A Predictive-Reactive Dynamic Scheduling under Projects’ Resource

Constraints for Construction Equipment

Mona Asudegi

and Ali Haghani

University of Maryland at College Park, College Park, U.S.A.

Keywords: Project Management, Dynamic Scheduling, Resource Constraints, Construction Equipment, Optimization.

Abstract: Major portion of projects’ cost is dedicated to construction equipment’s costs which signify the importance

of employing optimal equipment’s schedules in projects. In this paper the problem of construction

equipment scheduling for a company with several ongoing projects in different regions is studied. The goal

is scheduling heavy construction equipment and their assignments to jobs so that the total cost for the

company and disruptions in projects’ schedules is minimized while considering the priorities and critical

paths of the projects. A robust predictive-reactive integer model with a hybrid dynamic approach is

employed in modeling the problem. Case studies showed considerable savings in cost and minimizing

disruption in schedules in real time.

1 INTRODUCTION

Equipment scheduling problem is the problem of

allocating jobs to equipment over time. Since

availability of equipment and also jobs’ schedules

change during the projects, it is important to solve

the resource scheduling in projects dynamically.

Literature on dynamic equipment scheduling is very

sparse. Changes in resources or jobs could result in

dynamic characteristics of projects (Ouelhadj and

Petrovic, 2009).

A considerable number of studies have been

done on scheduling, but studies in construction

equipment scheduling are very rare (Słowiński and

Węglarz, 1989). In (Dodin and Elimam, 2008) a

static mixed integer model for scheduling equipment

based on tradeoffs among several costs is proposed;

however, a static model is not as efficient as

dynamic models in dynamic environment of

projects. Cost of ownership or renting construction

equipment such as cranes form main portion of

project costs. So implementing an optimal resource

management in construction industry is one of the

main ways in reducing costs. Moreover, Ernst et al.

(Ernst et al., 2004) highlights necessity of designing

mathematical models for each area of application

due to their unique characteristics. Here equipment

scheduling in the area of construction management

is studied.

2 PROBLEM STATEMENT AND

METHODOLOGY

2.1 Problem Statement and

Methodology

Large construction companies in the United States

and all over the world conduct several concurrent

projects at different sites in different locations, while

having a limited number of construction equipment

spread over the sites which are idle some of the time

during a project. Heavy construction machines are

highly costly and their ownership or rental cost

constitutes a significant portion of project cost.

Besides available owned equipment located in sites,

a company could use the option of renting similar

equipment from outside providers in different cities.

Schedule of the projects with the need of a specific

machine, and transportation network information is

assumed to be available in real time. The goal is to

solve the decision problem on using owned

equipment or rentals and to assign jobs to them in

order to maximize the benefit to the company. Some

assumptions are made through the study. Labours

are paid hourly and they do not cost when they are

idle. Rentals can be left at their job location after

finishing their task. Finally, rental and salvage price

during usage period is determined based on prices

on the start day of the task. The incorporated

notation is first shown below.

186

Asudegi M. and Haghani A..

A Predictive-Reactive Dynamic Scheduling under Projects’ Resource Constraints for Construction Equipment.

DOI: 10.5220/0004287003340337

In Proceedings of the 2nd International Conference on Operations Research and Enterprise Systems (ICORES-2013), pages 334-337

ISBN: 978-989-8565-40-2

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

= Set of job site locations

, = Indices used for locations ,∈

= Set of works being done in site ∈

= Index used for works

= Index used for time (day)

= Beginning time of scheduling

1

= Latest time possible for starting work

= Earliest time possible for starting work

= Duration of work (in units of time)

= Travel time from location to location

= Transportation cost from location to

= Rental price from location for use in location

at time ($/day)

= Usage cost (depreciation cost) for an owned

equipment in location at time ($/day)

= Available owned equipment in at time

= Utility value of doing work at time ($)

Variables used in the model are as following.

1amachinefromlocationiassignedto

worknattimetinlocationj

0otherwise

1arentalmachinefromlocationi

assignedtoworknattimetinlocationj

0otherwise

Numberofavailablemachineswithnowork

assignedtoinlocationiattimet

The problem is modelled as a multi-objective model

incorporating several objectives as following.

i. Maximizing utility:

.

∈

∈

∈

(1)

ii. Minimizing transportation cost:

.

∈

∈∈

(2)

iii. Minimizing rental cost:

.

∈

∈∈

(3)

iv. Minimizing usage cost:

.

∈

∈∈

(4)

To combine all objectives, without loss of generality

it is assumed that they all have same weight and

importance for the company; however, knowing the

trade-offs between different objectives, the decision

maker can decide on the weight vector based on his

utility function by studying the Pareto set of

attributes (Bui and Alam, 2008). Following are the

constraints in the model.

∈

1;∀∈,∀∈

(5)

∈

∈

;∀∈,∀

(6)

∈

∈

∈

∈

;∀

∈,∀

(7)

0 ;∀∈,∀

(8)

,

;∀∈,∀∈,∀,∀∈

(9)

Constraints (5) enforce exactly one piece of

equipment being assigned to each job in the

acceptable time period. Constraints (6) assure not

sending more than available idle equipment from

each location to other locations. Constraints (7)

define the number of available idle equipment in

each location at each time period.

To define

, value of doing a job at time t, as

in (10), three factors are employed. First is cost and

penalty of conducting the work at any time other

than the planned schedule. This signifies the

difference between critical and non-critical jobs.

Second is the importance and priority of conducting

a job from the perspective of managers which can be

calculated using Analytic Hierarchy Process method

(Saaty, 1990). Third is the linkage between different

jobs due to the technical issues in a project.

0;

∑

∈

1

∗

∗

∑

∈

∗;

(10)

is set of all projects which project is one of

their predecessors.

is set of all projects which are

in need of the equipment at time t. 01 is the

project

’s importance index for the managers, and

is the budget assigned to project .

The predictive-reactive scheduling has two steps.

The model presented above generates a predictive

schedule employing available data in the first stage.

In the second stage, which can be repeated several

times, the original model is adjusted in order to

revise the schedule in response to real time events

and changes. In this stage notations are borrowed

from the first stage; however, the additional letter

“P” identifies updated information and the new set

of variables after rescheduling time (tp

0

in stage

APredictive-ReactiveDynamicSchedulingunderProjects'ResourceConstraintsforConstructionEquipment

187

two; e.g. TLP

n

is the updated latest starting time for

work n. The multi-objective function in the second

step contains additional elements as following.

i. Minimizing rental cancelation penalty:

.

0.3

∈|

|

,

∈

|∈

(11)

ii. Minimizing rental cancelation after equipment is

sent:

.

∈|

|,

∈

|∈

(12)

iii. Minimizing transportation cost due to job

cancelation:

.

∈

|,

∈

|∈

(13)

iv. Minimizing equipment schedules’ disruption due

to changes in schedules:

.

∈|

∈

|∈

(14)

Objective (11) minimizes 30% cancelation fee for

rentals scheduled for the next 48 hours in step one

which are cancelled in step two. Rental fee is

assumed not to be refundable after a shipment is

occurred in objective (12). Objective (14) minimizes

number of disruptions in the new schedule

comparing to step one’s schedule. Assigning

appropriate weights to different objectives and

summing them up, the problem would be a multi-

objective problem. An additional constraint (15), is

also added to the original constraints to assure no

equipment being assigned to the cancelled jobs.

∈

0;∀∈,∀

∈

|

0

(15)

Employing updated data into the new model a new

optimal schedule will be generated in stage two.

2.2 Numerical Analysis

The proposed dynamic model is applied on several

randomly generated examples with different

problem sizes; however, due to space limit, some of

the results are going to be discussed here. A set of

cases for a company with 25 site locations, 30 jobs,

and 100 day schedule is studied. Changes to the

projects are detected on day 40th including addition

of different number of new jobs. Projects’

information and resources data are exogenous and

generated randomly. Machine used in solving the

problem is a desktop computer with a 2.8 GHz CPU

and 1.99 GB of RAM. Xpress-IVE 7.0 is employed

as the optimization software.

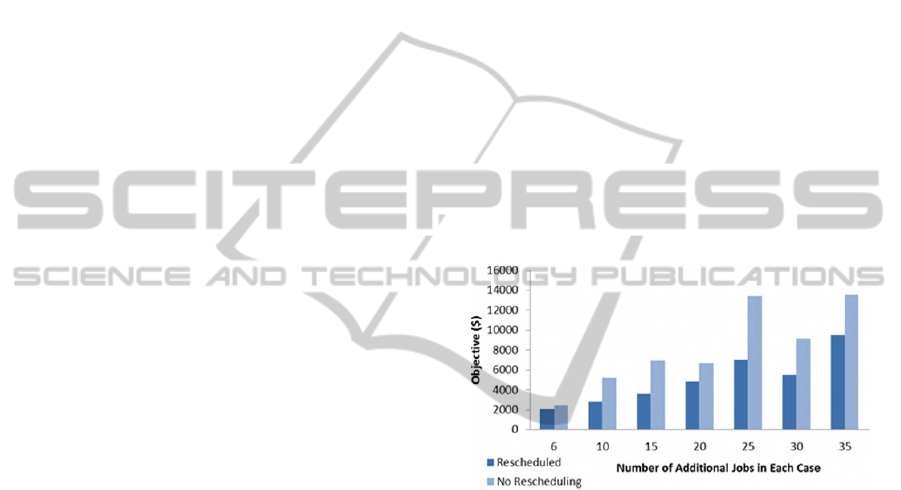

Project’s cost for both dynamic and static models

for several randomly defined cases with different

number of additional jobs are compared in Figure 1.

In dynamic model, rescheduling is run when

changes are detected, while in static model

equipment are assigned to projects on a first come

first serve basis without considering optimal

reduction of cancelation penalties, unnecessary

transportation costs and delays in critical jobs. The

figure shows that applying rescheduling has reduced

costs in projects.

Figure 1: Effectiveness of rescheduling in reducing

projects' costs for several cases.

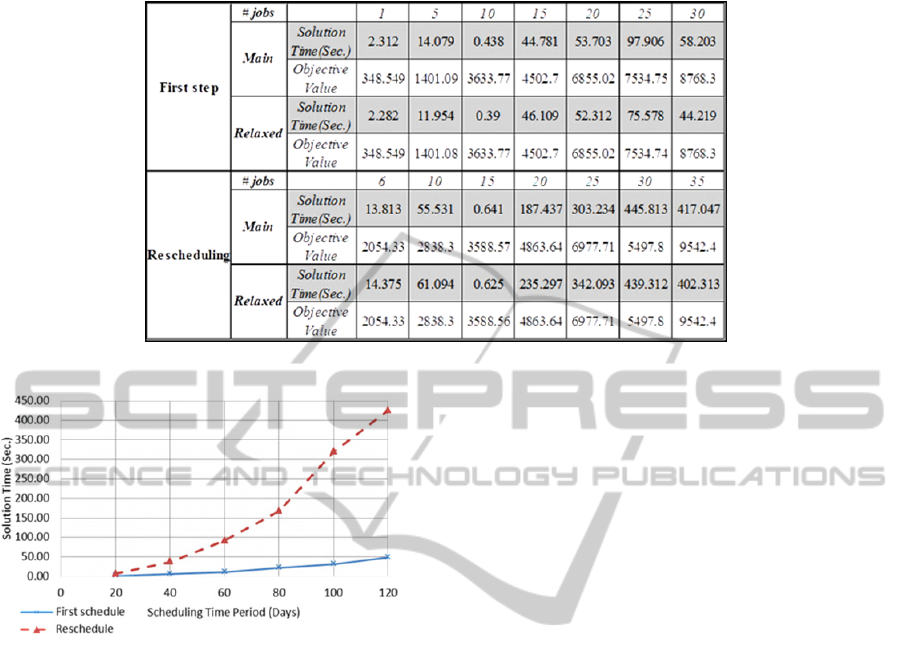

An interesting result from solving the model with

both binary variables and relaxed binary variables is

that although model’s coefficient matrix is not uni-

modular, both models give the same set of solutions

(Table 1). Interestingly enough, relaxing binary

variables which are the majority of the variables in

the problem does not improve the solution time

considerably. This might be due to dependency of

the node on which the algorithm is branching.

Another observation is that as the problem size

grows solution time increases significantly. Figure 2

illustrates sensitivity of solution time to time horizon

length in a case with 25 site locations and 5

additional jobs in the second stage. Results show, for

an average medium size problem, the dynamic

model can be solved in a reasonable amount of time

and is beneficiary to the economy of the project.

However, for a large size problem development of

an appropriate heuristic is inevitable.

ICORES2013-InternationalConferenceonOperationsResearchandEnterpriseSystems

188

Table 1: Objective function and solution time for main and relaxed models.

Figure 2: Increase in solution time with the increase of

scheduling horizon, for 20 jobs in the first step.

3 CONCLUSIONS

In this study the problem of assigning and

scheduling construction equipment to jobs of several

projects over several sites of a construction company

considering the priorities and critical paths of the

projects is modelled as robust predictive-reactive

model. In the proposed dynamic model not only the

demands are satisfied and the cost is minimized, but

also interruptions in the project schedules due to

resource availabilities are minimized. The model is

capable of solving a moderate size problem in a

reasonable amount of time; however, dynamic

model makes it complex for large scale problems

and finding optimal solution would be challenging.

Designing an appropriate heuristic for large scale

problems and also considering stochastic nature of

projects is remained for future work.

ACKNOWLEDGEMENTS

Authors would like to thank FICO for kindly

providing the academic license of XPRESS-IVE 7.0

for this research.

REFERENCES

Bui, L. T. and Alam, S. (2008) 'An Introduction to Multi-

Objective Optimization', Multi-Objective Optimization

in Computational Intelligence: Theory and Practice,

1-19.

Dodin, B. and Elimam, A. A. (2008) 'Integration of

equipment planning and project scheduling', European

Journal of Operational Research, 184(3), 962-980.

Ernst, A. T., Jiang, H., Krishnamoorthy, M. and Sier, D.

(2004) 'Staff scheduling and rostering: A review of

applications, methods and models', European Journal

of Operational Research, 153(1), 3-27.

Ouelhadj, D. and Petrovic, S. (2009) 'A survey of dynamic

scheduling in manufacturing systems', Journal of

Scheduling, 12(4), 417-431.

Saaty, T. L. (1990) 'How to make a decision: the analytic

hierarchy process', European journal of operational

research, 48(1), 9-26.

Słowiński, R. and Węglarz, J. (1989) Advances in project

scheduling, Elsevier Science Ltd.

APredictive-ReactiveDynamicSchedulingunderProjects'ResourceConstraintsforConstructionEquipment

189