Flatness based Control of a 2 DOF Single Link Flexible Joint

Manipulator

E. D. Markus

1

, J. T. Agee

1

, A. A. Jimoh

1

, N. Tlale

2

and B. Zafer

3

1

Department of Electrical Engineering, Tshwane University of Technology, Pretoria, South Africa

2

Mobile Intelligent and Autonomous Systems, CSIR, Pretoria, South Africa

3

Department of Mechatronics Engineering, Kocaeli University, Kocaeli, Turkey

Keywords:

Flexible Joint Manipulator, Differential Flatness, Position Control.

Abstract:

The demand for high speed robotic manipulators with little or no vibrations has been a challenging research

problem. In this paper, a position control for a 2 DOF single link flexible manipulator with joint elasticity

is studied. It is shown that using the flatness control approach, faster response and less oscillations and

overshoots can be achieved. The flat output of the linearized system is determined as the tip of the manipulator

end effector. This output and a finite order of its derivatives is defined in terms of the input and states variables

of the manipulator. Using the parameters of the output in flat space, a trajectory is planned and executed to

test the effectiveness of the designed control.

1 INTRODUCTION

The control of flexible robotic manipulators is re-

quired in many applications where faster response,

lower energy consumption, lighter body mass, and

high position accuracy at the end effector are de-

manded. The problem of vibration control in these

systems has been a subject of research over the years

(Ghorbel et al., 1989; Sira-Ramirez et al., 1992;

Ider and

¨

Ozg¨oren, 2000; Ozgoli and Taghirad, 2006;

Tokhi and Azad, 2008; Jiang and Higaki, 2011). Ma-

nipulators with flexible links are difficult to control

due to their slow control response, high oscillations

and high overshoots. The flexible joint manipulator is

also known to exhibit a nonminimum phase behaviour

(Tokhi and Azad, 2008). This makes trajectory track-

ing for the system harder to achieve. From a robot ma-

nipulator design perspective, these disadvantages are

minimised by building the robot from rigid links and

joints that results in high stiffness. However such stiff

systems have been shown to be ineffective in terms of

high power consumption and positional inaccuracy.

Many mathematical and analytical models have

been proposed in the past to achieve control of these

flexible systems (Dwivedy and Eberhard, 2006; Tokhi

and Azad, 2008). Among these include the classical

PID control, feedback linearization, fuzzy logic con-

trol, sliding mode, H∞ control, linear quadratic con-

trol and neuro-fuzzy inference system. A comprehen-

sive survey of research in the control of flexible ma-

nipulators can be found in (Dwivedy and Eberhard,

2006; Ozgoli and Taghirad, 2006).

The concept of differential flatness proposed by

Fliess, Levine, Martin and Rouchon(1995) has been

applied to complex control problems(Fliess et al.,

1995). This study will apply the differential flatness

technique for the control of the single link flexible

joint robot manipulator. The differential flatness ap-

proach through the flat output is used to design an

asymptotically stable controller for suppressing vi-

brations of the flexible joint manipulator. Abdul-

Razak (2007) and Quanser (2012) have reported the

use of the linearized model of the flexible manipu-

lator(Abdul Razak, 2007; Quanser, 2012). The lin-

earized model is simulated with a PID controller and

compared with the flatness based control.

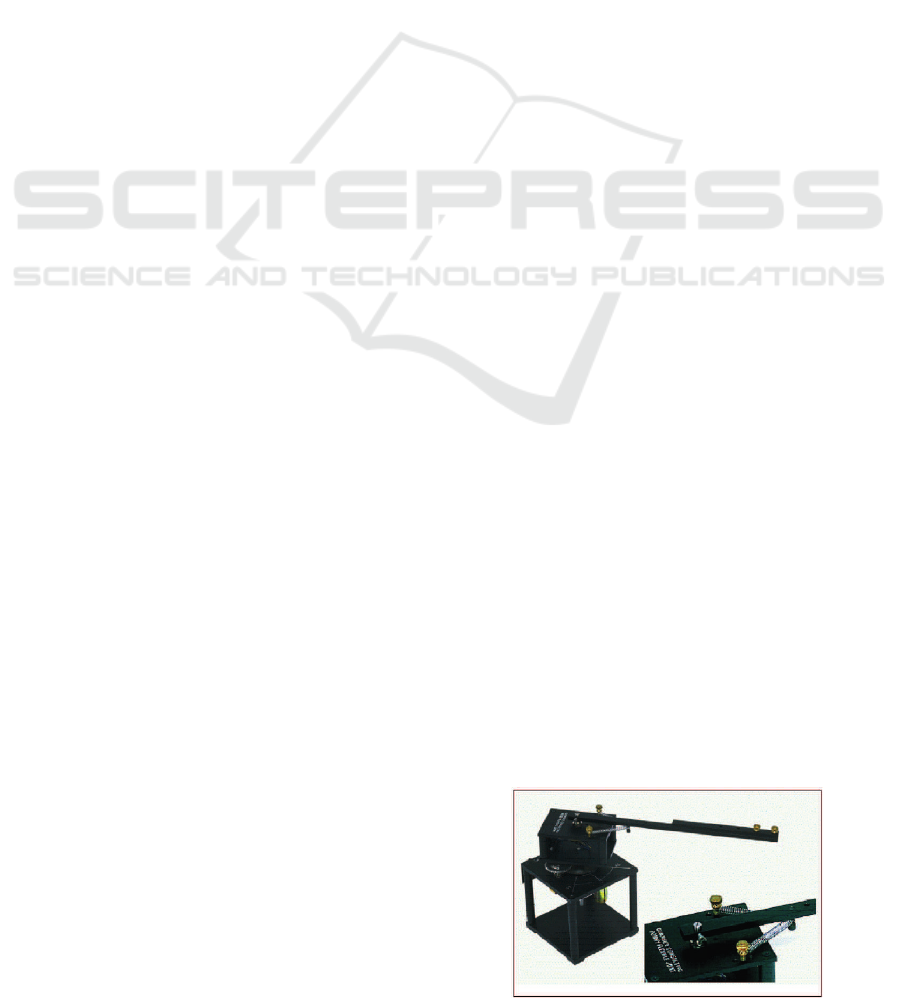

Figure 1: Physical model of flexible joint robot manipulator.

437

D. Markus E., T. Agee J., A. Jimoh A., Tlale N. and Zafer B..

Flatness based Control of a 2 DOF Single Link Flexible Joint Manipulator.

DOI: 10.5220/0004061104370442

In Proceedings of the 2nd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2012),

pages 437-442

ISBN: 978-989-8565-20-4

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

The main contribution of this study is to show that

using the differential flatness control model, faster re-

sponse and less oscillations and overshoots can be

achieved for the flexible manipulator. Furthermore,

the problem of finding rest to rest trajectories for the

nonminmum phase system is easily achieved without

resorting to iterative solutions by complex numerical

methods.

2 SYSTEM MODELING

The model used for the study is the standard Quanser

flexible joint manipulator platform (Quanser, 2012)

shown in figure(1). The nonlinear dynamic model of

the flexible joint robot is formulated using Lagrange

equations(Groves and Serrani, 2004). Other studies

have used this model to design control for the flexible

manipulator (Abdul Razak, 2007; Akyuz et al., 2011).

However, published results still suffer from oscil-

lations and overshoots due to the flexible nature of

the system. The single link flexible manipulator has a

flexible joint and an arm which is oriented vertically.

This introduces non-linearities in the system as a re-

sult of the potential energy due to gravity. Fig (2)

shows the schematic diagram of the single link ma-

nipulator with flexible joint.

The input to the system is the voltage applied to

the motor and the output is the tip angle which is

a sum of the motor angle and the joint deflection .

The system has two degrees of freedom which corre-

sponds to the motor rotation angle and the rotation of

the flexible joint . The coordinates of the flexible joint

manipulator are reflected in fig(3).

Figure 2: The schematic diagram of single link flexible ma-

nipulator with flexible joint.

Removing the nonlinear sinusoids enables the

computation of the flat output for the linear system.

This is computed using the technique proposed by

(Levine and Nguyen, 2003). The energy equation for

the system is formulated using the Lagrangian energy

θ

α

Figure 3: Co-ordinates of the flexible joint manipulator.

equation.

L = K −V (1)

where

K = K

h

+ K

l

V = V

g

+V

s

(2)

K and V are kinetic and potential energy respec-

tively. For a complete derivation of the dynamic

model of the single link flexible joint manipulator,see

(Akyuz et al., 2011). Choosing our state variables as:

θ = x

1

˙

θ = x

2

α = x

3

˙

α = x

4

(3)

The linearized equations of motion about zero

equilibrium point of the manipulator represented in

state space are given as a fourth order system in the

equation below:

˙

x =

x

2

K

s

J

h

x

3

−

K

2

m

K

2

g

R

m

J

h

x

2

+

K

m

K

g

R

m

J

h

V

x

4

−

K

s

J

h

x

3

+

K

2

m

K

2

g

R

m

J

h

x

2

−

K

m

K

g

R

m

J

h

V −

K

s

J

l

x

3

+

mgh

J

l

(x

1

+ x

3

)

(4)

2.1 Differential Flatness

A linear system

f(x, ˙x, u)

x ∈ ℜ

n

, u ∈ ℜ

m

, n ≥ m+ 1 (5)

is said to be differentially flat if there exists a variable

or set of variables h

1

∈ ℜ

n

called the flat output of the

form:

h

1

= y(x, u, ˙u, ¨u, ......, u

(p)

) (6)

defined by:

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

438

x = α(h

1

,

.

h

1

,

.

h

1

, ......, h

1

(q)

),

u = β(h

1

,

.

h

1

,

.

h

1

, ......, h

1

(q+1)

) (7)

p and q are finite integers, Such that the system of

equations

d

dt

α(h

1

,

.

h

1

,

.

h

1

, ......, h

1

(q+1)

) =

f(α(h

1

,

.

h

1

,

.

h

1

, ......, h

1

(q)

), β(h

1

,

.

h

1

,

.

h

1

, ......, h

1

(q+1)

))

(8)

are identically satisfied (Rouchon et al., 1993).

2.2 Determination of the Flat Output

According to Levine and Nguyen (2003), a linear

system of the form of equation (4) with one input

can be expressed in terms of equation (9)(Levine and

Nguyen, 2003).

A(s)x = Bu (9)

where x = P(s)h

1

(s), u = Q(s)h

1

(s) and A(s) = sI−A

The variable h

1

= (h

1

........h

m

) is the linear flat

output and the matrices P and Q are given by equa-

tions (10) and (11) respectively

C

T

A(s)P(s) = 0 (10)

A(s)P(s) = BQ(s) (11)

The matrix C is an n× (n− m) matrix of rank n-m

orthogonal to B such that:

C

T

B = 0 (12)

and

Q(s) = (B

T

B)

−1

B

T

A(s)P(s) (13)

Expressing equation (4) in terms of A(s), we have

A(s) =

0 −1 0 0

0 s+

K

2

m

K

2

g

R

m

J

h

−

K

s

J

h

1

0 0 s −1

−

mgh

J

l

−

K

2

m

K

2

g

R

m

J

h

K

s

J

h

+

K

s

J

l

−

mgh

J

l

s

(14)

B

T

=

h

0

K

m

K

g

R

m

J

h

0 −

K

m

K

g

R

m

J

h

i

(15)

For C

T

B = 0 we select

C

T

=

1 0 0 0

0 1 0 1

0 0 1 0

(16)

Noting that

P(s) =

P

1

(s) P

2

(s) P

3

(s) P

4

(s)

(17)

Equation (10) will yield

P

1

(s) =

s

2

+

K

s

− mgh

J

l

h

1

(s)

P

2

(s) = sP

1

(s)

P

3

(s) =

−s

2

+

mgh

J

l

h

1

(s)

P

4

(s) = sP

3

(s) (18)

From equation (18), we can express all the states

of the system in terms of the flat output h

1

and its

derivatives

x

1

(t) = θ(t) =

..

h

1

(t) +

K

s

− mgh

J

l

h

1

(t)

x

2

(t) =

.

θ

(t) =

...

h

1

(t) +

K

s

− mgh

J

l

.

h

1

(t)

x

3

(t) = α(t) = −

..

h

1

(t) +

mgh

J

l

h

1

(t)

x

4

(t) =

.

α

(t) = −

...

h

1

(t) +

mgh

J

l

.

h

1

(t) (19)

and u(t) = v

From equation (13), Q(s) = (B

T

B)

−1

B

T

A(s)P(s)

yields

Q(s) = β

1

s

4

+ β

2

s

3

+ β

3

s

2

+ β

4

s+ β

5

(20)

where:

β

1

=

J

h

R

m

K

g

K

m

β

2

= K

g

K

m

β

3

=

K

s

R

m

2K

g

K

m

+ J

h

R

m

(

K

s

J

h

+

K

s

J

l

−

mgh

J

l

)

2K

g

K

m

+

J

h

R

m

(K

s

− mgh)

2K

g

K

m

J

l

β

4

=

K

g

K

m

(K

s

− mgh)

J

l

and

β

5

=

mghR

m

J

h

(K

s

− mgh)

2K

g

K

m

J

l

2

−mgh

K

s

R

m

+ J

h

R

m

(

K

s

J

h

+

K

s

J

l

−

mgh

J

l

)

2K

g

K

m

J

l

Putting

K

s

−mgh

J

l

= W and

mgh

J

l

= Y into equation (20)

Then u(t) becomes

u(t) =

J

h

R

m

K

g

K

m

h

1

(4)

+ K

g

K

m

h

1

(3)

FlatnessbasedControlofa2DOFSingleLinkFlexibleJointManipulator

439

+[

K

s

R

m

+ J

h

R

m

(

K

s

J

h

+W) + J

h

R

m

W

2K

g

K

m

]

..

h

1

+K

g

K

m

W

.

h

1

+

R

m

J

h

YW −YK

s

R

m

− R

m

J

h

Y(

K

s

J

h

+W)

2K

g

K

m

h

1

(21)

Expressing the flat output h1 in terms of the states

h

1

(t) =

J

l

K

s

(θ+ α)

˙

h

1

(t) =

J

l

K

s

(

.

θ

+

.

α

)

¨

h

1

(t) =

mgh

K

s

(θ+ α) − α

h

(3)

1

(t) =

mgh

K

s

(

.

θ

+

.

α

) −

.

α

(22)

A new states space model in terms of the flat out-

put variables called the Brunovskys model can now

be described for the original manipulator system as:

˙

h

1

= h

2

˙

h

2

= h

3

˙

h

3

= h

4

˙

h

4

=

mghK

s

J

l

J

h

h

1

−

(K

g

K

m

)

2

(K

s

− mgh)

J

l

J

h

R

m

h

2

−[

K

s

J

h

+

K

s

J

l

−

mgh

J

l

]h

3

−

(K

g

K

m

)

2

J

h

R

m

h

4

+

K

g

K

m

J

h

R

m

u(t)

(23)

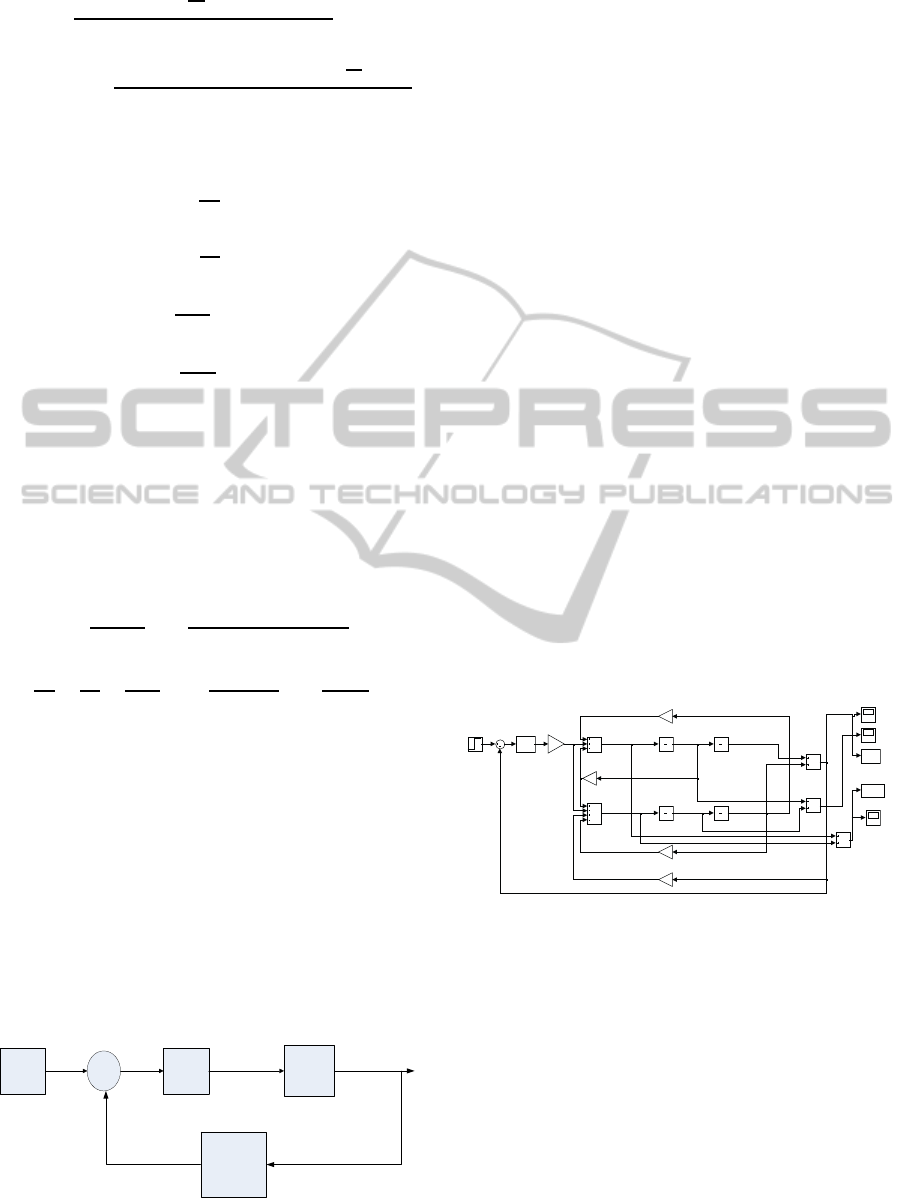

3 CONTROLLER DESIGN

Designing the controller in flat output space is easy

since the manipulator is represented by a chain of in-

tegrators. The flatness property decouples dynamics

of the position, velocity, acceleration and jerk. Their

trajectories can easily be generated without differenti-

ation. It should be noted that only the tip position was

used for feedback. Figure (4) illustrates the block di-

agram of the flatness based control.

Feedback

Controller

∑

Flexible

Manipulator

Transformation

to flat

coordinates

Reference

Trajectory

e

u

y

h1

+

-

Figure 4: Block diagram of flatness based control for the

flexible joint robot manipulator.

The reference trajectory is generated from the end

effectortip position which is the flat output of the flex-

ible manipulator. The state variables are transformed

to flat output coordinates. The aim of the control is

to track the position of the end effector as precisely

as possible. Based on the linear system of equation

(23), a controller will now be designed using the flat

variables. For the 4th order system:

˙

h

4

(t) =

ˆ

h

4d

− K

1

(h

1

(t) −

ˆ

h

1d

(t)) − K

2

(h

2

(t) −

ˆ

h

2d

(t))

−K

3

(h

3

(t) −

ˆ

h

3d

(t)) − K

4

(h

4

(t) −

ˆ

h

4d

(t)) (24)

This can be written in the form

.

h

4

(t) =

ˆ

h

4d

− K

1

e− K

2

.

e

−K

3

..

e

−K

4

...

e

(25)

where

e = h

1

−

ˆ

h

1d

,

.

e

= h

2

−

ˆ

h

2d

,

..

e

= h

3

−

ˆ

h

3d

,

...

e

=

h

4

−

ˆ

h

4d

K

i

, i = 1, 2, 3, 4 are the controller gains.

The expression in the complex field is

s

4

+ K

4

s

3

+ K

3

s

2

+ K

2

s+ K

1

= 0 (26)

The K parameters have to be chosen to minimise

the system error. PID is used to tune the gains

and drive the system error to a minimum. Figure

(5) shows the simulation environment for the linear

model in Simulink.

x1_d t

x1

x3

x3_d tdt

x3_d t

x1_d tdt

vel

positi on

accn

simou t4

To Workspace1

simou t6

To Workspace

Step

PID(s)

PID Con troller

1

s

Inte grato r3

1

s

Inte grato r2

1

s

Inte grato r1

1

s

Inte grato r

-K-

Gai n5

-K-

Gai n3

-K-

Gai n2

-K-

Gai n1

-K-

Gai n

Add 4

Add 3

Add 2

Add 1

Add

Figure 5: Simulink diagram of the linear model.

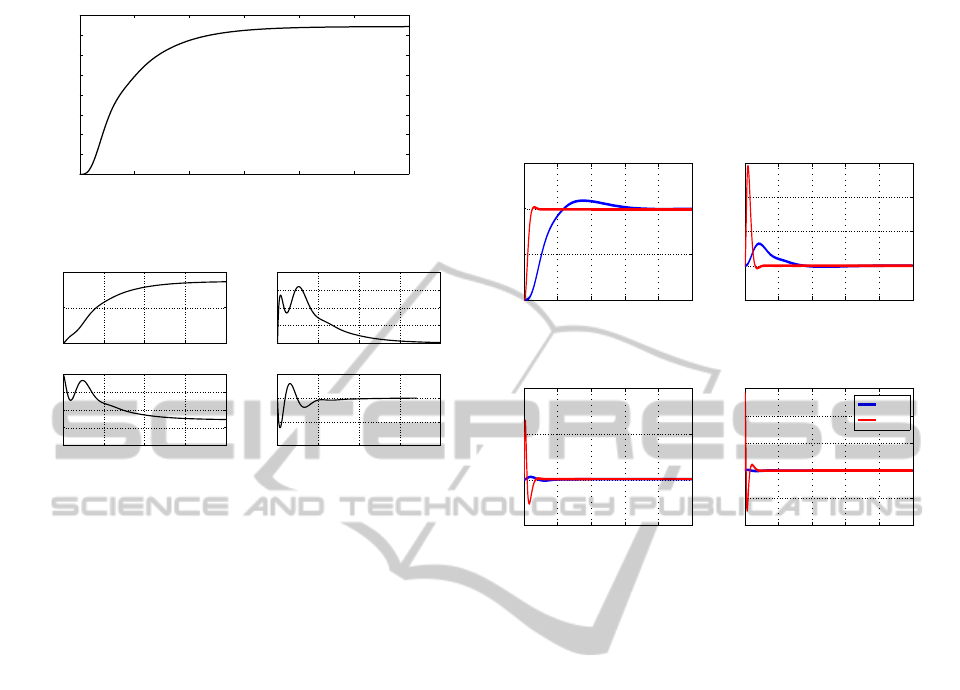

4 SIMULATION AND RESULTS

It is required to generate smooth point to point end

effector tip movements. For position control, motion

that has a velocity of zero at the start of motion and at

the end is desired. The motion should also accelerate

and decelerate smoothly. To check for the control-

lability of the modelled flexible manipulator, time re-

sponse analysis was carried out. Results show that the

system is stable and controllable. Figure (6) shows

the response of the tip position (θ+α) to a step input.

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

440

0 0.5 1 1.5 2 2.5 3

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

Time (secs)

theta+alpha(rads)

Tip displacement

Figure 6: Step response of end effector position (θ + α)

based on linear model.

0 0.5 1 1.5 2

0

0.5

1

Time (s)

Theta(rads)

0 0.5 1 1.5 2

0

0.5

1

1.5

2

Time(s)

theta vel.(rads/s)

0 0.5 1 1.5 2

−0.2

−0.15

−0.1

−0.05

0

Time(s)

alpha(rads)

0 0.5 1 1.5 2

−2

−1

0

1

Time(s)

alpha vel.(rads/s)

Figure 7: Step responses of motor angle (θ), joint displace-

ment (α) and their velocities.

The step input introduces an instantaneous rota-

tion on the motor shaft and results in a joint deflec-

tion. The system has a rise time of 0.84s, a settling

time of 1.6s and steady state of 0.74rads with no over-

shoots. This response is satisfactory given that the

flexible manipulator model has been linearized. A

further check on the motor angle response and joint

deflection and their velocities gives an insight of a sta-

ble system. The plots of figure (7) show the time re-

sponse on motor angle θ and joint deflection α of the

linear flexible manipulator model.

In order to check the steady sate error performance

of the proposed control, a closed loop feedback con-

trol was carried out as shown in figure (4). Compar-

isons were made from simulation results obtained for

two different controlled platforms of the flexible ma-

nipulator using the MATLAB/Simulink environment.

Position control is carried out on the linearized model

and then compared with the flatness based model.

The results in figure (8) shows that both PID

control and the flatness based control, achieved zero

steady state error. The flatness based control has a

percentage overshoot of less than 2% while the PID

control has 9%. This is caused by the instantaneous

effect of the step input on the motor. This effect can

be seen by the large overshoots in the velocity and

jerk. The reference trajectory however quickly settles

to steady state with a settling time of 1.8s for the lin-

ear PID control. When compared to the flatness based

control, a faster settling time of 0.3s is observed. This

means that the flatness based control is more toler-

ant to oscillations and vibrations much more than the

classical PID control. An observation of nonmini-

mum phase behaviour was made in the linear flat dy-

namics. The plots in figure (8) show that the Flatness

based controller was able to resolve this problem.

0 0.5 1 1.5 2 2.5

0

0.5

1

1.5

Tip displacement

h1(rads)

0 0.5 1 1.5 2 2.5

−5

0

5

10

15

Tip velocity

Velocity(rads/s)

0 0.5 1 1.5 2 2.5

−500

0

500

1000

acceleration

accn(rads/s

2

)

Time(s)

0 0.5 1 1.5 2 2.5

−4

−2

0

2

4

6

x 10

4

Jerk

jerk(rads/s

3

)

Time(s)

PID Control

Flat Control

Figure 8: Comparison of system response based on PID and

flatness based control.

5 CONCLUSIONS

This paper has presented a control for a single link

flexible joint robot manipulator. The flat output for

a linearized model of the manipulator was derived.

The model was analysed and control designed based

on differential flatness. The PID control on the lin-

ear model was compared with control of the flat-

ness based model. Results show a satisfactory perfor-

mance on the dynamics and control of both platforms.

The flatness based control however shows faster re-

sponse to instantaneous motor displacement with lit-

tle vibrations and less overshoots.

REFERENCES

Akyuz, I. H., Yolacan, E., Ertunc, H. M., and Bingul, Z.

(2011). Pid and state feedback control of a single-

link flexible joint robot manipulator. In Mechatronics,

pages 409–414. IEEE.

Dwivedy, S. and Eberhard, P. (2006). Dynamic analysis of

flexible manipulators, a literature review. Mechanism

and Machine Theory, 41(7):749–777.

Fliess, M., Lvine, J., Martin, P., and Rouchon, P. (1995).

Flatness and defect of non-linear systems: introduc-

FlatnessbasedControlofa2DOFSingleLinkFlexibleJointManipulator

441

tory theory and examples. International journal of

control, 61(6):1327–1361.

Ghorbel, F., Hung, J., and Spong, M. (1989). Adaptive con-

trol of flexible-joint manipulators. Control Systems

Magazine, IEEE, 9(7):9–13.

Groves, K. and Serrani, A. (2004). Modeling and nonlinear

control of a single-link flexible joint manipulator.

Ider, S. K. and

¨

Ozg¨oren, M. K. (2000). Trajectory tracking

control of flexible-joint robots. Computers & Struc-

tures, 76(6):757–763.

Jiang, Z. H. and Higaki, S. (2011). Control of flexible joint

robot manipulators using a combined controller with

neural network and linear regulator. Proceedings of

the Institution of Mechanical Engineers, Part I: Jour-

nal of Systems and Control Engineering, 225(6):798–

806.

Lvine, J. and Nguyen, D. V. (2003). Flat output character-

ization for linear systems using polynomial matrices*

1. Systems & control letters, 48(1):69–75.

Ozgoli, S. and Taghirad, H. D. (2006). A survey on the con-

trol of flexible joint robots. Asian Journal of Control,

8(4):332–344.

Quanser (2012).

Razak, N. B. A. (2007). Modelling of single link flexible

manipulator with flexible joint. PhD thesis, Universiti

Teknologi Malaysia.

Rouchon, P., Fliess, M., Lvine, J., and Martin, P. (1993).

Flatness, motion planning and trailer systems. In Proc.

Conf. on Decision and Control, pages 2700–2705 vol.

3. IEEE.

Sira-Ramirez, H., Ahmad, S., and Zribi, M. (1992). Dy-

namical feedback control of robotic manipulators with

joint flexibility. Systems, Man and Cybernetics, IEEE

Transactions on, 22(4):736–747.

Tokhi, M. O. and Azad, A. K. M. (2008). Flexible robot

manipulators: modelling, simulation and control, vol-

ume 68. London Institution of Engineering and Tech-

nology.

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

442