Modeling and Simulation of Pyroprocessing Oxide Reduction

H. J. Lee, W. I. Ko, S. Y. Choi, S. K. Kim, H. S. Lee, H. S. Im,

J.M. Hur, E.Y. Choi, G. I. Park and I. T. Kim

Department of Nuclear Fuel Cycle System Development, Korea Atomic Energy Research Institute, 111,

Daekdaero 989beon-gil, Yuseong-gu, 305-353 Daejeon, Republic of Korea

Keywords: Pyroprocessing, Oxide Reduction, Dynamic Material Flow, Material Balance, Operation Model.

Abstract: Pyroprocessing operation modeling features complicated batch type operation, tangled material flow logic,

handling many numbers of unit processes. Discrete event system (DES) modeling was applied to build an

integrated operation model of which simulation showed that dynamic material flow was accomplished. In

the model simulation, the amount of material transported through upstream and downstream in a process

satisfied the mass balance equation for every batch operation. This study also analysed in detail an oxide

reduction process and showed that every stream’s material flow could be exactly tracked under DES

modeling environment.

1 INTRODUCTION

Material balance for a newly developed process is

mainly studied in a flowsheet (Piet et al., 2011).

However, this is nothing more than an accumulated

amount of material transported through in and out

streams during a specific period, in other words,

equilibrium material balance. Thus, dynamic

changes according to the batch operation cannot be

predicted in an equilibrium material flow. This study

began to build a dynamic material balance model

based on the previously developed pyroprocessing

flowsheet (Lee

a

et al., 2013). As a mid- and long-

term research, an integrated pyroprocessing

simulator (Lee

b

et al., 2013) is being developed at

the Korea Atomic Energy Research Institute

(KAERI) to cope with a review on the technical

feasibility, safeguards assessment, conceptual design

of facility, and economic feasibility evaluation. The

most fundamental thing in such a simulator

development is to establish the dynamic material

flow framework. Therefore, this study focused on

the operation modeling of pyroprocessing to

implement a dynamic material flow. As a case study,

oxide reduction was investigated in terms of a

dynamic material flow.

There are some recent interesting works similar

to this study, the US devoted to developing a spent

nuclear fuel (SNF) reprocessing plant level toolkit

named RPTk (Reprocessing Plant Toolkit)

(McCaskey et al., 2011). Japan developed an

analysis code (Okamura and Sato, 2002) for an

estimation of the material balance for the system

design of the pyrochemical reprocessing plants

consisting of batch processes. As a preliminary

study, Korea also developed DES based model to

implement simplified dynamic material flow for

pyroprocessing (Lee et al., 2011).

2 OXIDE REDUCTION

2.1 Pyroprocessing

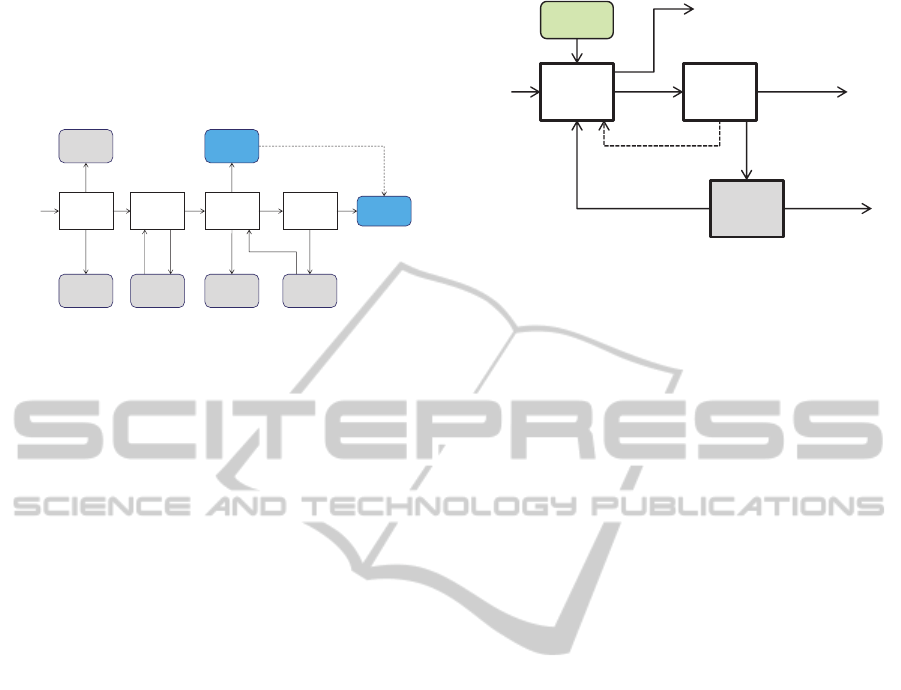

As shown in Figure 1, pyroprocessing includes

many processes and complex recycling flows. It is

still developing technology, and is not matured. A

lot of effort has been placed into an investigation of

its principle. Since the current experimental study

focuses on unit process technology, not an integrated

process, it is difficult to predict the overall behavior

and mutual influence. However, modeling and

simulation can make it possible to see unforeseeable

results. Since pyroprocessing mostly consists of

dozens of batch-type processes, a discrete event

system is preferred to model this system if main

concerns are not the chemical reaction within one

batch operation.

Each box in Figure 1 indicates a grouped process

and the number of unit processes is actually more

than in Figure 1. The arrows represent a material

flow direction. Pyroprocessing produces not

685

Lee H., Ko W., Choi S., Kim S., Lee H., Im H., Hur J., Choi E., Park G. and Kim I..

Modeling and Simulation of Pyroprocessing Oxide Reduction.

DOI: 10.5220/0005009906850692

In Proceedings of the 4th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2014),

pages 685-692

ISBN: 978-989-758-038-3

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

recyclable products from SNF but also wastes to be

disposed of. The final products of pyroprocessing

are a uranium (U) metal ingot and transuranic (TRU)

metal, and final wastes are the filter, metal, and

ceramic wastes.

Figure 1: Simplified pyroprocessing material flow diagram.

Pyroprocessing features complicated the batch

type operation, tangled material flow logic, and

numerous SNF elements to be tracked. Thus, the

material balance must be calculated whenever events

such as feed arrival and product departure occur.

Otherwise, a dynamic material flow cannot be

tracked. The basic understanding of the whole

process is well fulfilled by a flowsheet study, which

represents an equilibrium material balance at a

specific time.

2.2 Oxide Reduction

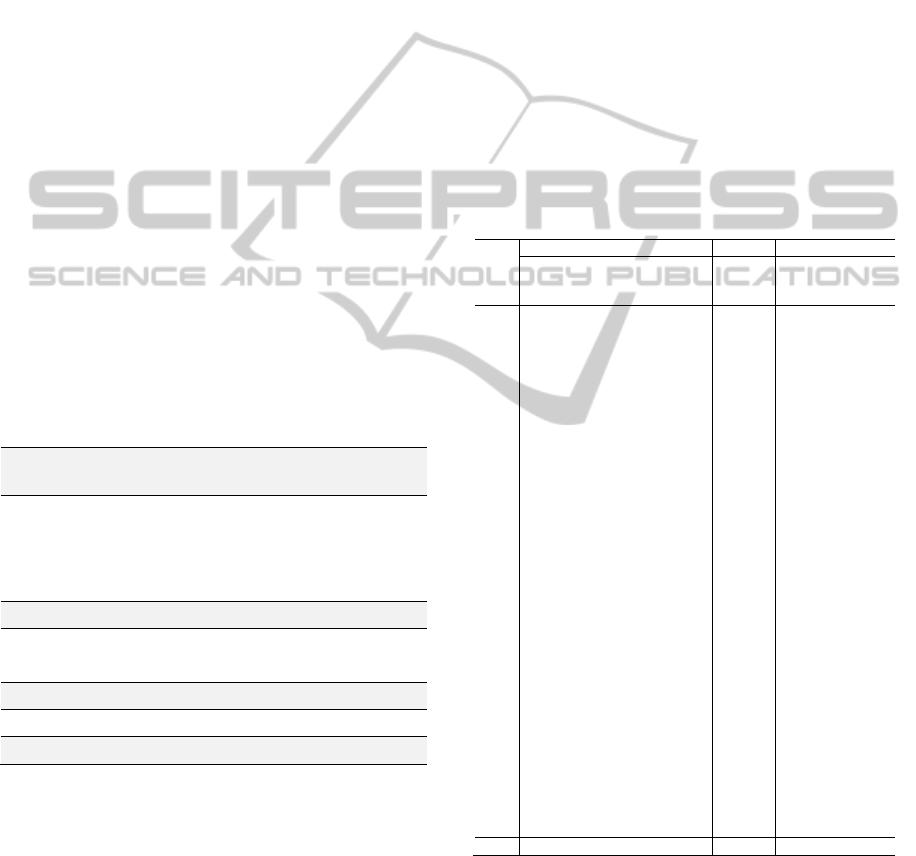

The oxide reduction process receives oxide SNF

feed material of porous pellet or fragment generated

from the headend process. The oxide SNF is

converted into metallic form in a LiCl molten salt

bath. During the electrolytic reduction process, the

oxide powder is reduced into a metal form, which

normally contains most of the transition elements,

all of the actinides and a certain fraction of rare earth

elements. The reduced metal is sent to cathode

processing to distill residual salt entrained in

reduced metal deposit and then transferred to the

next process, electro-refining. The remaining LiCl

salt in an electrolytic reduction bath after several

process operations contains most of the fission

products with a high heat load, such as Cs, Sr and Ba,

which are separated from the metallic powder. The

LiCl salt is sent to a LiCl salt purification process to

recycle it by separating LiCl residue concentrated

with Cs, Sr, and Ba from pure LiCl. Figure 2

illustrates three unit process and product streams

regarding oxide reduction.

Figure 2: Material flow diagram for oxide reduction.

3 MODELING

3.1 Operation Procedure

The pyroprocessing flowsheet study represents

equilibrium mass balance, i.e., accumulated amount

of material transported through in and out streams

during a specific period (one year is mostly used). It

does not provide detailed information regarding the

batch operation. Thus, the batch operation procedure

was investigated based on the process currently

under development. The electrolytic reduction (P2-1)

has 50kgHM/batch and 400kg-salt/batch. It receives

recovered salts after distillation in cathode

processing (P2-2) every other batch operation during

the 1

st

campaign (1

st

through 40

th

batch operations).

Since P2-1 at the 1

st

batch operation cannot receive

recovered salt from P2-2, the 3

rd

, 5

th

, … , 39

th

batch

operations are reasonably practicable to receive the

recovered salts. Process P2-1 does not receive any

salt from P2-2 during the 2

nd

campaign (41

st

through

80

th

batch operation) but receives fresh salt as much

as insufficient amount. It receives regenerated salts

for every other batch operation from the LiCl

purification process (W4-1) since the 3

rd

campaign,

i.e., the 81

st

batch operation. If the regenerated salt is

not enough to facilitate the process of P2-1, fresh

salt can be added. As the number of P2-1’s

campaign changes, the direction of material flow

changes in process P2-2, the recovered salts is

transferred to P2-1 during the 1

st

campaign but to

W4-1 since the 2

nd

campaign.

The above operation procedure is changed

according to the batch operation number.

Consequently, the amount of generated work in

process (WIP) and its direction of flow are affected

by the operation procedure. Such transient behavior

must be well described in a model in terms of the

inventory management, nuclear material

P1

Head‐end

P2

Oxide

Reduction

P3

Electro‐

Refining

P4

Electro‐

Winning

LiCl‐KCl

salt‐waste

treatment

Hullwaste

treatment

Offgas

treatment

LiCl salt

waste

treatment

Anode

sludge

treatment

Uingot

TRU+RE+U

SpentNuclear

Fuel(SNF)

P2‐1

Electrolytic

Reduction

P2‐2

Cathode

Processing

W4‐1

LiCl

Purification

FreshSalt

(LiCl,Li

2

O)

Reduced

metal

withsalt

RecoveredSalt

(1

st

campaign)

RegeneratedSalt

(from3

rd

campaign)

Reducedmetal

Pellet,

fragment

ConcentratedSalt

Offgas (O

2

)

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

686

accountancy, and productivity of the integrated

process.

3.2 Material Balance

Dynamic material balance describes the amount of

feed, hold-up, and product in any process for every

batch operation. If accumulating the amounts of

received and departed material for a specific period,

an exact equilibrium material balance can be

obtained. Because the above operation procedure is

difficult to implement, an equilibrium material

balance tends to simplify the complicated operation

to the averaged one, i.e., every batch operation is

assumed to be the same. However, if we can build

an exact model through appropriate tools or

methodologies to reflect such tangled operation

requirement, the assumed equilibrium material

balance obtained from a flowsheet study can be

replaced with an exact material balance in an exact

model.

For comparison between equilibrium and

dynamic material balance, it is assumed that the

oxide reduction treats 10tHM per year, which

corresponds to 200 batch operations of process P2-1.

An equilibrium mass balance in process P2-1 is

shown in Table 1.

Table 1: Equilibrium material balance in P2-1.

Material via

stream

type SNF

mass(kg)

Salt

(LiCl, Li

2

O)

new salt feed - 824

pellet/fragment feed 11,331 -

recovered salt feed 5 350

regenerated salt feed 6 1,146

Sum of inputs 11,341 2,320

cathode product product 9,997 1,935

O

2

product 1,331 -

Sum of outputs 11,328 1,935

remaining salt hold-up 13 385

Sum of hold-up 13 385

Since the equilibrium material balance shows

accumulated results over numerous batch operations,

the difference of each batch is ignored. Process P2-1

has a total of 4 inputs and 2 outputs. The sums of the

inputs and outputs are not the same because process

P2-1 can hold a small amount of SNF in its bath.

Therefore, the sum of inputs exactly matches the

sum of outputs and hold-up. We cannot predict from

equilibrium material balance any transient behavior

affected by operation procedure described in section

3.1. Tables 2 and 3 show dynamic SNF and salt

balances, respectively, obtained from a discrete

event system (DES) model of oxide reduction. It

shows different results from every batch operation:

amount of inputs, outputs, and hold-up in process

P2-1 for every batch operation. In Table 2, every

batch operation of P2-1 receives 50kgHM/batch

fragment or pellet from the previous process

excluding O

2

weight. The 2

nd

column in Table 2

represents the minimum weight of oxide form of a

fragment or pellet. Excluding oxide, only the SNF

element weight becomes 50kgHM/batch. The weight

of oxide form can be more than the sum of 50kg and

O

2 weight measured at the output stream because

reduction yield ratios are not 100% about all SNF

oxide elements. The reduction yield ratio is one of

the parameters that significantly influence the

material balance at the out stream.

Table 2: SNF material balance in P2-1.

batch #

inputs hold-up outputs

fragment/

pellet(kg)

recovered

salt(kg)

r

egenerate

d

salt(kg)

remaining

salt(kg)

cathode

product

(kg)

O2(kg)

1 56.67 - - 0.28 49.72 6.67

2 56.67 - - 0.5

4

49.73 6.67

3 56.59 0.02 - 0.83 49.74 6.59

4 56.67 - - 1.08 49.75 6.67

5 56.59 - - 1.33 49.75 6.59

6 56.67 - - 1.57 49.76 6.67

7 56.59 0.05 - 1.85 49.77 6.59

8 56.67 - - 2.08 49.77 6.67

9 56.59 0.08 - 2.38 49.78 6.59

…………………

41 56.59 - - 10.25 49.97 6.59

42 56.67 - - 10.27 49.98 6.67

43 56.59 - - 10.3

0

49.97 6.59

44 56.67 - - 10.32 49.98 6.67

45 56.59 - - 10.35 49.97 6.59

46 56.67 - - 10.37 49.98 6.67

47 56.59 - - 10.4

0

49.97 6.59

…………………

81 56.59 - 0.08 11.03 49.99 6.59

82 56.67 - - 11.0

4

50.00 6.67

83 56.59 - 0.08 11.13 49.99 6.59

84 56.67 - - 11.13 50.00 6.67

85 56.59 - 0.08 11.21 49.99 6.59

86 56.67 - - 11.22 50.00 6.67

87 56.67 - 0.08 11.3

0

49.99 6.67

…………………

194 56.67 - - 13.3

0

50.05 6.67

195 56.67 - 0.11 13.37 50.04 6.67

196 56.67 - - 13.32 50.05 6.67

197 56.67 - 0.12 13.39 50.04 6.67

198 56.67 - - 13.3

4

50.05 6.67

199 56.67 - 0.12 13.41 50.04 6.67

200 56.67 - - 13.36 50.05 6.67

tota

l

11,331.06 4.55 5.66 13.36 9,996.85 1,331.06

For example, actinide elements are almost

reduced to metal form such that 99.5% of those

oxides convert into metal form but lanthanide

elements are rarely reduced such that only 30% of

those oxides convert into metal form. Generally, the

overall reaction for oxide reduction of an arbitrary

ModelingandSimulationofPyroprocessingOxideReduction

687

metal oxide can be described as follows

(Phongikarron et al., 2011):

M

x

O

y

→ xM +

O

2

(g)

(1)

In the case of actinide, 99.5% of M

x

O

y

converts

into metal by electrolytic reduction but 0.5% of

M

x

O

y

still keeps its original form. Some elements (Se,

Rb, Cs, Sr, Ba, Eu, and Te) are dissolved and

transferred to a salt bath to become chloride forms.

Therefore, cathode product contains three types of

product forms: metal, oxide, and chloride form. The

chloride form is entrained in a cathode product along

with LiCl salt when the cathode product is

transferred to cathode processing P2-2. The 4

th

column represents only the element weight of

chloride form in salt. The 5

th

column in Table 2

represents the sum of the three types. The 3

rd

and 4

th

column indicate only element weights of chloride

forms contained in salt.

Table 3: Salt material balance in P2-1.

batch

#

inputs hold-up outputs

Fresh

salt(kg)

recovered

salt(kg)

regenerate

d salt(kg)

remaining

salt(kg)

cathode

product(kg)

O2(kg)

1 404.00 - - 394.06 9.94 -

2 - - - 384.13 9.93 -

3 - 19.67 - 393.88 9.92 -

4 - - - 383.96 9.92 -

5 - - - 374.06 9.91 -

6 - - - 364.15 9.90 -

7 - 19.64 - 373.90 9.89 -

8 - - - 364.01 9.89 -

9 - 19.61 - 373.74 9.88 -

… … … … … … …

41 42.26 - - 394.31 9.69 -

42 - - - 384.62 9.68 -

43 19.38 - - 394.31 9.69 -

44 - - - 384.63 9.68 -

45 19.37 - - 394.31 9.69 -

46 - - - 384.63 9.68 -

47 19.37 - - 394.31 9.69 -

… … … … … … …

81 0.17 - 19.17 394.33 9.67 -

82 - - - 384.66 9.67 -

83 0.17 - 19.17 394.33 9.67 -

84 - - - 384.67 9.66 -

85 0.17 - 19.16 394.33 9.67 -

86 - - - 384.67 9.66 -

87 0.17 - 19.16 394.33 9.67 -

… … … … … … …

194 - - - 384.77 9.61 -

195 0.17 - 19.06 394.38 9.62 -

196 - - - 384.77 9.61 -

197 0.17 - 19.06 394.38 9.62 -

198 - - - 384.77 9.61 -

199 0.17 - 19.06 394.38 9.62 -

200 - - - 384.77 9.61 -

total 824.24 349.83 1,146.07 384.77 1,935.37 -

Every unit process model must satisfy dynamic

material balance equation for every batch operation.

,

,

(2)

where is the number of inputs; the number of

outputs; the current number of batch operation;

,

the k-th input amount of mass transported through

the i-th upstream,

,

the k-th output amount of

mass transported through the i-th downstream;

hold-up until k-th batch.

When the equilibrium material balance equation

is considered instead of dynamic mass balance

equation, the equation (2) can be modified into:

,

,

(3)

where

,

is the k-th accumulated input amount of

mass transported through the i-th upstream so far;

,

the k-th accumulated output amount of mass

transported through the i-th downstream so far.

3.3 Operation Model

3.3.1 DES Modeling

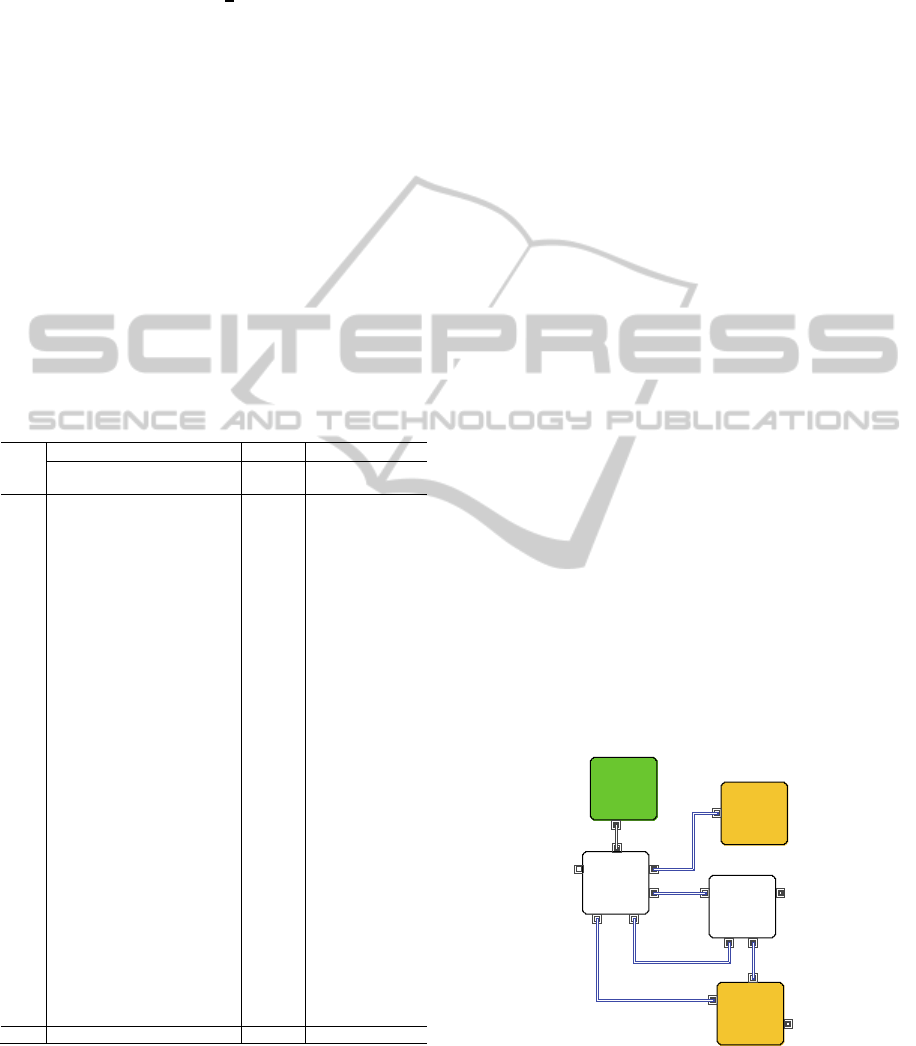

The material flow of oxide reduction as shown in

Figure 2 was modeled as shown in Figure 3 by using

multi-purpose system modeling software,

ExtendSim. Process P2-1 has four input connectors

to receive pellet/fragment, fresh salt (LiCl and Li

2

O),

recovered salt, and regenerated salt, and it also has

three output connectors to transfer cathode product

and O

2

to the next processes such as P2-2 and W3-1,

as shown in Figure 3.

Figure 3: Operation model of oxide reduction.

Each box in Figure 3 is a hierarchical block,

which contains many blocks and complicated flows

P2‐2

Cathode

Processing

P2‐1

Electrolytic

Reduction

W3‐1

OffgasO

W4‐1

LiCl

Purification

LiCl/Li2O

addition

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

688

to implement functions inherent to the process: feed

material receipt, hold-up calculation, product

material calculation, and so on. If any box is double-

clicked in the model, detailed models as shown in

Figures 4 and 6 pop up.

Figure 4: A selected part in P2-1 for receipt of feed

materials.

Figure 5: Selected blocks needed for operation logic in

Figure 4.

Figure 4 shows the first part of P2-1 representing

the receipt of feed materials. An item flow in the

DES model is controlled by transport blocks,

equation blocks and batch blocks, as shown in

Figure 5. Transport blocks move items from the start

of a path to the end based on distance and speed

information, so they are used here for simulating

feed material’s movements that consume time. An

oxide reduction model begins with transport blocks

that describe the receipt of four types of feed

materials (fragment/pellet, recovered salt,

regenerated salt, and fresh salts). The feed of

fragment/pellet (ORFeedIn in Figure 5(a)) is always

needed for every batch operation. However, the

recovered salt (RecSaltIn in Figure 5(a)), and

regenerated and fresh salts (RegenSaltIn and

freshSaltIn in Figure 5(a)), can be received or not

according to the batch operation procedure. The

complicated operation logic of section 3.1 was

perfectly built in equation block in Figure 5. Input

value connector (InCnt) in Figure 5(b) indicates the

number of receipt of fragment/pellet (ORFeedIn)

item. In other words, it indicates the number of batch

operation of P2-1 because fragment/pellet

(ORFeedIn) is always needed for every batch

operation. The equation block judges if RecSaltIn,

RegenSaltIn, and freshSaltIn feeds need to be

received for current batch, and sends out 1 or 0

output signals through its output value variables

(addRecycleedLiCl, addRegenLiCl, and

addNewLiCl) to the batch blocks’ second input

value connectors in Figure5(c) to determine the

corresponding feed is added to fragment/pellet feed.

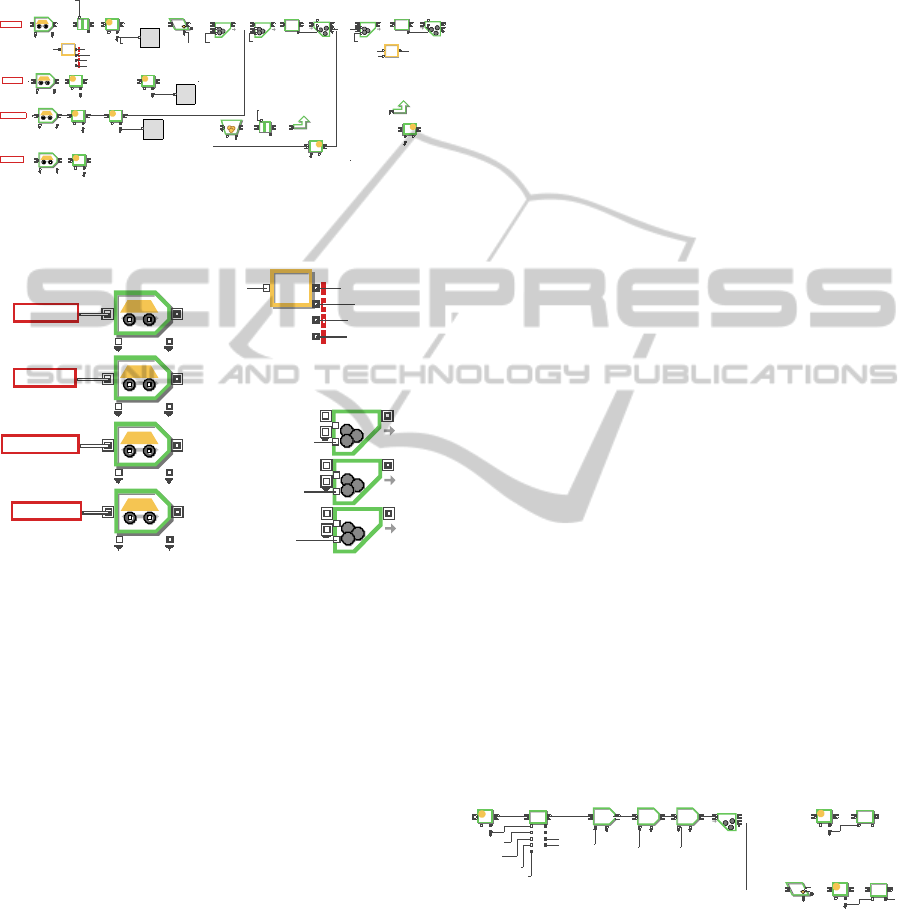

The materials generated in process P2-1 are

remaining salt in bath as a hold-up, and cathode

product and O

2

as products. The total amount and

elemental composition for the three types of material

are calculated in the later part of Figure 4, as shown

in Figure 6. Figure 7 shows some important blocks

to calculate the amounts of hold-up and products,

and to describe the operation time. The equation

blocks in Figure 7(a) calculates hold-up, i.e., the

remaining salt and fission products (FPs) dissolved

from fragment/pellet feed in the salt before electro-

chemical reaction occurs. In Figure 6, the equation

block is located right before three activity blocks

representing pre-process, main process, and post-

process of the electro-chemical reaction. Three

sequential activity blocks in Figure 7(b) merely play

a role of consuming the corresponding process time.

Actually, the electro-chemical reaction should be

simulated with a continuous system modeling

methodology if the main concerns are the changes

according to time by electro-chemical reaction

within a batch operation. However, this model

calculates only the final result after the electro-

chemical reaction because our main concern is how

consecutive batch operations affect the material

balance throughout the whole process.

Figure 6: A selected part in P2-1 for calculation of mass

compositions of hold-up and products (cathode product

and O

2

).

ORFeedInORFeedIn

RecSaltInRecSaltIn

D U

InCNT

y=f(x)

D U

i

r L

#

y=f(x)

{...}

1

2

demand

AD

addRegenLiCl

RegenSaltInRegenSaltIn

1

D U

i

r L

#

1

2

addRegenLiCl

addRegenLiCl

i

rL

addNew Li2O

addNewLiCl

addRecy cledL iCl

addRecy cledL iCl

VesselRegLiCl

FeedFormOR

TR U

BB RegLiCl

Stats

Calc ulate

P1-3-O Rf eed

Stat s

Calculate

P2-2-t oORRecLiC l

i

r L

#

Stat s

Calculate

W4-1-R egenSalt

i

r L

#

fresh SaltInfresh SaltIn

1

D U

i

r L

#

G_Open

demand

AD

i

r L

#

1

2

addNewLiCl

addNewLi2O

y=f(x)

addNewSalt

y=f(x)

InCNT

i

rL

#

LiClLi2Ob asket

addNewSalt

ORFeedInORFeedIn

D U

RecSaltInRecSaltIn

D U

RegenSaltInRegenSaltIn

1

D U

freshSaltInfreshSaltIn

1

D U

InCNT

y=f(x)

addRegenLiCl

addNewLi2O

addNewLiCl

addRecycledLiCl

1

2

addRecycledLiCl

1

2

addRegenLiCl

1

2

addNewSalt

(a)feedreceipt

(b)equation

(c)batchblocks

D F

preproces s

D F

process

D F

post proces s

{...}

O2

Cathod eDeposit

i

r L

#

i

r L

#

addRegenLiCl

addNewLi2O

addRecycle dLiCl

addNewLiCl

ReqLiCl

ReqLi2O

y=f(x)

FBChWeight

y=f(x)

i

r L

#

y=f(x)

remaining s alt R cdN um=2

Pretime

Posttim eProctime

ModelingandSimulationofPyroprocessingOxideReduction

689

Figure 7: Blocks for calculation of hold-up and product

compositions, and process operation delay.

Two equation blocks in Figure 7(c) calculates the

mass composition of cathode product and O

2

. These

blocks are located in downstream right after three

activity blocks representing the electro-chemical

reaction. Every calculation results are written in

internal database of ExtendSim by equation blocks

in Figure 7(a) and 7(c), so that a further detailed

analysis can be performed after simulation by an

investigation of the recorded data during simulation.

4 SIMULATION

4.1 Default Scenario

The basic input parameters resulted in Table 2 and 3

are as follows: The capacities of process P2-1, P2-2

and W4-1 are 20 kgHM/batch, 100 kgHM/batch and

50 kgHM/batch, respectively, and operation times

taken by the processes are 20 day/batch, 44 h/batch,

and 165 hours/batch, respectively. One piece of

equipment is deployed for each process. Chemically,

20% salt over the weight of the cathode product is

carried to the next process P2-2. Actinide oxide and

noble metal oxide has a 99.5% reduction yield ratio,

but a rare earth oxide has a 30% reduction yield ratio.

The process P2-2 recovers 99.9% salt by distillation

and 0.1% salt transfers to the next process. This is

the default scenario to run the simulation. To reflect

the experimental results in the future or to analyze

various alternative operations, these parameters can

be changed.

4.2 Experimental Results

Simulation is performed based on the above default

scenario for 200 batch operations of process P2-1.

The 200 batch operations end within 250 days.

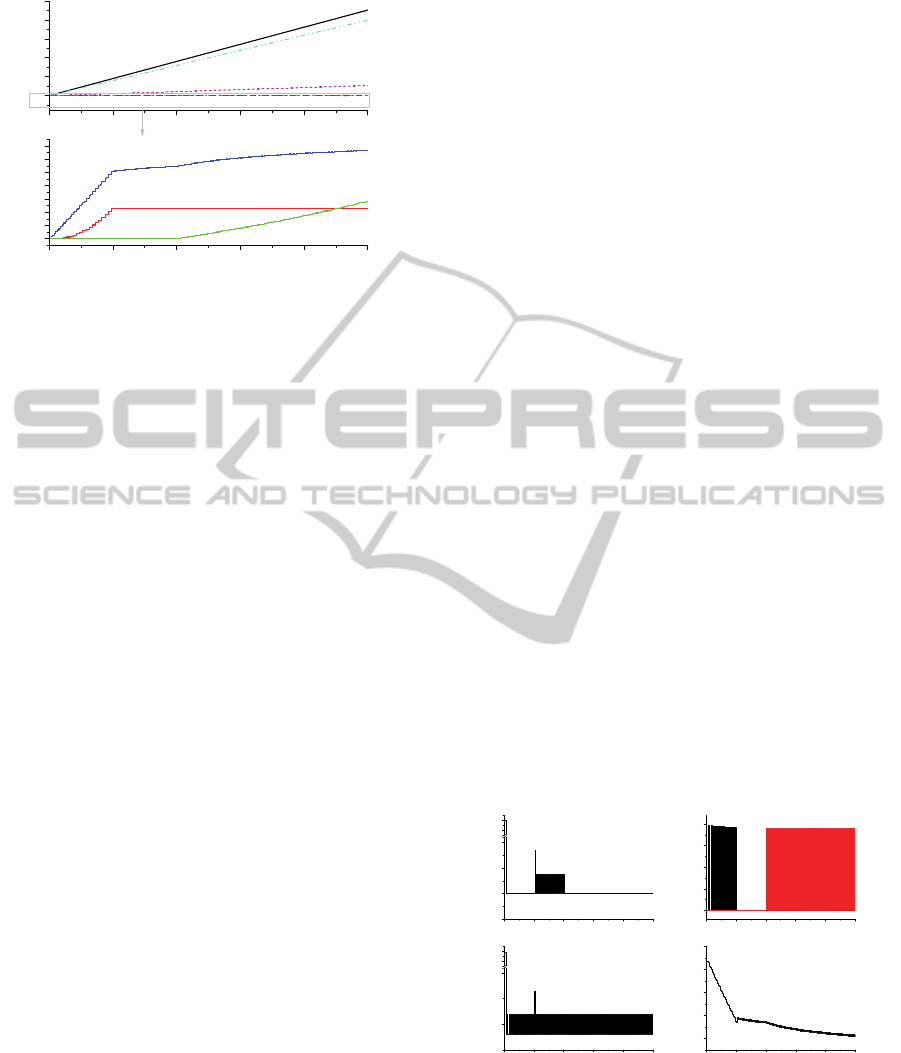

Figures 8 and 9, and Figures 10 and 11 show process

P2-1’s material balance for the SNF element, and

salt (LiCl+Li

2

O), respectively. Figures 8 and 10

show the material balance to indicate the amount of

material that is received from the input and sent to

output each batch. On the other hand, Figures 9 and

11 show the material balance for the amount

accumulated from the first batch. The amounts at the

end batch operation in Figures 9 and 10 mean the

equilibrium mass balance. In Figure 8, the

fragment/pellet includes 50kgHM plus oxide weight.

Therefore, after the process, the cathode product

losses as much weight as the oxygen generated

during the reduction. The top figure of Figure

indicates sum of inputs (fragment/pellet, recovered

salt and regenerated salt) are equal to sum of outputs

(cathode product and O

2

) and hold-up addition for

every batch operation. The bottom figure of Figure 8

is magnified to properly investigate small amounts

such as FPs contained in the hold-up, recovered salt,

and regenerated salt.

In the first batch operation, SNF addition in

hold-up (i.e., remaining salt) occurs owing to

dissolution of some of PFs of fragment/pellet feed.

Its contribution approximately amounts to 0.28kg

per batch operation by first row in Table 2. Without

any other contribution to SNF addition in hold-up,

the amount of 0.28kg is the same over the batch

operation. However, the SNF addition in remaining

salt until 40th batch operations fluctuates more or

less severely.

Figure 8: Material (a total SNF elements) balance every

batch in P2-1.

0

D F

preprocess

0

D F

process

0

D F

postprocess

Pretime

Posttime

Proctime

y=f(x)

O2

y=f(x)

Cathode product

addRegenLiCl

addNewLi2O

addRecycledLiCl

addNewLiCl

y=f(x)

AddedLiCl

AddedLi2O

ReqLiCl

ReqLi2O

(c)product

(a)saltaddition

(b)reaction

0 40 80 120 160 200

0

10

50

60

recoveredsalt,

O

2

hold‐upadditon

regeneratedsalt

cathodeproduct

SNFtotal(kg)

fragment/pellet

0 40 80 120 160 200

‐1

0

1

2

hold‐upadditon

SNFtotal(kg)

batch#

recoveredsalt

regeneratedsalt

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

690

Figure 9: Accumulated material (a total of SNF elements)

balance in P2-1.

When the hold-up addition is more than 0.28kg

is when recovered salt is recycled. In such batch

operation, PFs (which plays + contribution)

accompanied with the recovered salt is more than

PFs (which plays - contribution) accompanied with

the entrained salt with cathode product. On the other

hand, when the hold-up addition is less than 0.28kg

is when the recovered salt is not recycled. In such

batch operation, PFs accompanied with the entrained

salt with cathode product goes out of the remaining

salt. From the 2

nd

to the 40

th

operation, hold-up

addition is fluctuated according to whether

recovered salt is added or not. Since the recovered

salt is the salt recovered from the salt entrained in

cathode product, it contains the same FPs

concentrations as the remaining salt in salt batch of

P2-1. Hold-up addition increases every other batch

since the recovered salt is added every other batch

by operational procedure in section 3.1. During 2

nd

campaign (41~80 batch operations), neither

recovered salt with high concentration of FPs nor

regenerated salt with very low concentration of FPs

is received. Only fresh salt without FPs is added to

supplement a shortage of LiCl. It does not cause any

abrupt change of hold-up addition compared to the

1

st

campaign. Approximately, 0.03kg of SNF is

added in remaining salt for every batch operation

during 2

nd

campaign.

Compared to Figure 8, the Figure 9 represents

the accumulated in- and out-mass of P2-1. If the

Figure 8 is simply integrated over batch operation

number, it becomes Figure 9. In the bottom figure of

Figure 9, FPs increase in remaining salt (see the line

marked ‘hold-up acc.’ of the bottom of Figure 9)

because recycled salts containing high concentration

of FPs are constantly re-used without purification. In

steep increase during 1

st

campaign, supplementary

fresh salt addition during 2

nd

campaign does not

bring about a significant increase in remaining salt.

The gradual increase in remaining salt during 2

nd

campaign is only due to fragment/pellet’s

dissolution. Since 3

rd

campaign, the accumulation of

SNF in remaining salt increases gradually but more

steeply than 2

nd

campaign due to contribution of

both the dissolution of some FPs of fragment/pellet

and the regenerated salt addition with very low

concentration of FPs. The SNF input accumulation

by the recovered salt addition exponentially

increases during 1

st

campaign, however, the

accumulation stops increasing since 2

nd

campaign.

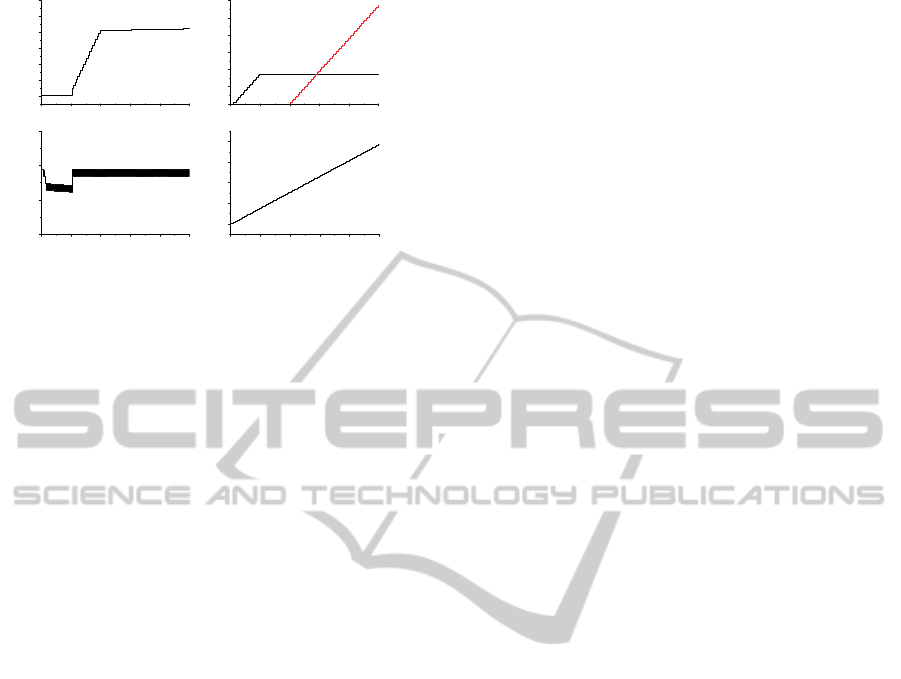

Figure 10 shows not the SNF material balance

but the salt material balance such that the sum of

fresh salt, recovered salt, and regenerated salt

exactly match the sum of salt entrained with the

cathode product and hold-up increment for every

batch operation. Fresh salt addition occurs during

only the 2

nd

campaign and the 1

st

batch of 2

nd

campaign needs more fresh salt than the others to

supply the accumulation of 0.1% loss amount during

the 1

st

campaign because cathode processing

recovers only 99.9% salt. An insufficient amount of

salt during the 1

st

campaign is supplemented through

a recycling of recovered salt but is through the

recycling of regenerated salt during the 3

rd

campaign.

Figure 11 shows an accumulation of batch mass

balance. The hold-up in Figure 11 indicates the

amount of remaining salt in bath right after transfer

of the cathode product, i.e., accumulation of hold-up.

Since the 3

rd

campaign, the remaining salt

approximately retains 400kg. The amount of salt

carried with the cathode product gradually decreases

because the FPs in proportion to the entrained salt

increases.

Figure 10: Material (salt: LiCl and Li

2

O) balance every

batch in P2-1.

0 40 80 120 160 200

0

2,500

5,000

7,500

10,000

12,500

O

2

hold‐up,recoveredsalt,regeneratedsalt

cathodeproduct

SNFtotal(kg)

fragment/pellet

0 40 80 120 160 200

0

2

4

6

8

10

12

14

hold‐upacc.

SNFtotal(kg)

batch#

recoveredsalt

regeneratedsalt

0 40 80 120 160 200

‐25

0

25

50

350

400

batch#

0 40 80 120 160 200

0

5

10

15

20

regeneratedsalt

recoveredsalt(kg)

batch#

recoveredsalt

0 40 80 120 160 200

0

50

350

400

freshsaltaddition(kg)

hold‐upaddtion(kg)

batch#

0 40 80 120 160 200

9.6

9.7

9.8

9.9

10.0

cathodeproduct(kg)

batch#

ModelingandSimulationofPyroprocessingOxideReduction

691

Figure 11: Accumulated material (salt: LiCl and Li

2

O)

balance in P2-1.

Validation of dynamic material flow was

performed in every level of details for guaranteeing

completeness of the model. Especially, dynamic

mass balance using equation (2) was carefully

checked for every batch operation and showed that

SNF and salt mass balance is always satisfied.

5 CONCLUSIONS

DES based modeling was applied to build a

pyroprocessing operation model, specifically, oxide

reduction model. A dynamic material flow as the

basic framework for an integrated pyroprocessing

was successfully implemented through ExtendSim’s

internal database and item blocks. Complex

operation logic behavior was verified, for example,

an oxide reduction process in terms of dynamic

material flow. Compared to the equilibrium material

flow, a model-based dynamic material flow provides

such detailed information that a careful analysis of

every batch is necessary to confirm the dynamic

material balance results. With the default scenario of

oxide reduction, dynamic material balance was

verified for every batch operation.

This study is a meaningful step to confirm a part

of an integrated pyroprocessing simulator in terms of

dynamic material flow and its implementation under

DES environment. The development of a multi-

purpose integrated pyroprocessing simulator is still

under progress with a mid-and long-term goal to

cope with safeguards assessment, economic

feasibility, technical evaluation, conceptual design,

and support of licensing for a future pyroprocessing

facility.

ACKNOWLEDGEMENTS

This work was supported by Nuclear Research and

Development Program of National Research

Foundation of Korea (NRF) funded by Ministry of

Science, ICT and Future Planning (MSIP).

REFERENCES

Piet, S. J., Soelberg, N. R., Pincock, L. F., Shaber, E. L.,

and Teske, G. M., 2011. The FIT 2.0 Model-Fuel

Cycle Integration and Tradeoffs, INL/EXT-10-20190

Rev.1.

Lee

a

, H. J. et al., 2013. Development of pyroprocessing

baseline flowsheet v4.0, Proceedings of the Korean

Radioactive Waste Society, May 9-10, 2013, Korea.

Lee

b

, H. J., Ko, W. I., Kim, I. T., and Lee, H. S., 2013.

Design for integrated pyroprocessing plant level

simulator, Annals of Nuclear Energy, 60, 316-328.

McCaskey, A., et al., 2011. The nuclear energy advanced

modeling and simulation safeguards and separations

reprocessing plant toolkit, ORNL/TM-2011/261.

Okamura, N., Sato, K., 2002. Computer code system for

the R&D of nuclear fuel cycle with fast reactor. IV.

Development of an object-oriented analysis code for

estimation of the material balance in the pyrochemical

reprocessing process, Cycle system technical report 3,

1–10.

Lee, H.J. et al., 2011. Discrete event dynamic system

(DES)-based modeling for dynamic material flow in

the pyroprocess. Annals of Nuclear Energy, 38, 860–

875.

Phongikarron, S., Herrmann, S., Simpson, M., 2011.

Diffusion model for electrolytic reduction of uranium

oxides in a molten LiCl-Li2O slat, Nuclear

Technology, 174, 85-93.

ExtendSim Simulation Software. Imagine That Inc, 2014.

Web. 24 Jun 2014. <http://www.extendsim.com>

0 40 80 120 160 200

400

500

600

700

800

900

1000

batch#

0 40 80 120 160 200

0

200

400

600

800

1,000

1,200

regeneratedsalt

recoveredsalt(kg)

batch#

recoveredsalt

0 40 80 120 160 200

300

350

400

450

freshsaltacc.(kg)

hold‐upacc.(kg)

batch#

0 40 80 120 160 200

0

500

1,000

1,500

2,000

cathodeproduct(kg)

batch#

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

692