Effect of Contralateral Condition during Bimanual Pinch Force

Control

Kazumi Critchley, Toshiyuki Kurihara and Tadao Isaka

Faculty of Sport and Health Science, Ritsumeikan University, Kusatsu, Shiga, Japan

Keywords: Bimanual, Pinch, Fine Motor Control.

Abstract: The purpose of this study is to investigate the effect of the interaction of different control of the opposite

side during bimanual finger pinch force output. Thirty two young adults (20.5±2.0y) participated in this

study. Participants were requested to control their pinch forces at 10%MVF with visual feedback.

Participants were asked to turn off their force output to zero (0%MVF) if visual feedback disappeared, and

maintain their force output at 10%MVF when it’s appeared. There are 4 different force producing types:

increase force output from 0 to 10%MVF (UP), decrease force output from 10 to 0%MVF (DOWN), keep

maintaining 10%MVF (KEEP) and waiting at 0%MVF force output level (WAIT). The error trial was

defined as when UP side of the hands’ force output exceeded 10.6%MVF. We calculated the error ratio as

the number of error trials per total numbers of trial. The number of error ratio was the fewest on UP&UP,

total 25/198 (Left: 17/96 Right: 8/96), followed by KEEP&UP total 52/192 (Left: 28/96, Right: 24/96) and

WAIT&UP total 64/191 (Left: 40/96, Right: 24/95). Most mistakable condition was DOWN&UP, total

81/192 (Left: 50/96, Right: 31/96). The overshoot error ratio in right hand was lower than that of left hand.

1 INTRODUCTION

In our daily life, we often use both hands at the same

time. During the bimanual movement, mirror-

symmetric movements are tending to produced

(Mechsner, 2001). In contrast, it is difficult to make

asymmetric movements and interference can occur

when two hands need to produce different forces or

directions (Harabst, 2000); (Hazeltine, 2003). It can

be said that control ability of one side limb is

affected by the other during bimanual movement.

The purpose of this study is to investigate the

effect of the interaction of different control of the

opposite side during bimanual movement. We

selected bimanual finger pinching as a task, because

finger pinching was often used for fine motor

control investigation.

2 METHODS

2.1 Participants

Thirty two young adults (20.5±2.0y) participated in

this study. All participants were right-handed,

evaluated by Edinburgh Handedness Inventory

(Oldfield, 1971). The participants gave informed

consent to the experimental procedures that had been

approved by the Local Ethics Committee.

2.2 Procedures

Before performing the experimental task, each

participant performed a series of finger-pinch

maximal voluntary force (MVF). During the MVF

measurement, participants were asked to press the

load cells with thumb and index finger as strong as

possible. The greatest value recorded in the two

MVF trials for a particular hand was considered as

the hand-specific MVF.

The experimental task was bimanual pinching

with thumb and index finger. Participants were

requested to control their pinch forces with visual

feedback of hand’s force production on the computer

monitor. Visual feedback was given each hand

separately. Target force was set at 10%MVF.

Participants were asked to turn off their force output

to zero (0%MVF) if visual feedback disappeared,

and maintain their force output at 10%MVF when

it’s appeared. We instructed them to switch the

control of their forces as quickly and accurately as

Critchley K., Kurihara T. and Isaka T..

Effect of Contralateral Condition during Bimanual Pinch Force Control.

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

possible. It consists of two switching points;

preliminary 5 s maintain both hands finger pinch

force output at 10%MVF, then disappearing or

appearing the feedback at 5 s (first switching point)

and remained till 10 s, then second switching point

at 10 s after the beginning of the measurement. The

task continues 15 s and participants didn’t know the

timing of switching point (Figure 1).

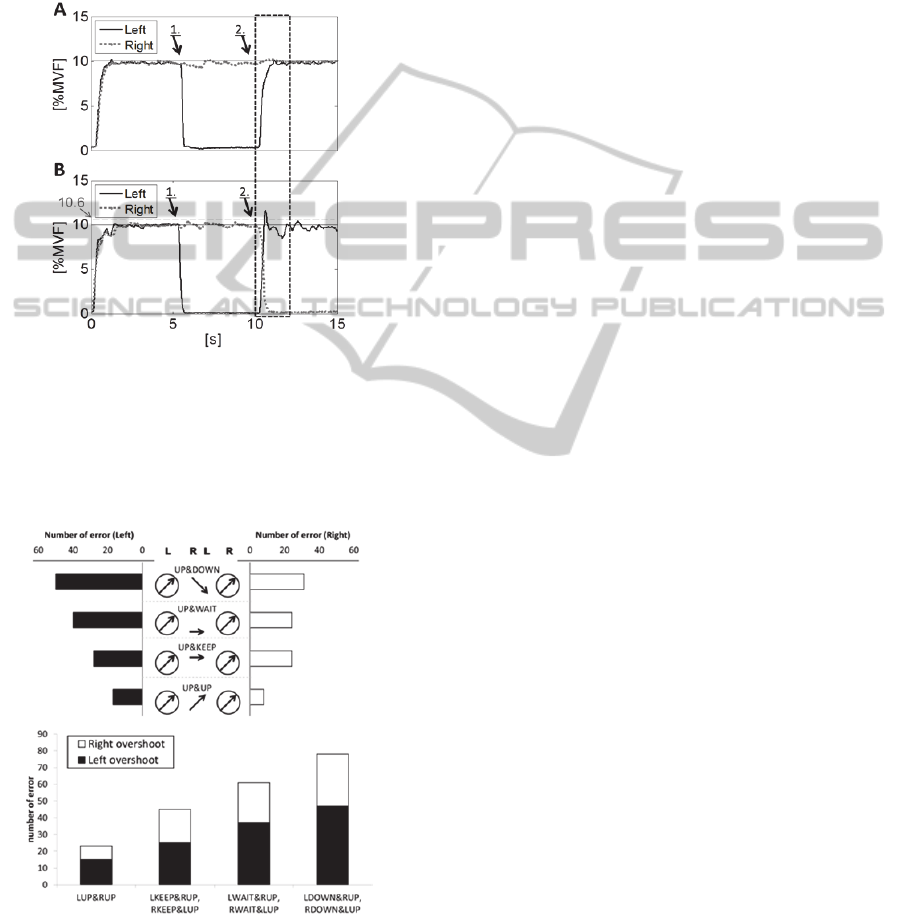

Figure 1: Representative force outputs for two conditions.

A: Force output of LUP&RKEEP condition. B: Force

output of LUP&RDOWN condition. 1 indicates first

switching point (after 5seconds) and 2 indicates second

switching point (after 10seconds). Rectangle with broken

line indicates analyzing area. Left hand force output

exceeded 10.6%MVF on B, became overshoot error trial.

Figure 2: Number of overshoot error. Graph above shows

a number of left and right overshoot error separately.

Arrows inside the circle denote UP side while arrows in

the middle of them indicate the opposite sides required

force production (UP, DOWN, KEEP and WAIT). Graph

below shows the total number of overshoot error.

2.3 Data Analysis

We focused on second switching point (Figure 1).

There are 4 different force producing types: increase

force output from 0 to 10%MVF (UP), decrease

force output from 10 to 0%MVF (DOWN), keep

maintaining 10%MVF (KEEP) and waiting at

0%MVF force output level (WAIT). Combination of

them with both hands, there are 7 different

conditions: LUP&RUP, LUP&RDOWN,

RUP&LDOWN, LUP&RKEEP, RUP&LKEEP,

LUP&RWAIT and RUP&LWAIT. Participants

engaged three trials on each condition, arranged in

random order. The error trial was defined as when

UP side of the hands’ force output exceeded

10.6%MVF before 2 s from second switching point.

We calculated the error ratio as the number of error

trials per total numbers of trial.

3 RESULTS

Error ratio of each condition was shown in Figure2.

The number of error ratio was the fewest on

UP&UP, total 25/198 (Left: 17/96 Right: 8/96),

followed by KEEP&UP total 52/192 (Left: 28/96,

Right: 24/96) and WAIT&UP total 64/191 (Left:

40/96, Right: 24/95). Most mistakable condition was

DOWN&UP, total 81/192 (Left: 50/96, Right:

31/96). A chi-square test of independence was

performed to examine the relationship between

experimental tasks and overshoot error ratio. The

relation between these variables was

significant,Χ

3, 767

42.3, 0.05.

4 DISCUSSION

When controlling one side of limb’s force output to

certain target, overshoot error is influenced by the

other side’s force producing type. It is easy to

control target force output when both hand’s task are

same force producing type. In contrast, it becomes

difficult to control force output when anti-phase task

is required on the other side. This may because the

attention to the difficulty and complexity of the

other side’s limb movement and/or task disturbs the

control of the force output.

The overshoot error ratio in right hand was lower

than that of left hand. Certainly, the participants

were all right-handed. Dominant limb is specialized

for dynamic, feed-forward controlled unimanual

tasks (Sainburg, 2002). There was relatively lower

difference, however, between right and left error

ration in UP&KEEP condition. In this condition,

10%MVF kept in one side seems to work as the

reference point for the other side that raising force

output from zero to 10%MVF. This reference was

same on right and left hand and maybe made easy to

increase force with feed-forward control.

The tasks used in this study were including with

the cognitive reaction task since the participants

were required to react as quickly and accurately as

possible. In order to clarify the bimanual fine motor

control, further studies are needed to expel the

anticipation of required force output.

REFERENCES

Franz, E. A. (1997). Spatial coupling in the coordination

of complex actions. Q J Exp Psychol A, 50(3), 684-

704. doi: 10.1080/713755726.

Harabst, K. B., Lazarus, J. A., & Whitall, J. (2000).

Accuracy of dynamic isometric force production: the

influence of age and bimanual activation patters.

Motor Control, 4(2), 232-256.

Mechsner, F., Kerzel, D., Knobiich, G., & Prinz, W.

(2001). Perceptual basis of bimanual coordination.

Nature, 414, 69-73.

Oldfield, R. C. (1971). The assessment and analysis of

handedness: the Edinburgh inventory. Neuropsychol, 9,

97-113.

Sainburg, R. L. (2002). Evidence for a dynamic-

dominance hypothesis of handedness. Exp Brain Res,

142(2), 241-258. doi: 10.1007/s00221-001-0913-8.