PZT AND PNZT-BASED THIN FILM CAPACITORS AND

TRANSMISSION LINES FOR MICROWAVE INTEGRATED

CIRCUIT APPLICATIONS

Z. Awang and S. Sulaiman

Microwave Technology Centre, University Technology MARA, 40450 Shah Alam, Malaysia

zaiki.awang@gmail.com, anisafiq2@yahoo.com

Keywords: Thin film capacitor, co-planar waveguide transmission line, PZT, PNZT, thin dielectric films, monolithic

microwave integrated circuits.

Abstract: Ferroelectric materials have superior dielectric properties but the processing conditions of thin ferroelectric

films influence their dielectric properties and thus affect the performance of devices which employ them. A

detailed characterization is carried out for lead zirconate titanate (PZT) and lead niobate zirconate titanate

(PNZT) thin films in this work by employing planar-circuit structures. The films were applied to built

microwave capacitors and co-planar waveguide transmission lines. S-parameter measurements were

performed from 40 MHz to 20 GHz using wafer probes in conjunction with a vector network analyzer. The

results show the loss tangent and relative permittivity of the films vary with frequency, with typical

permittivity values of the order of 110 to 350 and 200 to 780 for PZT and PNZT, respectively, over the said

frequency range. The investigation revealed the effect of dielectric polarization of the films over the broad

frequency range. The transmission lines showed acceptable insertion losses of the order of 17 dB from 5 to

20 GHz for lines of length 100 µm and width 5 µm fabricated on PNZT films 1 µm thick. These figures

demonstrate the feasibility of using thin ferroelectric films as a new substrate material for monolithic

microwave integrated circuits (MMIC).

1 INTRODUCTION

Ferroelectric materials are popular due to their

superior dielectric properties characterized by their

high dielectric constant and polarization values. The

review made by (Setter et. al., 2006) discussed their

dielectric properties and represented the state of the

art development of the material - the domain

structure and their effects on relative permittivity

and loss, and their implication in micro-systems and

high frequency device applications .

Lead zirconate titanate (PZT) and lead niobate

zirconate titanate (PNZT) belong to the family of

ferroelectric materials. Both are known for their high

dielectric constant as well as their superior

perovskite characteristics useful for high capacitor

density applications (Dimos and Mueller, 1998,

Riemens et. al. 2003 and Haccart et. al., 2006). With

the addition of a dopant such as Nb, the PZT can

demonstrate higher dielectric constant and promote

larger perovskite crystals, as well as increased film

resistivity (Souza et.al., 2004). The addition of Nb

also influences the film characteristics such as

microstructure, as well as the electrical properties.

Also, there is correlation between internal electric

field and ‘self polarization’ of the films that

increases with Nb concentration.

Souza et.al., 2004 found that the enhancement of

the piezoelectric and ferroelectric properties of

PNZT is possible with careful control of the

crystallographic orientation of the polycrystalline

films or growing the epitaxial films with preferred

orientation. Their study also investigated the film

thickness effects on the ferroelectric and

piezoelectric properties of PNZT thin films.

In our work, PZT and PNZT thin films prepared

differently were utilized to explore their microwave

95

Awang Z. and Sulaiman S.

PZT AND PNZT-BASED THIN FILM CAPACITORS AND TRANSMISSION LINES FOR MICROWAVE INTEGRATED CIRCUIT APPLICATIONS.

DOI: 10.5220/0004785800950103

In Proceedings of the Second International Conference on Telecommunications and Remote Sensing (ICTRS 2013), pages 95-103

ISBN: 978-989-8565-57-0

Copyright

c

2013 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

properties. The films were studied over two types of

applications – as thin film metal-insulator-metal

(MIM) capacitors, and as a new substrate material

for the construction of co-planar waveguides. The

principal motivation of this work was to exploit the

high dielectric constant of these films to reduce the

size of capacitors and transmission lines, two

components which traditionally take up large area of

MMIC. Thus using these ferroelectric films offer the

potential of reducing the size of MMICs, leading to

wireless systems having more efficient power

consumption.

Two capacitor test structures of 2500 μm

2

area

were fabricated on the films and measured by

employing the planar circuit technique. The

measurement was performed using Cascade

Microtech wafer probes and a vector network

analyzer with short-open-load (SOL) calibration

technique. The measurements were carried out over

a wide frequency range of 40 MHz to 20 GHz which

are suitable for MMIC applications. The

capacitance, loss tangent and relative permittivity of

the films were then extracted from the experimental

data. From the analysis, behavior of dielectric

polarization of PNZT and PZT over a broad

frequency range was deduced.

Various transmission lines were then constructed

in co-planar form with both films acting as the

substrate. The novelty of this work is to show the

feasibility of using ferroelectric materials as the

substrate for MMIC. This paper reports results of

further investigations of our previous work, which

has been extended to include tests on the various

transmission line structures.

2 METHODOLOGY

The films were prepared using standard methods

compatible with MMIC processing. The objectives

of the experimental work made were to two-fold: to

analyze the capacitance, loss tangent and their

relative permittivity at microwave frequencies, and

to measure the insertion loss of the films by

analyzing the transmission lines constructed out of

these films.

2.1 Sample Preparation

The PZT and PNZT samples were categorized based

on the method of deposition, doping, dielectric

thickness, orientation, crystallinity and grain size

obtained from the X-ray diffraction (XRD). The

PNZT films were grown using metal organic

deposition to give films of 1 µm thick, while the

PZT was prepared with RF sputtering with

thicknesses of the order of 0.5 µm. The PNZT films

were tetragonal (20/80) and doped with 4 % Nb,

while the PZT films were (50/50) cubic. The top

metallization layers of the capacitor structures were

Ti, while Pt was used as bottom electrodes.

2.2 Device Fabrication

The fabrication processes used are compatible with

semiconductor processing, details of which are

reported earlier (Bakar et. al., 2008). The fabrication

for PNZT sample was modified slightly due to the Pt

etchant which attacked the PMMA photoresist used.

For this sample, the capacitor test structures were

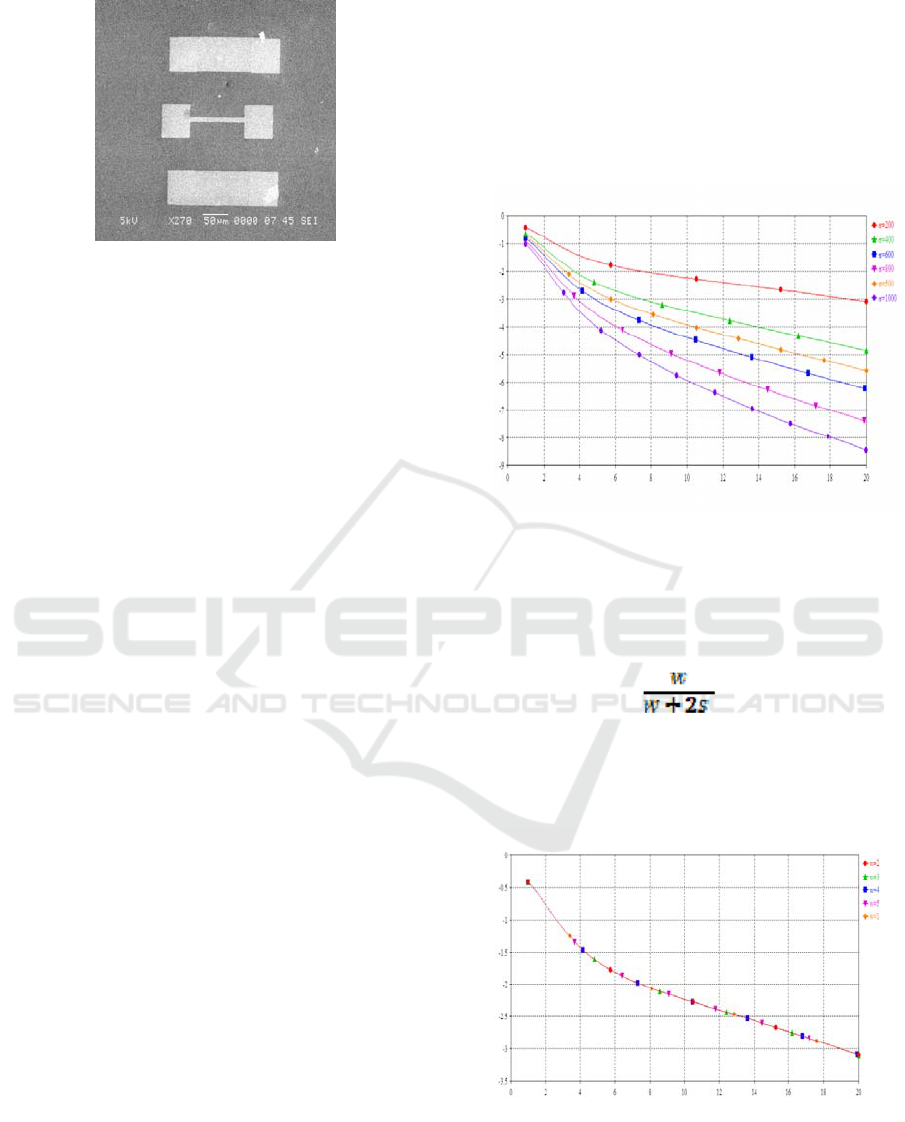

delineated after the Pt layer was removed. Figure 1

shows the capacitor prototype with area 50 µm × 50

µm.

Figure 1: A typical thin film capacitor test structure

constructed in this work, with ground-signal-ground

(GSG) pads on the left for wafer probing.

2.3 Measurement

High frequency measurements were carried out on

the capacitor using on-wafer probe and vector

network analyzer (VNA). The SOL one-port

calibration technique was performed for the

capacitance measurements, while SOLT was

employed to calibrate the two-port transmission line

structures to minimize measurement errors due to

parasitics (WinCal 3.2 User Guide, 2000). The Open

standard in SOL was obtained by lifting the probe at

least 0.25 mm in air, while the Short and 50

standards were provided by the manufacturer

impedance standard substrate (ISS). The probe tip

placements were ensured to be consistent to achieve

repeatable measurements and calibrations. The short

standard defines a zero-length reference plane. The

reflection coefficient, S

11

of the test structure is

obtained after the probe calibration is completed.

Second International Conference on Telecommunications and Remote Sensing

96

3 RESULTS AND DISCUSSION

3.1 Capacitors

The S-parameter data obtained from the

measurement consist of real and imaginary parts of

the input impedance of the test structures. The

complex permittivity of a dielectric is written as (Al-

Omari and Lear, 2005);

'

*"

j

ε

εε

=− (1)

where the

'

ε

is the real part that represents the

relative dielectric constant which characterizes a

material’s ability to store charges. On the other

hand,

"

ε

is the imaginary part that describes the

dielectric loss which is a measure of the dispersion

in the material. The data is then used to extract the

capacitance, relative permittivity and loss tangent of

the films.

The impedance equation is shown in equation

(2); where

0

ε

is the free space permittivity, A is the

capacitor area which is 2500μm

2

, d is the dielectric

thickness and

ω

is the angular frequency.

*

0

d

Z

j

A

ω

εε

=

(2)

The capacitance is calculated from S

11

using :

()

11

0

'"

11

0

1

1

meas

meas

S

d

Z

S

jjA

ωε ε ε

⎛⎞

+

=

⎜⎟

−

−

⎝⎠

(3)

where S

11meas

is the measured S

11

. Using (3) the real

and imaginary parts of

'

"

j

ε

ε

− give the following

expressions (Park et. al., 2002):

()

()

11

00 11

11

00 11

1

1

'Im

1

1

1

"Re

1

meas

meas

meas

meas

S

d

AZ S

S

d

AZ S

εω

ωε

εω

ωε

⎛⎞⎛ ⎞

−

=

⎜⎟⎜ ⎟

+

⎝⎠⎝ ⎠

⎛⎞⎛ ⎞

−

=

⎜⎟⎜ ⎟

+

⎝⎠⎝ ⎠

(4)

(5)

Both equations yield the frequency dependence

of

'

ε

and

"

ε

. Subsequently, these equations are

made use to evaluate the capacitance, the relative

permittivity as well as the loss tangent. The

capacitance of the structure is obtained by relating

the imaginary part of the impedance;

1

c

X

j

C

ω

= (6)

From the measured S

11

, the impedance is calculated

as in (4) using the equation:

11

11

1

50

1

meas

meas

S

Z

S

⎛⎞

+

=

⎜⎟

+

⎝⎠

(7)

The capacitance is extracted using the following

equation:

11

11

1

1

50 Im

1

meas

meas

C

S

S

ω

=

⎛⎞

+

××

⎜⎟

−

⎝⎠

(8)

The loss tangent is determined from the ratio of

the imaginary and the real parts of (4) and (5)

respectively;

"

tan

'

ε

δ

ε

=

(9)

Details of our work have been reported

elsewhere (Sulaiman et. al., 2011), and hence only

the main findings relevant to the discussion of our

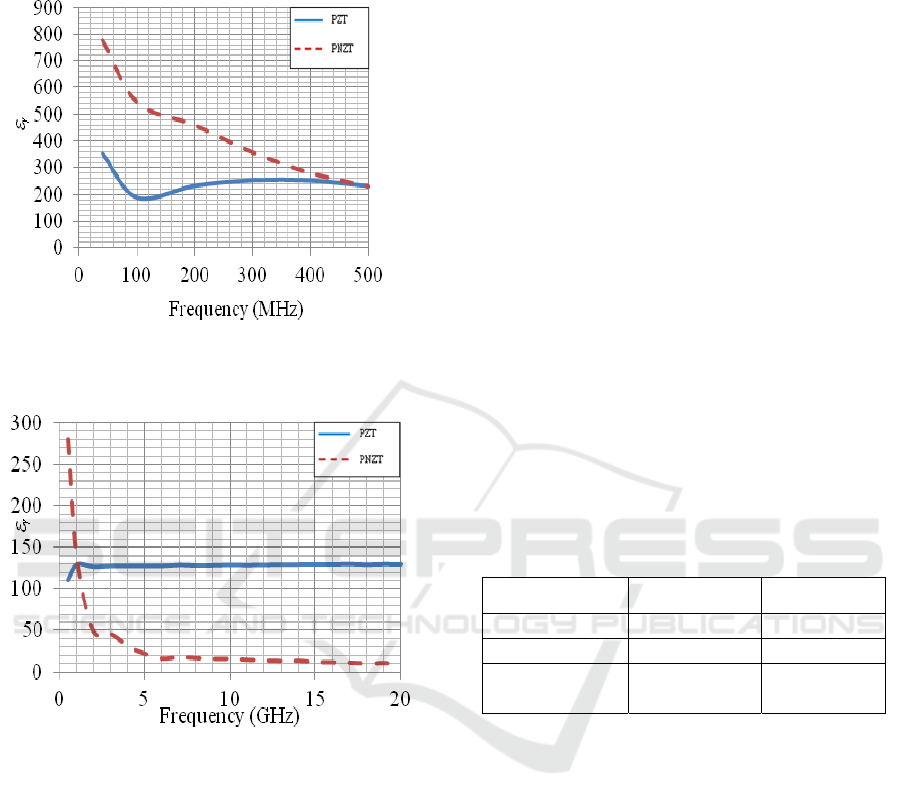

new results are repeated here. Figures 2 and 3 below

show typical response of the dielectric properties

over the frequency range mentioned. The PNZT

films exhibited higher permittivity compared to

PZT, this is expected due to the Nb doping. Both

films showed decreasing trends of ɛ

r

as the

frequency is increased, again this is expected as the

films get more lossy with frequency due to

polarization.

As expected, the decrease in ɛ

r

was accompanied

by an increase in loss tan for both samples

(Sulaiman et. al., 2011). The values of tan for the

PZT film were in the range of 0.04 to 0.18, while

similar behavior were seen for PNZT. This response

can be explained by the presence of the relaxation

phenomena where as the frequency of electric field

is increased, there is a point where the permanent

electric dipoles of the material can no longer rotate

fast enough to remain in phase with the field. Hence,

these mechanisms reduce the polarization and

PZT and Pnzt-Based Thin Film Capacitors and Transmission Lines for Microwave Integrated Circuit Applications

97

subsequently reduce the permittivity, while the loss

tangent increases (Al-Omari and Lear, 2005).

Figure 2: Permittivity versus frequency between 40 to 500

MHz.

Figure 3: Permittivity versus frequency between 0.5 to 20

GHz

From the results we could see the effect of

doping to PZT has significant impact on the

capacitor performance. Nb

5+

is a donor dopant which

replaces the Zr

4+

/Ti

4+

ions in the B-site of PZT - this

compensates the positive charge introduced

(Riemens et. al., 2003). Also, there is correlation

between the grain size and

r

with Nb concentration.

Riemens et. al, 2003, Haccart et. al. 2003 and Souza

et.al., 2004 reported enhancement to

r

with Nb

doping. However, the increase of

r

is also

influenced by composition as well as Nb

concentration. The work by Souza et.al 2004

showed that PNZT with high

r

has higher tan

ompared to PZT. Similar lossy behavior of PNZT in

our samples is seen in Figures 2 and 3.

The drastic decrease of

r

with frequency for

PNZT may be attributed to grain size as proposed by

(Chikuvula, 2000). The degradation of

r

can be

caused by several factors such as dielectric

relaxation and microstructure defects (Dimos and

Mueller, 1998; and Elisalde and Ravez, 2001). In

addition, different types of polarizations (which are

classified according to dipole type) can give rise to

several dispersion regions over the broad frequency

range. With the decreasing permittivity, therefore,

the loss is expected to increase with frequency. This

behavior was indeed observed for both our films

over the two frequency ranges. Many factors

contribute to dissipation in a ferroelectric material -

among them is the effect of oxygen and lead

vacancies (Park et. al., 2002; Chang and Anderson,

1997 and Zhu et. al., 2006), ferroelectric domain

wall motion, as well as film composition and

microstructure (Park, et. al., 2002; and Elissalde and

Ravez, 2001).

Table 1 summarizes the dielectric properties of

our films from 40 MHz to 20 GHz, and compares

with those of (Vilarinho, et. al., 2005). Though the

loss tangent in this work was higher, the permittivity

values were in the expected range for both thin

films.

Table 1: Comparison of material properties.

ɛ

r

tan д

PZT (this work) 110 - 353 0.04 – 0.1

PNZT (this work) 11 - 778 0.15 – 1.18

Vilarinho et. al.

2005

200- 1000 0.01 - 0.07

3.2 Transmission Lines

To demonstrate the feasibility of using these films in

MMIC, several transmission lines were constructed

on them. The lines were designed in both microstrip

and co-planar waveguide (CPW) form. The co-

planar waveguide format is preferred for high

frequency on-wafer probing due to the co-planar

arrangement of the Cascade probes used in this

work. The CPW is also preferred over microstrip in

MMIC applications since the former eliminates the

need to use via holes, which is difficult to realize,

and model, in MMIC. An example of the co-planar

waveguide line structure used in our work is shown

in Figure 4.

Second International Conference on Telecommunications and Remote Sensing

98

Figure 4: The test structure showing co-planar waveguide

transmission line fabricated on PNZT film.

3.2.1 Simulation Results

a) Effect of ɛ

r

The transmission lines were also simulated to predict

their behavior. The CST Microwave Studio

electromagnetic simulator was employed for this

purpose. In the simulation,

ε

r

values between 200 to

1000 were used to replicate the high-k properties of

the films. Figure 5 depicts the simulated insertion

loss values of CPW lines for different

ε

r

. The line

length and width were set to 100 µm and 5 µm

respectively. The CPW structure was treated as a

symmetrical configuration, (Kuang et. al., 2010;

Pozar, 2005 and Kitzawa and Itoh, 1991) with the

gap between the ground pad and the center

conductor set to 50 μm apart to comply with the

GSG probe pitch limitation. The tan value was

fixed to 1 as ceramic materials are normally lossy

(Pozar, 2005; and Mirshekar-Syahkal, 1983). The

results show that as

ε

r

increases; the insertion loss

increases with frequency. These results indicate that

for a given frequency; as the relative permittivity is

increased, the insertion loss is degraded. This is

because more rf energy is lost in the dielectric as

ε

r

is increased.

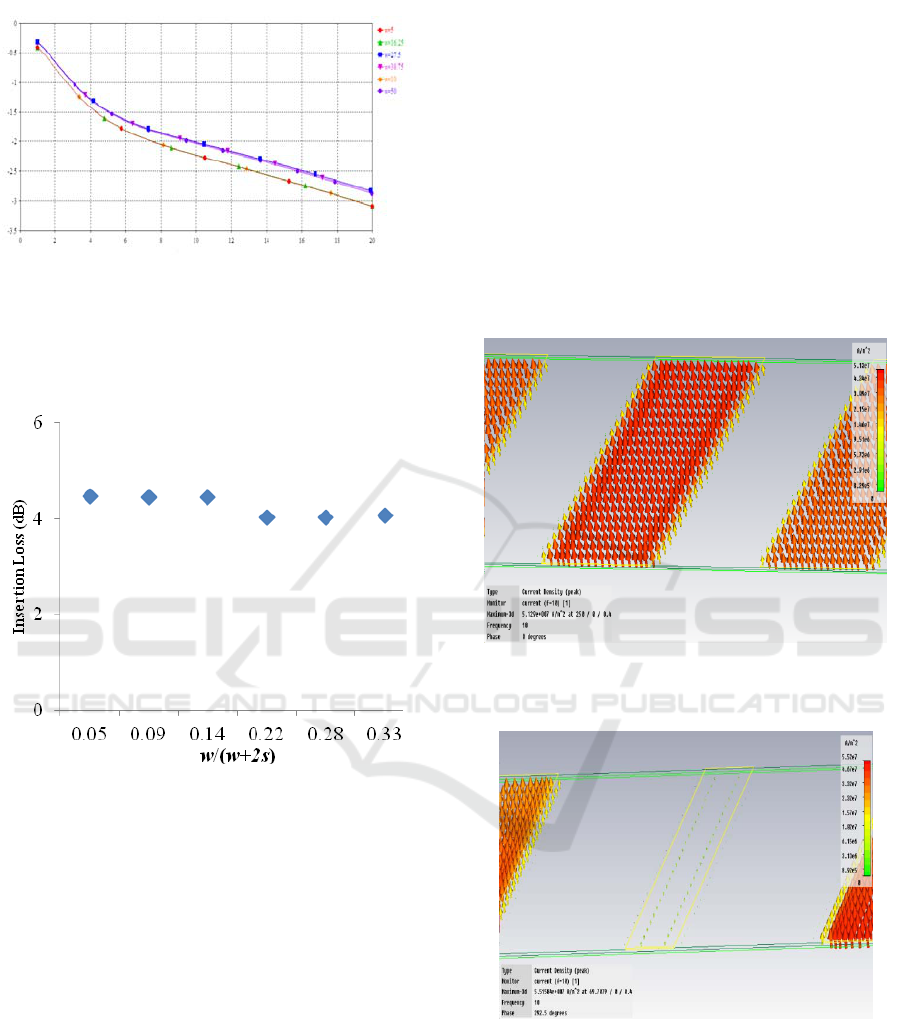

b) Effect of line geometry

The CPW was treated as symmetrical

configuration throughout the simulation. The gap s

was set to 50 μm to comply with the probe pitch,

while the centre strip line width w was varied.

However, the minimum w is limited by the

fabrication process. In this simulation the insertion

loss was computed when w was varied over two sets

of values - from 1 to 5 µm, and from 5 to 50 µm.

The results of these two sets of simulations are

shown in Figures 6 and 7 respectively.

ε

r

for both

simulations were set at 200, and the line length was

100 µm with loss tangent of 1. The electrode

thickness was fixed at 0.26 µm. The results in

Figures 6 and 7 illustrate that S

21

did not show a

significant dependency on the line width. Both sets

of results exhibit the same trend and comparable

insertion loss values.

Figure 5: Variation of insertion loss of CPW lines with

frequency for different

ε

r

values: 200 (), 400 (), 500

(), 600 (), 800 () and 1000 ().

Now, if the insertion losses are calculated with

different

ratios at a fixed frequency of 10 GHz, the response

obtained is shown in Figure 8 when w was varied

from 5 to 50 µm. It can be seen that the insertion

loss remain almost unchanged when w was varied.

Figure 6: Variation of insertion loss with frequency for

different line widths: 1 µm (), 2 µm (), 3 µm (), 4 µm

() and 5 µm ().

Frequency (GHz)

Insertion Loss (dB)

Insertion Loss (dB)

Frequency (GHz)

PZT and Pnzt-Based Thin Film Capacitors and Transmission Lines for Microwave Integrated Circuit Applications

99

Figure 7: Variation of insertion loss with frequency for

different line widths: 5 µm (), 10 µm (), 16.25 µm (),

27.5 µm (), 38.75 µm () and 50 µm ().

Figure 8: Insertion loss versus w/w+2s for w = 5 to 50 µm

at 10 GHz.

Using the electromagnetic simulator the current

density distribution over the conducting strip was

examined. These are shown in Figures 9 and 10 for

cases where the width is decreased gradually from

50 µm to 16.25 µm. It can be seen that when the

width of the conducting strip is equal to those of the

ground planes the currents are equally distributed

(Figure 9), and as the width was reduced the current

density in the center conductor decreased as well –

this is expected since the line impedances are now

higher.

Current crowding at the conductor edges may

also affect the performance of a CPW besides

conductor surface roughness (Wen, 1969 and

Jackson, 1986). Using an electromagnetic simulator

this current can be examined quite conveniently as

shown in Figure 9. In this figure current crowding at

the conductor edge is revealed by plotting the

current density across the width of the conductor.

The current density values at the edge was about

5.13 × 10

7

A/m

2

, the arrows are more densely

located at the conductor edges, indicating current

crowding. As the metal thickness was set to be 0.26

μm, which is less than the skin depth of Au at 10

GHz (0.8 μm); this implies that the rf current flow is

concentrated at the edge of the lines in the slot

region. In contrast, when the width-gap ratio

decreases, as expected the current distribution in the

center conductor decreases too (Riaziat, 1990), as

shown in the plot of current density in Figure 10.

Figure 9: Current density of CPW for w = 50 µm.

Figure 10: Current density of CPW for w = 16.25 µm.

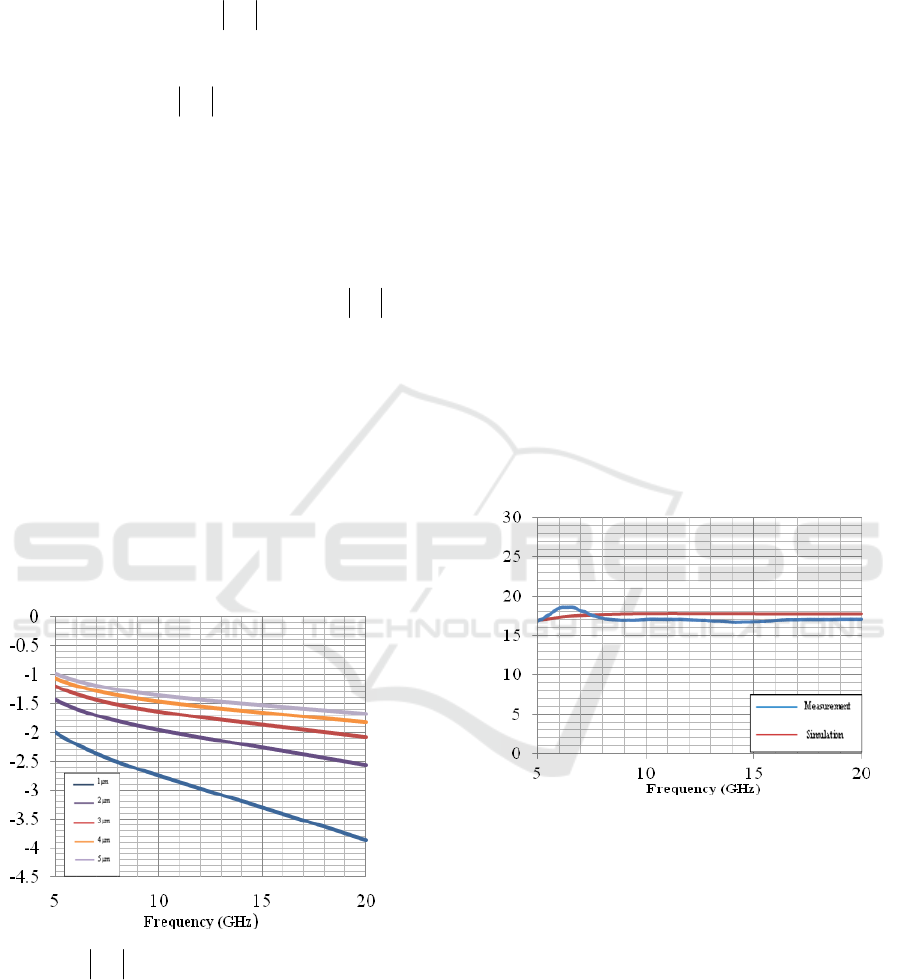

c) Effect of Film Thickness

As mentioned previously, the thicknesses of PZT

and PNZT films were 0.5 µm and 1.0 µm

respectively. In the simulation however, the film

thicknesses were varied to investigate the CPW

performance. The values of

ε

r

and tan

δ

were

obtained from the capacitance measurement: for

Frequency (GHz)

Insertion Loss (dB)

Second International Conference on Telecommunications and Remote Sensing

100

PZT they were 110 and 0.2, and for PNZT they were

280 and 1.

Figure11 shows the result of this simulation for

PNZT, where plots of

21

S

with PNZT film

thicknesses varying from 1 to 5 µm. Two things are

clear from the figure: firstly we see that the as the

film gets thicker,

21

S

decreases, implying a

reduction in the insertion loss. This behavior is

expected because as the film gets thicker, its

physical properties will be more uniform and

approach those of bulk samples. This is supported by

evidences reported in the literature (Zhi-Xiang et.

al., 2008, Haccart et. al., 2003 and Riemens et. al.,

2003) whereby bulk samples show better

performance than thin films. Secondly,

21

S

also

decreases with frequency, suggesting that the films

get more lossy with frequency. This is due to the fact

that at elevated frequencies the charges in the films

are unable to switch to the higher frequency electric

field. From the graphs it is important to note that for

practical integration circuit applications, it is

advisable not to use films thinner than 1 µm since

the losses degraded quickly after that. In this work,

the films used were 1 µm thick since it is quite

difficult to get thicker films using metal organic

deposition.

Figure 11:

21

S

versus frequency for PNZT films of

varying thicknesses.

3.2.2 Measurement Results

Test structures in the form of planar circuits such as

stripline, microstrip and co-planar waveguide are

commonly used for material property

characterization at microwave frequencies. These

test structures consist of dielectric substrates and

conductors that act as conducting strips and

grounding conductors. Microwave measurements are

made to examine the effect of substrate property and

conductor geometry so that microwave properties of

the circuit can be analyzed (Chen et. al. 2004).

In this work, experimental investigations of the

microwave behavior of both PZT and PNZT thin

films were performed using microstrip and co-planar

waveguide structures. In each structure, the PZT and

PNZT films which acted as a dielectric supported by

the silicon substrates.

The fabrication of the co-planar waveguide and

microstrip transmission lines was identical for both

films. The width and length of the lines are 5 μm

and 100 μm respectively. The structures were

measured with wafer probes in conjunction with a

vector network analyzer for high frequency

characterization. Measurement calibrations were

performed using the SOLT technique, aided by the

ISS impedance standard supplied by the probe

manufacturer. Two-port measurements were carried

out to evaluate the insertion loss of the films over a

frequency range of 5 GHz to 20 GHz.

Figure 12: Comparison of simulated and measured

insertion loss values of PNZT-based CPW.

Figure 12 shows the plot of one such result for

PNZT-based CPW, shown together with the

computer simulation for comparison. Both traces

show the same trend, and the agreement is quite

good, although the simulated values were slightly

higher. The results are the evidence that PNZT can

be used as a dielectric material in a CPW. The slight

discrepancies between the two results were probably

due to the mismatch loss that occurred in PNZT

films and to factors other than substrate properties –

this may include errors in the calibration and device

fabrication, and the electrode behaviour at high

Insertion Loss (dB)

PZT and Pnzt-Based Thin Film Capacitors and Transmission Lines for Microwave Integrated Circuit Applications

101

frequency. The mismatch happened due to the fact

the transmission lines were not exactly 50 – with

the high dielectric constants exhibited by the films,

the line width required to give 50 was too small to

be realized with our fabrication facilities. The

difference in the impedance of the line and that of

the probes would have given rise to reflections at the

input port, and this resulted in mismatch loss. In

addition, the loss of the PNZT-based CPW might not

only be due to the properties of the thin films

themselves, but to the geometrical aspects of the

transmission lines as well.

In the course of our work we found better

agreements with simulation were observed for

PNZT samples. We also found the PZT samples

exhibited higher insertion losses compared to PNZT

of the same line dimensions and film thickness.

PNZT-based CPW as a whole generally showed

better all round performance in our work.

In order to determine the film properties, as well

as to investigate the effect of microwave frequency

on PNZT as a high-k material; a parametric study

was carried out by varying the film parameters, to fit

the simulation results with measurements. The line

dimensions were actual ones used in the fabrication,

while the film parameters such as ε

r

and tan

δ

were

varied. The effects of these variations on the

insertion loss are shown in Figures 13 and 14

respectively.

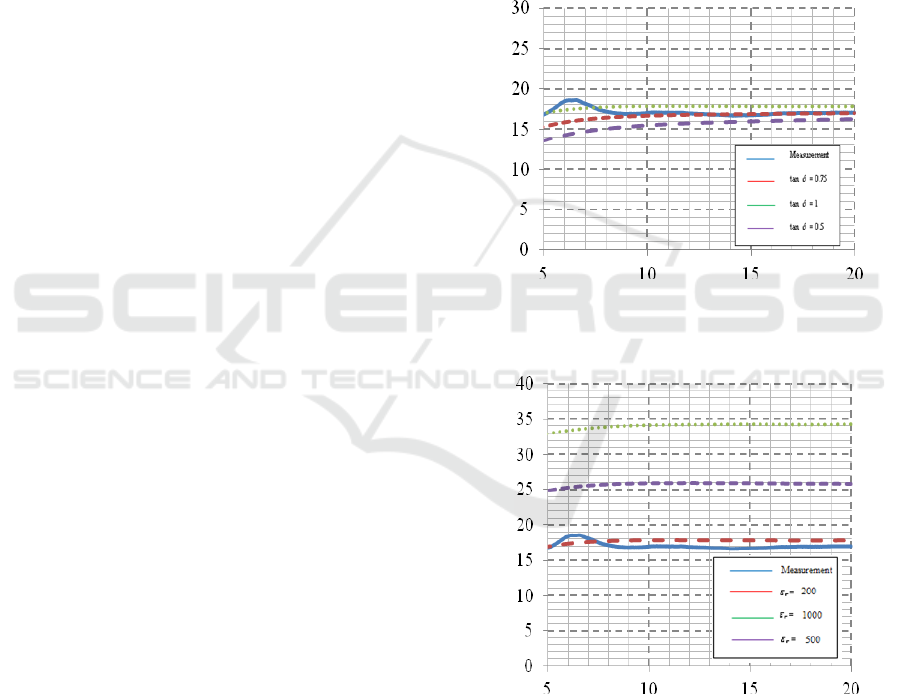

Figure 13 a) shows that as the loss tangent is

increased, the fit is better. This is expected from

theory since in a transmission line, the insertion loss

is mainly due to energy dissipation in the substrate

(in this case the ceramic film) – a material with high

loss tangent implies significant energy loss in the

material, and this leads to high insertion loss.

Ceramic materials in thin film form are known to be

quite lossy, and our results seem to concur with this.

In this example, a good fit between measurement

and simulation is obtained for ε

r

= 200 and tan

δ

= 1

as shown in Figures 13 a) and b) respectively.

Nevertheless our work has demonstrated that it is

possible to implement PNZT and PZT thin films for

use in MMIC.

4 CONCLUSIONS

PZT-based and PNZT-based thin film capacitors

have been fabricated and their performance

compared to investigate the effect of polarization at

high frequencies. The high frequency measurement

is divided into two frequency ranges; 40 MHz to

500

MHz and 500 MHz to 20 GHz. The results

reveal that Nb doping affect the relative permittivity

of the films, but the losses increased at high

frequencies. The relative permittivity values were

higher for PNZT films as expected due to doping.

The insertion loss characteristics of the films

were studied by implementing co-planar waveguide

transmission lines on PNZT. The films showed

acceptable performance and proved the feasibility of

using the films as a new substrate material for

microwave integrated circuits. Our future work will

include the use of these materials in the design of

passive MMIC devices such as filters and phase

shifters.

FREQUENCY (GHZ)

a)

FREQUENCY (GHZ)

b)

Figure 13: Comparison between simulated and measured

results of PNZT-based CPW transmission lines; with

adjusted a) tan

δ

and b) ε

r

.

INSERTION LOSS (DB)

I

NSERTION LOSS (DB)

Second International Conference on Telecommunications and Remote Sensing

102

ACKNOWLEDGEMENTS

The authors would like to thank Prof. Dr. Mohamad

Rusop and his team from the Nanotechnology

Research Group of University Technology MARA

for the assistance given in the fabrication. We are

also grateful to Dr. Sukreen Hana Herman for the

PZT thin film samples used in this work.

REFERENCES

Al-Omari A. N. and Lear K. L. 2005. Dielectric

Characteristics of Spin-Coated Dielectric Films using

On-wafer Parallel-Plate Capacitors at Microwave

Frequencies. IEEE Trans. on Electrical Insulation, 12,

1151-1161.

Bakar R. A. et. al. 2008. Optimized Fabrication Process of

PZT Thin Film Capacitor for MMIC Applications,

Proc. Int. Conf. on Nanosc. and Nanotech., Shah

Alam, Malaysia, Nov 18 – 21.

Chang L. H. and Anderson W. A. 1997. Single and

Multilayer Ferroelectric PZT on BaTiO

3

. Thin Solid

Films, 303, 94-100.

Chen L. F. et. al, 2004. Microwave Electronics:

Measurement and Material Characterization. New

York: John Wiley & Sons, Ltd., 382.

Chikuvula, V. et. al. 2000. Ferroelectric Dielectric for

Integrated Ciruit Applications at Microwave

Frequencies, US Patent 6146905.

Dimos D. and Mueller C. H., 1998. Perovskite Thin Films

for High-Frequency Capacitor Applications 1, Annual

Reviews in Materials Science, 28, 397-419.

Elissalde C. and Ravez J. 2001. Ferroelectric Ceramics:

Defects and Dielectric Relaxations”, J. of Mat. Chem.,

11, 1957-1967.

Haccart T. et. al, 2003. Substitution of Nb Doping on the

Structural, Microstructural and Electrical Properties

in PZT Films”, Thin Solid Films, 423, 235-242.

Jackson R. W. 1986. Considerations in the Use of

Coplanar Waveguide for Millimeter-Wave Integrated

Circuits, IEEE Trans. on Microwave Theory and Tech.,

34 (12), pp. 1450-

1456.

Kitzawa T. and Itoh T. 1991, Propagation Characteristics

of Coplanar Type Transmission Line with Lossy Media,

IEEE Trans. on Microwave Theory and Technique , 39

(10), 1694-1700.

Kuang, K. et. al. (eds). 2010. RF and Microwave

Microelectronics Packaging. Netherlands: Springer

Science + Business Media.

Mirshekar-Syahkal, D. 1983, An Accurate Determination

of Dielectric Loss Effect in Monolithic Microwave

Integrated Circuits Including Microstrip and Coupled

Microstrip Lines, IEEE Trans. on Microwave Theory

and Tech., 31(11), 950-953.

Park Y. et. al. 2002. Effect of Excess Pb on Fatigue

Properties of PZT Thin Films Prepared by Rf-

Magnetron Sputtering. Mat. Lett., 56, 481-285.

Pozar, D. M. 2005, Microwave Engineering, 3rd ed. New

York: John Wiley & Sons Inc.

Riaziat M. et. al,. 1990. Propagation Modes and

Dispersion Characteristics of Coplanar Waveguide,"

IEEE Trans. on Microwave Theory and Tech., 38 (3),

pp. 245-251.

Riemens D. et. al, 2003. Piezoelectric Properties of

Sputtered PZT Films: Influence of Structure,

Microstructure, Film Thickness (Zr,Ti) Ratio and Nb

Substitution, Materials Science in Semiconductor

Processing, 5, 123-127.

Setter N. et. al,. 2006. Ferroelectric Thin Films: Review of

Materials, Properties and Applications, J. App. Phys,

100, 510-606.

Souza, E. C. F. et.al. 2004. The Effect of Nb Doping on

Ferroelectric properties of PZT Thin Films Prepared

from Polymeric Precursors, Materials Chemistry and

Physics, 88, 155-159.

Sulaiman, S., Nadzar H. M. and Awang, Z. 2011,

Characterization of PZT and PNZT thin films for

monolithic microwave integrated circuit applications,

Proc. 2011 IEEE Region 10 Conf. (TENCON2011), pg.

1264 – 1268, Nov. 22 – 24, Bali, Indonesia.

Vilarinho, P. M. et al. (eds.). 2005. Scanning Probe

Microscopy: Characterization, Nanofabrication, and

Device Application of Functional Materials.

Netherlands: Kluwer Academic Publishers,

3-33.

Wen C. P. 1969. Coplanar Waveguide: A Surface Strip

Transmission Line Suitable for Non-reciprocal

Gyromagnetic Device Applications. IEEE Trans. on

Microwave Theory and Tech., 77 (12), pp. 1087-1090.

WinCal 3.2 User Guide. 2000, Cascade Microtech, Inc.

Zhi-Xiang et. al. 2008. Thickness and Nb-Doping Effects

on Ferro and Piezoelectric Properties Highly a-axis

Oriented Nb-doped Pb(Zr

0.3

Ti

0.7

)O

3

Films. J.of App.

Phys., 140, pp. 2003-2007, 2008.

Zhu C. et. al. 2006. The Effects of the PbO Content and

Seeding Layers upon the Microstructure and

Orientation of Sol-gel Derived PZT Films. J. Mat. Sc.:

Materials in Electronics, 17, 51-55.

PZT and Pnzt-Based Thin Film Capacitors and Transmission Lines for Microwave Integrated Circuit Applications

103