Model-based Inspection for the Control of Quality in Advanced

Manufacturing Environments

Shaniel Davrajh and Glen Bright

University of KwaZulu-Natal, Durban, South Africa

Keywords: Quality Control, Model-based Inspection.

Abstract: Manufacturing processes for markets that involve high levels of customization are inherently exposed to

unpredictable and often inconsistent demands. The use of statistical methods for controlling quality in these

environments is not suitable. The implementation of 100% inspection would guarantee high levels of quality

but involves high inspection costs, whereas 0% inspection is associated with high throughputs without being

able to guarantee the outgoing quality of products. This research used the Expected Value Formula to

provide a model that determined whether an inspection station should be activated or not. The model-

decision depended on specified parameters such as the internal, external and appraisal costs as well as the

significance of the inspected feature. The overall profits and Cost of Quality metric were used to analyse the

system performance and compare the model-based inspection criteria to the 100% and 0% inspection

strategies, using simulations performed in Labview. The model-based inspection showed an overall increase

in profits gained for both low and high customer significance ratings with a minimisation of the Cost of

Quality, and was therefore considered to be more suitable to manufacturing environments which

experienced frequent reconfigurations due to changes in customer requirements.

1 INTRODUCTION

Product markets are becoming highly unpredictable,

specialised and more difficult for manufacturers to

satisfy (Nambiar, 2009). The unpredictable nature of

changes in customer requirements necessitates a

response in product and process design that is able to

encapsulate these changes. At the forefront of the

competitive advantages that a manufacturer must

strive to achieve, is the ability to satisfy a customer

(Pollard et al., 2008). Manufacturers must then focus

on issues pertaining to quality. According to

Goetsch and Davis (2010), quality should not be

considered as a fixed metric, but instead should

timeously change according to customer

requirements. Advanced manufacturing

environments which implement high levels of

customer design must consider the effect of quality

repercussions on overall profit in a highly

competitive market. Current systems are unable to

match the future quality demands that will be placed

on manufacturers.

The manufacturing strategies of Reconfigurable

Manufacturing Systems (Koren et al., 1999) and

Mass Customisation (Da Silviera et al., 2001)

converge onto the common goal of providing high

levels of customisation through production of a

variety of parts within a defined family. These parts

are intended to be configured within boundaries

specified by the manufacturer and use

reconfigurable equipment to accommodate changes

in customer requirements. Research into the

implementation of reconfigurable inspection

equipment is still on-going and rare mention of the

implementation of this inspection equipment has

been made. The strategy of performing 100%

inspection using processes with high reliabilities is

certain to ensure that high levels of quality are

delivered to the customer. The disadvantage of this

inspection strategy is that it negatively impacts on

the profits associated with the manufacture of a

product by increasing manufacturing times and

costs. 0% inspection leads to the admittance of

defective products throughout the line and will lead

to an increase in unsatisfied customers as well as

loss in profits due to compensatory costs.

The research presented in this paper addresses a

solution to the implementation of reconfigurable

inspection equipment, and forms part of a holistic

solution to the management of quality within an

550

Davrajh S. and Bright G..

Model-based Inspection for the Control of Quality in Advanced Manufacturing Environments.

DOI: 10.5220/0004482705500557

In Proceedings of the 10th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2013), pages 550-557

ISBN: 978-989-8565-71-6

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

Advanced Manufacturing Environment. The

consideration of a product as a set of features

allowed for a user to specify the features that were

of most interest to them. The layout of the inspection

equipment was based on the classification of

significant features. A model that incorporated the

customer-rated significant features as well as

process non-conformance rates was then developed

using the Expected Value Formula (statlect, 2013).

This model was used to determine when to perform

inspection at a given inspection station. The

sanctioning of customers to choose the features of a

product that were personally significant allowed for

the maintaining of the dynamism in the quality

delivered to the customer. Labview

(www.ni.com/labview) was used to simulate the

model and quantify and compare the overall profits

and Cost of Quality (CoQ) metric (ASQ, 2013) of

the model-based inspection, 100% inspection and

0% inspection strategies. The results indicated that

the model-based inspection strategy was better

suited to environments in which the significance of

product features varied than the other two inspection

strategies.

2 QUALITY COSTS

It is imperative to maintain high levels of product

quality within a manufacturing environment;

however the process of quality control does not

necessarily change a product and hence does not

directly increase the value of the profit gained.

Quality management is considered to have the dual

objectives of maximizing the quality of conformance

and minimizing the associated costs. The CoQ

approach renders a single metric in reconciling these

two conflicting objectives and therefore allows for a

single metric to be optimized whilst accommodating

a wide range of individual customer needs.

According to Zaklouta (2011), no single definition

of CoQ and its constituent elements exists. Juran

(1951) considered CoQ as all the costs that would

disappear if every process in the lifecycle of a

product had a non-conformance rate of zero. Crosby

(1979) introduced the division of quality costs into

conformance and non-conformance costs. The

Prevention-Appraisal-Failure (PAF) model was the

most commonly accepted CoQ model since its

adoption, as discussed by Zaklouta (2011).

Prevention costs refer to the costs involved with the

reduction in frequency of non-conforming products.

Such costs include supplier audits, process

adjustment, calibration and maintenance, and can be

held constant in a defined manufacturing

environment according to (Zaklouta, 2011).

Appraisal costs are the costs associated with the

detection of the non-conformance of a product.

Inspection and testing are the two types of appraisal

costs. Failure costs are divided into the costs

associated with internal failures and external failures

respectively. Scrapping and reworking fall under

internal failures whilst complaint adjustment and

product recalls are external failure costs. The basic

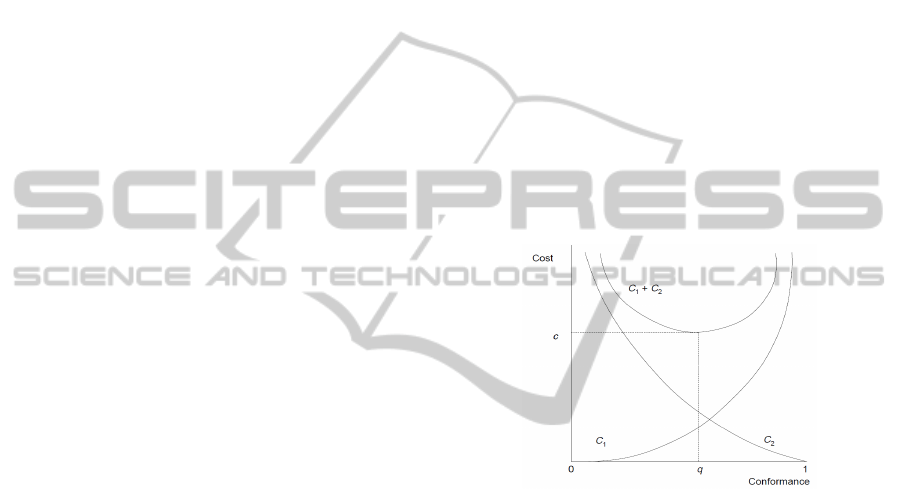

Lundvall-Juran curve, shown in Figure 1 was

represented by Foster (1996) and depicted the

Economic Quality Level (EQL). This level is

depicted by the point at which the cost of quality is a

minimum and hence provides a numerical goal that

should be achieved for a given system. The graph

indicates that the Appraisal and prevention costs

(C1) increase, whilst failure costs (C2) decrease, as

quality levels increase. The total quality costs are

determined by the summation of C1 and C2.

Figure 1: Lundvall-Juran curve (Foster, 1996).

The EQL approach was criticised by Crosby (1979)

as it implied the acceptance of defective parts

reaching the customer. This research was based on

satisfying the quality requirements of customers as

well as minimizing the costs associated with

inspection. The possibility of defective products

reaching customers through non-inspection was

considered acceptable, if and only if it was

financially feasible.

3 DEVELOPMENT

OF THE INSPECTION MODEL

A product family, as described in (Tseng and Du,

1998), was considered to be a set of components

wherein each component contributed both

individually and holistically to the functionality of a

product. This research considered a product as a set

of features which were governed by the selection of

Model-basedInspectionfortheControlofQualityinAdvancedManufacturingEnvironments

551

components from the product family. The

configuration of a product entailed the customer

selecting the modules of choice and then specifying

the values of the features associated with the

selected modules within the specified boundaries.

The customer was required to enter the significance

of the selected modules through specification of a

product rating and Significance Factor (SF), which

were used to determine the external costs associated

with failure of the product or component. The

product rating was defined as the rating that

described the consequences of failure of the product

whilst in use and would be determined by the

manufacturer. An assembly line with parallel lines

feeding into the assembly stations was considered

for the manufacturing of a completed product

configuration. The parallel lines represented the

feeding in of outsourced modules or performing in-

house fabrication of the relevant modules. The

locating of inspection stations throughout the

manufacturing lifecycle of a product has been

described in (Davrajh and Bright, 2012).

There were two options following a

manufacturing process namely inspection and non-

inspection from which the following possibilities

arose:

Inspect a good part

Don’t inspect a good part

Inspect a defective part

Don’t inspect a defective part

The selling price (Sell) of the product was assumed

to be determined through market related research.

The external failure cost was determined using

equation (1)

Sell

SF

SF

ratingoductC

ext

**_Pr

(1)

The cost of manufacture (C

m

) was considered as the

sum of all the manufacturing costs associated with

the product. C

i

was defined as the inspection costs

associated. The stochastic nature of manufacturing

systems forced the introduction of probabilities with

respect to the reliability of the manufacturing and

inspection processes. The probability of a

conforming product feature after going through a

process was modelled as the product of the

reliabilities of the current process and the processes

before it. The conformance rate of the inspection

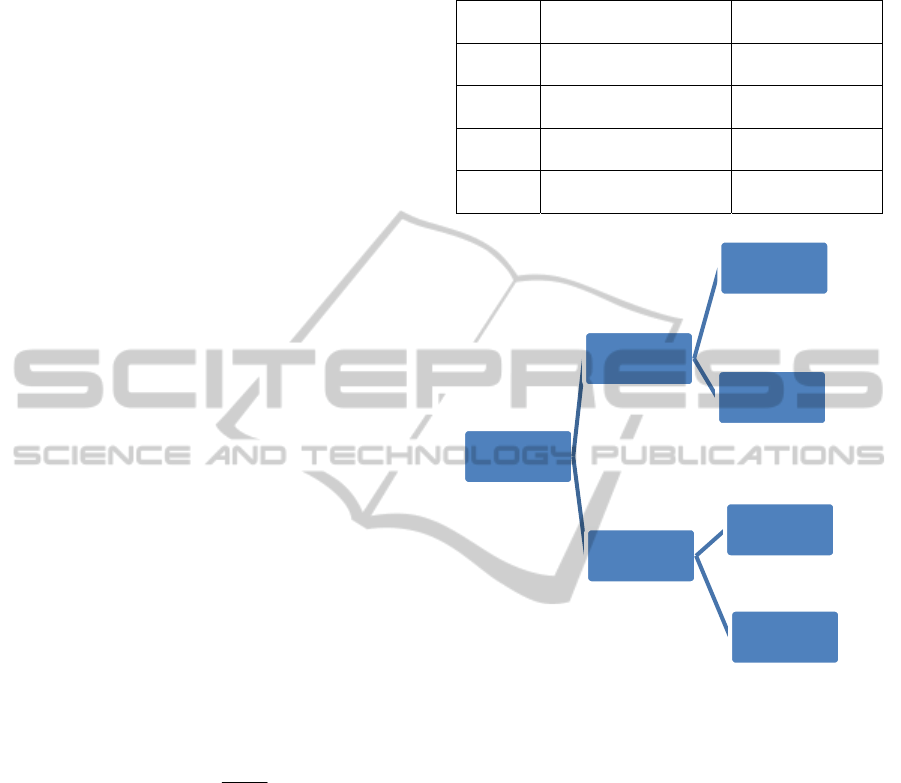

process was also considered in this model. Figure 2

shows the possible paths and profits that a product

may follow after a process. These profits were

quantified with respect to the formulae associated

with each path and are presented in Table 1.

Table 1: Tabulated profits for inspection and non-

inspection of defective and acceptable parts.

Profit

Variable

Description Formulae

PR

IG

Inspection of an

acceptable product

Sell – (Cm+ Ci)

PR

ID

Inspection of a

defective product

– (Cm+ Ci)

PR

DIG

Non-inspection of an

acceptable product

Sell – Cm

PR

DID

Non-inspection of a

defective product

Sell – (Cm+Cext)

Figure 2: Layout of possible Profits following a process

Wherein:

For the path involving inspection, the profit was

considered as a discrete random variable Xi, having

support R

xi

={PR

IG

,PR

ID

}

and a probability mass

function P

xi

(x) as shown below:

otherwise

PRxi

PRxi

p

p

xiXiP

ID

IG

:

:

:

0

1)(

Considering the case of non-inspection, the profit

was modelled as a discrete random variable Xdi

with

support R

xdi

= {PR

DIG

,PR

DID

} and a probability mass

function P

xdi

presented as:

otherwise

PRxdi

PRxdi

p

p

xdiXdiP

DID

DIG

:

:

:

0

1)(

The expected value for each case was represented by

equations (2) and (3) respectively:

Manufactuing

Process

Inspect

Good

Defective

Dontinspect

Defective

Good

PR

IG

PR

ID

PR

DIG

PR

DID

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

552

[] *() * (1 )

xi

I

GID

xi R

E

Xi xi P xi p PR p PR

(2)

[] *() * (1)

xdi

D

IG DID

xdi R

EXdi xdi Pxdi p PR pPR

(3)

The decision to inspect was then executed when the

following condition was satisfied

1

][

][

XdiE

XiE

The value of p was determined using the reliabilities

of the manufacturing processes. The initial

reliabilities as specified by the operator were

considered for the first run. Thereafter they were

updated based on the volume of products produced.

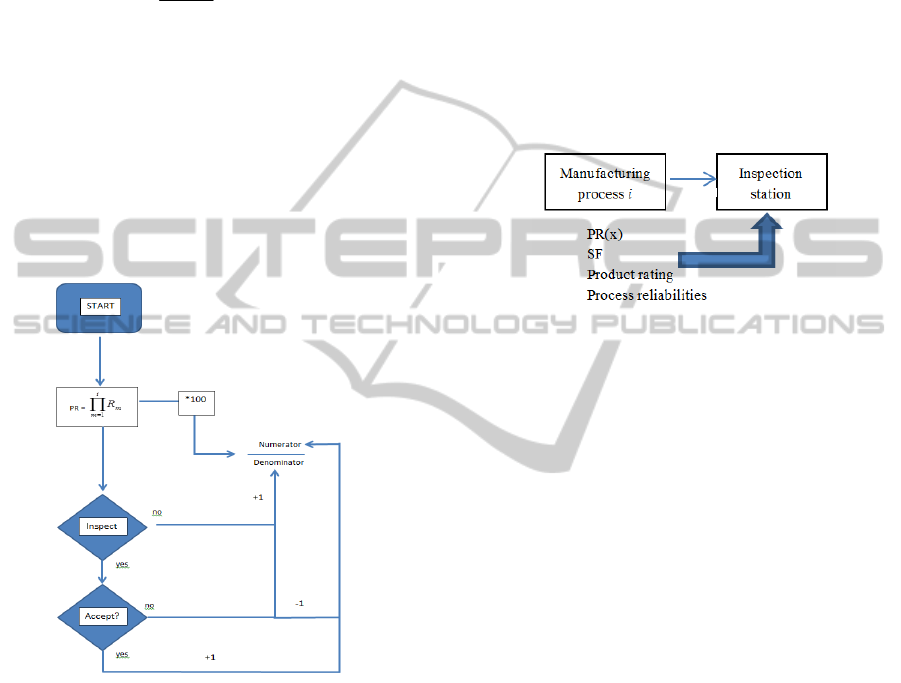

Figure 3 illustrates the process flow. For example, if

a reliability was 99% that meant that 99 out of 100

were successful. If one more passed through it and

was successful, it would have a reliability of 100 out

of 101.

Figure 3: Flowchart describing the updating of the

probabilities of the inspection criteria

Assuming that the prevention costs are constant, the

quality costs associated with the three different

appraisal and failure costs were determined as

follows:

COQ

100%

= Appraisal + Internal Failure (4)

COQ

0%

= External failure (5)

COQ

model

= Appraisal + internal failure

+ external failure

(6)

4 SIMULATION RESULTS

AND DISCUSSION

Figure 4 illustrates the manufacturing layout that

was simulated in Labview to compare the model-

based inspection criteria to 100% inspection and 0%

inspection frequencies. This layout depicted any

manufacturing process that was considered

significant in the product manufacturing cycle, as

discussed previously, with the possibility of an

inspection station following the process. The

simulation was based on the inspection of a single

feature passing through the station.

Figure 4: Simulated inspection station layout.

The manufacturing and inspection process

reliabilities were assumed to be constant whilst the

batch sizes, supplier reliability, processing costs,

product rating and SF were varied. The external

failure costs were modelled using equation 2 which

depended on the replacement costs to the customer.

The value of SF divided by the total sum of SFs was

used to determine the relative significance of the

feature in the context of the entire part. For this

simulation, this factor was considered to be 1. The

reason for this was that only a single feature

inspection was performed. This factor would change

when considering more features. Table 2 lists the

categorisation of the product rating and its influence

on the external failure costs. The use of two values

in the same category accounted for the upper and

lower extremes of relevant categories.

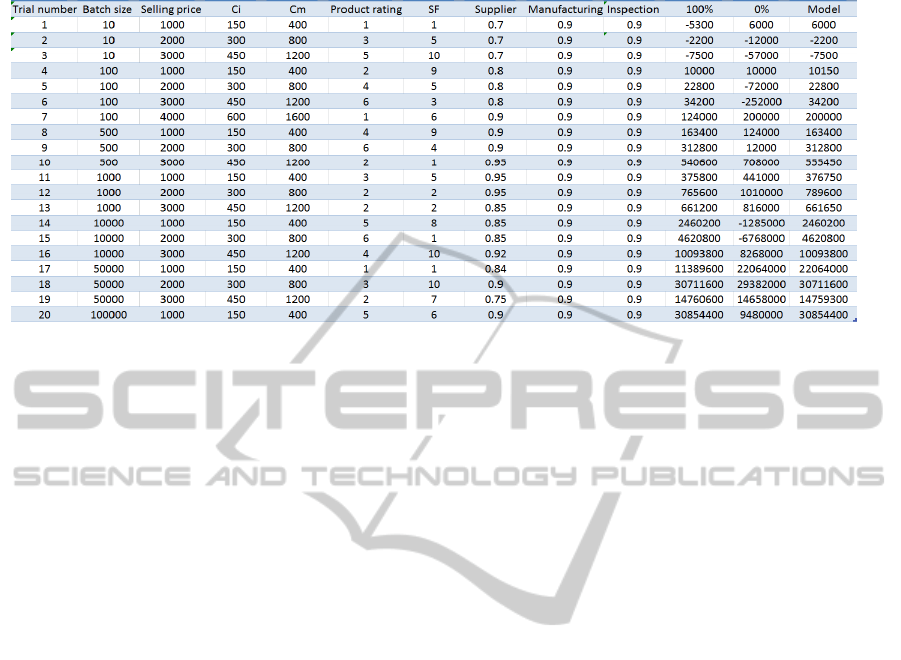

The inspection simulation interface and

numerical results are shown in Figure A1, in the

appendix. Twenty trials were performed; however

the results of only nineteen tests were plotted for

scaling reasons. The supplier rating was varied

between 0.7 and 0.95 to simulate the differences in

the reliability chain that would occur when

producing batches of custom products that would

require changes in process configurations. These

supplier ratings were inputs to the discrete random

generator using the Bernoulli probability function to

generate acceptable or defective parts randomly. The

tabulated results of the simulations are placed in the

Model-basedInspectionfortheControlofQualityinAdvancedManufacturingEnvironments

553

Table 2: Product rating list.

Product

rating

Description

1- 2

Low: These values indicate that the failure

of the product of component produced has

little repercussions and can be

accommodate by the replacement of a

defective component/product. A customised

cellular phone cover would be a typical

product with this rating

3- 4

Moderate: Used when failure of the

component/product is significant but not

critical. The incorrect spelling of a

customers’ name on a product label is an

example of this rating

5-6

Critical: Failure of a product with this type

of rating could lead to serious injury of a

person. A brake pad is an example of such a

product.

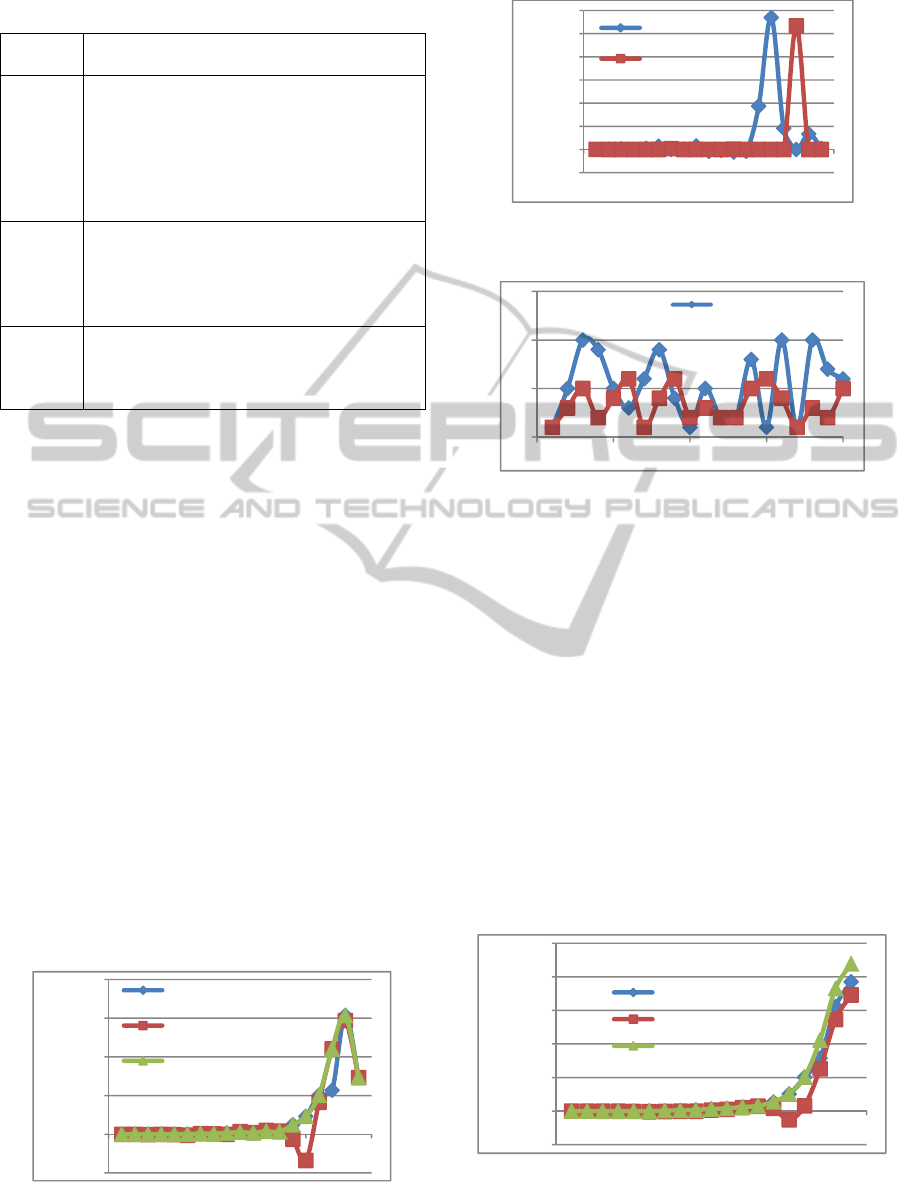

Appendix (Table A). Figure 5 (a) illustrates the

overall profits of all three inspection strategies

displayed on the same axes (y-axis being profit and

x-axis being trial number). The results indicated that

the model based inspection behaved similar to the

0% inspection strategy for low product ratings and

significant feature values. The response of the

model-based inspection converged onto the

behaviour of the 100% inspection strategy for higher

product ratings and significant feature values. The

greatest difference between the results of the model

and 0% inspection strategies occurred when the

product was rated moderate or critical (3-6). The

greatest difference between the model and 100%

inspection was seen when the product rating was

low. The SF directly affects the external costs but

due to there being only one feature, this factor did

not influence the overall inspection operation as seen

in Figures 5 (b) and (c). Negative profits were

recorded in some trials. These negative values were

a result of the combination of supplier and process

reliabilities, along with the product rating and

production costs.

Figure 5(a): Plot of the profits for the three inspection

strategies vs the inspection trial number.

Figure 5(b): Differences in profit between the Model-

based inspection and the 0% and 100% strategies.

Figure 5(c): Corresponding product rating and SF values

for the trials.

The cumulative profits for the 19 trials were plotted,

shown in Figure 6(a) to determine the overall

difference in performance of the inspection

strategies. The plot shows that all the inspection

strategies had the potential for profit with the 0%

inspection strategy being the most prone to loss in

profits for products rated moderate or critical. The

model responded like the other two inspection

strategies at their optimum when the conditions

dictated. This allowed for the model based

inspection strategy to have the highest overall profits

consistently. Figure 6(b) shows that the overall

profits obtained by the model-based inspection were

approximately 14% higher than the 100% inspection

strategy and 27% higher than the 0% inspection

strategy.

Figure 6(a): Plot of the cumulative profits of each type of

inspection strategy.

-10000000

0

10000000

20000000

30000000

40000000

0 5 10 15 20

100%

0%

Model

-2000000

0

2000000

4000000

6000000

8000000

10000000

12000000

0 5 10 15 20

M0%

M100%

0

5

10

15

0 5 10 15 20

Significance

Factor

-20000000

0

20000000

40000000

60000000

80000000

100000000

0 5 10 15 20

100%

0%

Model

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

554

Figure 6(b): Comparison of the total profits for the trials.

The COQ results for each type of inspection were

plotted using the results from Table 2. Six

simulations were performed with the only variable

being the product rating. The relative product rating

was divided by the maximum product rating (to

quantify conformance quality) and was then plotted

against the quality costs associated with each type of

inspection (preventative costs being kept constant

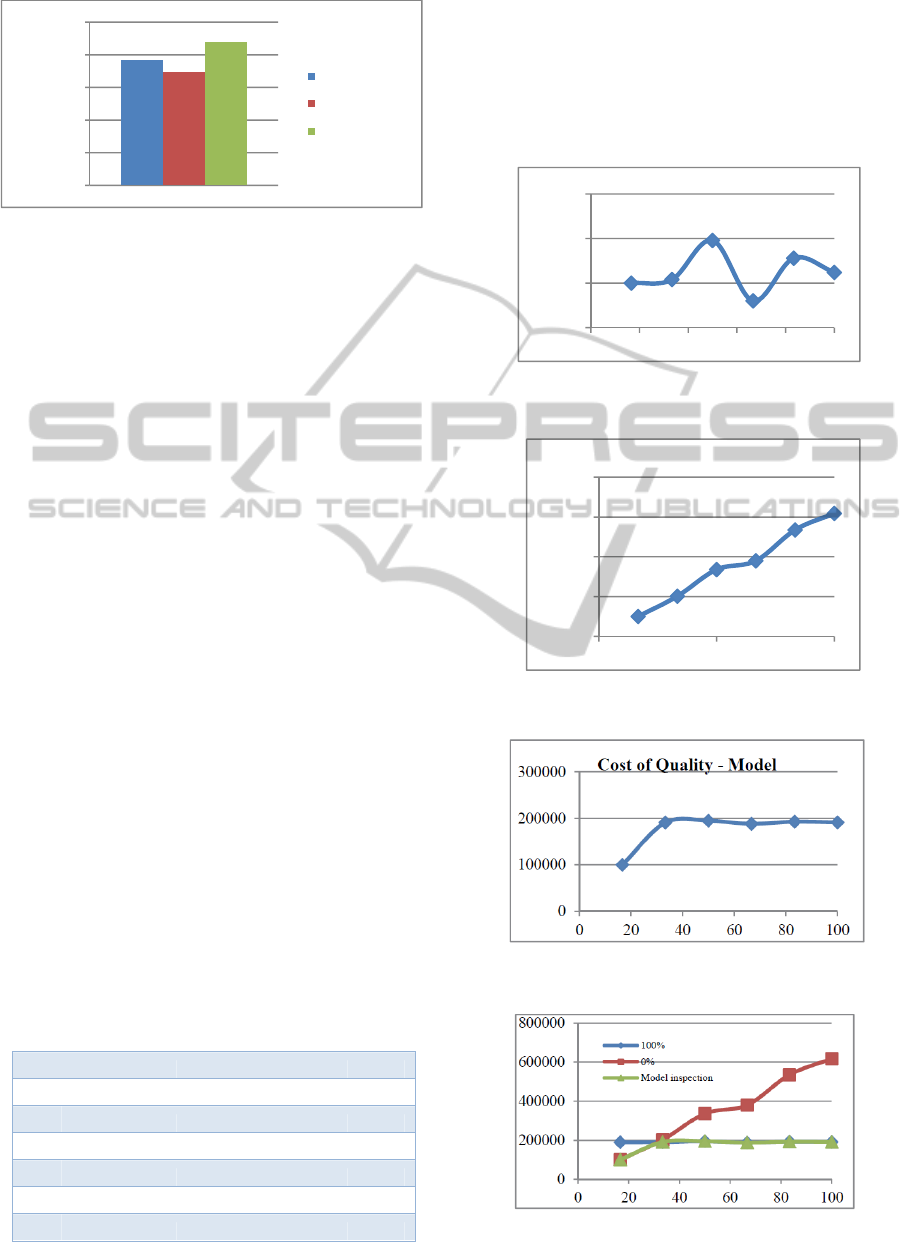

for each inspection type). Figure 7(a) shows a

fluctuation in the cost of quality for the 100%

inspection strategy. The appraisal costs for this

strategy were constant for the simulation, hence the

only factor influencing the plot were the internal

failure costs. These internal failures were based on

the random values generated during the simulation

and the graph shows a relatively low difference

between the maximum and minimum costs as

expected. Figure 7(b) indicates an increasing cost

due to the external failure costs increasing in

accordance with the product rating and equation. A

larger product rating significantly increases the

external failure costs and hence quality costs

associated with this inspection strategy. Figure 7(c)

show the results of the COQ associated with the

model-based simulation. The model was seen to

have a minimum COQ when the product rating was

low and a stabilisation onto a single cost as the

product rating increased. The increase in product

rating would have increased the external failure

costs and forced an increase in inspection frequency.

The only factor influencing this COQ at moderate

and critical product ratings were the internal failure

Table 3: Cost of quality values.

Quality of conformance 100% 0% Model

1 17% 190000 100000 100000

2 33% 190400 202000 190750

3 50% 194800 336000 194800

4 67% 188000 380000 188000

5 83% 192800 535000 192800

6 100% 191200 618000 191200

costs. Figure 7(d) illustrates the differences in COQ

of all three inspection strategies. It can be seen that

the model based inspection strategy always

maintains a low COQ which is required for

minimizing associated production costs and

maximising outgoing quality levels in accordance

with the customer requirements.

Figure 7(a): Plot of the costs associated with the relative

product ratings for the 100% inspection strategy.

Figure 7(b): Plot of the costs associated with the relative

product ratings for the 0% inspection strategy.

Figure 7(c): Plot of the costs associated with the relative

product ratings for the model-based inspection strategy.

Figure 7(d): Comparison of the costs of quality plotted on

the same set of axes.

0

20000000

40000000

60000000

80000000

100000000

Profit 100%

Profit 0%

Profit - Model

0

200000

400000

600000

800000

0 50 100

Cost of Quality 0%

185000

190000

195000

200000

0 20406080100

Cost of Quality 100%

Model-basedInspectionfortheControlofQualityinAdvancedManufacturingEnvironments

555

The twentieth trial involved a batch size of 100 000.

Due to the high product rating, the difference in

profit between the 100% and 0% inspection

strategies was extreme. The model was however

able to obtain the same profit a with the 100 %

inspection.

5 CONCLUSIONS

Advanced manufacturing environments involve

frequent changes in product design and process

configuration in accordance with changes in

customer requirements. The supply chain for such an

environment would also have to be dynamic to

accommodate these changes. A model to determine

the frequency of inspection at a strategically located

inspection station was developed using the expected

value formula. The inspection criteria considered

were the costs associated with the product, the

significance of the product to the customer as well as

the supplier and process reliabilities. Twenty trials

were performed whilst varying the inspection

criteria parameters to obtain an overall average

performance of the system. The results from the

simulation were compared to results of simulations

performed to quantify the performance of 100% and

0% inspection process strategies. The 0% inspection

strategy was best suited to processes involving high

reliabilities and low customer significance ratings.

The 100% inspection strategy was best suited to

high customer significance ratings. The model-

based inspection showed an overall increase in

profits gained, for both low and high customer

significance ratings, with a minimisation of the COQ

and was therefore considered to be more suitable to

manufacturing environments which experienced

frequent reconfigurations due to changes in

customer requirements. Further research into

reconfigurable manufacturing systems is currently

being performed globally. A fully functional

manufacturing environment is currently being

implemented at the University of KwaZulu-Natal

manufacturing laboratory. On completion, further

results will be generated and obtained for simulation

of industrial applications.

REFERENCES

Crosby, P. B., Quality is Free. 1979, New York, N. Y.:

McGraw-Hill.

Da Silveira, G., Borenstein, D., & Fogliatto, F. S., 2001.

Mass customization: Literature review and research

directions, International Journal of Production

Economics, 72, (1).

Davrajh, S., Bright, G., 2012. Implementation of

Commercial Products for Reconfigurable Quality

Inspection, M2VIP, NZ

Foster, S. T., 1996 An examination of the relationship

between conformance and quality-related costs,

International Journal of Quality & Reliability

Management, Vol. 13 Iss: 4, pp.50 - 63

Goetsch, D. L., Davis, S. B., 2010. Quality Management

for Organizational Excellence: Introduction to Total

Quality, Pearson, N. J.

ASQ, http://asq.org/learn-about-quality/cost-of-quality/

overview/overview.html, 2013

http://www.statlect.com/expval1.htm, 2013

Juran, J. M., 1951. Quality Control Handbook. 1st ed.,

New York, NY: McGraw-Hill.

Koren, Y., Heisel, U., Jovane, F., Moriwaki, T.,

Pritschow, G., Ulsoy, G., and Van Brussel, H.:

‘Reconfigurable Manufacturing Systems’, CIRP

Annals - Manufacturing Technology, 1999, 48, (2),

pp. 527-540

Nambiar, A. N.: ‘Mass customization : where do we go

from here?’,World Congress on Engineering , WCE

2009, 2009, pp. 687

Pollard, D., Chuo, S., Lee, B., 2008. Strategies For Mass

Customization, In Journal of Business & Economics

Research, 6, (7)

Tseng, M. M., and Du, X., 1998. Design by Customers for

Mass Customization Product, CIRP Annals -

Manufacturing Technology, 47, (1), pp. 103-106

www.ni.com/labview, 2013

Zaklouta, H., 2011. Cost of quality tradeoffs in

manufacturing process and inspection strategy

selection,MSc Thesis, MIT

APPENDIX

Figure A1: GUI for the inspection simulation.

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

556

Table A: Tabulated results from the inspection trials.

Model-basedInspectionfortheControlofQualityinAdvancedManufacturingEnvironments

557