Carbon Electrode based Urea Sensor

Modification of Graphite and New Polymeric Carriers for Enzyme Immobilization

Julija Razumiene

1

, Ieva Sakinyte

1

, Tatjana Kochane

2

, Sandra Maciulyte

2

, Antanas Straksys

2

,

Saulute Budriene

2

and Jurgis Barkauskas

3

1

Institute of Biochemistry, Vilnius University, Mokslininku 12, 08662, Vilnius, Lithuania

2

Department of Polymer Chemistry, Vilnius University, Naugarduko 24, 03225, Vilnius, Lithuania

3

Department of General and Inorganic Chemistry, Vilnius University, Naugarduko 24, 03225, Vilnius, Lithuania

Keywords: Urea Biosensor, Modified Graphite, Polymeric Carrier, Enzyme, Amperometry.

Abstract: The amperometric biosensor for urea determination was designed based on the electrochemical oxidation of

urea decomposition products produced by urease. The enzyme electrode, made of a specially developed

modified graphite (MG) paste, was produced by covering the electrode surface with new polymeric carriers

poly(urethane-urea) (PUU) microparticles containing immobilized urease from Canavalia ensiformis (E.C.

3.5.1.5.).

1 INTRODUCTION

Urea is a final product of metabolism of aliphatic

nitrogen in organisms. Generally, abnormal urea

concentration indicates kidney disease. Rapid

determination of urea is important not only in

clinical analysis but urea detection is great problem

in fertilizes industry and in agriculture as well. This

small molecule yet is a very important part for milk

component. A high concentration of milk urea

shows dietary disbalance, potential milk losses and

risk of infertility (Miglior et al., 2007). Milk urea

nitrogen levels are known to vary with the amount of

protein in the diet, amount of urine excreted, amount

of water intake, dry matter intake, sampling

methods, breed, parity, and days in milk, season and

herd management (Renny et al., 2005). These levels

increase with adulteration and are detrimental to

human health. Therefore, it is essential to test urea

level in milk in all stages - from producing to

consuming.

The most enzymatic methods of urea

determination are based on enzymatic hydrolysis of

urea in presence of urease with following

determination of hydrolysis products. A number of

photometric methods for the determination of NH

4+

(

Patton and Crouch, 1977) and using a piezo-

electric sensor

(Miglior et al., 2007) were created.

However obviously, their application for express

analysis, and especially in turbid media, is rather

complicated. In a field of amperometric biosensors

the most critical issues impeding their large-scale

application is still the inefficient and power-

demanding signal mediation from the biological

sensing element to the transducer as well as poor

stability of the employed biocatalyst (

Muti et al.,

2011). Thus, development of new electrode

materials promising for effective electron transfer

and immobilization of enzymes still is in a growing

interest. Carbon nanomaterials and various

polymeric carriers (PC) have been extensively

studied and proved to be ideal materials for these

purposes (

Agui et al., 2008; Wang et al., 2004;

Fan et al., 2006; Qureshi et al., 2009)

.

The goal of this work was to design urea

biosensor based on specially developed MG

electrode and newly proposed method of urease

immobilization onto polymeric carriers and

implement such electrochemical system for

detection of urea in milk or other biological liquids.

2 EXPERIMENTAL

2.1 Preparation of Polymeric Carriers

and Immobilization of Urease

Poly(urethane-urea) (PUU) microparticles from

197

Razumiene J., Sakinyte I., Kochane T., Maciulyte S., Straksys A., Budriene S. and Barkauskas J..

Carbon Electrode based Urea Sensor - Modification of Graphite and New Polymeric Carriers for Enzyme Immobilization.

DOI: 10.5220/0004326901970201

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2013), pages 197-201

ISBN: 978-989-8565-34-1

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

poly(vinyl alcohol) (PVA) and hexamethylene

diisocyanate (HMDI) were synthesized by one-step

method in dimethyl sulfoxide/water (99/1 vol.%)

solution according to previously described protocol

(Budriene et al., 2007).

.

Initial concentration of PVA

was 0.1 M. Initial molar ratio of PVA and HMDI

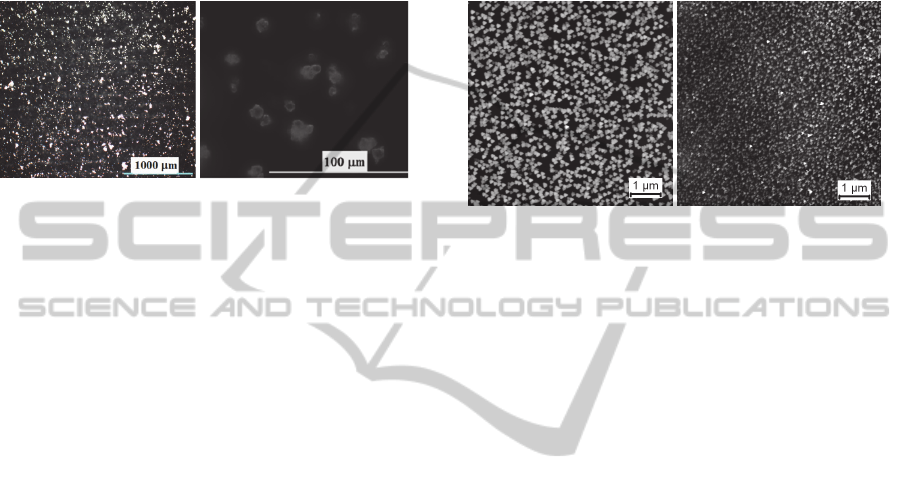

was 1.0:5.0. SEM image of lyophilized PC

microparticles is shown in Fig. 1.

Figure 1: Optical microscopy images of PC.

Immobilization of urease onto PUU

microparticles was carried out in 0.1 M phosphate

buffer solution, pH 7.2. The mixture of the enzyme,

buffer and PUU carrier (in different ratios) was

stirred at 25 °C for 30 min (immediately after

synthesis) and then left at 4 °C overnight. It was

prepared and investigated folowing ratios: using

1540 U of urease for 0.5 g of PC (1 PC); using of

770 U for 0.5 g of PC (2 PC); using of 389 U for 0.5

g of PC (3 PC) and using of 112 U for 0.5 g of PC (4

PC). Next day the immobilized enzyme was

thoroughly washed with buffer.

2.2 Preparation of MG and

Amperometric Biosensor

Modified graphite particles were synthesized from

pristine graphite (Merck KGaA) by oxidizing it with

potassium ferricyanide K

3

[Fe(CN)

6

] in alkaline

media. The obtained batches of MG were examined

by titration and AFM analysis methods (Fig. 2).

Titration analysis revealed the presence of small

amount (0.14 – 0.17 mmol/g) of basic surface

functional groups. AFM images show that sonication

procedure causes the formation of finely dispersed

MG particles (Fig. 2 A and B).

It was determined that the MG sample suitable

for biosensor design contains a fine fraction of 63 %

with an average diameter of the graphite particles of

20 nm.

MG powder was mixed with the pasting liquid

consisting of 10 % polyvinyl dichloride in acetone

and used for design of the electrodes.

Aiming to design working electrodes MG mixed

with pasting liquid was extruded by forming tablet

(Voitechovic et al., 2010). The tablet was sealed in a

Teflon tube. Electrodes were washed with bidistilled

water, and dried before use. Working urease-MG

electrode (biosensor) was designed by mechanically

attaching the polymeric carriers containing

immobilized enzyme urease to the surface of MG.

Further the constructed biosensor was protected by

using semipermeable terylene film.

Figure 2: AFM images of MG. (A) batches prepared

without sonication, and (B) bathes prepared including a

sonication procedure.

2.3 Electrochemical Measurements

Electrochemical measurements were performed

using an electrochemical system “PARSTAT 2273”

(Princeton Applied Reasearch, USA) with a

conventional three-electrode system comprised of a

platinum plate electrode as auxiliary electrode, a

saturated Ag/AgCl electrode as reference and

urease-MG (2 mm diameter) as working electrode.

The response of the prepared enzyme electrode

to the addition of substrate was investigated under

potentiostatic conditions at 0.4 V (vs. Ag/AgCl) in a

stirred buffer solution. As a substrate was used

phosphate buffer solution, pH 7.2, containing 1 M of

urea. The program Origin Pro 8.0 (free trial version

from http://www.originlab.com, OriginLab

Corporation, US) was used for data analysis.

2.3.1 Measurements in Milk

Commercial milk was analysed using the developed

biosensor. Taking into account that the concentration

of urea in dairy products is outside the working

range of the biosensor, a dilution of the samples

were necessary prior to analysis to adjust the sample

concentration to the linear range of the biosensor.

For this purpose, 1 M of urea solution was prepared

in milk. For each measurement 2, 3, 5, 7 and 10 µl

of the dairy product were added into electrochemical

cell containing of 1 ml of buffer solution. Thus, the

final dilution factor was from 50 to 500. Analogous

experiments were carried out by adding in the

AB

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

198

electrochemical cell of 1 M urea prepared in buffer

solution.

3 RESULTS

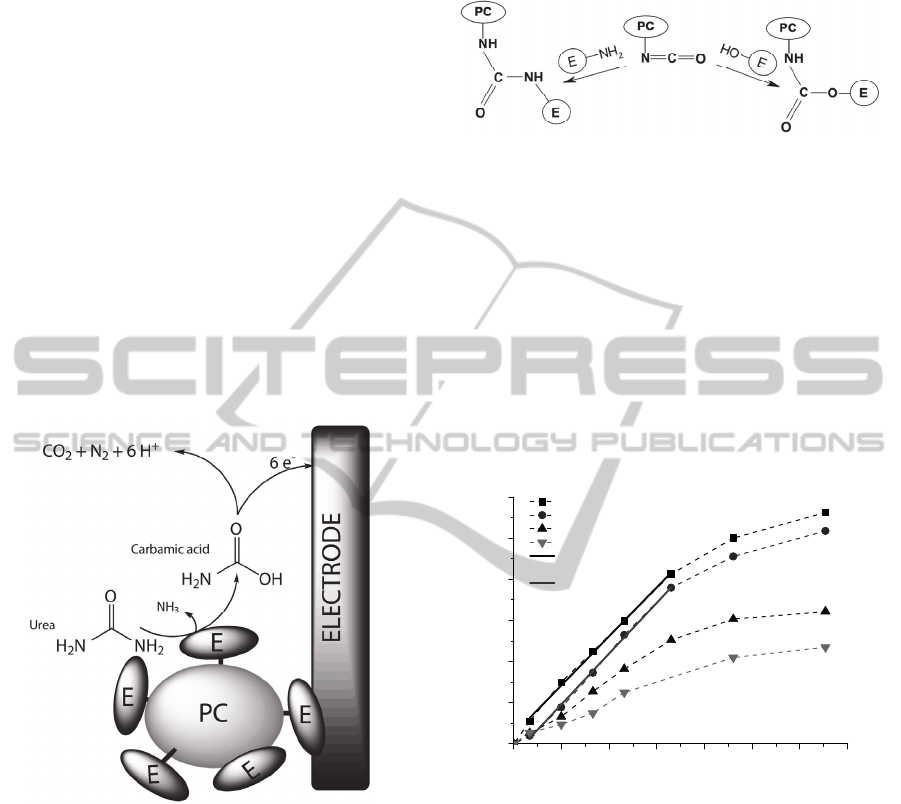

3.1 Principle of Urea Detection

The urea biosensor and the amperometric detection

principle based on the urease-catalyzed hydrolysis of

urea are shown in Fig. 3. Carbamic acid and

ammonia are the initial enzymatic reaction products

of urea, and the carbamic acid is further hydrolyzed

to ammonia and carbon dioxide. The final products

namely, ammonia and carbon dioxide are

electroinactive, thus, oxidation current observed

during the enzymatic reaction must be attributed to

the intermediate product. It can be assumed that the

carbamic acid undergoes electrooxidation by

forming nitrogen and carbon dioxide.

Figure 3: The biosensor and the amperometric detection

principle based on the urease-catalyzed hydrolysis of urea.

Aiming to obtain easy reproducible, sensitive

and stable biosensing system the enzyme was

immobilized onto polymeric carriers. Enzymes,

which have amino and hydroxyl groups, may be

covalently immobilized by attachment to PUU

microparticles, which have unreacted NCO groups

and urea or urethane linkages are formed (

Fig. 4).

NCO groups of PUU at low temperature react faster

with amino than with primary alcohol groups or

water (Randall and Lee, 2002).

Whereas

immobilization procedure followed in aqueous

media remained free NCO groups react with water

by formation of CO

2

and they do not have any

inactivation effect on enzyme latter (Budriene et al.,

2007).

Figure 4: Immobilization scheme of the enzyme onto PC.

3.2 Characterization of Urea Biosensor

Biosensor based on the urease-MG electrode after

addition of urea in to electrochemical cell shows

substrate-dependent anodic response. The biosensor

shows fast response (90 % of steady state current

achieved in 1 min) and this feature is desirable for

analytical instruments. The urea calibration curves

obtained using biosensors based on different amount

of enzyme immobilized onto polymeric carriers at

applied electrode potential 0.4 V are shown in Fig.

5.

Figure 5: The urea calibration curves and linear range

obtained using different amount of enzyme immobilized

onto polymeric carriers. Applied electrode potential 0.4 V,

phosphate buffer solution, pH 7.2.

The efficiency of electron transfer expressed by

sensitivity of the biosensor depends on amount of

immobilized enzyme. The best results were obtained

by using 1540 U of urease for 0.5 g of PC (1 PC in

Fig. 5). This enzyme and PC ratio was taken as

optimal and used for measurements in milk. Linear

response of this type of urea biosensor lies in the

range of 1 – 10 mM (Fig. 5). The obtained results

show that the method of immobilization of enzyme

plays crucial role in biosensor design. Doubtless, the

proper immobilization avoids the enzyme from fast

inactivation and affords an effective electron transfer

0 3 6 9 12 15 18 21

0

40

80

120

160

200

240

I, nA

C

(

Urea

),

mM

1 PC

2 PC

3 PC

4 PC

Linear fit of 1 PC,

R = 0.9985

Linear fit of 2 PC,

R = 0.9988

CarbonElectrodebasedUreaSensor-ModificationofGraphiteandNewPolymericCarriersforEnzymeImmobilization

199

from the active centre of the enzyme via

intermediate products toward the electrode surface.

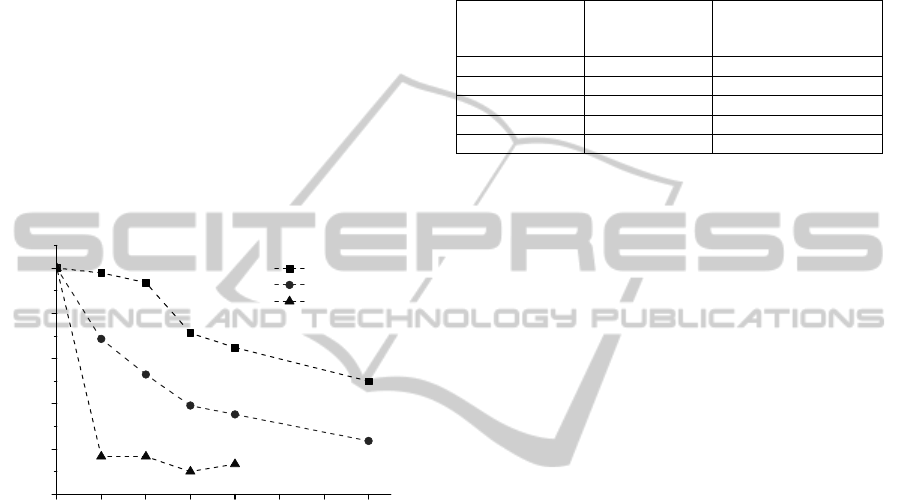

3.3 Urea Biosensor Stability

Stability of the biosensor designed using MG and

immobilized onto polymeric carriers urease was

investigated during one week (Fig. 6). The responses

to the standard urea solution (5 mM) were

periodically recorded at 20 °C. The residual

response of the best biosensor operated at potential

of 0.4 V was not less than about 50 % of initial

magnitude over the period of one week. Highest rate

of inactivation of the 4 PC biosensor activity

indicates that in this case the stability of the

biosensor was determined not by the inactivation

process of urease but just desorption of not cross-

linked to the PC enzyme (4 PC in Fig. 6).

Figure 6: Stability of the biosensors designed using MG

and different amounts of urease immobilized onto

polymeric carriers. Applied electrode potential 0.4 V,

phosphate buffer solution, pH 7.2.

3.4 Urea Determination in Milk

Amperometric type of sensors beside other well

known advantages such as comparable instrumental

sensitivity and amenability to miniaturization also

has one of very important feature – acceptability for

functioning in turbid media. Thus, in this report, we

present simple approach of the biosensor for

determination of urea in diluted milk. The

measurements have been carried out in conventional

electrochemical cell by adding urea spiked both

buffer solution and milk. The anodic current was

registered and the urea concentration was calculated

using urea calibration curve. The data are presented

in Table 1.

It was observed good correlation between data

obtained in buffer solution and in media containing

different concentrations of urea as well as amount of

milk (Table 1). The results encouraged us to carry

on further experiments concerning analysis of other

biological liquids.

Table 1: Comparison of urea concentration obtained in

buffer solution and in diluted milk using proposed

biosensor.

Added urea

concentration, mM

Detected urea

concentration in

milk, mM

Detected urea

concentration in buffer

solution, mM

1.99 2.10 2.08

2.99 3.04 3.00

4.98 4.94 4.89

6.95 6.77 6.70

9.90 9.52 9.50

4 CONCLUSIONS

For this research especially devoted MG and

polymeric carriers for enzymes have been fabricated

and tested as the electrode materials for the

amperometric urea biosensor.

It was revealed that the proposed biosensor can

be used for rapid and simple detection of urea in

diluted milk.

The biosensors exhibited fast response and

sensitivity dependent on amount of immobilized

enzyme. Although, synthesis of PC and enzyme

immobilization methodology was not optimized

properly yet, new polymeric carriers seems are very

promising for biosensors design. Thus, our future

investigations will be focused on improving of

synthesis of PC by using different initial molar ratios

of PVA and HMDI and immobilization of other

important biocatalysts.

ACKNOWLEDGEMENTS

This work was funded by the European Social Fund

under National Integrated Programme

Biotechnology and Biopharmacy, grant VP1-3.1-

SMM- 08-K01-005.

REFERENCES

Agui, L., Yanes-Sedeno, P., Pingarron, J.M., (2008). Role

of carbon nanotubes in electroanalytical chemistry: a

review. Anal. Chim. Acta 622, 11-47.

Budriene, S., Romaskevic, T., Pielichowski, K.,

Pielichowski, J., (2007). Synthesis and

characterization of polyurethane microspheres and

01234567

0

20

40

60

80

100

Response to 5 mM of urea

Time, days

2 PC

3 PC

4 PC

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

200

their application for immobilization of maltogenase.

Polym. Adv. Technol., 18, 67-71.

Fan, J., Yudasaka, M., Miyawaki, J., Ajima, K., Murata,

K., Lijima, S., (2006). Control of hole opening in

single-wall carbon nanotubes and single-wall carbon

nanohorns using oxygen. J. Phys. Chem. B, 110, 1587-

1591.

Miglior, F., Sewalem, A., Jamrozik, J., Bohmanova J.,

Lefebre, D. M., Motore, R. K., (2007). Genetic

Analysis of Milk Urea Nitrogen and Lactose and Their

Relationships with Other Production Traits in

Canadian Holstein Cattle. J. Dairy Sc. 90, 2468-2479.

Muti, M., Sharma, S. A. Erdem, Papakonstantinou, P.,

(2011). Electrochemical Monitoring of Nucleic Acid

Hybridization by Single-Use Graphene Oxide-Based

Sensor. Electroanalysis, 23 (1), 272-279.

Patton, C. J., Crouch, S. R., (1977). Spectrophotometric

and kinetics investigation of the Berthelot reaction for

the determination of ammonia. Anal. Chem. 49, 464-

469.

Randall, D. and Lee, S., (2002). The Polyurethane Book,

John Wiley & Sons, New York, USA.

Renny, E. F., Daniel, D. K., Krastanov, A. I., Zachariah,

C. A., Elizabeth, R., (2005). Enzyme based sensor for

detection of urea in milk. Biotechnol. & Biotechnol.

Equip. 19 (2), 198-201.

Voitechovic, E., Razumiene, E., Sakinyte, E., Barkauskas,

J., (2010). Investigation of bioelectrocatalytic systems

with PQQ-dependent GDH and carbonaceous

materials. Biologija. 56. (1-4), 83-87.

Wang, J., Kawde, A. N., Jan, M. R., (2004). Carbon-

nanotube-modified electrodes for amplified enzyme-

based electrical detection of DNA hybridization[J].

Biosens. Bioelectron. 20, 995-1000.

Qureshi, A., Kang, W. P., Davidson, J. L., Gurbuz, Y.,

(2009). Review on carbon-derived, solid-state, micro

and nano sensors for electrochemical sensing

applications. Diamond & Related Materials, 18, 1401-

1420.

CarbonElectrodebasedUreaSensor-ModificationofGraphiteandNewPolymericCarriersforEnzymeImmobilization

201