The ERP Systems in Modern Business and Corporate Management

Boris A. Staykov, Tatiana V. Atanasova, Vladimir V. Monov and Lyubka A. Doukovska

Institute of Information and Communication Technologies, Bulgarian Academy of Sciences,

Acad. G. Bonchev str., bl. 2, 1113 Sofia, Bulgaria

bstaykov@iinf.bas.bg, {atanasova, vmonov, doukovska}@iit.bas.bg

Keywords: Enterprise Resource Planning (ERP), Management, Integration, Business Processes.

Abstract: The purpose of this paper is to make an analysis and assessment of the increasing need of using

sophisticated software systems for managing business processes. In our days the most important thing is the

information and the success of every business depends on how fast and effective managers deal with

information. Business processes usually include manufacturing, sales order management, inventory and

warehouse control, logistics, advanced forecasting and planning, financial management, customer

relationship management and many others, all of them connected and depending on each other. It is

practically impossible to manage all those processes effective without using software that gives a

convenient, easy understandable and user friendly interface to the end user. End user of such system can be

anybody from top to the bottom level of the company hierarchy. It is commonly recognized that ERP

(Enterprise Resource Planning) systems are the software systems that provide the functionality to manage

all that information. A major issue for these systems is that these processes are very different and specific

for each business and company. Because of this there is impossible to create one universal ERP system that

is good enough for everyone. Instead of this, software companies produce core software which can be

expanded and tuned according to each specific company. This automatically includes a process of

integration that is a key part of the ERP system.

1 INTRODUCTION

Nowadays when we speak about business modelling

and software information systems, it naturally comes

to ERP systems as the most significant, large,

complex and sophisticated implementation of

information technologies into the contemporary

enterprises, business companies and corporations.

But what exactly is or isn’t an ERP software system?

First of all we can say that it isn’t software in the

traditional meaning that we all know – programme

that you can buy, install, run and start to use right

away. ERP is a large sophisticated software solution

that combines many parts (modules) that are used to

manage different business processes in certain

company or enterprise. The development of such a

system is long and difficult process that involves

many people – software engineers; programmers;

business consultants; even field workers from all

levels of the hierarchy of the client company that

will be using the ERP system. In fact there are no

two absolutely identical ERP systems. That is

because each ERP solution is designed and

developed for one exact client company, according

to their business models, processes, needs and

desires. That’s why they are very expensive (the

investment for ERP system can cost to the client

company as high as hundreds of thousands of US

dollars) and complex because they integrate many

functional and cross-functional business processes.

Typical ERP systems support Operations

(Production), Human Resources, Finance &

Accounting, Sales & Distribution, and Procurement

(Magal, 2012). As mentioned before – the

development of an ERP system is a long demanding

task, involving many specialists and unfortunately

there is no guarantee for success at the end.

Many ERP implementations have been classified

as failures because they did not achieve

predetermined corporate goals (Umble, 2003). The

process of implementation of one ERP system has

few major steps and can take between 6 months and

1 year of time! Those steps are:

- Analyzing the company business processes and

creating abstract models of each one of them and the

corresponding relationships between them.

281

Staykov B., V. Atanasova T., V. Monov V. and Doukovska L.

The ERP Systems in Modern Business and Corporate Management.

DOI: 10.5220/0004776502810285

In Proceedings of the Third International Symposium on Business Modeling and Software Design (BMSD 2013), pages 281-285

ISBN: 978-989-8565-56-3

Copyright

c

2013 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

- Designing database models that contain all the

necessary information for those models and

relationships.

- Designing the actual software. This includes user

interfaces, security management system, backup and

archiving systems and mechanisms etc.

- Integration of the system and training the end

users how to work with the software.

Each one of these steps involves constant dialogs

and communication between the ERP vendor, Client

Company, different consultants in certain areas,

software engineers and end users. Should any of

these steps fails, there is a very high probability that

the whole project will fail and lead to huge financial

losses for the vendors and the clients.

But when implemented and integrated correctly

and precisely, one ERP system gives to the company

very powerful tools for running their business in the

most effective way. That means sharp resource

planning and decision making using analytical

instruments; better fast and effective communication

and coordination between company departments and

external counteragents; efficient accounting and

warehouse management; minimizing loses and

abuses of any kinds.

2 EVOLUTION OF THE ERP

SYSTEMS

To understand how the contemporary complex ERP

systems started to exist, we will follow briefly the

natural software evolution during the past 50 years,

using an article on implementation procedures in

ERP systems, written in 2002 by Elisabeth Umble,

Ronald Haft, and Michael Umble.

During the 1960’s the use of software

technologies was mainly for inventory control.

Companies could afford to keep lots of ‘‘just-in-

case’’inventory on hand to satisfy customer demand

and still stay competitive. Consequently, techniques

of the day focused on the most efficient way to

manage large volumes of inventory (Umble, 2003).

Most of the software packages then were designed

and served the purpose for more efficient inventory

control and warehouse management (Ptak, 2000,

Shankarnarayanan, 2000).

In the 1970’s, it became increasingly clear that

companies could no longer afford the luxury of

maintaining large quantities of inventory. This led to

the introduction of material requirements planning

(MRP)systems. MRP represented a huge step

forward in the materials planning process. For the

first time, using a master production schedule,

supported by bill of material files that identified the

specific materials needed to produce each finished

item, a computer could be used to calculate gross

material requirements. Using accurate inventory

record files, the available quantity of on-hand or

scheduled-to-arrive materials could then be used to

determine net material requirements. This then

prompted an activity such as placing an order,

cancelling an existing order, or modifying the timing

of existing orders. For the first time in

manufacturing, there was a formal mechanism for

keeping priorities valid in a changing manufacturing

environment (Umble, 2003). Later the MRP systems

expanded to “closed loop MRP” (Oden, 1993), that

besides inventory planning included also tools for

planning the production levels, sales planning and

scheduling, making business promises to customers,

forecasting and different analysis tools.

In the 1980’s, companies began to take

advantage of the increased power and affordability

of available technology and were able to couple the

movement of inventory with the coincident financial

activity. Manufacturing resources planning (MRP II)

systems evolved to incorporate the financial

accounting system and the financial management

system along with the manufacturing and materials

management systems. This allowed companies to

have a more integrated business system that derived

the material and capacity requirements associated

with a desired operations plan, allowed input of

detailed activities, translated all this to a financial

statement, and suggested a course of action to

address those items that were not in balance with the

desired plan (Ptak, 2000).

By the early 1990s, continuing improvements in

technology allowed MRP II to be expanded to

incorporate all resource planning for the entire

enterprise. Areas such as product design,

information warehousing, materials planning,

capacity planning, communication systems,

humanresources, finance, and project management

could now be included in the plan. Hence, the term,

ERP was coined (Ghosh, 2012).

Since then the ERP systems are becoming larger,

more sophisticated and they are being integrated in

enterprises and companies of all sizes – large

business corporations, medium and small business

enterprises.

Third International Symposium on Business Modeling and Software Design

282

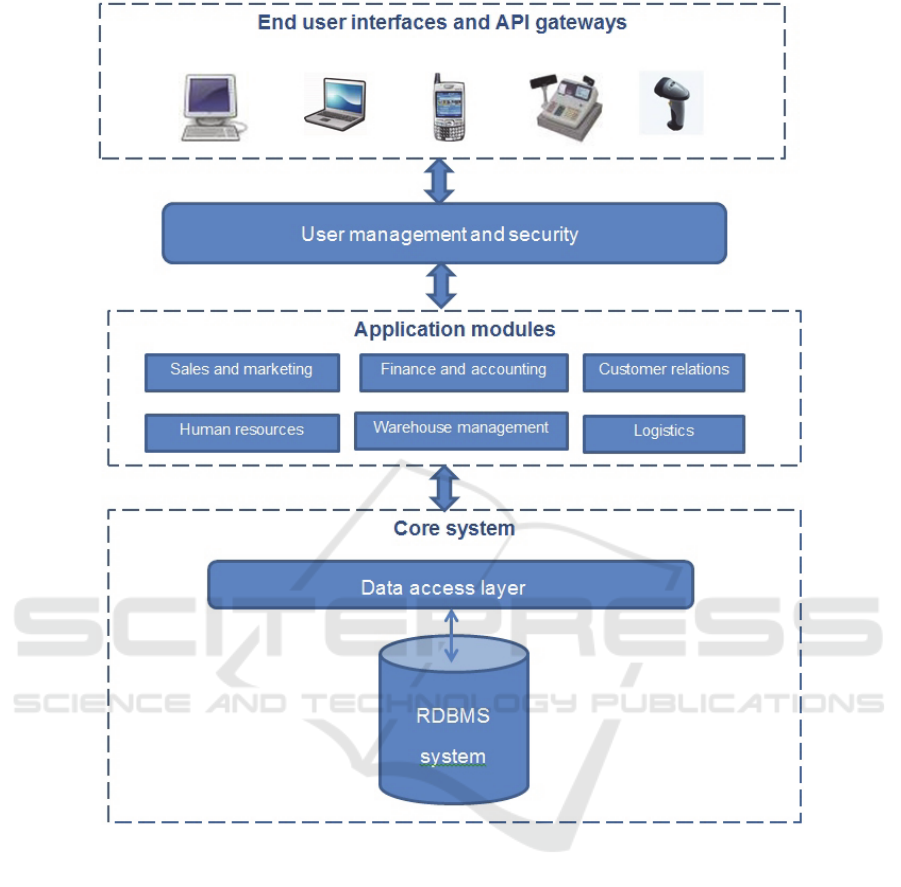

Figure 1: Common ERP system structure.

3 STRUCTURE OF THE ERP

SYSTEMS

All contemporary ERP systems are client-server

based applications and they allow interaction with

and operation from many types of computer devices

– desktop or mobile computers, industrial mobile

devices, POS (point of sale) devices and even cell

phones. Of course this is impossible without using

the Internet, VPN and LAN networks. Also because

of the big variety of devices and operating systems

that interact with the ERP systems, the most

convenient and maybe the only way of

implementing ergonomic, user friendly and

convenient user interface is to use web based

technologies.

The web interface is universal,platform

independent and the only thing that one device is

required to have in order to interact with the ERP

modules is the web browser.

Key feature of successful ERP systems are to be

flexible – in order to respond to the constantly

changing needs of an enterprise; to be modular – that

means that different functionalities must be logically

separated in the system, which allows them to be

detached, modified and attached back to the system

without affecting unintentionally any other

functionality or part of the whole system;

comprehensive – must support wide range of

The ERP Systems in Modern Business and Corporate Management

283

business processes within one or more organisations.

Beyond the company – it should support online

connectivity and information exchange with other

business-related companies (usually using web

service API interfaces).

As mentioned before – the ERP system is not

single software that can be produced once and

distributed as is to various companies, but is a

complex modular system that is being engineered

and developed according the company needs.

Therefore the ERP vendors are using their own ERP

development frameworks – software environment

that allows them fast and efficient implementation of

the software system. Most significant vendors of this

type of software are SAP, Oracle, Microsoft, SAGE

and Info Global (IBM) (Low, 2013).

The common structure of ERP systems is shown

on Figure 1. It consists of database management

system (RDMS) – where all the information is

stored and managed; data access layer; application

layer which consists of various modules that

represent different business processes and activities,

analytical tools and other instruments and tools; user

management and security layer; end user interfaces.

4 THE IMPORTANT ROLE OF

THE ERP SYSTEM FOR THE

BUSINESS

As regarded in this article, integrating well designed

and developed ERP system into enterprises and

companies has a crucial role to their successful

business. With today’s information variety and

amount, constantly increasing market needs and

demands, complex services, intra and inter-

companies processes and relationships, it’s

impossible to be successful without actively and

even aggressively using the power of the

contemporary information technologies. Each stage

of one’s enterprise activity must be precisely

planned, implemented, monitored and analyzed.

ERP systems combine everything in a way so that

managers can have wide view of the whole picture

in front of them, so they can make effective and in

time decisions. Efficient warehouse management is

important for materials ordering and production

planning. This is directly connected to customer

management, logistics, effective distribution and

service support. Efficient accounting and financial

planning depends on how fast and precise the

information about all those business processes is

maintained, presented and analyzed.

The most important benefits of using ERP

systems, based on Kay Roman detailed research

article (Roman, 2009) are as follows:

1. Enhanced Technology – the old legacy

software systems can’t meet the current technology

needs. ERP systems allow speeding up all

operations;

2. Efficiency in Processes – The new system will

eliminate labour-intensive manual processes and

current duplication of efforts; will streamline critical

business processes for many departments; will make

data collection better and more efficient;

3. Integrated and consistent information - A

major benefit of a new system will be replacing

multiple, disconnected databases with a single,

integrated system;

4. Easier Reporting - An advantage of a new

system will be improved and more customizable

reporting;

5. User Friendliness of the System - A new

system will provide easier access to information and

overall improvements in its use for the functional

staff;

6. Access to Data - Increased self-service for

data needs, real time data, Better access to

information and decision making;

7. Ability to Provide Better Customer Service -

Speedier and more applicant friendly service;

8. Increased Functionality - Better functionality

for users;

9. Better Communications- Promotes more

collaboration with business partners;

10. Increased Security of Data - Data restrictions

can be enhanced.

5 CONCLUSIONS

ERP systems have a key role for successful business

in modern enterprises and business companies. They

are natural evolution of the general software systems

and the use of constantly expanding nowadays

information technologies. ERP are the most complex

and sophisticated software systems, developed for

certain company according to its needs and specific

business processes. Therefore their integration is a

long difficult process, involving many specialists

and consultants. If not planned and designed

precisely and carefully, such a project can be easily

turned into a failure and huge financial loses. When

done correctly, once integrated this system brings

big benefits to the companies, allowing them better

planning, managing forecasting and expanding their

successful business.

Third International Symposium on Business Modeling and Software Design

284

ACKNOWLEDGEMENTS

The research work reported in the paper is partly

supported by the project AComIn “Advanced

Computing for Innovation”, grant 316087, funded

by the FP7 Capacity Programme (Research Potential

of Convergence Regions).

REFERENCES

Magal Simha R., Jeffrey Word, Integrated Business

Processes with ERP Systems, 2012.

Umble Elisabeth J., Ronald R. Haft, Michael M. Umble,

Enterprise resource planning: Implementation

procedures and critical success factors, European

Journal of Operational Research 146, 241–257, 2003.

Ghosh Rittik, A Comprehensive Study on ERP Failures

Stressing on Reluctance to Change as a Cause of

Failure, Journal of Marketing and Management, 3 (1),

123-134, 2012.

Ptak C., E. Schragenheim, ERP: Tools, Techniques, and

Applications for Integrating the Supply Chain, St.

Lucie Press, Boca Raton, FL, 2000.

Shankarnarayanan S., ERP systems – using IT to gain a

competitive advantage, 2000.

Oden H., G. Langenwalter, R. Lucier, Handbook of

Material and Capacity Requirements Planning,

McGraw-Hill, New York, 1993.

Low Terry, Top ERP systems in 2013.

http://www.dvalde.com/top-erp-systems-in-2013.html

Roman Kay, Benefits of Implementing an ERP, Collegiate

Project Services 2009.

http://www.collegiateproject.com

The ERP Systems in Modern Business and Corporate Management

285