Ontology Driven Approach for Intelligent Energy Management in

Discrete Manufacturing

Hendro Wicaksono

1

, Sven Rogalski

2

and Jivka Ovtcharova

2

1

Intelligent Systems and Production Engineering/ Process and Data Management in Engineering,

FZI Research Center for Information Technology, Haid-und-Neu Str. 10-14, D-76131, Karlsruhe, Germany

2

Institute for Information Management in Engineering, Karlsruhe Institute of Technology,

Zirkel 2 Building 20.20, D-76131, Karlsruhe, Germany

Keywords: Energy Efficiency, Energy Management, Knowledge Acquisition, Machine Learning, Manufacturing,

Ontology.

Abstract: In recent years ontologies have been used for knowledge representation in different domains, such as energy

management and manufacturing. Researchers have developed approaches in applying ontologies for

intelligent energy management in households. In the manufacturing domain, ontologies have been used for

knowledge management in order to provide a common formal understanding between the stakeholders, who

have different background knowledge. Energy management in a manufacturing company involves different

organizational entities and technical processes. This paper proposes an approach to applying ontology for

intelligent energy management in discrete manufacturing companies. The ontology provides a formal

knowledge representation that is accessible by different human stakeholders as well as machines in the

company. This paper also demonstrates the methods used to construct and to process the ontology.

1 INTRODUCTION

Facing a politically challenging future - determined

by environmental targets, the finite nature of fossil

energy and a constant population increase - energy

and resource efficiency has developed into one of

the most crucial issues of the 21st century.

Following industrialisation, especially in countries

with emerging markets, there has been a significant

increase of energy demands in the past decade.

Besides the ecological and social motivation,

costs also play a decisive role. Products with many

variants have made processes more complex. These

are often very energy intensive and therefore

expensive. This implies that on one hand,

manufacturers need to be flexible in order to satisfy

these diverse demands. On the other hand, customers

demand high quality and often more precise

products (Kinkel, 2005). In addition, increasing

energy prices reduce the revenue span. Hence,

energy efficiency in accordance with the

economization of production costs is an important

competitive factor in the energy-intensive industries,

such as manufacturing.

A suitable solution to address this problem is the

introduction of corporate energy management. This

can be established depending on the size and energy

intensity of the company. Energy management

defines the sum of all processes and measures which

are developed and implemented to ensure minimal

energy consumption with the given demand. An

energy management system (EnMS) is a systematic

way to define the energy flows and serves as a basis

for decisions to improve energy efficiency. An

EnMS includes the implementation of organization

and information structures that are necessary for

energy management, including the required tools for

this purpose (Kahlenborn et al., 2010). The standard

ISO 50001 describes the requirements for energy

management systems for industrial companies.

Most manufacturing companies face problems in

implementing the energy management standards.

There are often no standardizations in their operation

portfolios (plants, sites, etc.). The energy consuming

production processes, building infrastructures, as

well as power plants are documented and managed

separately and in an unstructured manner.

Management has little insight into the usage of

energy in the operation, due to the knowledge gap

between managers and operators. Managers do not

108

Wicaksono H., Rogalski S. and Ovtcharova J..

Ontology Driven Approach for Intelligent Energy Management in Discrete Manufacturing.

DOI: 10.5220/0004141601080114

In Proceedings of the International Conference on Knowledge Engineering and Ontology Development (KEOD-2012), pages 108-114

ISBN: 978-989-8565-30-3

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

have the tools to manage the energy usage over

different vertical and horizontal levels of the

organization. Operators often do not realise whether

their activities and decisions create excessive energy

usage or demand. Best practices to avoid energy

wastage are only known by some employees, but the

other employees do not have access to this

knowledge.

An important step in energy management is to

measure the energy consumption at different levels

of granularities. This can be done using data

acquisition systems. The framework of a data

acquisition system contains signals, sensors, signal

conditioning, hardware and a computer with

software. Due to the various technologies of data

acquisition systems, connectivity and

standardization are important issues to establish an

automated energy management system. Most of the

meters have to be read manually and thus it presents

problems in accuracy.

The energy data acquisition systems are not

integrated with other IT systems, such as Enterprise

Resource Planning (ERP) or Material Execution

System (MES). It is difficult to relate the energy

consumption and demand with manufacturing

operations, employee activities and business

processes. It causes an inaccuracy of energy cost

allocation to the produced goods or services.

This paper proposes an ontology based approach

to solve the problems mentioned above and at the

same time providing a knowledge base that can be

accessed by intelligent systems.

2 THE APPLICATION OF

ONTOLOGIES IN ENERGY

MANAGEMENT AND

MANUFACTURING DOMAINS

For the last ten years researchers have been applying

ontologies as knowledge representation in various

domains, such as medicine, agriculture, biology,

software engineering, etc. Ontology has proven to be

a solution to the shared understanding problems

among people and even software. It is used to

harmonize the knowledge gap between customers

and manufacturers during the requirement elicitation

in the pre-contract phase of the product lifecycle

(Wicaksono et al., 2012). An ontology driven

approach is also used to detect semantic ambiguities,

uncertainties and contradictions in business and IT

service management, therefore it overcomes the

business gap between many IT service providers

(Valiente et al., 2012).

In the energy management domain, ontology has

been utilized as a representation of the knowledge

base for an intelligent system that monitors and

controls the energy consumption in a household

(Wicaksono and Rogalski, 2010). The rules

represented in SWRL are integrated in the OWL-

Ontology. Wicaksono, Rogalski, and Kusnady

(2010) developed an approach to allow the semi-

automatic generation and instantiation of ontology

elements using a machine learning algorithm

(Wicaksono et al., 2010). Ontology is also used to

classify home electrical appliances produced by

various home appliance vendors and manufacturers

to allow a comparative analysis of their energy

consumptions (Shah et al., 2011). Furthermore it is

also used to represent functionalities of

heterogeneous devices from different technologies

used for home energy management (Rossello-

Busquet et al., 2011).

In the manufacturing domain several studies

have already been conducted on the application of

ontology to structures and the integration of

knowledge from the different systems or

stakeholders. It begins with an approach from

Lemaignan et al., (2006), which proposed an upper

OWL ontology for manufacturing domain and

presented two applications in cost estimation and

multi-agent systems (Lemaignan et al., 2006).

Lin and Harding developed an approach to

support information autonomy that allows the multi-

disciplinary, inter-enterprise stakeholders to use

their own terminology and information model and

simultaneously facilitate the communication and

information exchange among them (Lin and

Harding, 2007).

In chemical industries, ontologies are also used

to model different types of work processes. It allows

the formal representation of operational processes

throughout the plant life cycle (Hai et al., 2011).

Panetto et al., (2012) proposed an approach for

facilitating a system’s inter-operability in a

manufacturing environment based on an ontological

model for inter-operating, all-application software

that shares information during a product lifecycle.

The approach tried to address the difficulties in

managing heterogeneous information scattered

within organizations. It focused on the concept that a

product should embed the information about itself

(Panetto et al., 2012).

Until today, there have been no researchers who

have developed approaches in the use of ontology to

support energy management in manufacturing. In

this paper we propose an approach that adapts the

OntologyDrivenApproachforIntelligentEnergyManagementinDiscreteManufacturing

109

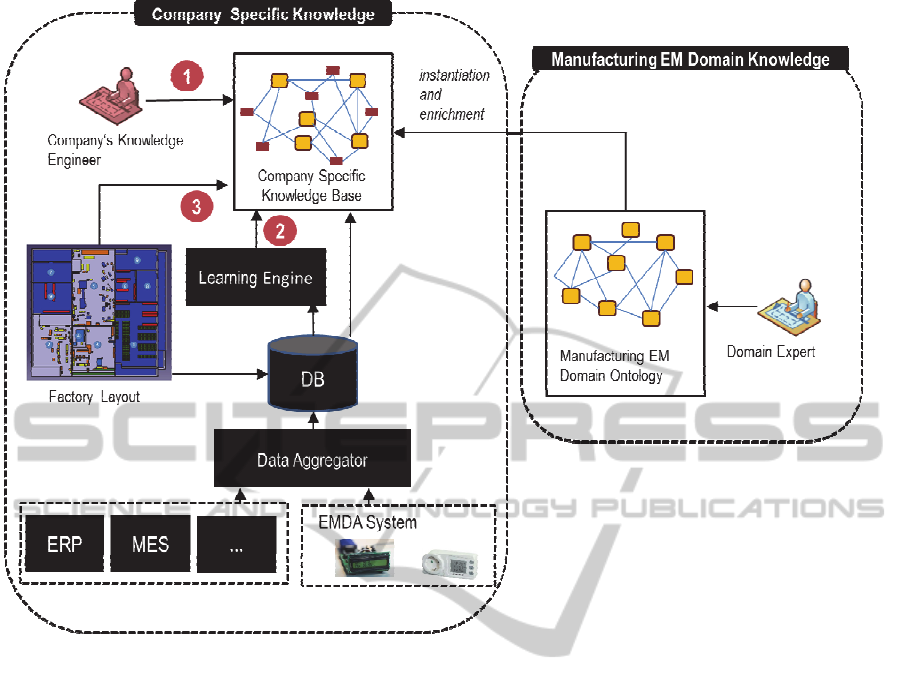

Figure 1: Architecture overview of intelligent energy management in manufacturing using ontology.

home energy management ontology to the

manufacturing domain, resulting in manufacturing

energy management ontology. We present some

methods to generate the ontology as well.

3 CONCEPT OF ONTOLOGY

BASED INTELLIGENT

ENERGY MANAGEMENT IN

MANUFACTURING

In our work, we use OWL – Web Ontology

Language to express the knowledge model. OWL is

originally a mark-up language for publishing and

sharing ontologies on the web (Bechhofer et al.,

2004)

The ontological classes as well as their attributes

and relation definitions representing automation

devices; for instance sensors, energy meters,

building environments, production facilities,

products and resources; are created manually by

experts. The ontology containing these hand-crafted

elements builds the knowledge base corresponding

to the manufacturing energy management domain

knowledge. It contains only the ontological classes

or Tbox elements that describe the knowledge

structurally and terminologically. It provides a

common conceptual vocabulary in the

manufacturing energy management domain. It does

not contain any ontological individuals or Abox

components.

The domain knowledge represents the meta

model of a manufacturing energy management

system, therefore it owns the validity for any

manufacturing company and does not contain any

instance-specific information. It also includes

SWRL rules corresponding to common practices of

energy management in manufacturing. SWRL is a

mark-up language that combines OWL and RuleML

(Rule Markup Language) and enables the integration

of rules in OWL ontology (Horrocks et al., 2004).

The domain knowledge is added with company-

specific rules. Some rules are created by the

knowledge engineers in the company. Other rules

are created semi-automatically by applying machine

learning algorithms. The algorithms generate

association and classification rules from the hidden

KEOD2012-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

110

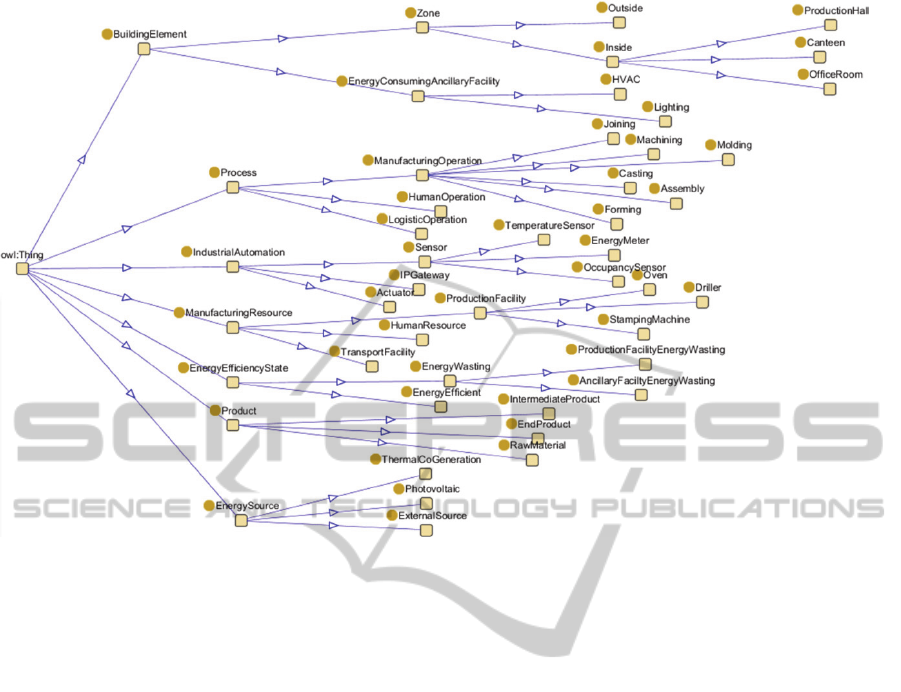

Figure 2: Class hierarchy of manufacturing energy management domain ontology.

knowledge that is extracted from the collection of

energy, production and energy-related infrastructure

data. The rules are converted to SWRL format and

integrated into the ontology.

The Abox knowledge elements are created semi-

automatically based on factory configuration and

layout. For this purpose, we have developed a

method for interpreting the semantic information

from building and factory construction drawings

(Wicaksono and Rogalski, 2010). This will result in

an instance of the manufacturing energy

management domain ontology containing company-

specific knowledge elements. Figure 1 depicts the

architectural overview of our approach for

developing the intelligent energy management

system.

4 THE ONTOLOGICAL

KNOWLEDGE DOMAIN

MODEL

Raza and Harrison (2011) have developed an

ontological knowledge model for Product Lifecycle

Management (PLM) in the automotive industry,

based on relationships among products, processes

and resources (Raza and Harrison, 2011). In our

approach, we propose a similar method and add

knowledge elements representing energy

management related knowledge such as ancillary,

transport or intra-logistics and energy conversion

facilities.

Figure 2 depicts the class hierarchy of the

manufacturing energy management domain

ontology. At the highest level of ontology under the

concept

Thing, we put the classes Product,

Process, ManufacturingResource,

BuildingElement, EnergySource, and

EnergyEfficiencyState. Product represents

the discrete products, such as the purchased

materials or products, the intermediate products that

are manufactured within the factory and the end

products that will be sold to the customers. We

define energy relevant properties on the concept

Product, for instance

hasVolume, hasWeight,

hasMaterialType. Based on these properties, it

can be decided which machine the product should be

manufactured with and how much energy it

consumes.

We develop the process hierarchy similar to the

one in the MASON approach (Lemaignan et al.,

2006) consisting of

ManufacturingOperation,

HumanOperation and LogisticOperation. All

of those processes can affect the energy

consumption in the company. For the sake of

OntologyDrivenApproachforIntelligentEnergyManagementinDiscreteManufacturing

111

simplicity, in this paper we present only several

main manufacturing operations classes, for instance,

Forming, Joining, Assembly, Machining,

Molding, and Casting. The Process class has the

property

hasEnergyConsumption. We put the

object property

produces in

ManufacturingOperation, to relate it to

Product and operatedOn to

ProductionFacility. The concept

LogisticOperation represents the intra-logistic

operation or transport between production facilities.

It has the properties

hasOrigin and

hasDestination with ProductionFacility

being the range of both properties.

The class

ManufacturingResource consists

of the subclasses

ProductionFacility,

TransportFacility, and HumanResource. It has

a relationship to

Process through the object

property

operates.

EnergySource represents the energy generation

sources that are possibly used by the company. They

can be from a utility company or internally

generated, such as photovoltaic or thermal co-

generation. We add the object property

supplies

with the classes

ProductionFacility and

EnergyConsumingAncillaryFacility as the

ranges, in order to allow the modelling of the energy

flow within the company.

The class

EnergyEfficiencyState

corresponds to energy efficiency that should be

achieved and energy wasting or peak loads that have

to be avoided within energy management activities.

Through this class we can classify which practices

or constellations could improve the energy

efficiency, or which cause energy inefficiency. We

consider a peak load as a state that should be

prevented, since it can instantaneously cause high

energy allocation, thus causing higher energy costs.

The class

BuildingElements models the

building structures, such as rooms, production halls,

canteen, offices, as well as the energy consuming

facilities that indirectly affect the production

processes, such as lighting and HVAC systems. By

using the approach in interpreting the factory layout

drawing, the ontological elements of the classes can

be generated semi-automatically (Wicaksono and

Rogalski, 2010).

The class

IndustrialAutomation represents

the integrated application model for different

industrial automation technologies. The actuator for

controlling the production or ancillary facilities is

modelled as a sub class. The energy consumption

meter, temperature sensor, occupancy sensor and

other sensors are also included as subclasses. The

object property

isAttachedOn is created to relate

them to production and ancillary facilities.

5 COMPANY SPECIFIC

KNOWLEDGE BASE

As shown in Figure 1, there are three ways to

generate a company-specific knowledge base. The

first is through the manual generation by knowledge

engineers in the company. If necessary, the

knowledge engineers can enrich the domain

ontology with sector-specific ontological sub

classes. For example, for a metal or stainless steel

industry, the sub classes

Forging,

HeatTreatment

and Milling are added as the sub

classes of

Forming. The energy efficient or

inefficient practices are modelled with SWRL. An

example of a condition, which describes energy

wasting conditions of ancillary facility, is if an oven

is active during a heat treatment process and the

heating system located in the same zone or hall is

still turned on, then it is considered as an energy

inefficiency condition. Equation (1) illustrates the

SWRL representation of such a condition.

Oven(?o)˄ HeatTreatment(?ht) ˄

operates(?o,?ht)˄ isActive(?ht,

true)˄ HeatingSystem(?hs) ˄

hasState(?hs, true) ˄ Zone(?z) ˄

isLocatedIn(?o,?z) ˄

isLocatedIn(?hs,?z)→

AncillaryFacilityEnergyWasting(?hs)

(1)

The knowledge inferred from the SWRL rules in

equation (1) can be retrieved using Semantic Query-

Enhanced Web Rule Language (SQWRL). SQWRL

is a SWRL-based query language that supports SQL-

like operations like negation, disjunction, counting,

and aggregation (O’Connor and Das, 2009). The

SQWRL shown in equation (2) can be used to

retrieve all the ancillary facilities that are in under

energy wasting conditions.

AncillaryFacilityEnergyWasting(?h)→

sqwrl:select(?h)

(2)

Since ontology is both human and machine readable,

the knowledge base can be connected to an alerting

or messaging system. If the SQWRL in Equation (2)

returns some elements, a message can be generated.

This can sharpen the awareness of employees in

order to improve the energy usage efficiency within

the company. The energy efficient/inefficient

conditions that are formalized and stored in the

ontological company’s knowledge base, allow

KEOD2012-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

112

simple access and query from any employee as well.

This accelerates the knowledge transfer among the

employees in practicing energy management.

The second method is to semi-automatically

generate the SWRL rules using machine learning

algorithms. In the manufacturing sector, companies

have to deal with large amounts of data from

different systems. There is often knowledge hidden

in the data that cannot be directly identified due to

the complexity of the data. The Knowledge

Discovery in Database (KDD) process extracts the

knowledge from the data using machine learning

techniques. As shown in Figure 1, the product,

process and resource data from different IT systems,

such as Enterprise Resource Planning (ERP) and

Manufacturing Execution System (MES) are

accumulated in a software module for data

aggregation. The module is also responsible for

performing the data pre-processing, such as data

cleaning, selection and transformation. The energy

related data from the Energy Monitoring and Data

Acquisition (EMDA) system are incorporated by the

module and they are finally stored in a relational

database.

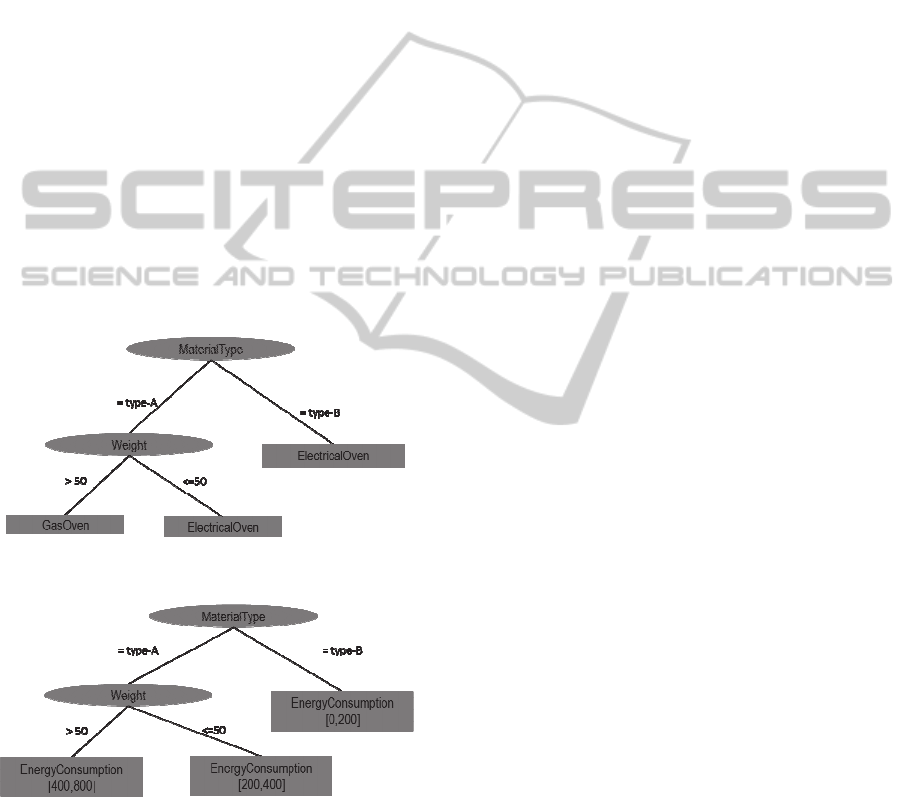

Figure 3: A result example of machine learning algorithm.

In our work, we develop a learning engine

module containing machine learning algorithms to

generate rules from the database. Figure 3 shows an

example of a result of a machine learning algorithm

that determines on which machine a product with the

particular characteristics, i.e. weight and material

type, should be heat treated and how high the energy

consumption is. We develop a classification

algorithm to generate rules for this purpose. Rules

generated by the algorithm are then transformed into

SWRL rules. Equation (3) gives an example of a

SWRL rule arising from the algorithm results

illustrated in Figure 3.

Based on the algorithm result shown in Figure 3,

it can be concluded that if the weight of the product

is less than or equal to 50 kg, the heat treatment

process has to be performed in an electrical oven. It

will consume energy between 200 and 400. That

means, if it consumes more energy than 400, it can

be considered an energy inefficient condition or

anomaly.

Product(?p)˄ hasMaterialType(?p,

“Type-A”) ˄ hasWeight(?p,?w) ˄

swrlb:greaterThan(?w,50) ˄

ElectricalOven(?o)

˄

HeatTreatment

(?h) ˄ operates(?o,?h) ˄

produces(?h,?p) ˄

hasEnergyConsumption(?o,?e) ˄

swrlb:greaterThan(?e,400) →

ProductionFacilityEnergyWasting(?e)

(3)

By querying the ontology using SQWRL, it is

possible to ascertain which machines or production

facilities currently operate energy-inefficiently.

Therefore a quick operative action can be performed

to solve the problem. Since the ontology represents

the semantics of the manufacturing energy

management and allows a shared understanding

among stakeholders, the management can have an

overview of the state of their factory with respect to

energy efficiency. An alarm system can be built

based on the knowledge base.

The ontological individuals of the class

Product

are generated based on the data from the order

management system and ERP (see Figure 1). The

energy consumptions are assigned with data from

EMDA system.

The third method is to generate ontological

elements from building construction drawings and

factory layouts. This method is not further presented

in this paper. This paper focuses only on the

knowledge representation using ontology and how

the knowledge is generated.

6 CONCLUSIONS

This paper presented an approach to an intelligent

energy management system in discrete

manufacturing using ontology as the knowledge

representation. We developed domain ontology for

manufacturing energy-management. It consists of

OntologyDrivenApproachforIntelligentEnergyManagementinDiscreteManufacturing

113

OWL classes and SWRL rules representing common

constellations of energy (in) efficiency. It is further

instantiated and enriched, resulting in the company-

specific knowledge. This paper explained three ways

to generate the company-specific knowledge, i.e.

manual generation by a knowledge engineer, semi-

automatic SWRL rule generation using machine

learning, and semi-automatic ontological element

instantiation from building construction drawings

and factory layouts.

The relationships among different energy related

elements such as products, processes, resources,

building elements and energy sources built in the

ontology, enable a holistic analysis for any

stakeholder on which factors can affect the energy

(in) efficiency in the company. The knowledge gap

among employees or between operative employees

and management can thus be overcome. The

approach allows the integration and standardization

of different IT and EMDA systems within the

context of a corporate energy management system.

However, to implement the approach, the role of

the knowledge engineer and domain expert to

generate the knowledge is still vital. Knowledge

modelling could be a time-consuming, error-prone

and inefficient task. The approach proposed in this

paper could be further developed by applying

ontology learning from text documents to

automatically generate the ontological classes.

REFERENCES

Bechhofer, S., van Harmelen, F., Hendler, J., Horrocks, I.,

McGuinness, D. L., Patel-Schneider, P. F. and Stein,

L. A., 2004. OWL Web Ontology Language Reference.

Retrieved on 15 April 2012, from http://www.w3.org/

TR/owl-ref/.

Hai, R., Theissen, M. & Marquardt, W., 2011. An

ontology based approach for operational process

modelling. In Advanced Engineering Informatics, no.

25, pp. 748–759, Amsterdam, The Netherlands:

Elsevier Science Publishers B. V.

Horrocks, I., Patel-Schneider, P., Boley, H., Tabet, S.,

Grosof, B. and Dean, M., 2004. SWRL: A Semantic

Web Rule Language Combining OWL and RuleML.

Retrieved on 14 April 2012, from http://www.w3.org/

Submission/SWRL/.

Kinkel, S., 2005. Anforderung an die Fertigungstechnik

von morgen - Wie verändern sich Variantenzahlen,

Losgrößen, Materialeinsatz, Genauigkeitsanfor-

derungen und Produktlebenzyklen tatsächlich?. Nr.

37. Karlsruhe: Fraunhofer Institut ISI.

Lemaignan, S., Siadat, A., Dantan, J. Y. and Semenenko,

A., 2006. MASON: A Proposal For An Ontology Of

Manufacturing Domain. In Proceeding IEEE

Workshop on Distributed Intelligent Systems:

Collective Intelligence and Its Applications, pp.195-

200. Washington, USA: IEEE Computer Society.

Lin, H. K. & Harding, J. A., 2007. A manufacturing

system engineering ontology model on the semantic

web for inter-enterprise collaboration. In Computers in

Industry, no. 58, pp. 428–437. Amsterdam, The

Netherlands: Elsevier Science Publishers B. V.

O'Connor, M. & Das, A., 2009. SQWRL: A Query

Language for OWL. In Proceeding 6th International

Workshop on OWL: Experiences and Directions

(OWLED 2009), Chantilly, VA, United States.

Panetto, H., M. Dassisti, and A. Tursi., 2012. ONTO-

PDM: Product-driven ONTOlogy for Product Data

Management interoperability within manufacturing

process environment. In Advanced Engineering

Informatics, no. 26, pp. 334-348. Amsterdam, The

Netherlands: Elsevier Science Publishers B. V.

Raza, M. B. and Harrison, R., 2011. Ontological

Knowledge Based System for Product, Process and

Resource Relationships in Automotive Industry. In

Proceedings of the 1st International Workshop on

Ontology and Semantic Web for Manufacturing, pp.

23-36. Heraklion, Crete, Greece.

Rossello-Busquet, A., Brewka, L., Soler, J. and Dittmann,

L., 2011. OWL Ontologies and SWRL Rules Applied

to Energy Management. In Proceeding 13th

International Conference on Modelling and

Simulation, pp. 446 - 450. Washington DC, USA:

IEEE Computer Society.

Shah, N., Chao, K. M., Zlamaniec, T. and Matei, A., 2011.

Ontology for Home Energy Management Domain. In

Digital Information and Communication Technology

and Its Applications - International Conference.

Berlin, Heidelberg: Springer.

Valiente, M. C., Garcia-Barriocanal, E. and Sicilia, M. A.,

2012. Applying an ontology approach to IT service

management for business-IT integration, In

Knowledge-Based Systems, vol. 28, April 2012, pp.

76-87. Amsterdam, The Netherlands: Elsevier Science

Publishers B. V.

Wicaksono, H. & Rogalski, S., 2010. Ontology Supported

Intelligent Energy Management System in Buildings.

In Proceeding of IEEE International Conference on

Industrial Engineering and Business Management

(ICIEBM), pp.637-642. Yogyakarta, Indonesia.

Wicaksono, H. Rogalski, S. and Kusnady, E., 2010.

Knowledge-based Intelligent Energy Management

Using Building Automation System. In IEEE IPEC,

2010 Conference Proceedings, pp. 1140-1145,

Singapore.

Wicaksono, H., Schubert, V., Rogalski, S., Ait Laydi, Y.

and Ovtcharova, J., 2012, Ontology-driven

Requirements Elicitation in Product Configuration

Systems. In H. ElMaraghy (ed.), Enabling

Manufacturing Competitiveness and Economic

Sustainability, pp. 63-67. Heidelberg: Springer.

KEOD2012-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

114