Numerical Simulation of Odorous Dispersion Hydraulics

and Aeration Device in WWTP’s

Hatem Dhaouadi

1

and Hatem Mhiri

2

1

Science Faculty, Monastir University, Bvd de l’Environnement, Monastir, Tunisia

2

National Engineering School, Monastir University, Ibn El Jazzar Street, 5000 Monastir, Tunisia

Keywords: CFD, Odour Dispersion, Airlift Hydraulics, Aeration.

Abstract: Most of the WWTP use biological processes which are intrinsically dynamic because of the large variations

in the wastewater flow rate, pollutants concentration and composition. These variations are to a large degree

not possible to control and the use of simulator may be helpful. CFD, one of the most used numerical tool, is

employed in this study to prospect three particular technical aspects of WWTP, namely odors dispersion,

hydraulics of a high rate airlift algal pond and mass transfer performances of surface aerators. Fluent

®

software is used and the validation of the developed models is made using a real scale WWTP data. This

experimental validation is supported by the monitoring of the main odour pollution parameter (gaseous H

2

S

concentration) through different zones around El-Frina WWTP. CFD models are also used to examine the

behavior of gas and liquid phase dynamic throughout the high rate airlift algal pond and results are

compared to those obtained with measurements made at Sidi Bouali WWTP. Concerning the aeration

system capacity, gas liquid mass transfer study of surface aerators has been conducted on a lab scale

Rushton blades.

1 INTRODUCTION

Computational Fluid Dynamics (CFD) is more and

more used in the environmental system analysis. We

will present here three different applications of CFD

utilisation in the field of wastewater treatment plant

(wwtp) management.

The first case, the atmospheric dispersion of

odours issued from an urban biological wwtp. The

second study deals with the surface aerator from gas

liquid mass transfer point of view and finally, the

CFD contribution to the hydrodynamic study of a

real scale high rate airlift algal pond. In the three

cases, a powerful software is used, Fluent

®

.

Concerning the first case, the study of wwtp

odours atmospheric dispersion and on the basis of

olfactometric measurements, the sludge drying beds

are identified to be the principal emission source of

hydrogen sulphide, the main odorous component

(Maïzi et al., 2010). This study has been applied to

El Frina WWTP (Monastir, Tunisia).

Concerning the second case related to the study

of surface aerators from the gas liquid mass transfer

point of view, a lab scale Rhuston turbine blades are

used to validate the developed model before going

on with a real scale aerator. The only measured

parameter is the dissolved oxygen concentration.

The variables are the blades immersion rate and the

turbine radial speed. Experiences are made with

different liquid viscosities and surface tension.

Several immersion rates and blades speed has been

investigated and the dissolved oxygen is measured

using the gassing off method with nitrogen. An exact

analytical solution is used to evaluate the K

l

a

coefficient. The volumetric mass transfer coefficient

is then correlated to the gas holdup in the reactor for

aeration capacity calculations, which allows the

model validation (Achouri et al., 2013). Finally and

concerning the last case, a real scale (Sidi Bouali,

Tunisia) high rate airlift algal pond is studied from

the hydrodynamic point of view. The novelty in Sidi

Bouali WWTP is that the used device for fluid

motion in the algal pond is an airlift. Hydraulic

control in such system is primordial because it

directly affects the algae to bacteria growth rate.

Here, the velocity contour curves allow the

diagnostic of stagnant zones especially at the pond

extremity and the phase holdup contours shows

clearly how efficient is the airlift porous aerators and

their influence towards the global liquid velocity

fixing the algal / bacterial mass growth rate.

377

Dhaouadi H. and Mhiri H..

Numerical Simulation of Odorous Dispersion Hydraulics and Aeration Device in WWTP’s.

DOI: 10.5220/0004508003770381

In Proceedings of the 3rd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2013),

pages 377-381

ISBN: 978-989-8565-69-3

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

2 MATERIAL AND METHODS

In what follows will be detailed the mathematical

modelling and the numerical resolution using a

commercial software, FLUENT

®

for the odours

atmospheric dispersion only. The same methodology

is adopted for the two other case of study, namely

the gas liquid mass transfer in the case of the surface

aerators and the hydrodynamic study of an airlift

algal pond used for a real scale municipal

wastewater treatment plant.

2.1 Mathematical Modelling

Atmospheric dispersion consists of two processes:

transport and diffusion. Equations governing this

problem are obtained using the Favre decomposition

and are given in the following table.

The introduction of fluctuating terms makes this

equation system open. Its closure requires the use of

a turbulence model that allows getting an equal

equation’s number to the unknown number. For this

survey, a first order closing model was adopted.

With the use of the latter, transport equations for the

turbulent kinetic energy (k) and its dissipation rate

(), are given in the table below, where R is the

dissipation rate production term, C

1

, C

2

, C

3

are

empiric coefficients having the values of 1.42, 1.68

and 1, respectively (Fluent User Guide, 2006).

Mass balance

0

j

j

u

x

Momentum

balance

()

ji

ij

ij

jij

uu

p

uu

xxx

Concentration

balance

'' ''

()

m

m

j

m

j

jjj

uC

C

DuC

xxx

Energy balance

Pr

j

T

x x

j

pt

jjt

uT

C

x

(k)

Pr

t

i

ijkj

k

ku P G

xx x

()

132

²

Pr

t

i

ij j

uCPCGCR

xx xk k

(k): Turbulent kinetic energy balance

(): Dissipation rate balance

In the present work, all simulations are carried

out using a finite volume method FLUENT to model

3D steady turbulent atmospheric dispersion of

odorous compounds. In the present finite volume

method, the solution domain is subdivided into a

finite number of continuous control volumes.

2.2 Numerical Solver

The FLUENT software offers several CFD models:

the Reynolds Average Navier–Stokes (RANS)

models which include the standard renormalisation

group (RNG) and real (RSM) model. After testing

each of these, respectively, the RNG k– model was

selected because odour emission velocity at the

source outlet is feeble, besides RNG k– model

generated the least cells number, compared to other

models. Its calculating time per iteration was

obviously small compared to the calculating time per

iteration of the RSM model.

The RNG k– model is based on two transport

equations for the turbulent kinetic energy k and its

dissipation rate which uses a cross-diffusion term

in the equation to ensure the appropriate equations

model behaviour in both the near-wall and far-field

zones (Fluent user guide, 2006).

The FLUENT 6.2 steady three-dimensional

segregated solver was used to solve the RNG k–

model using the implicit scheme. The upwind

second and first orders of discretisation schemes

were used to convert the governing equations into

algebraic equations for their numerical solution. The

Standard scheme was used to solve for pressure

while the upwind first and second orders were used

to solve for odorous compounds dispersion,

momentum, turbulent dissipation rate, turbulent

kinetic energy and energy. The SIMPLE method

was used to calculate for pressure-velocity coupling.

Several wind speeds were used to study the

influence of aerodynamic aspects on odorous

compounds dispersion in the vicinity of the WWTP

of Monastir and to estimate the distribution of the

contaminants concentrations released by that source

in the atmosphere, and consequently characterizing

the propagation of their odours in the neighbouring

buildings.

2.3 Meshing

Previous runs proved that the contribution of drying

beds is by far great compared to the odours intensity

released by the other devices in the WWTP of

Monastir, and this is due to their important size. In

fact the pollutant plume emitted by the drying beds

was by far great compared to the plume emitted by

the other devices. Therefore, the study was limited

to odorous compounds emitted by the drying beds,

in order to reduce the calculation time and the

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

378

number of cells. Drying beds have a rectangular

shape, their whole length is 200 m and their whole

width is 86 m. Buildings were designed as a brick

shape located at a distance L

1

downwind of 550 m

from the source. The “GAMBIT” software was used

to create the computational volume, since it allows

meshing domains into two or three dimensions with

different geometric shapes. The flow topology

requires a very fine meshing in a big part of the

domain. In order to follow with precision every mass

and aerodynamic fields variation, particularly in

regions where gradients are important, a non

uniform meshing, greatly contracted in the drying

beds and buildings vicinity, which allows to display

the recirculation and the vortices created, was

adopted. Meshes are made extremely contracted in

the neighbouring of the drying beds and around

buildings.

2.4 Boundary Conditions

The boundary of the computed domain included

the clean air and odour inlet, the fluid outlet, the

walls of the computational volume and the

buildings. The bottom and the upper surfaces of

the computational domain were modelled as wall

surfaces. The vertical profile of the horizontal

wind velocity and the temperature were inputs, as

well as the turbulence kinetic energy k and its

dissipation rate .

In this paper, the assumptions taken to solve

odorous compounds dispersion are:

- The flow is considered three-dimensional,

turbulent and stationary,

- The wind speed is considered constant and its

direction is parallel to the passage centre line,

- Continuous pollutants emission with constant

concentration,

Temperature gradients are negligible.

Furthermore, the evolution of the ammonia

plume was the same as the H

2

S plume, so that the

study was limited to follow the distribution of H

2

S

concentration.

3 RESULTS

3.1 Odours Dispersion

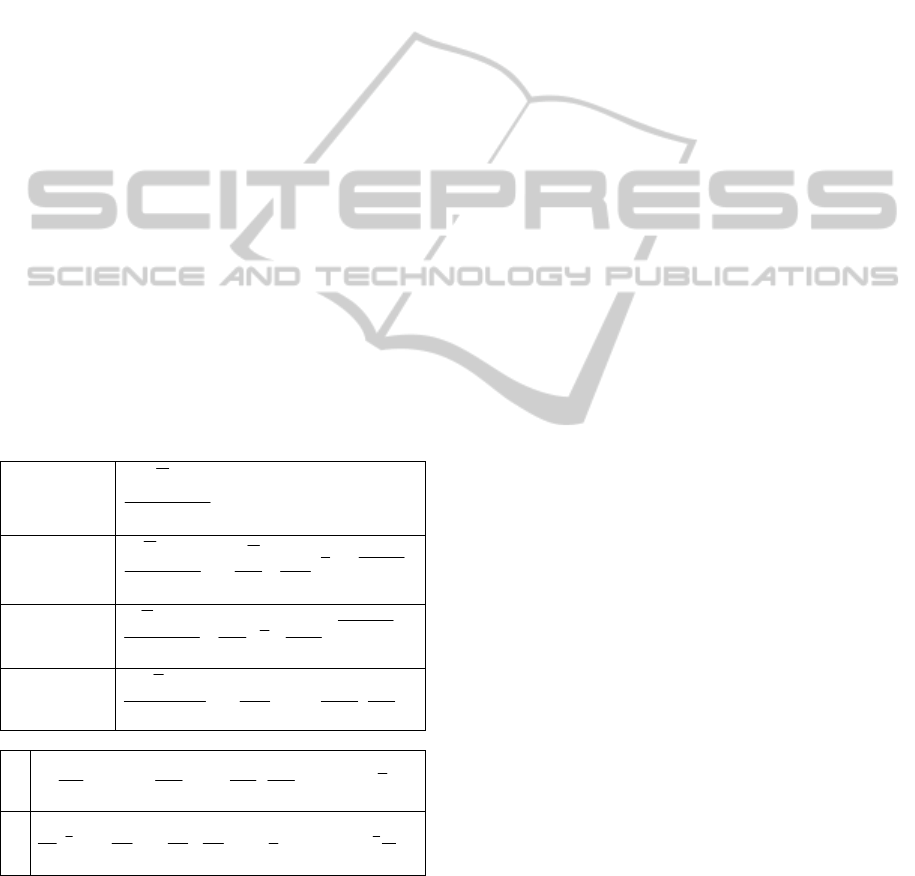

When a pollutant passes beyond buildings, several

turbulence scales can be identified. Near the

release source, there are diffusion scales that

cause the pollutant dispersion. In the case of

numeric simulations of odorous compounds

dispersion around buildings, this phenomenon is

rarely reported in other papers. The different

parametric studies achieved in the current work

are made in the case of brick buildings as shown

in Fig. 1.

Figure 1: Iso-concentration of hydrogen sulphide on

buildings roofs.

The survey of pollutant mass dispersion

requires a good understanding of the flow

behaviour around an obstacle.

Figure 2: Distribution of longitudinal velocity around

buildings.

The extent of the recirculation zone (Fig. 2),

the boundary layer separation, the reattachment

and the nature of vortices that are separated from

the obstacle, will interact with the pollutant and

thus influence its dispersion since the buildings

have sharp edges, which amplify instability. With

the developed model, many scenarios can be

studied varying the odorant components, wind

speed and building shapes.

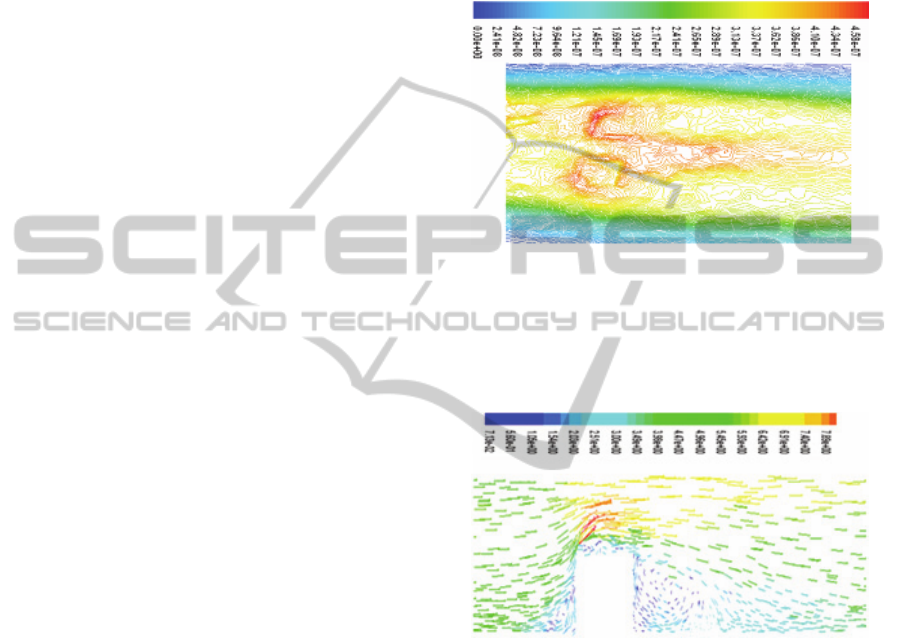

3.2 Surface Aerators Mass Transfer

Gas liquid mass transfer study of surface aerators

has been first conducted on a lab scale Rushton

blades. Several immersion rates (Fig. 3) and blades

NumericalSimulationofOdorousDispersionHydraulicsandAerationDeviceinWWTP's

379

speed (Fig. 4) has been investigated. The dissolved

oxygen (DO) variation is measured using the gassing

off method with nitrogen. An exact analytical

solution is used to evaluate the K

l

a coefficient by

fitting the experimental DO results.

Figure 3: Paddle immersion effect on gas liquid transfer.

The volumetric mass transfer coefficient is then

correlated to the gas holdup, a CFD result, which

allows the model validation. The K

l

a value is

proportional to the aeration capacity, which is the

most crucial energetic parameter in WWTP (50 to

70% of energetic expenses in activated sludge

WWTP are for aeration needs).

Figure 4: Paddle velocity effect on gas liquid transfer.

The determination of the best blade geometry

profile, allowing minimum energy consumption,

with the same aeration capacity (Achouri et al.,

2012), is the main target of this investigation

3.3 Airlift Algal Pond Hydrodynamics

The hydraulic study of the high rate airlift algal pond

is essentially based on the study of the bubble pump

(airlift). The developed model for the real scale

pond, 150*4*0.5m, showed reliable results and

allows the evaluation of all hydraulic parameters, i.e.

the gas holdup (Fig. 5a) and liquid velocity all over

the algal pond.

In the computing domain, meshes are made

extremely contracted in the bubble pump, which

is t

he most interesting study zone. Within this area

the liquid gets the needed energy, resulting from the

injected air isothermal expansion, allowing its

motion across the entire channel.

The current design of algae ponds lacks visual

assessment of hydrodynamic characteristics,

resulting in the appearance of dead zones where the

flow is stagnant and in the presence of non-uniform

velocity throughout the pond (Fig. 5b). Dead zones,

because of their negative impact on algae growth,

have to be avoided (Hadiyanto et al., 2013).

Figure 5: Gas holdup (a) and liquid velocity (b) profile in

the high rate airlift algal pond.

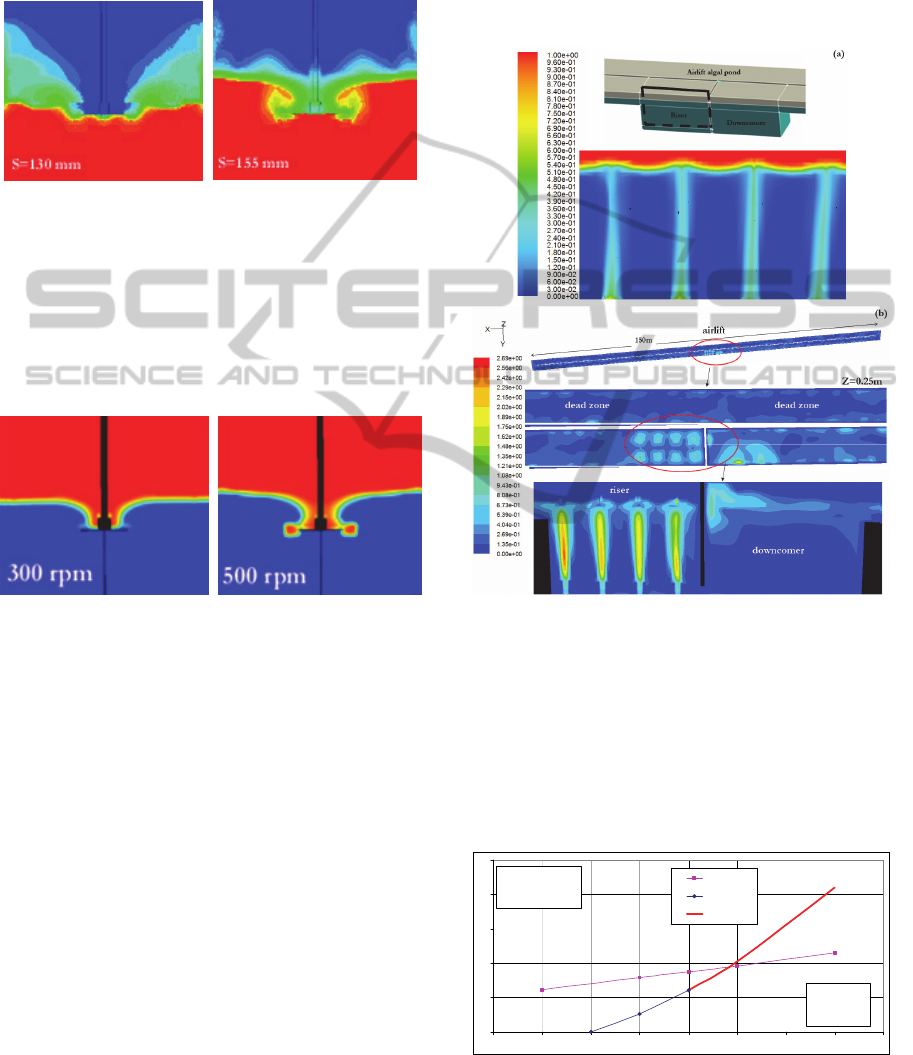

In the figure 6 below are compared the liquid

mean velocity in the channel to the measured liquid

velocity at the surface.

Experimentally, the former is very hard to get

and the latter is far from the real mean velocity

which is the most important parameter in fixing the

growth rate between algal and bacterial species.

air flow rate

(Nm

3

h

-1

)

5

10

15

20

25

30

0 5 10 15 20 25 30 35 40

mean water

velocity (cm s

-1

)

CFD

Exper.

Extrap.

Figure 6: CFD and experimental mean water velocity in

the airlift algal pond.

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

380

Tracer technique is used to get the experimental

measurement of surface liquid velocity while the

CFD result is a mean of more than 300,000 value of

local velocity all over the algal pond.

4 CONCLUSIONS

The CFD contribution to the WWTP management

is well appreciated when the developed models

are validated and compared with experimental

investigations. In our case the model elaboration

is the limiting step in the simulation process while

the experimental validation generally comes to

comfort the obtained results. We do not think that

CFD can contribute to the automation of the

studied process but it can make it clearer and

many scenario can be tested without being obliged

at each step to make experiments. CFD results can

be notably improved in gas liquid system studies

(airlift bubble pump, surface aerators, etc...) by

introducing the population balance module in

local properties calculations and this is one of our

main concerns for the moment. Further CFD

investigations related to the optimisation of

anaerobic digesters mixing are now conducted.

The power consumption and the reduction of

WWTP energetic expenses being our main target.

ACKNOWLEDGEMENTS

The authors would like to thank all the contributors

to this work: Amira Maïzi, Ryma Achouri and Rym

Ben Moussa.

REFERENCES

Achouri, R., Ben Hamza, S., Dhaouadi, H., Mhiri, H.,

Bournot, P., 2013. Volumetric mass transfer

coefficient and hydrodynamic study of a new self-

inducing turbine. Energy Conversion and

Management 71, 69–75.

Achouri, R., Mokni, I., Mhiri, H., Bournot, P., 2012. A 3D

CFD simulation of a self inducing Pitched Blade

Turbine Downflow. Energy Conversion and

Management 64, 633–641.

Fluent User Guide, septembre 2006, Fluent Inc., Lebanon

NH03766.

Maïzi, A., Dhaouadi, H., Bournot, P. Mhiri, H., 2010.

CFD prediction of odorous compound dispersion:

Case study examining a full scale waste water

treatment plant. Biosystems Engineering 106, 68 – 78.

Hadiyanto, H., Elmore, S., Van Gerven, T., Stankiewicz,

A., 2013. Hydrodynamic evaluations in high rate algae

pond (HRAP) design. Chemical Engineering Journal

217, 231–239.

NOTATION

C concentration (kg m

-3

)

Cp calorific capacity (J kg

-1

K

-1

)

D mass diffusivity (m

2

s

-1

)

G

buoyancy production term

K Stevens equation constant

k turbulence kinetic energy (m

2

s

-2

)

P turbulence kinetic energy production

term due to mean velocity gradients

R velocities quotient (v

0

/u

∞

)

T temperature (K)

u, v, w velocity component on x, y and z (m.s

-1

)

"

j

"

i

uu

Reynolds tension

x, y, z longitudinal, vertical and lateral

components (m)

Greek symbols

energy dissipation rate (m

2

s

-3

)

thermal conductivity (w m

-1

K

-1

)

viscosity (m

2

.s

-1

)

Index

Favre mean

─ mean

ambient area

0 at the source outlet

k turbulent kinetic energy

m mixture species

t turbulent

th threshold

ε turbulent dissipation rate

NumericalSimulationofOdorousDispersionHydraulicsandAerationDeviceinWWTP's

381