Artificial Intelligence

Applications on Bioinformatics and Textile Industry

H. İbrahim Çelik

1

, M. T. Daş

2

, L. C. Dülger

3

and M. Topalbekiroğlu

1

1

University of Gaziantep, Textile Engineering Dept., Gaziantep, Turkey

2

Roketsan Missile Company, Elmadağ /Ankara, Turkey

3

University of Gaziantep, Mechanical Engineering Dept., Gaziantep, Turkey

Keywords: Artificial Intelligence, Biometric Authentication, Signature Verification, Fabric Defect Detection, Fabric

Defect Classification, ANN’s, PSO-NN.

Abstract: AI techniques have been successfully used in many fields of engineering. A brief description of possible

applications of AI in engineering are dated with future prospects. This study reviews two different

experimental systems; bioinformatics and textile engineering. The experimental systems are described.

Different databases are used and their implementation results are also presented by using AI methods; like

ANN and PSO-NN. Implementation accuracies are given with tables for their use in these cases.

1 INTRODUCTION

Artificial Intelligence (AI) in engineering

applications is continuously increasing. Systems are

used for design, planning, classification and

intelligent control and other expert applications.

Different real world problems were solved.

Biometric authentication is critically important

to provide personal identification and verification.

ANN’s have also been used for solving variety of

problems including pattern classification and

recognition in biometric. Complex and nonlinear

characteristics can be effectively modelled by using

ANN’s rather than traditional methods. These

applications are seen in biometric as; speech,

handwritten character, fingerprint and signature

recognition system and real-time target identification

for security applications. Biometric authentication

must be highly reliable conforming high degree of

security. Improvements and contributions on

biometric technologies are yielded to solve this

problem (Daş, 2008). Daş et al., 2009 have studied

system performance statistically. Bhattacharyya et

al, 2009 have presented a survey on biometric

authentication on the past, present and future views.

Daş et al. 2012 have designed an optomechatronic

device for biometric authentication especially for

document base.

Defect detection is an important problem in

fabric quality control. Many attempts have been

performed to solve this problem in textile industry.

Textile industry is also very concerned with quality.

Fabric defects are responsible for nearly 85% of the

defects found by the garment industry. It is

imperative therefore to detect, to identify, and to

prevent these defects from reoccurring. Currently,

the quality of the fabric is evaluated by the human

vision in most of the weaving factory and even with

the most highly trained inspectors only about 60% of

the defects is being detected. The inspection speed

of a fabric even woven with an efficiency of 97% is

observed as 30 m/min. A prototype intelligent

system for woven fabric defect detection is

developed and operated in real time using AI

techniques. The defects are detected with image

processing methods and classified with AI by using

neural networks. (Çelik, 2013)

This paper is organized with two case studies as

signature verification and fabric defect detection

using NN’s. Implementation results are given with

numerical and statistical figures. Experimental

studies are performed at Gaziantep University,

Department of Mechanical Engineering and Textile

Engineering Laboratories as PhD. research projects.

Studies are successively completed at present, but

the improvements in AI algorithms are still

continuing.

425

Çelik H., T. Da¸s M., C. Dülger L. and Topalbekiro

˘

glu M..

Artificial Intelligence - Applications on Bioinformatics and Textile Industry.

DOI: 10.5220/0004862504250431

In Proceedings of the 16th International Conference on Enterprise Information Systems (ICEIS-2014), pages 425-431

ISBN: 978-989-758-027-7

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

2 STUDIES USING ARTIFICIAL

INTELLIGENCE (AI)

Artificial intelligence techniques such as Artificial

Neural Network (ANN), Fuzzy Logic (FL) and

Genetic Algorithm (GA) are used for many

unlimited applications including bio-informatics,

biomedical etc. providing an ideal platform in

engineering. Majority of recent engineering

applications are still being performed on heuristics

since reliable results are obtained.

This study is analysed any base for

bioinformatics and textile engineering as signature

verification and fabric defect detection with

classification. During the procedure similar steps are

performed. The texture features of the fabric

samples are extracted and these features are used as

input. AI system learns the texture features and

distinguishes them into categories. NN’s are

classified with their connections or architectures

used to represent a neuron and the learning rule as a

single layer or multi-layer perception.

2.1 Signature Verification with Neural

Networks (NN)

Sabourin and Drouhard, 1992 have described a

handwritten SV system. The directional probability

density function (PDF) and feed forward NN with

back-propagation (BP) learning are applied to

random signatures in verification process. NN

algorithm is described by

See and Seng, 1993 to

analyse and obtain the optimal values of factors such

as learning rates, skilled forgeries and pre-

processing of images which affect the performance

and also accuracy of a SV system. Drouhard et

al.,1994 have improved PDF and BP-NN by using

the global classification error in memorization and

generalization. Pottier et al., 1994 have used multi-

layer perceptron for identification and authentication

of handwritten signatures. Murshed et al., 1995 have

been presented a Fuzzy Artmap NN trained genuine

signatures based on off-line SV system. Zhou and

Quek, 1996 have developed an automatic fuzzy NN

driven SV system. Dehghan and Fathi, 1997 have

presented multiple multi-layer perceptron NN

modules trained with global features cooperating in

taking an off-line SV. Huang and Yan, 1997 have

studied on off-line SV based on geometric feature

extraction and NN classification.

Sabourin, et al. 1996-1997 have studied on local

granulometric size distributions. A signature was

centred on to a grid of rectangular retinas, which

were excited 36 by the signature’s trajectory pixels

at that location. Baltzakis and Papamarkos, 2001

have used a two stage NN for off-line SV. Santos et

al., 2004 have proposed to reduce the number of

signature samples required by each writer in the

training phase of off-line SV. Jose et al., 2003 have

studied on a new robust technique for the off-line

signature verification The technique was based on

the use of compression NN’s, and in the automatic

generation of the trained set from only one signature

for each writer. Marinai and Gori, 2005 have studied

on the survey of ANN applications on off-line

document image processing. Daş, 2008 have

performed statistical figures for the application

success in this thesis. Daş and Dülger, 2009 have

studied on signature verification by using a universal

data base with PSO-NN with significant success.

2.2 Fabric Defect Detection with

Neural Networks (NN)

Off-line defect detection is initially studied by using

Wavelength analysis and Gabor functions. Their

classification is then performed by using an interface

with NN’s (Çelik, 2013). Huang and Chen, 2001

have presented a method with FL and BP learning

algorithm using NN’s with nine categories of defects

including normal fabrics and eight fabric defects:

missing end, missing pick, double ends, double

picks, hole, light filling bar, cobweb, and oil stain.

Tilocca et al, 2002 have presented a method using a

different optical image acquisition system and ANN

to analyze the acquired data by using different light

sources. A three layered FFNN with sigmoidal

activation function and BP were used. Four defects;

large knot, slub, broken thread and knot were

classified by the presented system with success of

92%. Kumar, 2003 has presented an approach for

local textile defects using FFN and fast web

inspection method using LNN. A twill weave fabric

sample with defect miss pick was tested by using

FFN method. Fabric inspection image with the

defects slack-end, dirty-yarn, miss pick and thin bar

were tested by LNN method. Kuo and Su, 2003 have

made fabric defect classification by using GLCM

and NN methods. GLCM of the fabric sample

images were obtained. The features such as energy,

entropy, contrast and dissimilarity were extracted.

The defect types were introduced to NN, tested and

trained by using four fabric defect images; warp

lacking, weft lacking, oil stain and hole. Kuo and

Lee, 2003 have classified the defects as; warp

lacking, weft lacking, hole and oil stain defects by

training a three layer BPNN with plain weave white

fabric. The fabric samples were acquired via an area

ICEIS2014-16thInternationalConferenceonEnterpriseInformationSystems

426

scan camera with 512 x 512 resolutions. The

classification was achieved with high recognition for

all types of defects. Islam et al., 2006 have

developed an automated textile defect detection

system based on adaptive NN.

This is based on to combine thresholding

techniques and ANN for defect classification with a

performance of 77%. Liu et al., 2008 have studied

on fabric defect classification by applying PSO-

BPNN. PSO algorithm was introduced into BPNN

training to determine NN connection weight and

threshold values reasonably. Suyi et al, 2008 have

presented a study by using sub-images of DB3

wavelet transform function. These features were

used as input to PSO-BP NN for classification of

five types of defects; warp direction, weft direction,

particle, hole and oil stain. Suyi et al., 2009 have

proposed a defect detection algorithm by combining

cellular automata theory and fuzzy theory. Jianli et

al., 2007 have proposed a method of Gray Level Co-

occurrence Matrix (GLCM), Principle Component

Analysis (PCA) and NN. GLCM of the image was

obtained and 13 different features of the matrix were

extracted by using Haralick method. The features

vectors were prepared for NN input. NN was trained

for four types of fabric defects; warp lacking, weft

lacking, oil stain and hole with success.

3 CASE STUDIES

Two case studies are highlighted applications of AI

especially on biometric field and textile industry in

everyday life in the following. A study on signature

verification based on PSO-NN is presented (Daş

M.T., 2008). A study for denim fabric defect

detection is then presented and classified using NN’s

(Çelik İ.H, 2013).

3.1 Case Study I

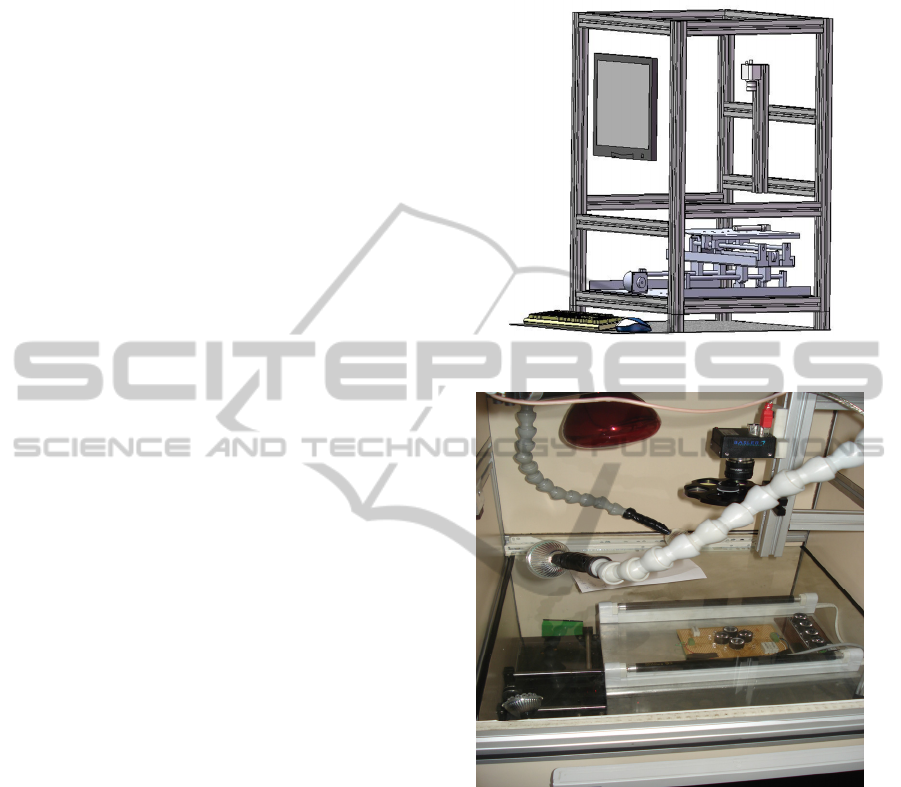

This device is built at Gaziantep University,

Department of Mech. Eng., and Dynamic Systems

Laboratory. The parts of the device are the frame,

the X-Y table (two stepper motors), a camera &

filter wheel and light sources (IR, UV, Daylight-

Figure 1). Figure 2 shows details of lights available

in the system. A Graphical User Interface (GUI)

program, IMPQD (Image Processing for Questioned

Document) software is prepared. Signature

Verification (SV) toolbox is also included. Menu

options are shown in Table 1.

Addition to classical menu toolbox, image

processing applications, SV toolbox, a camera

control and a position control of X-Y table are

performed with IMPQD in Figure 1.

Figure 1: Designed Device.

Figure 2: Illumination Details.

The software is designed either examining the

questioned document and/or signature verification

with PSO-NN algorithm. Satisfaction is obtained at

the end. A universal signature database is used for

this purpose. Parameters of the proposed method

PSO-NN are the number of particles, the number of

dimensions, the number of parameters and the

constants for PSO and NN for training process.

After training, weights of the network are

obtained in data file used in test part of the

algorithm. During application, 25 sets of 54 different

signatures have been used. Numbers of 24 genuine

and 30 forgery signatures have been performed for

each set. Different number of inputs have been

generated and tried for verification process.

ArtificialIntelligence-ApplicationsonBioinformaticsandTextileIndustry

427

Table 1: IMPQD with Image Processing Units (8 Dialog

boxes).

File

New, Open, Save, Save As, Print,

Send, Exit

Image Mirror, Flip, Negative, Rotate Left,

Rotate, Right, Skew, Resample

Image 2 Grey Scale, Negative, Dither

Image 3 Lighten, Darken, Contrast, Erode,

Dilate

Image 4 Blur, Gaussian, Median, Soften,

Sharpen, Edge, Emboss, Threshold,

Noise, Jitter, Pinch, Bathroom, Swirl,

Punch

Mat + C Neural Network and Signature

Verification Toolbox

Table Control X-Y table and Camera controller

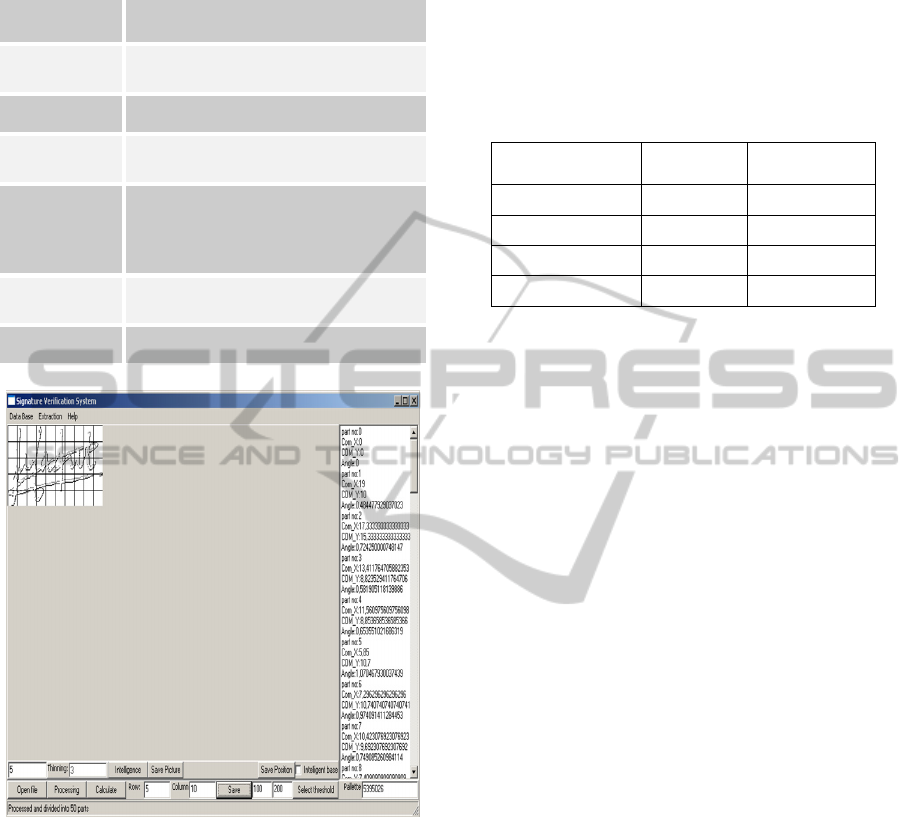

Figure 3: Signature Processing Window.

In this study two different division techniques can be

applied onto the signature. The same signatures set

are tried with 3, 6, 9, 12, and 20 parts. Numbers of

divisions are chosen randomly, in order to compare

small and large parts. One of the set is divided

vertically with equal size. The other one is divided

with square constant sizes such as (3x1, 3x2, 3x3,

4x3, and 5x4). Different number of particles (25, 30,

40, 50) and iterations (1000, 2000, 5000, 10000) are

also applied onto the same signatures. The number

of particles and iterations are adjusted with trial and

error method. (Daş M.T., 2008) Genuine 15

signatures and 16 forgery signatures are trained for

NN training. PSO-NN algorithm has been performed

with 40 particles and 5000 iterations. Input nodes

(18) are adapted for each input set and hidden layer

(32) nodes adapted system with trials in the training

section. Parameters of the network have been used

with 0.8 learning rate and λ is 1. Table 2 presents

verification results of database.

Table 2: Verification Results.

Skilled

forgery

Genuine

signatures

Tested signatures 350 225

Accepted

94 186

Rejected

256 39

Results(%)

26.85 FAR 17.33 FRR

3.2 Case Study II

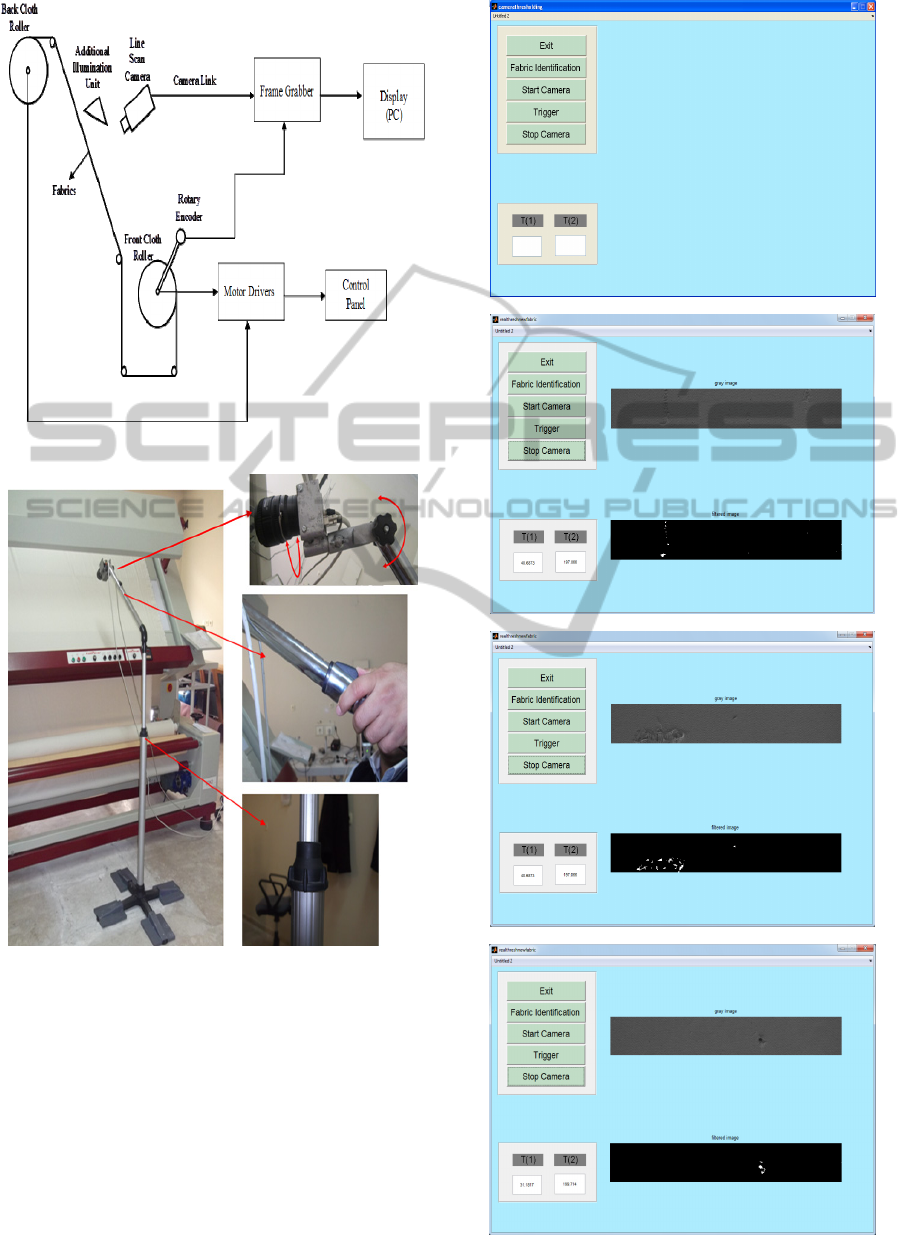

A fabric inspection system is built to recognize

fabric defects then a classification is performed

afterwards (Çelik İ.H., 2013). An industrial fabric

inspection machine is the main body. It is being

modified by a camera system, camera attachment

equipment, an additional lightening unit, a rotary

encoder and PC. CCD line-scan camera, frame

grabber card, lens and camera link cable are

included in camera system. This system is available

at Gaziantep University, Textile Engineering

Department Laboratory in Turkey. The system

architecture is given in Figure 4. The experimental

system is shown in Figure 5.

Off-line and real-time fabric defect detection

processes are carried out by using three different

algorithms. A defect database is prepared for off-line

applications. The database consists of five kinds of

fabric defects such as warp lacking, weft lacking,

hole, soiled yarn and knot and defect-free fabric

samples. Defect detection algorithms; Double

Thresholding (DT), Wavelet Analysis (WA), and

Gabor Filter (GF) methods are applied both off-line

on the database images and real-time by using the

experimental set-up. Classification is then performed

with neural networks on denim fabric. (Çelik İ.H.et

al 2013)

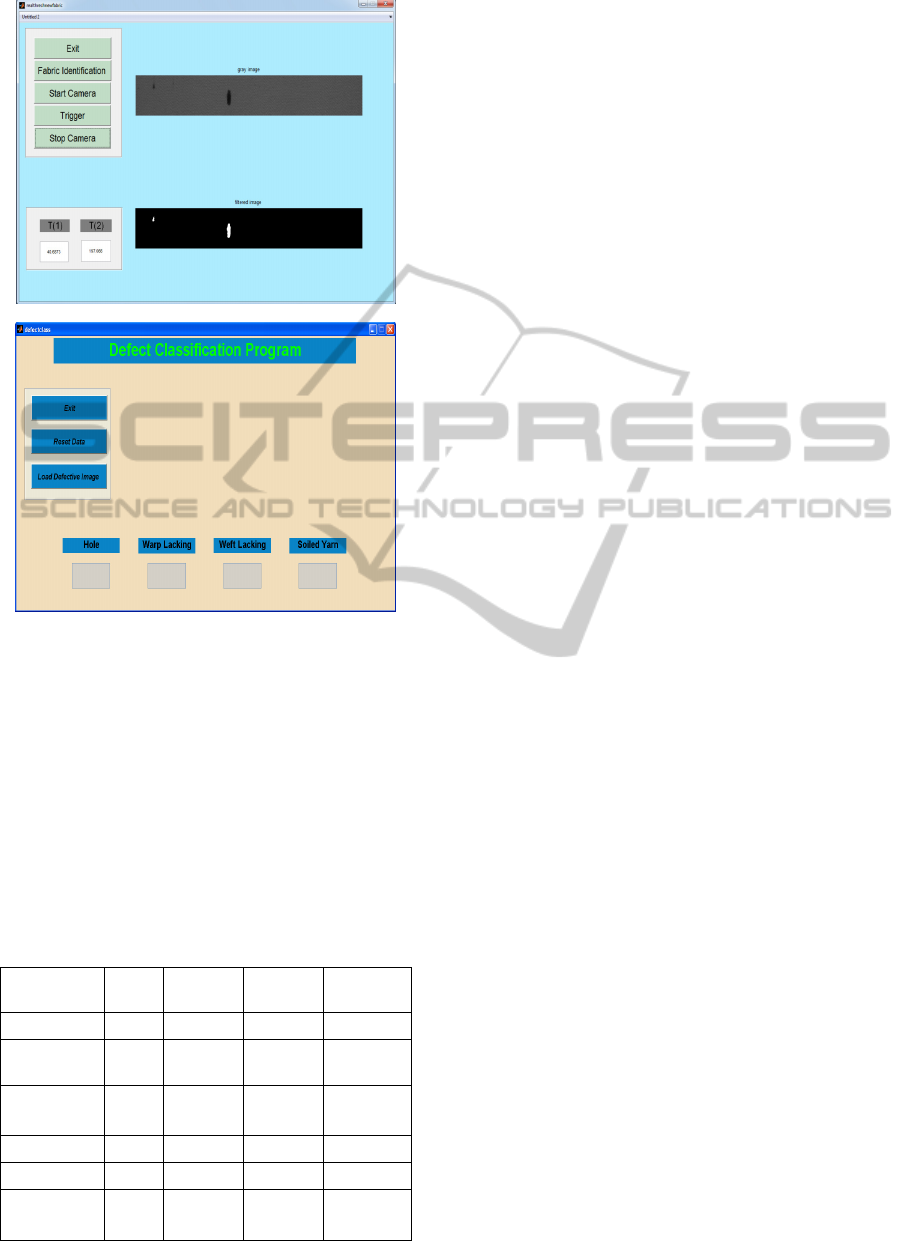

Different interfaces are prepared. An interface is

used for defect detection as ‘Exit’, ‘Fabric

identification’, ‘Start Camera’, ‘Trigger’ and ‘Stop

camera’ (Figure 6.a) The Fabric Identification

button is used to calculate thresholding limits.

ICEIS2014-16thInternationalConferenceonEnterpriseInformationSystems

428

Figure 4: Schematics of Defect Detection System.

Figure 5: The Experimental System.

The average of lower limits and upper limits is

calculated and displayed on the screen as T(1) and

T(2) respectively. The camera is started again by

using Start Camera button. Trigger button is pressed

by starting the defect detection process. Stop

Camera button stops the image acquisition by the

fabric winding stop. The second interface is

automatically used to determine the defect type of a

selected defective image. The user interface consists

of three buttons as; ‘Exit’, ‘Reset Data’ and ‘Load

Defective Image’ as in Figure 6.f.

(a) User Interface

(b) Warp lacking

(c) Weft lacking

(d) Hole

ArtificialIntelligence-ApplicationsonBioinformaticsandTextileIndustry

429

(e) Soiled yarn

(f)

Figure 6: Defect detection and classification program user

interface.

The defective fabric images are stored and then used

for network training and testing. The features of the

25 defective fabric images are extracted for each

defect type and the input matrix of the network is

formed. Having trained NN successfully, 20 samples

of each type of defects are used to test the network

classification accuracy. Table 3 shows defect

classification accuracy rates. Studies are continuing

on the subject.

Table 3: Defect classification accuracy rates.

Defect type

Hole

Warp

Lacking

Weft

Lacking

Soiled

Yarn

Hole

20 0 1 0

Warp

Lacking

0 19 0 1

Weft

Lacking

0 1 19 0

Soiled yarn

0 0 0 0

Samples

20 20 20 20

Accuracy

(%)

100 95 95 95

4 CONCLUSIONS

Since biometric application is quite common in our

daily lives, signature verification is mostly used as

forms of identification. Off-line signature

verification (SV) with PSO-NN is performed;

handwritten signatures are collected from an

available database with preparation of SV toolbox.

An improved verification method; PSO-NN is

adopted and applied on the signatures. PSO is used

to train neural network system. The performance of

the method is successfully tried on a different

database in many applications.

A prototype intelligent system is developed for

woven fabric defect detection and operated it in real

time using AI (Artificial Intelligence) techniques.

The prototype system consists of the fabric

unwinding and rewinding machine, lighting system,

image processing hardware, and software. Meantime

four types of defects; hole, warp lacking, weft

lacking and soiled yarn were classified on the fabric

using NN’s. A user interface was prepared for this

application. The upper and lower threshold limits T

1

and T

2

were measured by using defect-free fabric

frames when determining fabric defects.

Two case studies are presented here to show

applications of AI in different fields of engineering.

Both studies are performed experimentally and

supported by the theory. Satisfaction in the results is

definitely seen.

ACKNOWLEDGMENTS

Both studies are supported by Gaziantep University

Scientific Research Projects Management Unit

(BAP). The names of research projects are ‘Design

of a Mechatronic Device for Documents’ and

‘Development an Intelligent System for Fabric

Defect Detection’.

REFERENCES

Daş M. T.,’ Design and Implementation of Biometric

Recognition using Off-Line Signature, Gaziantep

University-Turkey, Ph.D.Thessis, 2008.

Daş M. T., L. C. Dülger, H. E. Dülger, ‘A Statistical

Approach for Off-Line Signature Verification (SV), J

.of Medical Informatics and Technologies’,

Vol.13/pp.34-40, 2009.

Bhattacharyya ,D., Ranjan R., Alisherov F., Choi M.,

‘Biometric Authentication: A Review’, Int. J. of

Science and Tech., Vol.2, No.3, 13-27, 2009.

ICEIS2014-16thInternationalConferenceonEnterpriseInformationSystems

430

Daş M. T., L.C.Dülger, H.E.Dülger, ‘An Optomechatronic

Device for Document Analysis: Design and

Application’, Int. Conf. on Medical Physics And

Biomedical Eng., Vol.13/pp.8-14, 2012.

Çelik İ. H.,’Development of an Intelligent Fabric Defect

Inspection System’, Gaziantep University-Turkey,

Ph.D.Thessis, 2013.

Sabourin R., Drouhard J.P., “Off-Line signature

verification using directional PDF and neural

networks”, Pattern Recognition IEEE, Vol.2, pp. 321-

325, 1992.

See N. G., Seng O. H., “A Neural network approach for

off-line signature verification”, IEEE Int. Conf. on

Speech and Image Tech. for Comp. and Telecom.,

pp.770-773, 1993.

Drouhard J.P., Sabourin R. , Godbout M., “Evaluation of a

training method and of various rejection criteria for

NN classifier used for off-line signature verification”,

IEEE World Congress on Comp. Int., IEEE Int. Conf.

on NN’s, Vol. 7, pp.4294-4298, 1994.

I. Pottier, G. Burel, “Identification and authentication of

Handwritten signatures with a connectionist

approach”, IEEE World Congress on Comp. Int.,

IEEE Int.Conf. on Neural Networks, Vol.5, pp. 2948-

2951,1994.

N. A.Murshed, F. Bortolozzi, R. Sabourin, “Off-line

signature verification using fuzzy artmap NN”, Pr. of

IEEE Int. Conf. on NN’s, Vol.4, pp.2179-2183, 1995.

Zhou R.W., Quek C., “An automatic fuzzy NN driven

signature verification system”, Pr. of IEEE Int. Conf.

on NN’s, Vol.4, pp.1034-1039, 1996.

Dehghan M., Fathi M., “Signature verification using

shape descriptors and multiple NN’s”, IEEE Int. Conf.

on Speech and Image Tech. for Comp. and

Telecomm., pp.415-418, 1997.

Huang K., Yan H., “Off-Line Signature Verification Based

on Geometric feature Extraction and NN

Classification”, Pattern Recognition, Vol.30, No.1,

pp.9-17, 1997.

Baltzakis H.,Papamarkos N., “A new signature verification

Technique based on a two-stage NN classifier” Eng.

App.of Artificial Int., Vol. 14, pp.95-103, 2001.

Santos C. , Justino E.J.R., Bortolozzi F., Sabourin R., ”An

Off-Line SV method based on the questioned document

expert’s approach and NN classifier”,IEEE Comp.

Society, Pr. of 9th Int. Workshop on Frontiers in

Handwriting Recognition., 2004.

Sabourin R., Genest G., and Preteux F., ‘Pattern Spectrum

as a Local Shape Factor for Off-Line Signature

Verification”, In Pr. of ICPR, Vol. 3 pp. 43-48, 1996.

Sabourin R., Genest G., and Preteux F.,”Off-Line

Signature Verification by Local Granulometric Size

Distributions”, IEEE Trans. on Pattern Analysis and

Machine Int., Vol. 19, No. 9, 1997.

Jose F. Velez, Sanchez A. and A. Moreno B. “Robust Off-

Line Signature Verification Using Compression

Networks And Positional Cuttings”, IEEE XIII

Workshop on NNs for Signal Processing, page 627-

636, 2003.

Marinai S, Gori M.,”

Artificial Neural Networks for

Document Analysis and Recognition ”, IEEE Trans. on

Pattern Analysis and Machine Int., Vol.27, No.1,2005.

Daş M. T, Dülger L. C., ‘Signature Verification (SV)

Toolbox: Application of PSO-NN’, Engineering App.

of Artificial Intelligence, 22, 688-694, 2009.

Huang C. C, and Chen C. I.,‘Neural-fuzzy classification

for fabric defects’. Textile Research Journal. 71(3),

220-224, 2001.

Tilocca A., Borzone P., Carosio S., and Durante A.

Detecting fabric defects with a neural network using

two kinds of optical patterns’. Textile Research J.

72(6), 745-750, 2002.

Kumar A. ‘Neural network based detection of local textile

defects’. Pattern Recognition. 36, 1645-1659, 2003.

Islam A., Akhter S., and Mursalin T. E., ‘Automated

textile defect recognition system using computer vision

and artificial neural networks’. WASET. 13, 1-6,

2006.

Liu S. Y., Zhang L. D., Wang Q. and Liu J. J., ‘BP neural

network in classification of fabric defect based on

PSO’,Pr. of 2008 Int. Conf. on Wavelet Analysis and

Pattern Recognition, Hong Kong. 216-220, 2008.

Suyi L., Liu Jingjing, L. and Leduo Z.,‘Classification of

fabric defect based on PSO-BP neural network’. Pr. of

2008 2nd Int. Conf. on Genetic and Evol. Comp. 137-

140, 2008.

Suyi L., Qian W. and Heng Z. ‘Edge detection of fabric

defect based on fuzzy cellular automata’. Intelligent

Systems and Applications. 1-3, 2009.

Jianli L., Baoqi, Z.,‘Identification of fabric defects based

on discrete wavelet transform and BP NN’. J.of the

Textile Institute. 98:4, 355-362, 2007.

Kuo C. J., Su T., ‘Gray relational analysis for recognizing

fabric defects’, Textile Research Journal. 73(5), 461-

465, 2003.

Kuo C. J. and Lee C. J., ‘A Back-propagation neural

network for recognizing fabric defects’. Textile

Research Journal. 73(2), 147-151, 2003.

Çelik İ. H., L. C.Dülger, M. Topalbekiroglu ‘Development

of a Machine Vision System: real time fabric defect

detection and classification with neural networks’, J.

of The Textile Institute, pp.1-10, September 2013.

ArtificialIntelligence-ApplicationsonBioinformaticsandTextileIndustry

431