AMICO: The Asset Management for Industrial Complex Enterprise

Stefano Alì

2

, Giulio Cantali

1

, Salvatore Cavalieri

1

, Ferdinando Chiacchio

1

, Liberina Guarnaccia

2

,

Fabio Scibilia

1

and Alfio Scuderi

2

1

Department of Electrical, Electronic and Computer Engineering, University of Catania, Viale A.Doria, 6, Catania, Italy

2

Xenia Progetti s.r.l., Via Acicastello, 71, Catania, Italy

Keywords: Factory Automation, Information Management, Workflow, Expert System.

Abstract: Asset management plays a crucial role in productive activities of an industrial factory. Several commercial

softwares exist but they generally present some limitations, among which the closed nature towards

integration. The paper presents the AMICO project, a software platform conceived to overcome traditional

limits of existing commercial solutions. A research investigation has preceded the definition of the system;

it allowed to highlight the current state of the market related to the asset management softwares and pointed

out the technological enhancements which could have been implemented. Among them, it highlighted the

importance of a central information system able to synchronize information flows and activities. Thanks to a

centralized architecture, powerful and innovative features like a cooperative workflow engine and an expert

system has been introduced in the AMICO project.

1 INTRODUCTION

This paper presents the first results achieved inside a

research project called AMICO (The Asset

Management for Industrial Complex plant). AMICO

is an ongoing project carried on by XENIA Srl, a

SME Software Company located in Catania, and the

DIEEI (Department of Electrical, Electronic and

Computer Engineerings) of the University of

Catania with the contribution of the Regione Sicilia

(ITALY), based on European Regional

Development Fund (P.O. FESR Sicilia line 4.1.1.2).

The main objectives motivating the development

of AMICO take the cue by the matters of the Digital

Factory (Wenzel, S., Jessen U. and Bernhard J.,

2005) which set the integration of the activities

characterizing modern enterprises as one of most

important goal to reach.

In the past few decades, ICT has offered several

software tools but only recently holistic solutions

(such as ERP, MRP, etc.) able to fulfil the

requirement of digital integration have started to

take place (Umble, E. J, Haft R. R and Umble M.

M., 2003), (Aloini D., Dulmin R. and Mininno V.,

2007). Such type of software solutions aim to be

easy scalable, agile in customization and modular.

The software solution proposed by AMICO has to

be framed within this context. AMICO wants to

offer an innovative solution for the management of

the industrial factory assets and corresponding

documentation, able to integrate the workflows of

the associated industrial processes and provide an

environment of co-design and interoperability

among the people involved in the work-orders

activities.

The initial requirements of the projects have

been determined according to the result of a detailed

survey of the current art of market aimed to

generalize and extend, as much as possible, the

scope of the platform. In this direction, innovative

features like a cooperative workflow and an expert

system to support the management of the work-order

activities have been highlighted and implemented.

The paper is organized as it follows. Section 2

presents a short survey about some of the most

diffused commercial solutions of asset management

software and it points out the enhancements

proposed within the project AMICO. In Section 3 an

overview of the AMICO platform is presented with

particular emphasis on its main features, i.e. the

cooperative workflow engine and the expert system.

Finally, in Section 4 conclusions involving the use

of the AMICO platform in real industrial scenarios

are discussed.

423

Alì S., Cantali G., Cavalieri S., Chiacchio F., Guarnaccia L., Scibilia F. and Scuderi A..

AMICO: The Asset Management for Industrial Complex Enterprise.

DOI: 10.5220/0004416704230429

In Proceedings of the 15th International Conference on Enterprise Information Systems (ICEIS-2013), pages 423-429

ISBN: 978-989-8565-59-4

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

2 STATE OF ART

One of the most important activities inside an

enterprise consists in the management of existing

asset documentation; such an activity has to

warranty freshness and consistency of all the

documentation containing information about

productive processes and corresponding equipment.

In general, these types of information are not

homogeneous and can vary depending on the type of

activity and equipment (i.e., the number of

documents, certification, reports and so on);

moreover, information’s stakeholders may be either

internal or external to the enterprise organization

(i.e., collaborative design).

Asset management software has to be conceived

to support this critical activity. Currently, several

commercial solutions are available on the market;

they support asset documentation management in

different ways. For this reason, a preliminary survey

concerning the main features of some well known

commercial software of asset management was

conducted. This investigation was used to determine

what improvements can be valuable in respect with

current state of art. The analysis was focused on the

core functionalities (e.g. presence of an unified

platform of document and asset management, the

main features of the repository and the workflow

management) and some advanced functionalities

(like use of expert systems, dynamic workflows,

RFID support and so on).

More than 10 well known and commonly used

asset management tools have been considered; their

references have been intentionally omitted. The

results of this investigation are summarised in Table

1; for each of the functionalities considered in the

analysis, the table shows if it is generally supported

(), partially supported (P), and not supported at all

(N).

One of the main limits observed is that

commercial products do not fully support centralized

repository. Traditionally, the very different

functional departments of an enterprise rely on

different specific tools (electronic spread sheets, text

editor, etc.) for the implementation of their activities

and workflows. In these scenarios, departments

independence and activities parallelization lead to

sacrifice the consistence and freshness of the

information knowledge.

The drawbacks of not having a centralized

database are that:

information are fragmented into several

repositories, if not even maintained into a paper

documentation;

due to unreliability of databases, activities

concerning new developments and updating

must be preceded by on-site inspections;

report activities concerning status of the

equipment are difficult and the impossibility to

access reliable and fresh information increases

the risk of non-compliance with security

standards and legal requirements.

On account of what said, the adoption of a

central database is one of the most challenging

features to realize; the implementation of a unique

common information repository represents one of

the key features of the AMICO project.

Table 1: Functional Requirements offered by several

existing commercial solutions.

Functional Requirements Availability

CORE

Unified platform of document

and asset management P

Centralized repository

(documents and asset) P

Integrated management of workflow P

ADVANCED

Dynamic/flexible workflows P

Expert system for the verification

of assets consistency N

Co-design environment supported

by synchronized workflow N

Management of concurrent updating N

RFID support

Browsing of CAD files N

Wireless client

LEGEND: : Available; P: Not fully supported; N: not

supported at all.

Another limitation of the available solutions in

the market is relevant to the “Integrated management

of workflow”; this limitation consists in the lack of

workflow management platforms to favour a

collaborative approach for the execution of the

work-order activities. Traditional software solutions

offer workflow platforms of management which are

just able to track and monitor the status of work-

order activities; in these solutions, more complex

operations (like authorizations to create, access,

update documentation, etc.) have to be performed

outside the workflow environment by the operators

involved in the activity. Another important goal

aimed to reach within the AMICO platform, is the

implementation of a collaborative workflow

environment, realized thanks to the availability of

the above mentioned centralized repository (which

maintains assets status and work-orders information

fresh and consistent) and by the use of customizable

rules of permission which enable the operators to

ICEIS2013-15thInternationalConferenceonEnterpriseInformationSystems

424

access secured resources and asset documentation.

Considering the advanced functionalities shown

by Table 1, the analysis carried on has highlighted

that none of the main software solutions implement

any type of Expert System for the verification of

assets consistency. This feature would be of valuable

support for software of asset management since it

can help users in the preparation of work-orders or

in the activity of co-design with third-party

companies.

The features listed so far can contribute to the

achievement of another important goal, namely the

realization of a quite general asset management

platform, easily adaptable to a wide variety of

industrial enterprises (Jordan, W. C. and Graves S.

C., 1995), (Jenkins G. P and Wright D. S., 1998),

(Chase, R. B. and Aquilano, N. J., 1977),

(Brandolese A., Brugger G., Garetti M. and Misul

E., 1985). In fact, the adoption of a centralized

architecture in support to a co-design workflow

management environment allows adaptability to any

type of asset management activities and guarantees

independence from a specific implementation.

3 AMICO

The AMICO projects aims to the implementation of

a centralized information system for the integrated

management of the enterprise, supporting all

functional areas activities providing a unified vision

of data, documents and equipment and warranting

information freshness and consistency.

The initial objectives of the project were inspired

by requirements identified in large industrial

enterprises to have a centralized tool warranting the

alignment of assets and documentation and

integrating the operating workflows with the work

order activities.

The main idea behind the project AMICO is

based on the definition of asset, intended as any type

of element which contributes to the enterprise

activity, be it a physical object or an immaterial

element. In this way, assets are the main objects

handled by the integrated software platform: they are

stored and kept updated inside a central database

which supports all the process activities for the

entire life of the equipment.

In order to satisfy the project requirements, the

following activities must be performed:

creation of a functional and organisational

model for asset and documentation

management;

implementation of an integrated information

system warranting integration among data and

processes activities performed by distinct

enterprise functional areas (i.e., people of

different teams);

integration of a co-design environment for the

management of workflows, related to enterprise

process activities;

the implementation of innovative applications

able to automatically control, verify and

warranty consistency of database information

with the real status of assets either stored or

checked out.

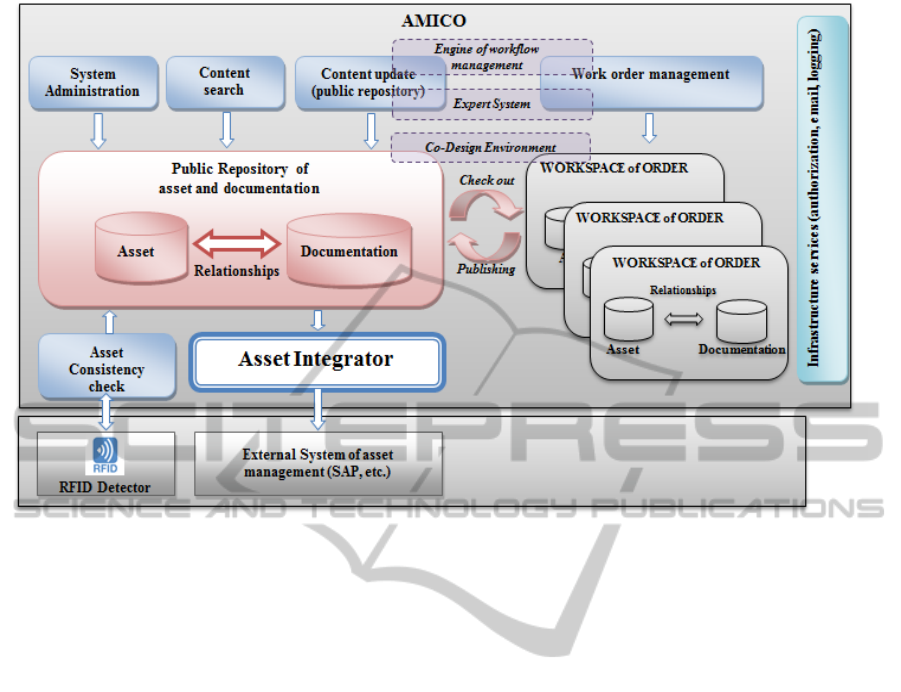

Figure 1 shows the functional blocks which

constitute the AMICO platform: it is possible to

highlight two distinct functional information flows

which are interfaced by both “Engine workflow

management” and “Expert System” entities. On the

left, the functional blocks handling production

server’s repository of the production server are

shown; asset and documentation can be accessed and

managed by the authorized personnel the System

Administration panel; moreover high level functions

of search and update are provided by the related

functional blocks. Consistency and congruence is

maintained by the functional blocks “Asset

Integrator” and “Asset Consistency Check”. On the

right part of Figure 1, a generic order workspace is

presented: when a work order has to be processed,

the most fresh asset’s status to be used (i.e.,

information and documentation about the elements

of the process involved) is retrieved (Check out) and

transferred into the so called “order’s workspace”.

This workspace is the information environment,

within the production server, used by all team units

authorized to operate on the work order; in this way

modifications of the work order are carried out in a

safe way, as the coherence of the asset is maintained

in the repository of the production server (as shown

in the left part of Figure 1).

Publishing and check-in operations are

performed during the work order activities, with the

support of a powerful workflow engine guaranteeing

a step by step verification of asset modifications’

and implementations.

In order to realise this important feature, the

platform includes a software module implementing a

collaborative workflow management and co-design

environment to monitor and support the

authorization processes on for external contractors

involved in work-orders operations. The latter (as

shown in Figure 1) is positioned between a generic

workspace of order, typically managed by personnel

of a contractor team, and the Public Repository of

Asset and Documentation (i.e., the central

AMICO:TheAssetManagementforIndustrialComplexEnterprise

425

Figure 1: Functional Blocks constituting the AMICO Platform.

repository): in this way, when a documentation

stored in the central repository is required by the

contractor, the request is automatically taken in

charge by authorized personnel.

The next subsection will describe the workflow

management here implemented.

The other novel feature of AMICO is the

implementation of an Expert System supporting

documentation management activities. As it will be

shown in the following, the Expert System

implements a Business Rule Management System

(BRMS) to provide users with a list of possible

relationships among all documents related to a work-

order.

3.1 Workflow Management

As well as the internal know-how of the enterprise is

well maintained inside the public repository of the

AMICO platform, so robust protocols for the

execution of work-orders are ensured by the

definition of appropriate dynamic workflows

(Biegus L. and Branki C., 2004), (Dogac, D.,

Kalinichenko, L., Özsu, T. and Sheth, A., 1998).

AMICO fulfils this requirement by providing an

engine implementing a collaborative environment

for the design of workflows (Held M., Blochinger

W., 2009); such workflows gurantee the integrity of

the entire work order process and related know-how.

This feature is implemented through a continuous

synchronization among internal and external

enterprise resources (i.e., management and teams in

charge to perform the operations).

The basic principle is to map any type of work-

order into an electronic workflow. Through a user-

friendly design tool, the authorized personnel will be

able to create the workflows associated to any types

of work-order process: these workflows will be

collected in a catalogue populated and maintained in

the central database. More complex workflow

structures can be designed by also involving

multiple actors and granting different level of

authorizations.

These workflow models can be instantiated and

executed when a work-order (or a set of work-

orders) is going to be processed. A dedicated

runtime environment will maintain and concurrently

execute all instantiated workflows, while data

congruency will be guaranteed through

synchronization with the central database.

Check-in and check-out operations are required

to access the workspace related to the work-order

(right side of Figure 1, where publishing

corrensponds to check-in operation). Centralized

repository (left side of Figure 1) will not be modified

until the work-order is completed or updating

operation (scheduled in the workflow) has been

authorized. In order to ensure integrity of multiple

ICEIS2013-15thInternationalConferenceonEnterpriseInformationSystems

426

accesses, mechanisms of automatic communication

among the actors accessing the same resources are

used (e.g. automatic emails, etc.).

3.2 Expert System

The activity of asset and documentation

management requires specific skills, related to the

different processes and domains of the enterprise.

Such competence acquisition requires a long and

wide experience. A deep knowledge about enterprise

processes may be not sufficient to have a

comprehensive view of the relationship occurring

among large amount of assets.

The utilization of an Expert System (Malhotra

Y., 2001) has to be framed within this context; it

may solve the aforesaid limitation. The use of an

Expert System provides two main advantages: the

first is that it can partially replace the role of the

expert user, supporting and training inexperienced

personnel; the second is that it can also support

expert users when operating on activities

characterized by a large amounts of inter-

dependencies.

AMICO’s Expert System is providing also

support for documentation management in the

preparation of work-orders or co-design with third-

party companies. The Expert System, by processing

of relevant rules and input parameters, will be able

to suggest a set of documents to be included as part

of the work-order. This process and the achieved

results are similar to the analysis that an expert user

would apply. In addition, the Expert System is

scheduled in order to process data periodically,

providing a result that is always synchronized with

the changes of the database.

The Expert System will make use of the central

database (through appropriate views or other data

structures) to access data concerning work-orders,

assets and documents as required by the inferential

algorithms. The output of the Expert System (i.e.,

the list of suggested documents and the set of

information provided) will be stored inside

dedicated data structures within the central database.

The inferential engine is based on two main

broad categories of rules:

rules related to relationships which exist in the

work-order management model, as inferred by

the analysis of the historic;

rules not directly related to existing

relationships, but obtained by "experience"

through the analysis of the historic.

For each document in the recommended list, the

Expert System will provide an indication of the

proposed criteria and the level of criteria reliability

(likelihood) calculated through the analysis of the

historic.

The Expert System behaviour is based on the

concept of Facts and Rules. Facts are information

used to verify whether or not particular events or

conditions occur. Rules are more complex criteria

that look for the occurrence of a combination of

facts and indicate the actions to execute.

These actions can, in turn, modify the status of

the system and trigger the execution of other actions.

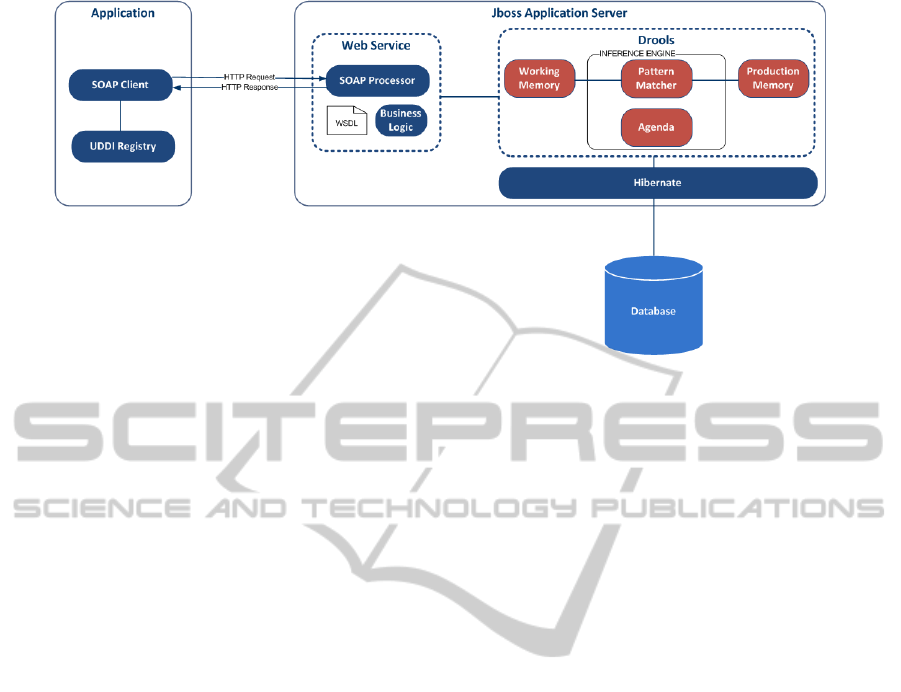

Figure 2 shows the Expert System Architecture

defined and implemented inside AMICO platform.

As it can be noticed, the Expert System is deployed

within an Application Server and can be interrogated

by a generic Client application through a Web-

service. The Expert System includes the following

key components:

Working Memory: where System knowledge is

stored. Each element of knowledge is called

"Fact". Facts can be inserted, updated, and

removed from the Working Memory. In our

specific implementation Facts are data related

to documents, checklists, contracts, taxonomies,

facilities, assets, etc...;

Production Memory: it contains the guidelines

used by the Inferential Engine to verify the

conditions stored into the Rules and related

actions have to be undertaken;

Inference Engine: it is composed by the Pattern

Matcher and by the Agenda. The former is in

charge to verify matches among Rules and

Facts, while the latter handles the order of

execution of actions, being capable of solving

the conflicts raising from simultaneous

matching of multiple Rules.

The Expert System is based on the Drools Open

Source Framework (JBoss Community, 1), a

Business Rule Management System (BRMS)

distributed by the application server JBoss (JBoss

Community, 2).

Drools implements an object oriented formalism

to describe information knowledge: data can be

mapped into a JAVA object, through the Object

Relational Mapping (ORM) Hibernate (JBoss

Community, 3) and exposed to the Expert System

inside the Working Memory.

Drools implements and extends the algorithm

RETE, RETEOO (Sottara D., Mello P. and Proctor

M. A., 2008), (Sottara D., Mello P., Proctor M. A.,

2010).

AMICO:TheAssetManagementforIndustrialComplexEnterprise

427

Figure 2: Architecture of the Expert System.

4 CONCLUSIONS

In this paper the AMICO platform, a software for

the asset management of complex industrial

enterprise, has been presented.

Key features of the platform were pointed based

on the results of a preliminary research activity

highlighting the main limits of existing commercial

solutions.

The implementation of a unique centralized

database able to store and ensure consistency among

all the enterprise information has been targeted as

the main key feature to be provided. The effort

required by the implementation of the centralized

architecture is justified by the advantages which

such an architecture provides, i.e., a powerful

workflow engine for co-design, able to coordinate

internal and external teams and an Expert System

supporting management of the work-orders

documentation.

In order to implement such centralized

architecture for the information knowledge

management, the concept of asset was introduced

and used to create a functional and organisational

model of taxonomy.

Some big companies operating in the Oil/Energy

industrial sectors have already expressed interest in

the AMICO Platform. One of these companies is

Raffineria di Milazzo, an oil refinery based in Sicily,

which has declared its availability to act as a pilot

site for the global validation of the system, once it

will be completed. The company has also expressed

the willingness to subsequently adopt the system as

the reference platform for document and asset

management activities. So far, it has acted as

external consultant of XENIA and has provided

much of its information content and business data in

order to create a development environment which

will be used later on and exploited as test

environment for further experimentation. In such

context, the system will handle approximately

60.000 to 70.000 assets and 40.000 to 50.000

documents, it will manage complex workflows

involving co-design activities with third party

companies and will integrate with the existing IT

infrastructure (SAP, etc.).

ACKNOWLEDGEMENTS

The research results presented in this paper have

been achieved inside the AMICO project (Asset

Management for Industrial COmplex plant), carried

on by Xenia Progetti srl and University of Catania-

DIEEI with the contribution of European Regional

Development Funds (P.O. FESR line 4.1.1.2) by

Regione Sicilia (Italy); the AMICO project is

identified by Regione Sicilia by the code CUP:

G23F11000810004.

A special thanks has to go do Dr. Raffaele

D’Angelo, IT Manager of Raffineria di Milazzo, for

his fundamental support, guidelines and

recommendation.

REFERENCES

Aloini D., Dulmin R., Mininno V., 2007. Risk

management in ERP project introduction: Review of

ICEIS2013-15thInternationalConferenceonEnterpriseInformationSystems

428

the literature, Information & Management, Volume

44, Issue 6, pp. 547–567.

Brandolese A., Brugger G., Garetti M., Misul E., 1985.

Analisi dei sistemi di produzione manifatturieri,

Finanza, Marketing e Produzione.

Biegus L., Branki C., 2004. InDiA: framework for

workflow interoperability support by means of multi-

agent systems, Engineering Applications of Artificial

Intelligence, Volume 17, Issue 7, pp: 825-839.

Chase, R. B., Aquilano, N. J., 1977. Production &

Operations Management: A Life Cycle Approach,

Homewood, Ill: R.D. Irwin.

Dogac, D., Kalinichenko, L.; Özsu, T., Sheth, A., 1998.

Workflow Management Systems and Interoperability,

Springer, Berlin.

Held M., Blochinger W., 2009. Structured collaborative

workflow design, Future Generation Computer

Systems, Volume 25, Issue 6, pp. 638–653.JBoss

Community, 1: DROOLS Documentation,

http://www.jboss.org/drools/documentation.

JBoss Community, 2: http://www.jboss.org.

JBoss Community, 3: http://www.hibernate.org.

Jenkins G. P, Wright D. S., 1998. Managing Inflexible

Supply Chains, International Journal of Logistics

Management, Vol. 9 Issue: 2, pp.83-90.

Jordan, W. C., Graves S. C., 1995. Principles on the

Benefits of Manufacturing Process Flexibility,

Management Science, 43, pp. 577-594.

Malhotra Y., 2001. Expert systems for knowledge

management: crossing the chasm between information

processing and sense making, Expert Systems with

Applications Volume 20, Issue 1, pp. 7–16.

Sottara D., Mello P., Proctor M. A., 2010. Configurable

Rete-OO Engine for Reasoning with Different Types

of Imperfect Information, IEEE Transactions on

Knowledge and Data Engineering, Volume 22 , Issue:

11, pp. 1535-1548.

Sottara D., Mello P., Proctor M., 2008. Adding

Uncertainty to a Rete-OO Inference Engine, Lecture

Notes in Computer Science Volume, 5321, pp. 104-

118.

Umble, E. J, Haft R. R, Umble M. M., 2003. Enterprise

resource planning: Implementation procedures and

critical success factors, European Journal of

Operational Research, Volume 146, Issue 2, pp. 241–

257.

Wenzel, S., Jessen U., Bernhard J., 2005. Classifications

and conventions structure the handling of models

within the Digital Factory, Computers in Industry -

Special issue: The digital factory: an instrument of the

present and the future archive, Volume. 56 Issue 4,

pp. 334-346.

AMICO:TheAssetManagementforIndustrialComplexEnterprise

429