Modeling Anisotropic Permeability of Coal and Its Effects

on Coalbed Methane Reservoir Simulation

Geoff Wang

1

, Xiaorong Wei

2

, Hui An

1

, Fu-Yang Wang

1

and Victor Rudolph

1

1

School of Chemical Engineering, The University of Queensland, St Lucia, Brisbane, Qld 4072, Australia

2

Sinopec Oil & Gas Australia Pty Ltd, Level 1, 139 Coronation Drive, Milton, Brisbane, Qld 4064, Australia

Keywords: Coal, Coalbed Methane (CBM), Anisotropic Permeability, Reservoir Simulation.

Abstract: In this study, an alternative permeability model was developed and compared with data from laboratory

investigations. The model was further applied for reservoir simulation with several cases in order to

evaluate the effects of the anisotropic permeability variation on the CO

2

-sequestration and CO

2

-

sequestration enhanced coalbed methane (CO2-ECBM) recovery. The permeability model developed in this

study is based on a discontinuum medium approach, in which coal is treated as a discontinuum medium

containing anisotropic matrixes and cleats. The permeability variations and anisotropic permeability ratios

under isotropic net stresses were tested with relatively large coal samples. The simulations show good

agreements with the experimental data, revealing that the developed model is superior for describing stress-

and sorption-induced permeability variations in coals compared with models using constant values for

stress-dependent parameters. The results from reservoir simulation incorporating the developed permeability

model show the anisotropic permeability exhibit significant effect on CO2-ECBM recovery.

1 INTRODUCTION

Coal is typically an anisotropic porous media

consisting of butt and face cleats, featured by

anisotropy of the permeability to fluids flowing

through the cleats. The anisotropic permeability

often varies due to stress change and gas

adsorption/desorption occurring during coalbed

methane recovery. The deformations of coal and

permeability evolution have a significant influence

on reservoir performance. Therefore understanding

of coal deformation and permeability evolution

underlies the use, management and optimization of

deep coal as an economic resource for CO

2

sequestration, CBM recovery and underground

gasification. So far this phenomenon has not been

well understood (Wang et al., 2008; Wei et al.,

2007), and it is considered as one of the critical

problems for improved CO2-ECBM processes.

In the last several decades many attempts have

been made in both the theoretical and experimental

studies on the permeability of coal, including the

permeability evolution in underground coal

reservoirs associated with gas storage and gas

production. The currently published permeability

models can be generally classified into two types:

analytical permeability models (Gray, 1987;

Harpalani and McPherson, 1985; Puri and Seidle,

1991; Shi and Durucan, 2004; Somerton, 1975) and

coupled permeability models, which include

continuum medium coupled (CMC) model and

discontinuum medium coupled (DMC) model. Gu

and Chalaturnyk (Gu and Chalaturnyk, 2006)

compared these models and suggested that the DMC

model provides better estimates of permeability and

production than analytical models because it

includes the influences of many factors, such as

discontinuity and anisotropy. While considerable

efforts have been made in modelling permeability

changes during CO2-ECBM processes, significant

limitations exist in these permeability models due to

the complexity of the behaviour of coal under

dynamically changing stresses. So far there is no

model considering the anisotropic permeability

evolution associated with CO2-ECBM processes.

This work seeks to investigate anisotropic

physical and mechanical properties of in-situ coal

and to develop a more practicable and reliable model

for reservoir simulations. It will provide a better

understanding of structure and anisotropic

permeability evolution of coals for prediction and

simulation of processes associated with CO

2

477

Wang G., Wei X., An H., Wang F. and Rudolph V..

Modeling Anisotropic Permeability of Coal and Its Effects on Coalbed Methane Reservoir Simulation.

DOI: 10.5220/0005006504770483

In Proceedings of the 4th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2014),

pages 477-483

ISBN: 978-989-758-038-3

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

sequestration and CO2-ECBM recovery.

2 PERMEABILITY MODEL

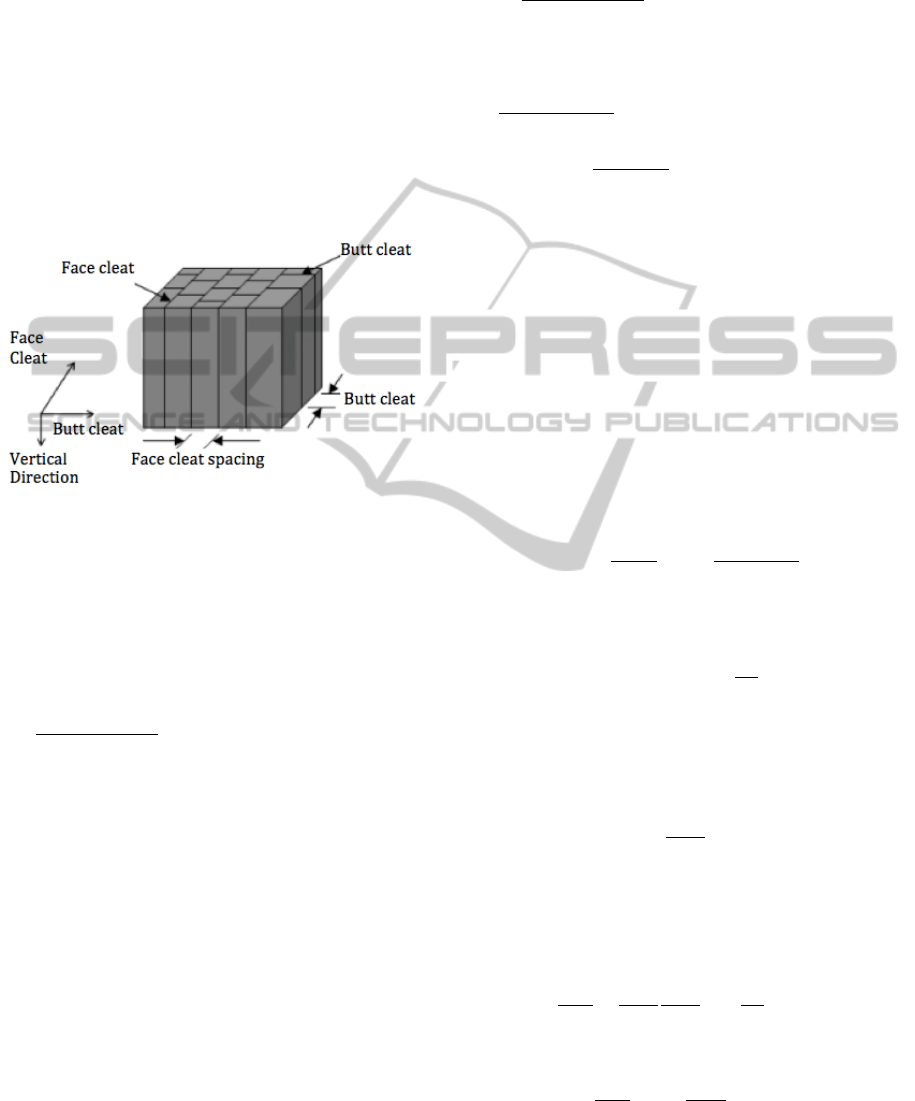

Figure 1 shows the conceptual model of anisotropic

permeabilities for a coal core. The anisotropic

permeabilities of the coal specimens usually include

horizontal permeability and vertical permeability,

and the horizontal permeability can be divided into

two directional permeabilities of face cleats and butt

cleats. The vertical permeability consists of

contributions from both face and butt cleats.

Figure 1: Anisotropic permeability model of a coal

specimen.

The 3-dimensional stress and strain relationship for

an isotropic specimen can be described as

1

12

1

1

1

(1)

where E is Young’s modulus,

is Poison’s ratio,

and

are effective stress and strain, respectively.

The subscripts B, F, and V means butt cleat, face

cleat and vertical direction, respectively.

,

and

represent the effective stresses of butt cleat,

face cleat and the cleat in vertical direction,

respectively

Due to sorption induced dimensional changes

(Gilman and Beckie, 2000), Equation (1) can be

extended to

1

12

1

1

1

1

12

1

1

1

312

∆

1

1

1

(2)

where

is the volumetric swelling coefficient, S is

the adsorbed mass,

S is the variation of the

adsorbed mass,

SB

,

SF

and

SV

are the sorption

induced strains in three directions.

For the problem of CO2-ECBM recovery from a

coal reservoir, we may well assume that overburden

stress is constant and uniform. The following

assumptions are made

0

∆

(3)

where P

f

is the pressure in fractures.

Applying Equation (3) to Equation (2), the

Equation (2) can be simplified to

1

∆

312

∆

(4)

For isotropic coal specimens, since the cleats are

nearly vertical, we have

(5)

where a is the mean fracture aperture and E

f

is the

Young’s modulus for the fracture. The vertical

permeability can be represented as (Wang, et al.,

2008)

(6)

where c is a constant depending on cleat geometry

and surface roughness, h is the cleat spacing, and

f

is the fracture tortuosity. Through calculus and

algebraic operations on Equation (6), we obtain

3

3

(7)

Substituting Equation (5) to Equation (7) gives

3

(8)

The vertical permeability variations during CO

2

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

478

sequestration and enhanced coalbed methane

recovery processes can be estimated as

3

1

1

9

where subscript 0 represents initial condition, and

the adsorbed mass S can be estimated based on

Langmuir isotherm under following assumptions: 1)

The adsorbed phase should be in instantaneous

equilibrium with the cleat pressure; and 2) The

Langmuir isotherm is valid for the determination of

the adsorption equilibrium.

For anisotropic coal specimens, the contributions

from face cleats and butt cleats can be treated

independently. The vertical permeability consists of

contributions from both butt and face cleats,

represented by

3

3

(10)

where K

FV

and K

BV

are vertical permeability

contributions from face and butt cleats, respectively;

E

Ff

and E

Bf

are Young’s moduli for face cleats and

butt cleats, respectively. Thus

exp3

1

exp3

1

(11)

Preliminary experimental results obtained from our

lab suggested that the variations of anisotropic

permeabilities of coals with average net stress,

defined by the difference between confined stress

acting on a coal sample and fluid pressure in pores,

are similar in three directions. Therefore, to simplify

the model, we assumed that the permeability

variations with average net stress are approximately

the same in different directions. Three parameters

PAR

FB

, PAR

FV

and PAR

BV

are defined in the model

to describe the anisotropic permeability ratios of

face cleat to butt cleat, face cleat to vertical direction

and butt cleat to vertical direction, respectively.

Thus, the horizontal permeabilities, i.e. face cleat

and butt cleat permeabilities, can be estimated using

the following equations.

(12)

3 MODEL PARAMETERS

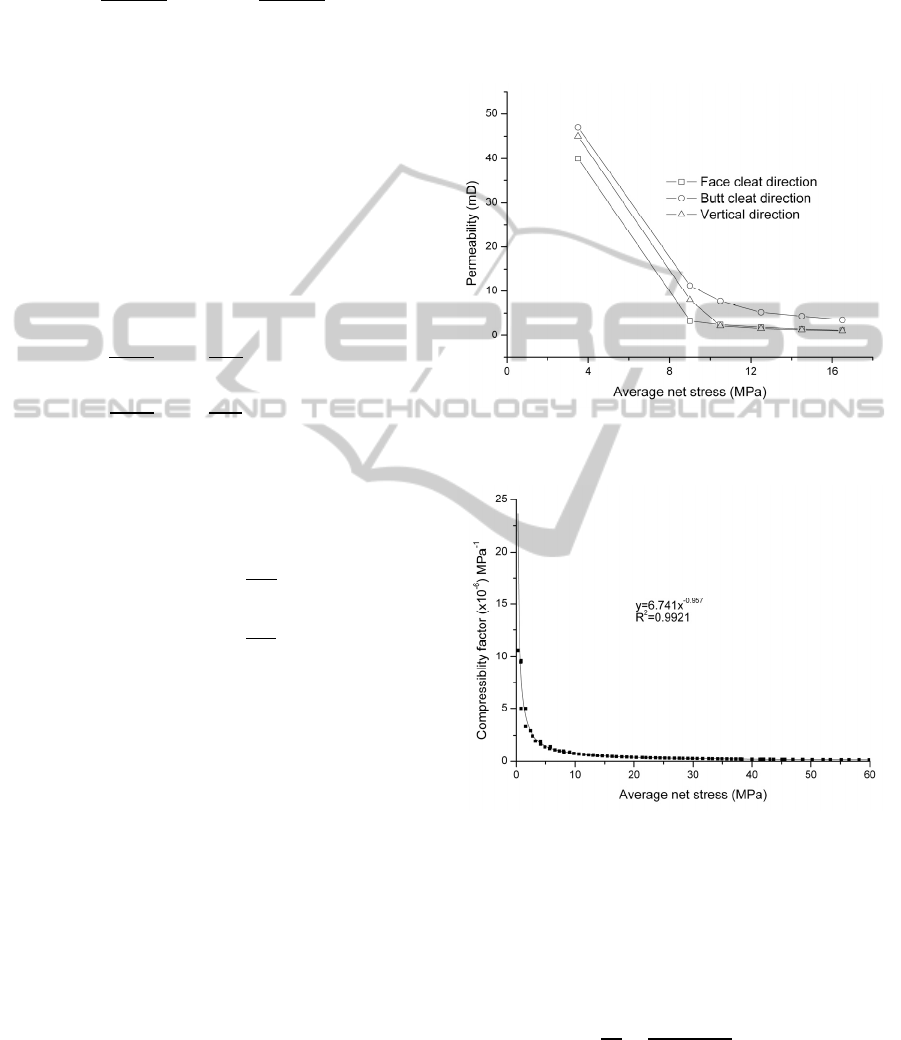

The model as indicated in Eq. (9) deals with some

stress-dependent parameters such as directional

permeability, compressibility and Young’s modulus

for cleats. Those parameters can only be determined

experimentally, as shown in Figures. 2-3.

Figure 2: Helium permeabilities through face cleat, butt

cleat and vertical directions of a 80 mm cubic coal sample.

Figure 3: Compressibility factor of coal varying with

average net stress.

Mechanical properties of bulk coals such as bulk

moduli and total bulk moduli Young’s modulus are

also stress-dependent and can be estimated as

follows.

The bulk modulus is defined as

1

312

(13)

where K

bt

is the total bulk moduli of coal, including

the contributions from cleats (or fractures) and

matrix; C

p

denotes coal compressibility; E

t

and

ModelingAnisotropicPermeabilityofCoalandItsEffectsonCoalbedMethaneReservoirSimulation

479

represent the Young’s modulus and Poison’s ratio of

coal, respectively. The contributions of cleats and

matrix to total bulk moduli of coal are largely

depended on the coal compressibility, which can be

approximately estimated using the correlation as

follows

1

1

⁄

⁄

(14)

where K

bf

and K

bm

are cleat (fracture) and matrix

bulk moduli, respectively; denotes stress; and

max

is the maximum stress above which the

compressibility variation in coal can be negligible,

that is, the cleat or fracture contribution to the coal

compressibility approaches zero. If the Poison’s

ratio in Eq. (13) is a constant, the Young’s modulus

can be estimated by

1

1

⁄

⁄

(15)

where E

f

and E

m

are defined as the moduli for cleats

and coal matrix, respectively.

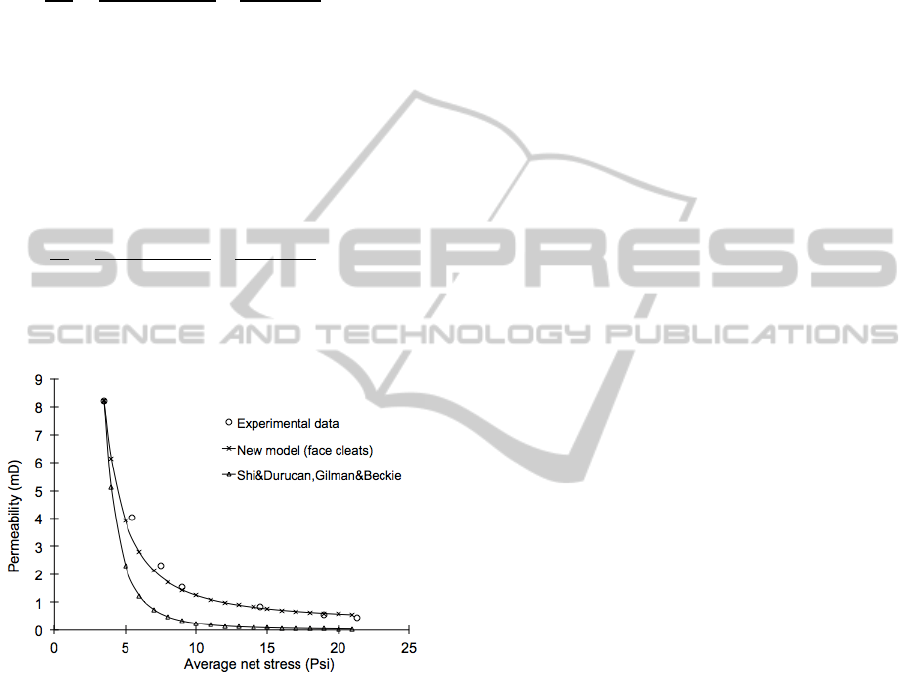

Figure 5: Comparison of methane permeability variations

with net stress.

Given the Young’s modulus for the coal matrix as

2.8210

6

MPa, the estimated maximum stress

max

is

about 20MPa. Thus the estimated Young’s modulus

for cleats can be estimated using Eq. (15), as shown

in Figure 4. The results show that the Young’s

modulus for cleats increases remarkably in the lower

stress range and then slowly approaches ~2.1010

6

MPa at an average net stress of 60 MPa.

4 RESERVOIR SIMULATION

The methane permeability variations with average

net stress under constant pore pressure can be

comparatively calculated using three permeability

models, i.e. the model developed in this study, Shi-

Durucan model and Gilman-Beckie model. The

calculated results were then compared with the

experimental data, as shown in Figure 4. The

experimental data of methane permeability

variations were measured under constant pore

pressure (7.2 MPa) at different average net stresses.

Figure 4 shows that the predicted results using the

model developed in this study fit the experimental

data very well, while the other two models

apparently underestimated permeability at higher

average net stresses. This is because the values of

compressibility factor and Young’s modulus for

cleats are constant in these two models, ignoring

changes in net stresses. In other words, these two

models cannot predict the permeability variation

with average net stress well by not taking into

account the influence of compressibility and

Young’s modulus for cleats on permeability,

particularly at a higher average net stress.

In order to evaluate the effects of the anisotropic

permeability variation on the CO

2

-sequestration and

CO

2

-sequestration enhanced coalbed methane (CO

2

-

ECBM) recovery, a 3-dimensional and two-phase

numerical reservoir model was further developed for

reservoir simulations by incorporating the developed

permeability model to simulate the multi-component

gas and water diffusion and flow in coal seams.

Details on the reservoir simulation will be reported

separately and some results will be discussed later.

5 RESULTS AND DISUSSION

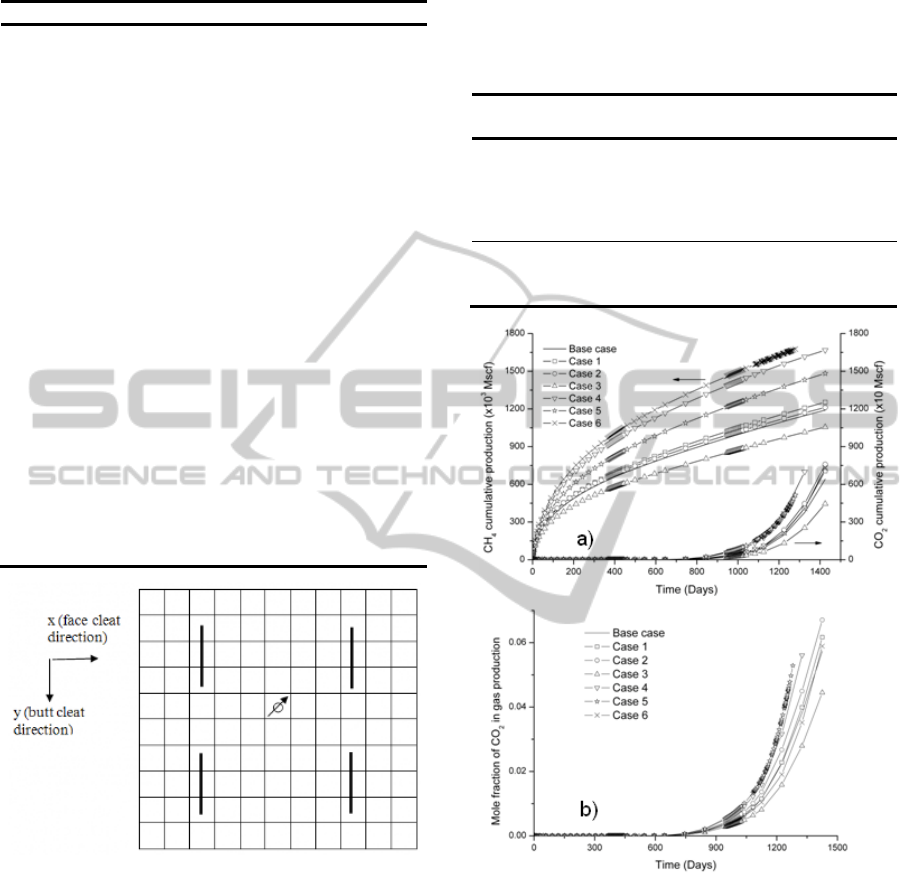

A base case was designed for the reservoir

simulations. A five-spot well pattern with one

vertical injector in the centre of four horizontal

producers was used to represent a pilot-scale project,

as shown in Figure 5. The orientation of horizontal

producers was assumed to be parallel to the direction

of butt cleats. Methane production took place one

year before CO

2

injection-ECBM recovery was

initiated. The production and injection wells are to

be shut-in at the time of CO

2

breakthrough, at which

the mole fraction of CO

2

in the gas production

stream is equal to 5%. The parameter values used in

simulations for the base case are listed in Table 1.

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

480

Table 1: Parameter values used in simulations.

Parameter Value

Reservoir drainage area (ft

2

) 25.00×10

6

Coal seam thickness (ft) 10.00

Initial coal seam porosity (%) 2.00

Initial pressure (psia) 800.00

Coal density (g/cc) 1.36

Face, butt and vertical

permeability (mD)

1.95, 0.23, 1.35

Poisson’s ratio 0.32

Young’s modulus for coal matrix

(MPa)

2.82×10

6

Micropore diffusion coefficient of

CH

4

, CO

2

(ft

2

/day)

8.37×10

-5

, 7.44×10

-4

Cleat spacing (in) 0.50

Sorption time constant (days) 7.60

Sorption volume (CH

4

, CO

2

)

(scf/ton)

600.00, 1500.00

Sorption pressure (CH

4

, CO

2

)

(psia)

700.00, 300.00

Critical saturation (gas, water) (%) 0.00, 10.00

Initial water saturation (%) 45.00

Initial mole fraction of coal gas

(CH

4

, CO

2

) (%)

100, 0

Reservoir temperature (ºF) 113.00

Wellbore radius (ft) 0.25

Skin factor 0.00

Figure 5: Well patterns for base case (thick lines

representing horizontal producers).

5.1 Impact of Anisotropic Permeability

In order to investigate the effects of anisotropic

permeabilities on the gas production, six cases were

designed based on the experimental measurements.

Table 2 lists the cases with different PARs for model

simulations.

The values of directional permeabilities used in

the six cases were set to be 1.7 times higher or lower

than those in base case. The results from the

simulations are shown in Figure 6. This forms two

groups of data for a better comparative study, i.e. the

first three cases comparing with the base case, and

Cases 4-6 forming the other group, which will be

discussed in details as follows.

Table 2: Cases designed for simulations.

Cases

K

vertical

(mD)

K

butt

(mD)

K

face

(mD)

PAR

FB

PAR

FV

PAR

BV

Base

case

1.35 0.23 1.95 8.48 1.44 0.17

Case 1

1.35 0.39 1.95 5.00 1.44 0.29

Case 2

2.28 0.23 1.95 8.48 0.86 0.10

Case 3

1.35 0.23 1.15 5.00 0.85 0.17

Case 4

0.80 1.44 4.32 3.00 5.40 1.80

Case 5

0.80 2.45 4.32 1.76 5.40 3.06

Case 6

0.80 1.44 2.54 1.76 3.18 1.80

Figure 6: The effects of anisotropic permeability ratios on

gas productions.

The comparison of base case and first three cases

suggested that face cleat permeability has major

effect on CH

4

and CO

2

production. The vertical

permeability has major effect on CO

2

injection, but

little influence on methane production. For coal

reservoir with lower PAR

BV

, the influence of

directional permeabilities on CO

2

breakthrough time

deceases in the order of face cleat permeability,

vertical permeability and butt cleat permeability. For

the cases with higher PAR

BV

, i.e. Cases 4-6, the face

cleat permeability has major effect on CH

4

ModelingAnisotropicPermeabilityofCoalandItsEffectsonCoalbedMethaneReservoirSimulation

481

production and CO

2

injection, while butt cleat has

major effect on CO

2

production. Increasing butt

cleat permeability may expedite CO

2

breakthrough

in produced gas.

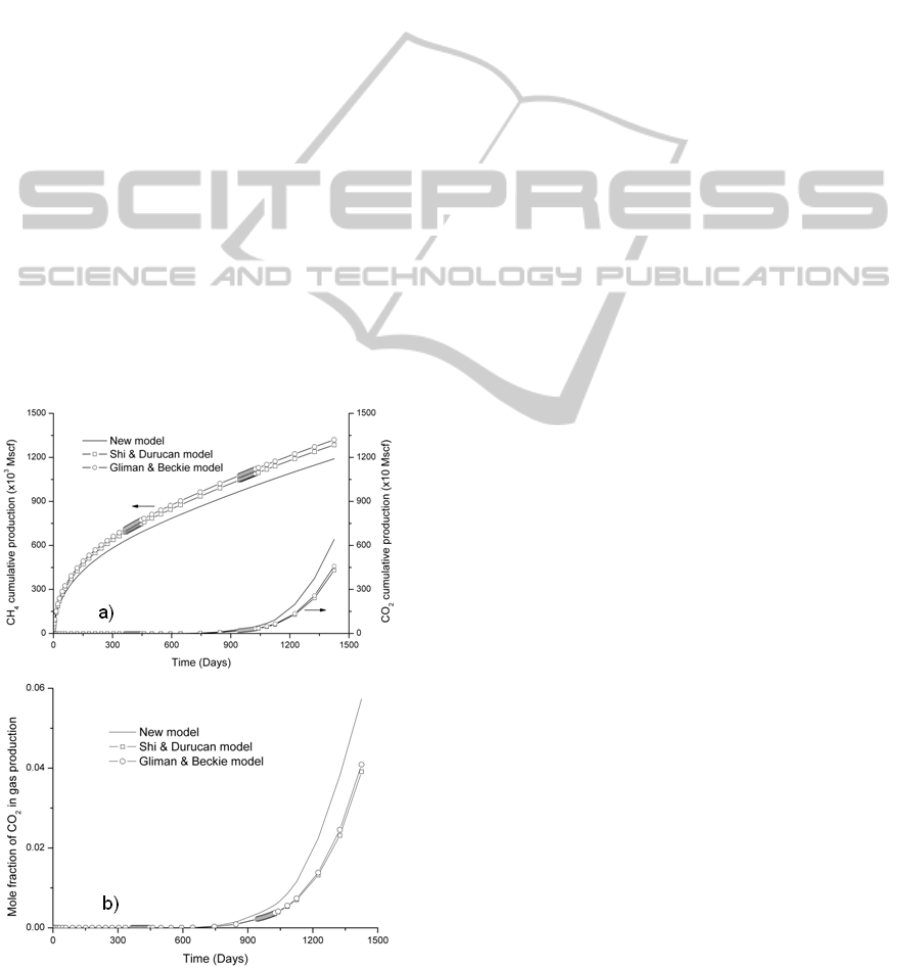

5.2 Influence of Permeability Variation

Figure 7 shows the cumulative productions of CH

4

and CO

2

and associated mole fraction of CO

2

in gas

production predicted in the designated base case

using three permeability models, i.e. model

developed in this study, Shi & Durucan model and

Gilman & Beckie model.

In fact, the latter two models are essentially one

model in which the isotropic permeability is used. In

this comparison study, an initial isotropic

permeability used in Shi & Durucan model and

Gilman & Beckie model was 1.35 mD.

Permeability variation of coal reservoirs is not

only affected by the changing stress during the gas

production but also, maybe more importantly,

controlled by permeability anisotropy of coal. It can

be seen from Fig. 8 that the anisotropic permeability

clearly has some effect on CH

4

and CO

2

productions

using the model developed in this study, compared

with Shi & Durucan model and Gilman & Beckie

model. The new model predicts that cumulative CH

4

Figure 7: The calculated results of three permeability

models for the base case.

production will be lower, but cumulative CO

2

production will be higher than results predicted by

the other two models. Additionally, CO

2

breakthrough time will be shorter. These comparison

results suggest that the permeability anisotropy has

major effects on gas flow dynamics in coal

reservoirs, although stress- and sorption-induced

permeability variations also affect gas productivity

to some extent.

6 CONCLUSIONS

An alternative permeability model was developed to

describe anisotropic permeability variations of coal

due to stress change and gas sorption. The model has

unique features by taking into account separate

Young’s moduli for coal matrix and cleats, stress-

dependent Young’s modulus for cleats, and

anisotropic permeability ratios etc. These make the

model more practicable and reliable to be

incorporated into reservoir simulations for the gas

and water flow in coal reservoirs. The simulations

provide further information to investigate the effects

of anisotropic permeability variations on CO

2

-

ECBM recovery. The results suggested that

anisotropic permeability has significant effects on

gas production and CO

2

breakthrough time,

implying it is a critical parameter in determining

well pattern and orientation of horizontal wells.

ACKNOWLEDGEMENTS

This work was supported by the Australian Research

Council (ARC). Thanks to Dr. Paul Massarotto and

Professor Sue Golding of the University of

Queensland for their helpful discussion. It is

thankful to Dr. Dean Biddle for provision of

experimental data used in this study.

REFERENCES

Gilman, A. and Beckie, R. (2000). Flow of coal-bed

methane to a gallery. Transport in Porous Media, 41,

1-16.

Gray, I. (1987). Reservoir engineering in coal seams: Part

1 - the physical process of gas storage and movement

in coal seams. SPE Reservoir Engineering, 2, 28-34.

Gu, F. and Chalaturnyk, R.J. (2006). Numerical simulation

of stress and strain due to gas adsorption/desorption

and their effects on in situ permeability of coalbeds.

Journal of Canadian Petroleum Technology, 45, 52-62.

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

482

Harpalani, S. and McPherson, M.J. (1985). Effect of stress

on permeability of coal. Quarterly Review of Methane

from Coal Seams Technology, 3, 23-28.

Puri, R. and Seidle, J. (1991). Measurement of stress

dependent permeability in coals and its influence on

coalbed methane production. In Situ (United States),

16 (3), 183-202.

Shi, J.Q. and Durucan, S. (2004). Drawdown induced

changes in permeability of coalbeds: A new

interpretation of the reservoir response to primary

recovery. Transport in Porous Media, 56, 1-16.

Somerton, W.H. (1975). Effect of stress on permeability of

coal. International Journal of Rock Mechanics Mining

Science and Geological Abstracts, 12, 129-145.

Wang, F.Y., Massarotto, P., Wei, X. R. and Rudolph, V.

(2008). Anisotropic geomechanical properties of coal

for permeability and fluid transport applications. 2008

Asia Pacific Coalbed Methane Symposium, Brisbane,

Australia.

Wei, X.R., Wang, G.X., Massarotto, P., Golding, S.D.

and Rudolph, V. (2007). A review on recent advances

in the numerical simulation for coalbed methane

recovery process. SPE Reservoir Evaluation &

Engineering, 10, 657-666.

ModelingAnisotropicPermeabilityofCoalandItsEffectsonCoalbedMethaneReservoirSimulation

483