Task-based Method for Designing Underactuated Elastic Mechanisms

Shoichiro Kamada

1

, Youngwoo Kim

1

and Goro Obinata

2

1

Graduate School of Engineering, Nagoya University, Nagoya, Japan

2

EcoTopia Science Institute, Nagoya University, Nagoya, Japan

Keywords: Underactuated Mechanism, Task-based Design, Principal Component Analysis, Elastic Element.

Abstract: In this paper, we introduce a task-based method for designing underactuated mechanisms which actuators

are linked with the joints via elastic elements. We consider multi-joint mechanisms that contain fewer

independent actuators than the joints. The elastic elements work as convertors from the displacement of the

actuators to the joint torques of the mechanisms. In our method, we analyze the joint motions of the

mechanisms during the completion of each task and the level of participation of each joint for few specific

tasks. The results of this study can be used for the synthesis of dedicated underactuated mechanisms that can

operate in a low task coordinate space and for the systematic design of underactuated mechanisms.

1 INTRODUCTION

The design of robot mechanisms has often been

inspired by the structure and functioning of the

human body. Such an approach in designing robot

hands leads to the synthesis of mechanisms that can

handle the objects more dexterously; however, the

designing of robot hands with a large number of

joints by mimicking the human structure often

becomes very complicated because of the necessity

of many actuators. While human muscles can

generate very high energy per unit weight, electrical

motors do not have high power-to-weight ratio. This

leads to serious design difficulties and the designed

robot hands becoming large, heavy and less

powerful.

Various studies show that specific human

movement tasks can be expressed by only a small

number of variables. Kim et al. (2011) confirmed

that only four to five principal components are

sufficient for achieving human walking patterns on a

smooth surface. A study of human hand motions

proved that a relatively small number of principal

components are engaged during the completion of

specific motions (Santello et al., 1998).

It is often suggested that hand prostheses and

robot grippers must possess a kinematic structure

that is similar to those of the natural human hand

that allows grasping or pinching of various objects

of different sizes and forms. Anthropomorphic hands

with a large number of joints are highly dexterous,

but the independent joint control requires a large

number of actuators. As a solution to the problem,

many design concepts of robotic hands have been

introduced with fewer actuators than degree-of-

freedom (DoF) in the hand mechanisms. For an

example in such concepts, one actuator is connected

with several joints and operates them simultaneously.

In this research field such mechanisms are often

called “underactuated” mechanisms. In our previous

research we already proposed a task-based method

for underactuated mechanisms in a systematic way

(Kamada et al., 2012). The method was based on the

analysis of the set of predefined tasks that should be

performed by the new robot hand, which the analysis

leads to the approximated motion trajectories with

fewer independent variables than the variables for

the exact achievement of the tasks. If such

approximation is allowed, we can design a robot

hand for the predefined tasks with a specific type of

device which is called linear dependent drive (LDD).

The approach allowed the synthesis of hands with a

simple structure that include fewer actuators than

joints and that possess high functionality and precise

motions for the named set of tasks. Generally, the

synthesized underactuated mechanisms can achieve

only the approximated motions to the exact ones of

mechanisms with the same kinematic structure and

independently controlled joints. To cope with such

deterioration on the accuracy of the motion

trajectories, Birglen et al. (2004) and Dollar et al.

(2007) introduced an approach that uses elastic

383

Kamada S., Kim Y. and Obinata G..

Task-based Method for Designing Underactuated Elastic Mechanisms.

DOI: 10.5220/0004121503830387

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 383-387

ISBN: 978-989-8565-22-8

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

elements for connecting the output of actuator to the

joints in a simple robot hand. Such solution solves

the problem on motion trajectories; moreover, the

feature of self-adaptability to the object different

shapes can be also expected because of the

characteristics of the elastic elements. However, this

robot hand is single purpose; only hard gripping the

object is possible but other types of tasks, for

examples pinching and twisting, are impossible.

To extend the good feature of such elastic robot

hands for multi-purpose, we apply the task-based

design method suggested by Kamada et al. in 2012

to design dextrous robot hands which possess more

than one actuator with several elastic elements. We

propose an index to analyze the level of participation

of each joint for the named set of the given tasks.

The kinematic and elastic parameters of the designed

underactuated mechanism are determined by

minimizing the criterion. We have verified the

proposed method with few numerical design

examples and provide here some of the key results

that demonstrate its effectiveness.

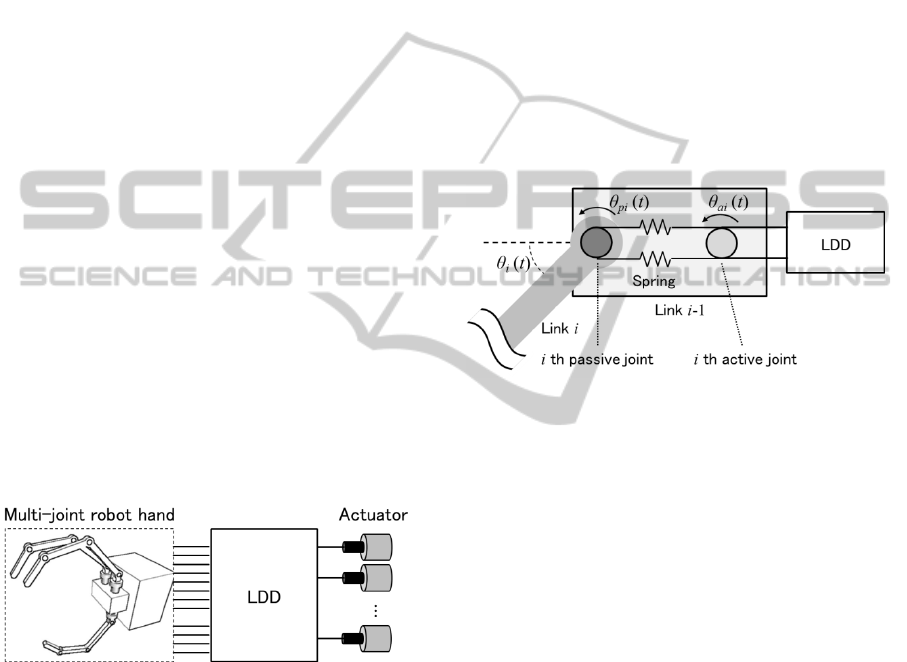

2 SYSTEM STRUCTURE

In the present study we consider gripper mechanisms

that consist of three components as represented in

Figure 1. The fingers of a multi-joint robot hand are

connected to a small set of actuators via Linear

Dependent Drives (LDDs).

Figure 1: Components of designed mechanisms.

The structure of the joint between the i th link and

the (i-1) th link is represented in Figure 2. Here,

θ

ai

(t) is the i th active joint angle, θ

pi

(t) is the i th

passive joint angle, θ

i

(t) is the i th actual joint angle

of the robot hand. Active joint angles are determined

by LDDs and displacements of actuators. LDDs are

mechanisms that transmit the displacements of the

actuators to the joints as follows:

cφθ

a

)()( tAt

(1)

Here, θ

a

(t)={θ

ai

(t)}R

n

is a vector of active joint

angles, AR

nr

is a constant matrix, φ(t)R

r

is a

vector of displacements of actuators (n>r), c R

n

is a

constant vector. The number of actuator r is smaller

than the number of the joints n. Passive joint angles

θ

p

(t)={θ

pi

(t)}R

n

are determined by the torques

which act on joints. The relation between passive

joint torques τ

p

(t)R

n

and passive joint angles is

given as follows:

)()( tKt

pp

θτ

(2)

Here, K=diag(k

1

, k

2

, … , k

n

) is a matrix of spring con

stants. k

i

(i=1, … , n) are positive values. If there is n

o external force, the actual joint angles of the hand θ

(t)={θ

i

(t)} R

n

equal to the active joint angles. With

some external forces, the actual joint angles of the h

and θ(t) are the sum of the active joint angles θ

a

(t) a

nd the passive joint angles θ

p

(t).

)()()( ttt

pa

θθθ

(3)

Figure 2: Connection between joints and LDD.

3 MECHANISM DESIGN

3.1 Principal Component Analysis

In this section we introduce a method for design of a

LDD. Initially, it is assumed that the mechanism is

fully actuated. Each joint of the mechanism is

connected with an independent actuator via a pair of

linear springs. From (2) and (3), joint angles of

active joints θ

a

(t) are represented as follows:

)()()(

1

tKtt

pa

τθθ

(4)

In our study, the joints of the hand and the actuators

are connected linearly via springs. The torques of the

active joints τ

a

(t)R

n

equal to the torques of the

passive joints τ

p

(t).

)()( tt

pa

ττ

(5)

From (4) and (5), the joint angles of the active joints

θ

a

(t) can be represented as follows:

)()()(

1

tKtt

aa

τθθ

(6)

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

384

In equation (6), the active joint angles θ

a

(t) are the

sum of the actual joint angles of the hand θ(t) and

the weighted active joint torques τ

a

(t). The joint

angles θ(t) determine the positions/orientations of

the links of the hand. The active joint torques τ

a

(t)

determine expressing forces of the hand. If we

generate appropriate θ

a

(t) for the tasks, the hand

accomplish them. In our approach, the active joint

angles θ

a

(t) are analyzed and the information is used

for design of a LDD.

In the paper (Kamada et al. 2012), the design

method of a LDD based on Principal Component

Analysis (PCA) have been introduced. We follow

the method. PCA is a method which converts a

multivariable data set into a set of uncorrelated

variables called principal components by

orthonormal transformation. We apply PCA to the

joint angles data sets of the active joints for the

executed task motions. The relation between the

principal components p(t)R

n

and the active joint

angles θ

a

(t) is represented by the following equation:

a0a

θθp )()( tWt

(7)

Here, θ

a0

R

n

is the average of θ

a

(t), WR

nn

is the

translation matrix of PCA. We can calculate a

contribution rate for each principal component. Each

contribution rate indicates the proportion of the

variance of the principal component to the total

variance of the joint angles of the active joints θ

a

(t).

If we group all principal components into two

groups depending on their contribution rates, (7) can

be presented as follows:

a0a

l

h

θθ

p

p

p

)(

)(

)(

)( tW

W

W

t

t

t

l

h

(8)

where p

h

(t)R

r

is the r principal components with

higher contribution rates, p

l

(t)R

n-r

is the n-r

principal components with lower contribution rates,

W

h

R

rn

, W

l

R

(n-r)n

are the submatrices of W. The

reconstructed joint angles from p

h

(t) are given as

follows:

a0a

θpθ )()(

ˆ

1

tWt

T

h

(9)

where

)(

ˆ

t

a

θ

R

n

is the reconstructed active joint

angles. Since the relationship (9) corresponds to (1),

it can be used for calculation the matrix A and the

vector c. In this approach, the number of the

actuators equals to the dimension of p

1

(t).

Without external force, the fingers of the robot

hand generate approximated motion for the selected

tasks. If the contact points of the finger is similar to

the given task motions, the passive joint angles θ

p

(t)

take similar values to the given ones.

3.2 Design Method

In Section 3.1, the group of the principal

components with low contribution rates is excluded.

Therefore there is the reduction errors

(t) between

the original joint angles θ

a

(t) and the reconstructed

joint angles

)(

ˆ

t

a

θ

. The reduction errors

(t) can be

defined as follows:

)()()()(

ˆ

)( tIWWttt

nh

T

h

aaa

θθθΔ

(10)

If we change the link lengths or the spring constants,

the errors

(t) also change. We define the index J to

select the parameters. In this paper, ‖·‖ means the

Euclidean norm.

f

t

dttJ

0

2

)(Δ

(11)

Here, tasks are executed from t=0 to t=t

f

.

Minimizing J yields the optimal parameters for the

design.

4 DESIGN EXAMPLE

4.1 Structure of the Robot Hand

In this example, we consider a robot hand with two

fingers and six links (Figure 3). Here, θ

ai

are the

joint angles of the active joints, θ

pi

are the joint

angels of the passive joints (i = 1, …, 6). The spring

constants at each joint are given as

90,90,90

80,80,80

654

321

kkk

kkk

(12)

The units above are mN·m/rad. The hand has an

asymmetrical shape.

Figure 3: Shape of robot hand.

Task-based Method for Designing Underactuated Elastic Mechanisms

385

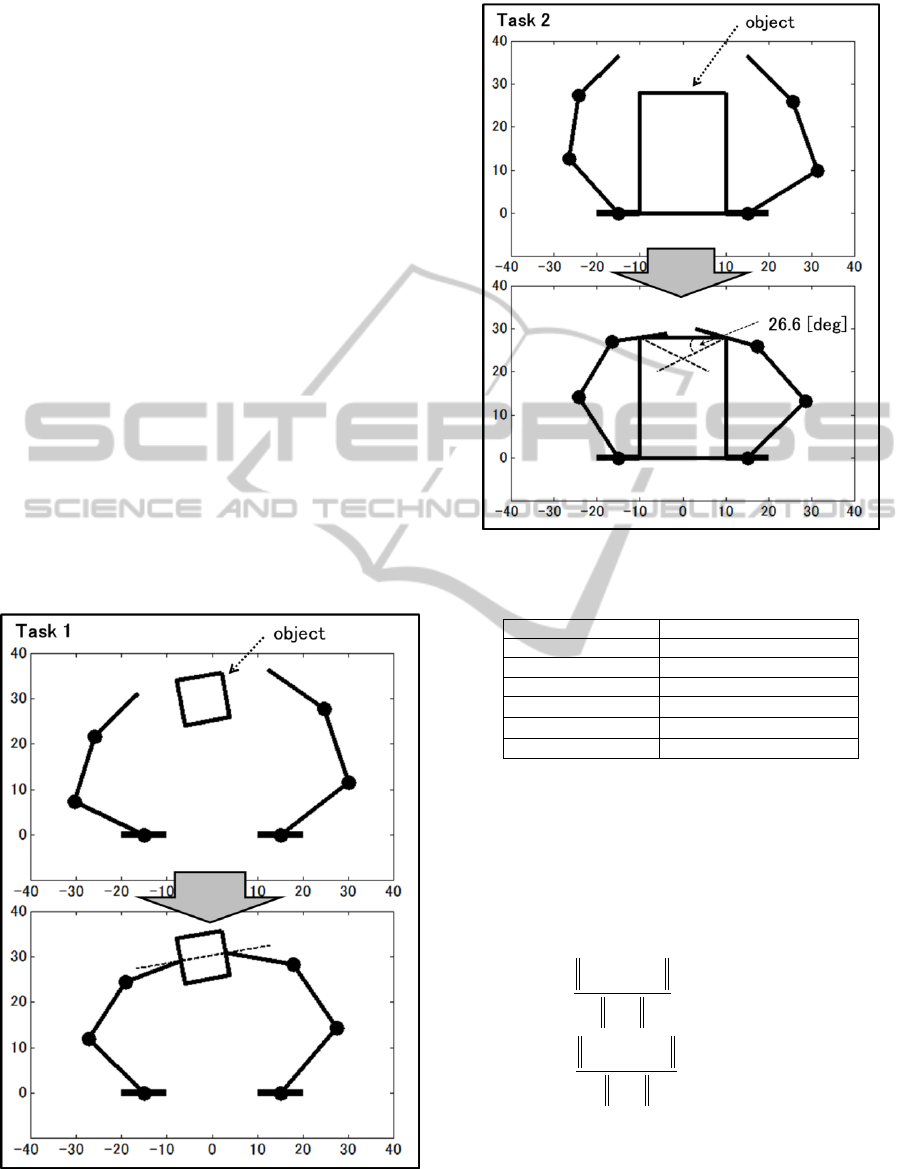

4.2 Given Tasks

We consider two tasks and design one robot hand

which can accomplish the given two tasks. The

dashed lines are applied forces. The motions for the

tasks are shown in Figure 4 and 5. Task 1 is to pinch

the target object with two fingers. The forces are

applied vertically to the both sides of the object by

the finger tips. The magnitudes of the forces are 0.5

N. Task 2 is to wrap the fingers around the target

object. The forces are applied to the object as

represented by Figure 5. The magnitudes of the

applied forces are 0.447 N. It is assumed that the

object is fastened on the floor plane. We analyzed

the motion for tasks as indicated in Figure 4 and 5.

We apply PCA to the joint angles of the active joints

while the gripper in Figure 3 executes the both tasks

in Figure 4 and 5. In Table 1, the contribution rates

of the principal components are shown. The

accumulate contribution rate of 2 major principal

components is 97.7%. If the size of the object

changes, the contribution rates also change.

However, the change of the accumulated

contribution rate of the two major principal

components is relatively small. In this chapter, we

design the mechanism with 2 actuators.

Figure 4: Motion for task 1.

Figure 5: Motion for task 2.

Table 1: Contribution rates.

Principal component

Contribution rate [%]

1

69.2

2

28.5

3

1.84

4

3.5610

-1

5

5.6710

-2

6

5.6310

-3

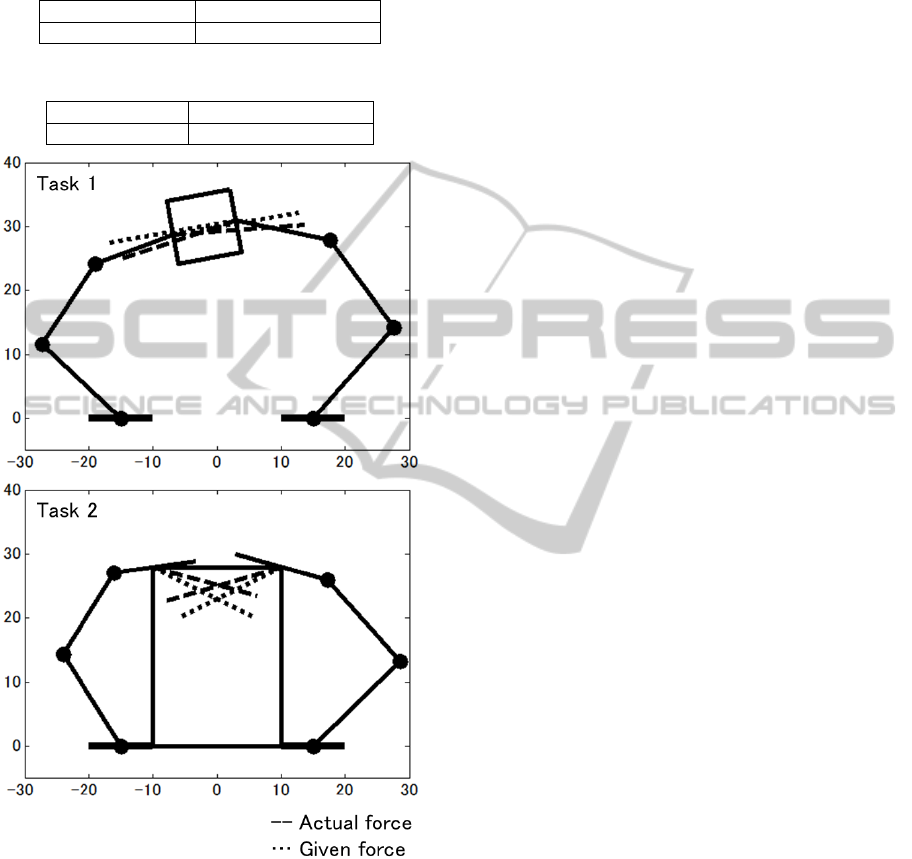

4.3 Motions of Designed Hand

The designed hand can apply forces to the target

objects as shown in Figure 6. We use the index of

(13) to evaluate the error between the force given as

the task motion and the force applied to the object

by the underactuated robot hand.

[%]100

[%]100

gr

argr

gl

algl

f

ff

f

ff

r

l

E

E

(13)

Here, f

gl

is the given force of the left finger, f

al

is the

actual force of the left finger, f

gr

is the given force of

the right finger, f

ar

is the actual force of the right

finger. In Table 2 and Table 3, we show the values

of E

l

and E

r

for each task. The results show that in

this simulation design example the forces to the

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

386

object are similar to the given ones and the

difference between them does not exceed 20 %.

Table 2: Error of force (Task1).

E

l

[%]

E

r

[%]

10.9

16.3

Table 3: Error of force (Task2).

E

l

[%]

E

r

[%]

19.7

18.9

Figure 6: Motions of designed hand.

5 CONCLUSIONS

We introduced a task-based method for design of

underactuated mechanisms attached elastic elements

between joints and actuators. The given tasks are

defined by the trajectories and the contact forces of

the links in the task coordinate space. At the

beginning, it is assumed that the given tasks are

performed by fully actuated mechanisms. We

analyze the joint motions of the mechanisms during

the completion of each task and synthesize dedicated

underactuated mechanisms. The proposed approach

allows the synthesis of underactuated mechanisms

that have fewer actuators than joints. Without

external force, the joint angles of the synthesized

mechanism are linearly dependent on the

displacements of the actuators. We presented an

example that shows promising results and potential

of the proposed method in various practical

applications.

ACKNOWLEDGEMENTS

We would like to thank to Dr. Dimitar Stefanov. He

gave us constructive comments and improved

English writing.

REFERENCES

Hirai, K., Hirose, M., Haikawa, Y., and Takenaka, T. 1998.

The Development of Honda Humanoid Robot, In Proc.

1998 IEEE International Conference on Robotics &

Automation, pp. 1321-1326.

Kawasaki, H., Komatsu, T., and Uchiyama, K. 2002.

Dexterous Anthropomorphic Robot Hand With

Distributed Tactile Sensor: Gifu Hand II, IEEE/ASME

Trans. on Mechatronics, Vol. 7, No. 3, pp. 296-303.

Kim, Y., Tagawa, Y., Obinata, G., and Hase, K. 2011.

Robust control of CPG-based 3D neuromusculo-

skeletal walking model, Biological Cybernetics, Vol.

105, Issue 3, pp. 269-282.

Santello, M., Flanders, M., and Soechting, J. F. 1998.

Postural Hand Synergies for Tool Use, The Journal of

Neuroscience, Vol. 18, No. 23, pp. 10105-10115.

Birglen, L., and Gosselin, C. M. 2004. Kinetostatic

Analysis of Underactuated Fingers, IEEE Trans. on

Robotics and Automation, Vol. 20, No. 2, pp. 211-221.

Dollar, A. M., and Howe, R. D. 2007. The SDM Hand as a

Prosthetic Terminal Device: A Feasibility Study, In

Proc. 2007 IEEE 10th International Conference on

Rehabilitation Robotics, pp. 978-983.

Kamada, S., Kim, Y., Obinata, G., and Stefanov, D., 2012.

Task-Based Method for Designing Underactuated

Mechanisms, International Journal of Advanced

Robotic Systems, Vol. 9, pp. 1-12.

Task-based Method for Designing Underactuated Elastic Mechanisms

387