Statistical Process Control for a Limited Amount of Data

José Gomes Requeijo

1

, António Abreu

2,3

and Ana Sofia Matos

1

1

UNIDEMI, Departamento de Engenharia Mecânica e Industrial, Faculdade de Ciências e Tecnologia,

Universidade Nova de Lisboa, 2829-516 Caparica, Portugal

2

ISEL/IPL – Instituto Politécnico de Lisboa, Lisboa, Portugal

3

CTS – Uninova, Lisboa, Portugal

Keywords: SPC (Statistical Process Control), Q Control Charts, MQ Control Charts, Process Capability.

Abstract: Some production systems control many quality characteristics with a restricted amount of data, not allowing

a convenient estimation of the process parameters (mean and variance), thereby creating a difficulty in

implementing the traditional Statistical Process Control (SPC). In order to address this question, the

approach suggested is to adopt the developments proposed by by Charles Quesenberry, which consists in

the statistics sample transformation at time i. This transformation is based on a parameter estimation at time

(i – 1). This paper addresses two situations, the univariate and multivariate SPC, with the use of Q

dimensionless statistics. Both univariate (Q) and multivariate (MQ) statistics are distributed according to

standard Normal distribution. It is also suggested the application of new capability indices Q

L

and Q

U

to

study the univariate process capability, which are represented in the mean Q control chart to evaluate in real

time the performance of the various processes and predict the possibility of production of nonconforming

product, which will increase customer satisfaction. The methodology is applicable to different production

systems, both for industry and services. Based on a methodology developed, a case study is presented and

discussed.

1 INTRODUCTION

Initially the SPC was presented by Shewhart (1931)

in Bell Telephone Laboratories. The Shewhart’s

developments were a valuable contribution to the

continuous improvement of quality.

However, the traditional Shewhart control charts

have some limitations such as: it considers only a

characteristic of quality control, and its

implementation in a real process requires a large

amount of data. In order to implement these control

charts, it is necessary to ensure the following

principles:

1) The data is grouped in rational subgroups.

2) The sampling frequency must maximize the

possibility of variation between samples.

3) The data should be independent, that is,

ikik

x

( n,,i 1 ; m,,k 1 ), where

2

0

,N~ is a random variable, called white

noise.

4) The control limits are distant from the central

line (mean of the control variable) 3 standard

deviations of this variable, it means the

significant level is 0.27%.

5) The data has a Normal distribution with mean

and variance

2

(

2

,N~X ).

The current productive systems (lean production)

have distinct characteristics from those of the

Shewhart period (mass production). Nowadays,

firms have new constraints, such as: they produce

simultaneously a large number of different products

in small amounts and need to control, at the same

time, several quality characteristics. Consequently, it

is necessary to develop other approaches that meet

these new constraints. This topic has been the

subject of study by several researchers, such as

Bothe (1988), Wheeler (1991), Pyzdek (1993),

Quesenberry (1997), Montgomery (2012) and,

Pereira and Requeijo (2012), among other authors.

This approach is commonly known as the Short

Run SPC. When there is a restricted amount of data,

the estimation of the process parameters is not

possible. Thus, Quesenberry (1997) suggested the

application of a new kind of control charts, named Q

charts (univariate approach) and MQ charts

190

Gomes Requeijo J., Abreu A. and Matos A..

Statistical Process Control for a Limited Amount of Data.

DOI: 10.5220/0004812101900195

In Proceedings of the 3rd International Conference on Operations Research and Enterprise Systems (ICORES-2014), pages 190-195

ISBN: 978-989-758-017-8

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

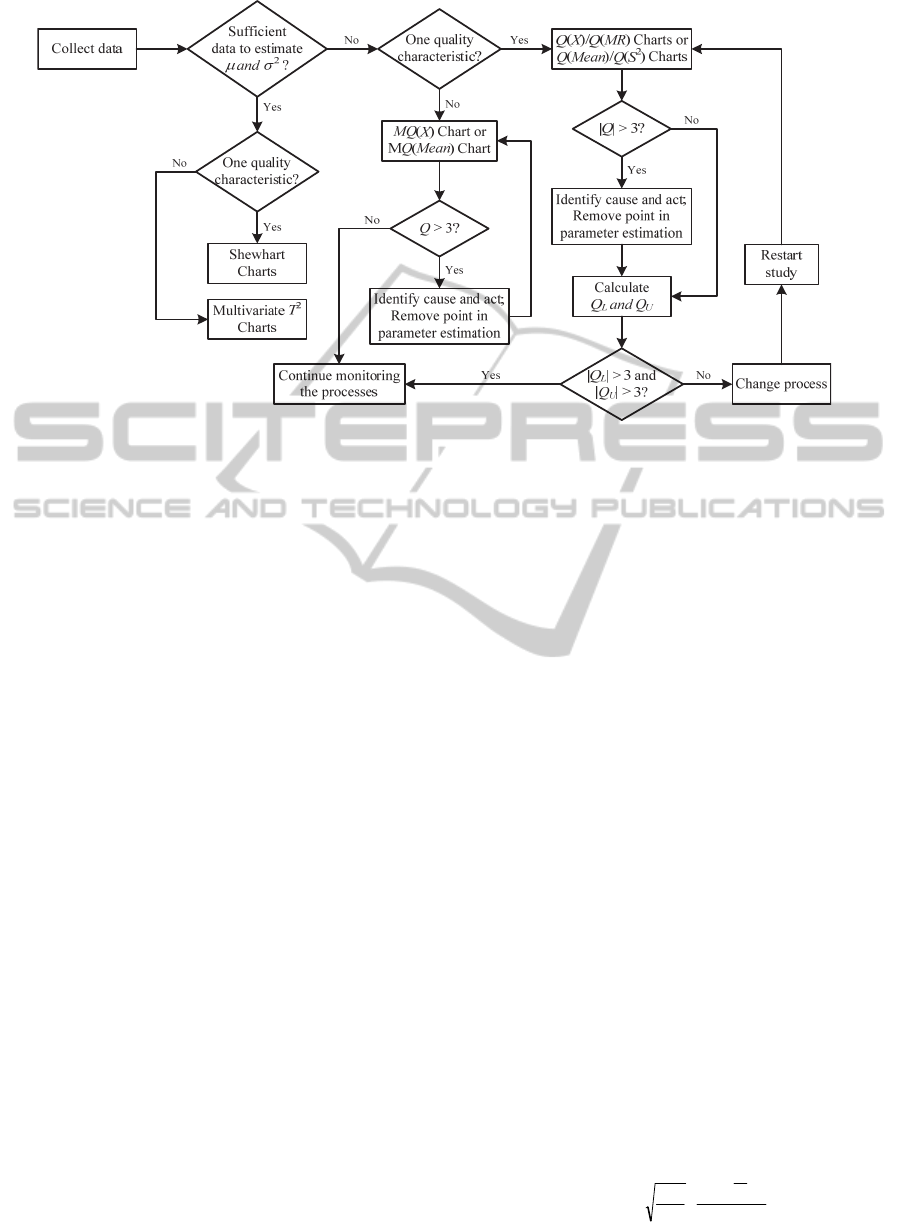

Figure 1: Methodology for implementation of SPC for a limited amount of data.

(multivariate approach). The implementation of

these control charts is done in order to include in the

same chart all products/quality characteristics, and

based on this approach it is possible to control the

stability of all processes.

In this paper the Short Run SPC approach is

discussed for continuous variables, when a restricted

amount of data in two distinct control contexts

(univariate and multivariate) exists.

In order to apply correctly the univariate and

multivariate SPC, the data must be Normality

distributed for all characteristics. To support a

continuous evaluation of the process capability, the

application of new indices Q

L

and Q

U

developed by

Pereira and Requeijo (2012) is suggested. The

implementation of these two indices allows the

capability of the process to be analyzed in real time.

In order to demonstrate the importance of these

charts and validate the methodology proposed in this

paper, a case study is presented and discussed.

2 METHODOLOGY

When there is a limited amount of data, that is, when

there is not enough information to properly estimate

the processes parameters, the authors of this paper

suggest the methodology presented in Figure 1.

3 SHORT RUN SPC TO A

LIMITED AMOUNT OF DATA

3.1 Univariate SPC

In some cases, due to the existence of a restricted

amount of data, process parameters cannot be

properly estimated, creating an obvious difficulty in

the construction of traditional Shewhart, Z and W

control charts. To answer this question, the adoption

of the methodology developed by Charles

Quesenberry is suggested, which consists in

transforming the quality characteristic X in a

variable Q, where X is a continuous variable. The

variable Q follows approximately the standard

Normal distribution, with zero mean and variance 1,

if the variable X is independent and approximately

Normal

2

,N . This method transforms the

statistics calculated at time i by estimating the

process parameters at time (i1), considering all data

prior to this time.

There are two situations to consider, the data are

samples or individual measurements.

3.1.1 Q Control Charts for Individual Data

The statistic Q at time i is calculated from the

measurement X at th3at moment, and it is defined by

4 3

1

1

1

2

1

,,i

S

XX

i

i

GXQ

i

i

i

iii

(1)

StatisticalProcessControlforaLimitedAmountofData

191

The variability process should be calculated based

on the moving range of two consecutive

observations. Thus, the statistic Q at time i, which is

obtained from the statistics at that moment MR, is

defined by

12 ; 6 4

2

2

2

2

2

1

1

i,,i

MRMR

MR

FMRQ

i

i

,ii

(2)

In equations (1) and (2) the following variables

denote:

X

i

– individual measurement at time i

1i

X – average of (i1) observations

1i

S – standard deviation of the sample of

(i1) observations,

MR

i

– moving range at time i

1

– inverse of the standard Normal

distribution function

G – Student-t distribution function,

21

,

F

– Fisher distribution function with

1

and

2

degree of freedom.

3.1.2 Q Charts for Subgrouped Data

The

XQ

statistic at time i is calculated from the

sample average

X

, defined by

i

j

j

i

j

jji,pii

p,i

ii

i

ii

i

iii

SSn

s

XX

nn

nnn

,,i,GXQ

i

11

22

1

1

1

1

11

1

;

32

1

(3)

Also, the sample variance is transformed in the

Q(S

2

) statistic, defined by

2

1

2

12

32

11

i,pii

i,ii

SS

,,i,FSQ

ii

(4)

In equations (3) and (4) the following variables

denote:

n

i

sample size at time i

i

X average of the sample i

i

X grand average of i samples

2

i,p

S

pooled variance of i samples

3.1.3 Control Limits

The Q statistics are random variables with standard

Normal distribution. Thus, the control limits are

3

(

%.270

) for

XQ ,

MRQ ,

XQ and

2

SQ

charts.

One of the serious problems of the

Q charts is its

poor sensitivity in the detection of special cause of

variation. In order to solve this drawback, it is

important to apply rules to increase the sensitivity of

the charts. The application of Rule 1 (a point outside

the control limits) and Rule 6 (four out of five

consecutive points in zone B or A on the same side

of the center line) referred to in ISO 7870-2:2013 is

suggested.

3.1.4 Process Capability

The application of the Q

L

and Q

U

capability indices

developed by Pereira and Requeijo (2012) is

advisable; these indices are defined at time

i by

i

i

i

L

ˆ

k

ˆ

LSL

Q

ˆ

(5)

i

i

i

U

ˆ

k

ˆ

USL

Q

ˆ

(6)

In equations (5) and (6) USL and LSL are

respectively the upper and lower specification limits

and

k is the minimum value to processes capability.

3.2 Multivariate SPC

Similarly to univariate SPC, when there is a limited

amount of data, the best solution to implement the

multivariate SPC is to use the

Q statistics. The

present developments are based on the assumption

that the joint distribution of

p variables is a

multivariate Normal distribution

,N

p

. The

control of the mean vector is made by

X

MQ or

X

MQ

charts.

3.2.1 MQ Control Charts for Individual

Data

The X vector is transformed in the MQ statistic.

Considering the intention of detecting shifts between

X vector and vector and the structure of the

statistic,

MQ at time i is

XX SXX

X

,p,p i,

iip

pii

f

.fA

AF;maxMQ

i

i

-

i-

i

ii

ipi,pii

32

2

11

0

1

1

1

1

1

1

(7)

ICORES2014-InternationalConferenceonOperationsResearchandEnterpriseSystems

192

Whiteness (Paint 88)

Q

(

X

) CHART

-5

-3

-1

1

3

5

1 3 5 7 9 11 13 15 17 19 21 23 25

Batch n.

Q (X)

Q(X) LCL CL UCL QL Qu

De nsity (Paint 88)

Q

(

X

) CHART

-6

-4

-2

0

2

4

6

1 3 5 7 9 11 13 15 17 19 21 23 25

Batch n.

Q (X)

Q(X) LCL CL UCL QL Qu

Opacity (Paint 88)

Q

(

X

) CHART

-5

-3

-1

1

3

5

1 3 5 7 9 11 13 15 17 19 21 23 25

Batch n.

Q (X)

Q(X) LCL CL UCL QL Qu

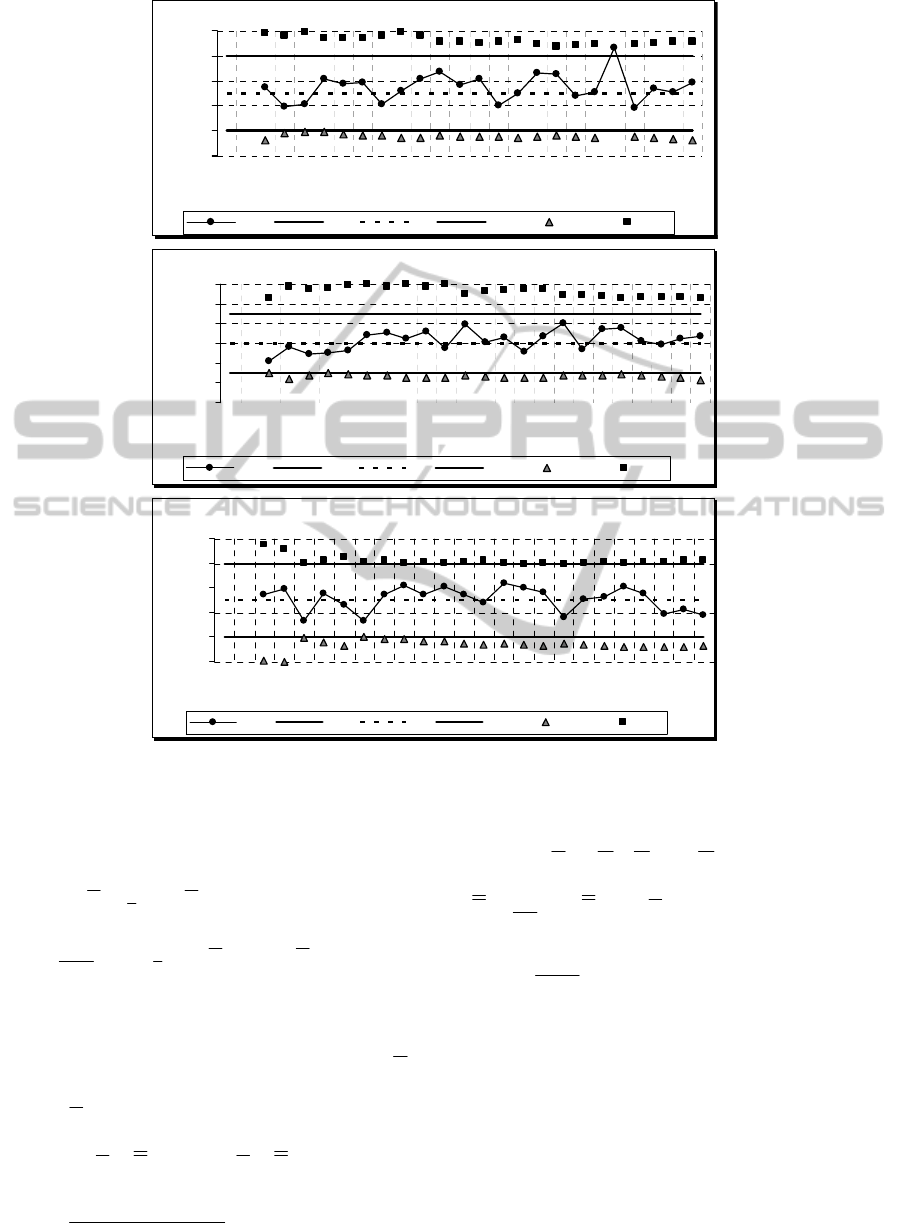

Figure 2: Q

X

Charts for Whiteness, Density and Opacity of the Paint 88.

where

ipiii

X,,X,X X

21

(8)

i

ii

i

i

XX X

1

1

1

(9)

11

1

1

1

2

i

i

i

iii

ii

i

XXXX S S

(10)

3.2.2 MQ Charts for Subgrouped Data

The MQ statistic at time i is calculated from X

vector at that time by

XXSXX

X

,,, i

iNpN

piNNn

g

.gA

AF;maxMQ

ii

iii

ii

-

pool,i

ii

r

ipiN,p

i

i

i

32

1

0

1

1

1

1

1

1

(11)

where

ipiii

X,,X,X X

21

(12)

ii

i

i

i

i

i

i

nnN;nN

N

1

1

1

1

XXX

(13)

0S

S S S

0

11

11

1

1

pool,

iipool,ii

i

pool,i

niN

N

(14)

3.2.3 Control Limits

As the T

2

charts, the MQ charts only contemplate the

upper control limit (UCL). The lower control limit

(

LCL) is zero and the upper is + 3.

StatisticalProcessControlforaLimitedAmountofData

193

4 CASE STUDY

To illustrate the potential applicability of the Short

Run SPC approach for continuous variables, when a

restricted amount of data exists, two distinct control

charts (univariate and multivariate) will be applied.

The study focuses on production of paint, named

"Paint 88." With the purpose of controlling three

quality characteristics: whiteness, density and

opacity, 25 sample batches of this paint were

analyzed.

The univariate approach contemplates the

construction of

Q

X

chart for each one of three

characteristics, as shown in Figure 2. In order to

calculate the

Q statistic, equation (1) was used.

However, to calculate indices Q

L

and Q

U,

equations

(5) and (6) were used.

Looking at univariate

Q

X

chart (figure 2) it is

possible to detect a special cause of variation related

to whiteness characteristic (see batch 21). However,

all characteristics have capability since

3

L

Q and

3

U

Q occurs in all batches.

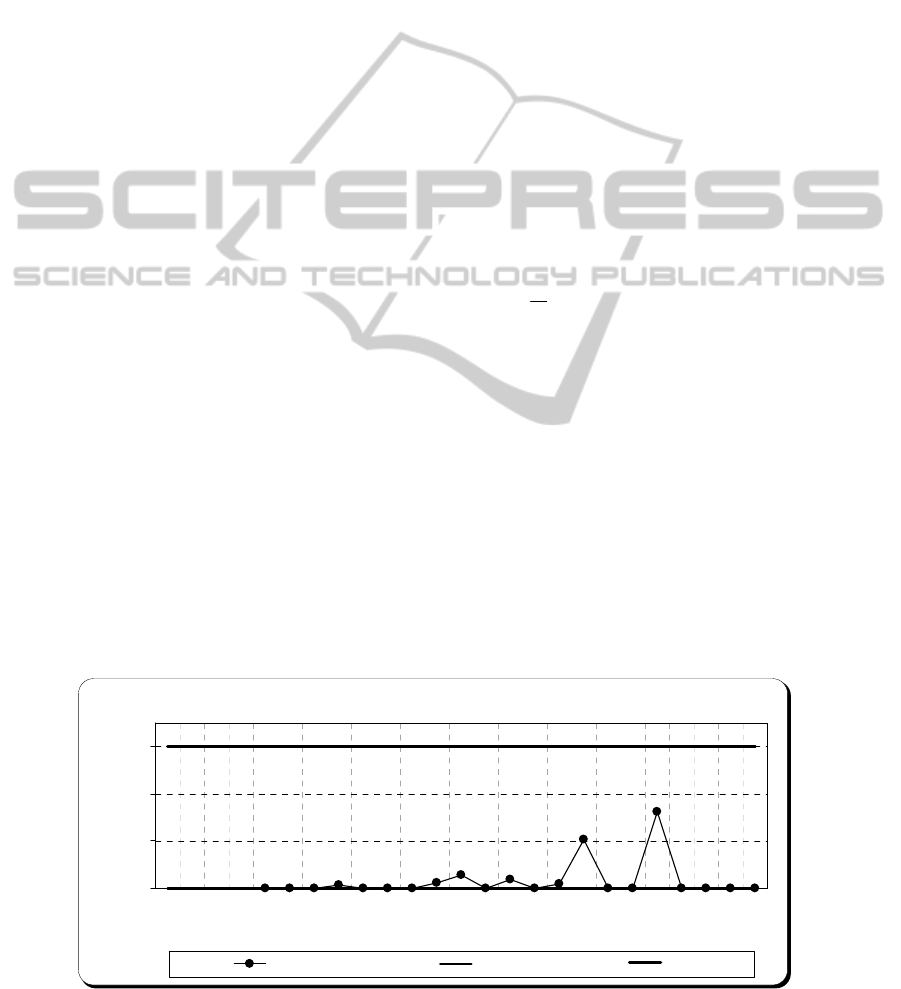

The multivariate approach contemplates the

construction of only one

MQ

X

chart, as shown in

Figure 3, and the multivariate statistics of the 25

sample batches were calculated based on equations

from (7) to (10).

Analysing the

MQ

X

chart for paint 88, it is

possible to verify that there are no problematic

situations, and therefore, we might conclude that the

process is stabilized for the three quality control

characteristics.

5 CONCLUSIONS

When there is a restricted amount of data, it is

impossible to implement the traditional SPC,

univariate or multivariate, because in these scenarios

it is necessary to estimate the process parameters.

The methodology presented in Figure 1, has

several advantages over traditional approaches such

as:

1)

Q charts allow the statistical control of all

products/quality characteristics in the same

document (control chart), even when there is

insufficient data to conveniently estimate the

process parameters (mean and variance);

2)

MQ charts allow the simultaneous control of

several statistical quality characteristics of

various products in the same document, even

when there is insufficient data to favorably

estimate process parameters (mean vector and

covariance matrix);

3) it allows the study of different characteristics in

the same chart;

4) it simplifies the processes analysis;

5) based on application of the capability indices

Q

L

and

Q

U

in the univariate approach (

XQ charts

or

XQ

) it allows the monitoring of the process

capability, revealing an important added value;

6) Using

Q

L

and Q

U

indices, permits the study of

the process capability in real-time, and reduces

the probability of producing nonconforming

units.

On the other hand, one disadvantage of

Q control

charts is the difficulty in analyzing the existence of

non-random patterns; consequently, this limitation

increases with the number of products/quality

characteristics.

Another disadvantage of the

Q and MQ control

charts is the poor sensitivity in detecting special

cause of variation, especially at the beginning of the

study. Although the lack of sensitivity in detecting

Paint 88

MQ

(

X

) CHART

0

1

2

3

12345678910111213141516171819202122232425

Batch n.

MQ (X)

MQ(X) LCL UCL

Figure 3: MQ

X

Chart for the characteristics Whiteness, Density and Opacity of the Paint 88.

ICORES2014-InternationalConferenceonOperationsResearchandEnterpriseSystems

194

non-random patterns is a limitation of the Q and

MQ control charts, its use is of great importance and

utility, since traditional approaches based on

univariate and multivariate analysis cannot be

implemented when there is a restricted amount of

data.

One way to increase the sensitivity of these

techniques is to use memory charts, such as

Cumulative Sum charts (e.g.

CUSUMQ and

MCUSUMQ) and Exponentially Weighted Moving

Average charts (e.g. EWMAQ and MEWMAQ), as

mentioned in Requeijo and Pereira (2012).

REFERENCES

Bothe, D. R., 1988. SPC for Short Production Runs,

Quality, Vol. 27, pp. 58-59, 1988.

Montgomery, D. C., 2012. Introduction to Statistical

Quality Control, 7th Edition, John Wiley & Sons, Inc.,

New York.

Pereira, Z. L. e Requeijo, J. G., 2012, Quality: Statistical

Process Control and Planning, 2

th

Edition, Fundation

of FCT/UNL, Lisbon (in portuguese).

Pyzdek, T., 1993. Process Control for Short and Small

Runs, Quality Progress, Vol. 26(4), pp. 51-60, 1993.

Quesenberry, C. P., 1997. SPC Methods for Quality

Improvement, John Wiley & Sons, Inc., New York.

Shewhart, W. A., 1931. Economic Control of Quality of

Manufactured Product, D. Van Nostrand Company,

Inc., New York.

Wheeler, D. J., 1991. Short Run SPC, SPC Press,

Knoxville, Tennessee.

StatisticalProcessControlforaLimitedAmountofData

195