagon (min)

Produced

Wagons in 24h

30 60.89 23

40 45,76 31

50 36,47 39

60 30,33 47

70 25,95 55

80 22,82 63

90 22,10 65

That is, if we want to produce X wagons the next

day, we should put wagons at a rate A, thus we

provide Y soil supply at current day (about 13 hours

earlier because of the residence time in the drying

stage and preparation time). So depending on the

Figure 14: Time for wagon preparation (vertical axis) as a

function of soil supply.

Figure 15: Wagons produced in 24 hours (vertical axis) as

a function of soil supply.

value of X someone can find the appropriate value

for Y from tables or rerun the experiment for the

desired value of X.

6 CONCLUSIONS

A 3D model of the system and examples of

experiments using SIMIO were implemented in this

paper. The simulation experiments protect us from

wasting resources and poor choices. In addition, it

can help to investigate investment projects. For

instance, it can be studied on the model a new

machine installation to replace an old and with

respect to the new performance of the particular

stage, to study the impact to the whole production.

Thus we can estimate the feasibility, viability and

usefulness of the candidate investment. Results show

that such a model could be proven quite a useful tool

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

722

in the hands of the production organizing engineer,

the investment consultant as well as the investor.

It should be noted that such models, while

powerful are only used to support the decision

making process only offline. It is open to future

research, the implementation of simulation models

that dynamically communicate with the operating

furnace, predicting its sort term behavior to a

possible decision so as to support a real time

decision support tool.

REFERENCES

Ameida, G, Silva J. et al. (2013) Heat and mass transport

in an industrial tunnel dryer: modeling and simulation

applied to hollow bricks. Applied Thermal Eng., Vol.

55, pp 78–86.

Bleininger, A. V. (1917) “The development of the ceramic

industries in the United States” Journal of The

Franklin Institute, Vol. 183, 1917.

Jahangirian, M.et al. (2010) Simulation in manufacturing

and business: A review European Journal of

Operational Research, Vol. 203, pp 1–13.

Lianyang Zhang (2013) Production of bricks from waste

materials – A review, Construction and building

materials, Vol. 47, pp 643-655.

Matthew, P. et al. (2000) Technological innovation

antecedents in the UK ceramics industry, Int. J.

Production Economics, Vol. 65, pp 85-98.

Oba, R., et al. (2014) Thermal analysis of a tunnel kiln

used to produce roof tiles Applied Thermal

Engineering Vol. 63, pp 59-65.

Pegden, D. C. (2014) “An Introduction to Simio® for

Beginners” www.simio.com, Simio LLC 504 Beaver

St.Sewickley, PA 15143, U.S.A.

SIMIO LLC. Documentation (2011), SIMIO Reference

Guide, Version 4.

Terzia, S. & Cavalieri S. (2004) Simulation in the supply

chain context: a survey, Computers in Industry, Vol.

53, Issue 1, pp 3-16.

Warren, M. P. et al. (2000) Technological innovation

antecedents in the UK ceramics industry, Int. Journal

Production Economics, Vol. 65, pp. 85-98.

http://www.simio.com/index.html.

3DSimulationofIndustrialLarge-scaleCeramicsFurnaceinSIMIOPlatformEnvironment

723