OR-based Eco-efficiency Measuring for Economic-ecological

Trade-offs Analysis

L. Lauwers

1,2

and J. Van Meensel

1

1

Institute for Agricultural and Fisheries Research, Burg. Van Gansberghelaan 115, Merelbeke, Belgium

2

Department of Agricultural Economics, Ghent University, Coupure Links 653, Ghent, Belgium

Keywords: Eco-efficiency, Productive Efficiency, Data Envelopment Analysis, Materials Balance Principle.

Abstract: Traditional eco-efficiency measurements insufficiently support trade-offs analysis. The objective of the

paper is to explore trade-offs analysis support from the branch of productive efficiency analysis techniques.

The paper focuses on the linear programming based data envelopment analysis (DEA) models, adjusted for

an analogous treatment of the economic and environmental outcomes. In particular, the models are adjusted

for the materials balance principle. They allow for differentiating between win-win and trade-offs while

substituting for inputs or outputs. Their results are obvious for simple production processes, but the message

gets blurred with multiple inputs, outputs and outcomes. The paper explores multiple economic-ecological

trade-offs with materials-balance-based efficiency DEA models with a simple illustrative case of 62 typical

pig firms. Separate DEA models calculate technical, economic and the efficiency for nutrient, water and

energy use. Mutual win-wins and trade-offs are shown. Shortcomings are discussed and further model

adjustments based on directional distance functions, instead of radial ones, are proposed.

1 INTRODUCTION

Eco-efficiency indicators integrate economic and

ecological values in a ratio key figure (Dahlström

and Ekins, 2005) and compare performances on a

discrete basis. They fail to derive more continuous

management information on how an outcome, e.g.

the economic one, evolves when trying to improve

another, e.g. the environmental one. One solution is

to consider the underlying production process, and

to analyse drivers for both economic and

environmental outcomes. The production process is

a physical transformation of inputs into outputs

(Coelli et al., 2005). As such, it contains no

economic or ecological value, unless more

information is provided. Prices are necessary to

derive costs, revenues and profit. When linking

production data with materials balance information

also ecological values can be derived (Coelli et al.,

2007); (Lauwers, 2009).

Huppes and Ishikawa (2005) and Kuosmanen

and Kortelainen (2005) show how eco-efficiency

can be measured with frontier models. Reviews of

environmentally adjusted frontier models are given

by Tyteca (1996), Scheel (2001) and Lauwers

(2009). Two types exist: parametric stochastic and

non-parametric data envelopment analysis (DEA)

models. The first draws a functional form

enveloping a set of observed data, the second

envelops data with a piece-wise linear frontier. In

this paper, we concentrate on the non-parametric

methods, based on linear programming. An on-going

discussion in literature is how to incorporate the

environmental outcome in the production model and

to derive eco-efficiency. This paper will shortly

summarize this state-of-the-art in order to allow the

reader to get pace with the modelling challenges.

The objective of the paper is to explore multiple

economic-ecological trade-offs with materials-

balance-based efficiency DEA models. Trade-offs

are illustrated with one economic, profit, and three

environmental outcomes from a simple illustrative

case of 62 typical pig finishing firms. Besides DEA

models for calculating technical efficiency and

economic efficiency, similar models are conceived

for calculating the efficiency for nutrient, water and

energy use. This allows to derive their mutual win-

wins and trade-offs. Shortcomings are discussed and

further model adjustments are proposed.

339

Lauwers L. and Van Meensel J..

OR-based Eco-efficiency Measuring for Economic-ecological Trade-offs Analysis.

DOI: 10.5220/0004276201410144

In Proceedings of the 2nd International Conference on Operations Research and Enterprise Systems (ICORES-2013), pages 141-144

ISBN: 978-989-8565-40-2

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

2 MODELS OF PRODUCTIVE

EFFICIENCY ANALYSIS

This section shortly describes, first, how productive

and eco-efficiency differ, but to a certain extent are

interlinked and, second, how these differences and

similarities can appropriately be modelled.

2.1 Productive and Eco-efficiency

Firms differ in efficiency to transform inputs into

outputs. For measuring a firm’s efficiency, frontier

functions are used. Frontier functions represent the

efficient transformation, this is no other firm can be

found that use less input for the same output, or

generates more output with the same input. The

distance of a firm’s input-output configuration to the

frontier is a measure for technical efficiency.

When price information is added to the physical

input-output transformation, economic outcomes

such as profit can be derived. More, the optimal

input-output combinations that maximise profit can

be searched. The concept of optimal combination of

input is measured as allocative efficiency.

The production process has various outcomes.

We consider an outcome as issuing from the net

utility or disutility of the set of outputs, corrected for

the sacrifices that had been put into the

transformation. As such, outcome is distinguished

from the mere physical output. When prices of

inputs (P

Xi

) and output (P

Yj

) are known, economic

margin (Π), e.g. profit, can be calculated as:

Π = ∑P

Y

j

* Y

j

- ∑ P

Xi

* X

i

(1)

The pressure a firm exerts on the environment is

another outcome, e.g. the nitrogen balance is an

indicator for disutility from by-products resulting

from pig finishing. When nitrogen contents of inputs

(N

Xi

) and output (N

Yj

) are known, the balance (B)

can be calculated similar to the economic margin:

B = N

Xi

* X

i

- ∑N

Y

j

* Y

j

(2)

Eco-efficiency measures how much profit is

obtained over the (potential) environmental burden:

Π / B (3)

2.2 Data Envelopment Models

Technical efficiency, TE, (θ) can be measured with a

linear programming model drawing a piece-wise

linear envelop around the data set. The general form

is described by the formula (4) – (7). For each farm

i, with (x

i

, y

i

) as input –output configuration, another

LP and efficiency score (θ) is obtained. Each

solution also gives a vector of weight λ that

determines the envelop, or production frontier. This

technique of deriving the frontier and a TE score is

called DEA, data envelopment analysis. Technical

inefficiency, as the distance from the actual (x

i

, y

i

)

to the frontier, can be measured in various way, the

model (4)-(7) measures TE from a radial input –

minimising perspective:

min

θ

,

λ

Θ (4)

s.t. - y

i

+ Y λ ≥ 0 (5)

θx

i

- X λ ≥ 0 (6)

λ ≥ 0 (7)

with:

(x

i

, y

i

) the input –output of farm i;

Y is the output matrix of all n firms;

X is the input matrix of all n firms;

λ is a scalar of weights.

With price information p

i

, economic efficiency

scores can be measured from similar models. The

model (8)-(11) results in a cost-minimising vector

x°

i

for each firm i:

min

λ

,

x°i

p

i

x°

i

(8)

s.t. - y

i

+ Y λ ≥ 0 (9)

x°

i

- X λ ≥ 0 (10)

λ ≥ 0 (11)

with:

(x

i

, y

i

) the input –output of farm i;

Y is the output matrix of all n firms;

X is the input matrix of all n firms;

λ is a scalar of weights;

p

i

is the vector of input prices

The economic efficiency CE is then calculated from

the observed cost-minimizing vector and the overall

optimum, OO (12), which then can be decomposed

in a technical, TE, and an allocative efficiency,

CAE, component (13).

CE= p

i

x°

i

/ OO (12)

CAE= CE / TE (13)

We build similar models with the resource use

coefficients n

i

, w

i

, and e

i

instead of the prices p

i

, and

search for the resource use minimizing vector.

Similar to (12), nitrogen (NE), water (WE) and

energy (EE) use efficiency can be calculated. As TE

remains the same over the four efficiency

ICORES2013-InternationalConferenceonOperationsResearchandEnterpriseSystems

340

measurements, the various environmental efficiency

scores then leads to nitrogen use allocative

efficiency (NAE), water use allocative efficiency

(WAE) and energy use allocative (EAE) score.

Scores estimate improvement potentials. TE

scores show the physical improvement margin,

which will not differ across the various outcome-

optimisation models. Regardless whether we want to

minimise cost or resources use, a radial contraction

of inputs will proportionally save on both objectives.

The interpretation of AE concerns the substitution of

inputs and provides a differentiated picture of trade-

offs.

3 RESULTS

3.1 The Pig-finishing Case

The pig-finishing process is used as a case with kg

marketable pig as desired output and feed and

piglets as the main variable inputs. In the short run,

the number of pig places (capital input) and labour

can be considered as fixed. The finishing activity

starts with a piglet of 23 kg and ending with a hog of

about 113 kg. This takes about 140 days, thus each

pig place can be occupied by more than one piglet

per year to finish as a marketable pig. A set of 62

typical farms are drawn from an original data panel

of about 300 farms over 3 bookkeeping years (2007-

2009). Summarizing statistics are given in table 1.

Table 1: Statistics of the data set of 62 typical farms.

Feature Mean Minimum Maximum

Y, tonnes marketable pig /year 262 56 771

Pig price, euro/kg 1.12 0.96 1.20

Nitrogen content pig, kg/kg 0.026 0.026 0.026

Feed input, kg/year 633 143 1944

Feed price, euro/kg 0.23 0.17 0.26

Nitrogen content feed, 0.025 0.025 0.025

Water use, liter per kg 1.59 1.06 2.22

Energy use, MJoule/kg 3.40 3.40 3.40

Number of piglets per year 2467 484 6216

Price per piglet 40 31 52

Nitrogen content, kg/ piglet 0.58 0.52 0.65

Water use, liter/piglet 462 328 614

Energy use, MJoule/piglet 827 718 971

3.2 Efficiency Analysis

Results of the various efficiency measures issuing

from the input-minimising approach, are given in

table 2. TE is 0.90, so improvement margins on the

farm set is about 10%. Cost allocative efficiency is

0.97, improvement margin is about 3%. Total cost-

minimising potential is about 13%. Improvement

potential on environmental performance is larger for

nitrogen, smaller for water and energy use.

Table 2: Statistics on the efficiency indicators.

Efficiency indicator Average Minimum MaxiMum

Technical efficiency 0.903 0.786 1

Cost allocative efficiency 0.969 0.846 1

Nitrogen all. efficiency 0.918 0.737 1

Water use all. efficiency 0.986 0.932 1

Energy use all. efficiency 0.977 0.879 1

3.3 Trade-offs Analysis

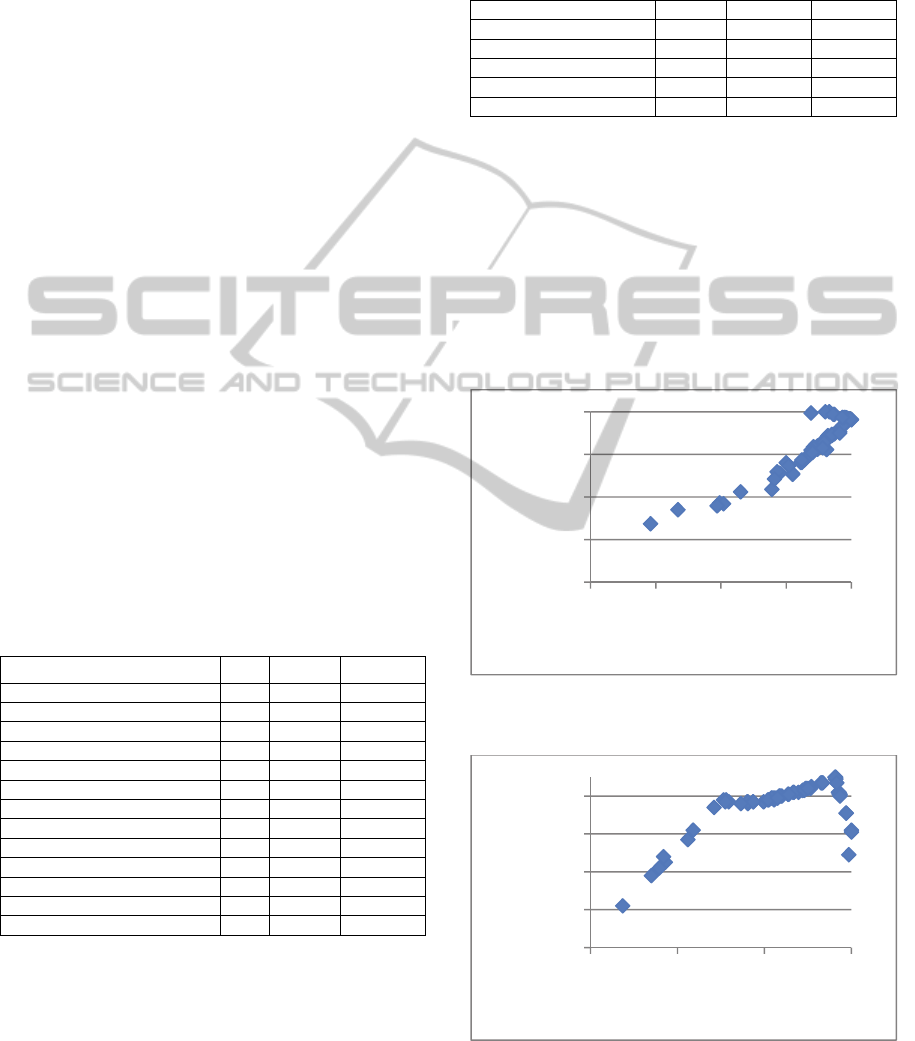

Figure 1 show the link between CAE and NAE. A

majority of farms face a win-win when substituting

inputs for optimising costs: they will also win on

environmental performance. A minority faces trade-

offs. This confirms theoretical derivations (Lauwers,

2009). More atypical is, e.g. the link between NAE

and WAE (Figure 2). Other pairwise comparisons

yielded much more blurred information.

Figure 1: Win-win and trade-offs between cost (CAE) and

nitrogen allocative efficiency (NAE).

Figure 2: Win-win and trade-offs between nitrogen (NAE)

and water use allocative efficiency (WAE).

0,600

0,700

0,800

0,900

1,000

0,800 0,850 0,900 0,950 1,000

NAE

CAE

0,910

0,930

0,950

0,970

0,990

0,700 0,800 0,900 1,000

WAE

NAE

OR-basedEco-efficiencyMeasuringforEconomic-ecologicalTrade-offsAnalysis

341

4 DISCUSSION

The research reported in this paper confirms, to

some extent, previous trade-offs analysis results,

found for only one economic and one environmental

performance indicator (Van Meensel et al., 2010).

However, challenging observations are made and

needs further discussion. Some of the pair-wise

trade-off analyses deviate strongly from the ideal-

type differentiation between win-wins and trade-

offs. Moreover, extra inputs, e.g. labour and capital,

further blur this picture. Finally, improvement

margins seem rather low, which is not a big

problem, because small differences at the cost

minimisation side will be leveraged to bigger

relative differences at profit level, but the problem

rather becomes one of detecting causal links.

As the conventional approach show some

inconveniencies, other types of models need to be

explored on their ability to provide equivalent

information. From literature, we see at least three

eligible types of directional distance functions: one

based on a directional vector that is firm-specific

(see also Picazo-Tadeo et al., 2012), another based

on a profit maximisation model (see e.g. Singbo and

Lansink, 2010), and finally a similar one for

materials balance minimisation.

5 CONCLUSIONS

Environmentally adjusted data envelopment models,

built in an analogous way to the economic efficiency

model, yield allocative efficiency scores that support

economic-ecological trade-offs analysis. This

confirms that earlier work can be generalised, but

the multiple outcome (economic plus three

environmental) comparison that has been done in

this paper reveals that other paths for a more

integrated eco-efficiency and trade-offs analysis are

necessary. Eligible is the use of directional distance

functions.

REFERENCES

Coelli, T. J., Rao, D. S. P., O’Donnell, C. J., Battese, G.,

2005. An introduction to efficiency and productivity

analysis. Springer, New York.

Coelli, T., Lauwers, L., Van Huylenbroeck, G., 2007.

Environmental efficiency measurement and the

materials balance condition. Journal of Productivity

Analysis, 28, 3-12.

Dahlström, K., Ekins, P., 2005. Eco-efficiency trends in

the UK steel and aluminium industries: differences

between resource efficiency and resource productivity,

Journal of Industrial Ecology, 9, 171-188.

Huppes, G., Ishikawa, M., 2005. A framework for

quantified eco-efficiency analysis. Journal of

Industrial Ecology, 9, 25-41.

Kuosmanen, T., Kortelainen, M., 2005. Measuring eco-

efficiency of production with data envelopment

analysis. Journal of Industrial Ecology, 9, 59-72

Lauwers, L., 2009. Justifying the incorporation of the

materials balance principle into frontier-based eco-

efficiency models. Ecological Economics, 68, 1605-

1614.

Picazo-Tadeo, A. J., Beltran-Esteve, M., Gomez-Limon J.

A., 2012. Assessing eco-efficiency with directional

distance functions. European Journal of Operational

Research, 220, 798-809.

Scheel, H., 2001. Undesirable outputs in efficiency

valuations. European Journal of Operational

Research, 132, 400-410.

Singbo, A.G., Oude Lansink, A., (2010). Lowland farming

system inefficiency in Benin (West Africa): directional

distance function and truncated bootstrap approach.

Food Security, 2, 367-382.

Tyteca, D., 1996. On the measurement of the

environmental performance of firms - a literature

review and a productive efficiency perspective.

Journal of Environmental Management, 46, 281-308.

Van Meensel, J., Lauwers, L., Van Huylenbroeck, G.,

2010. Communicative diagnosis of cost-saving options

for reducing nitrogen emission from pig finishing.

Journal of Environmental Management, 91, 2370-

2377.

ICORES2013-InternationalConferenceonOperationsResearchandEnterpriseSystems

342