Simulation of the Thermal Management of the Semiconductor

Disk Laser

Yanrong Song, ZhenHua Yu, Peng Zhang and Zili Li

College of Applied Sciences, Beijing University of Technology, Beijing 100124, China

Keywords: Optically Pumped Semiconductor Disk Lasers, Finite-Element Analysis Method, Thermal Management.

Abstract: For the optically pumped semiconductor disk lasers, the thermal problem is the key to obtain the high out

power. To solve this problem, we simulated the heat distribution of the gain chip by finite-element analysis

method to discover the heat spread affected by the thickness of the substrate and found the outstanding heat

spread result of the diamond chip.

1 INTRODUCTION

The semiconductor disk laser (SDL), which is also

known as the Vertical external cavity surface

emitting laser (VECSEL) (Kuznetsov, 1999),

combining the advantages of compact, small size,

low loss and good beam quality (Maclean, 2008), is

an ideal candidate for applications such as

biomedicine (Daukantas, 2007), high density optical

data storage (Risk, 2003), chemical sensor

(Garnache, 2005), and pump sources for other lasers

(Richter, 2005).

In the past decade, output powers of SDL s

have been upgraded significantly, but still not very

high. Limitations to the output power of a V SDL

come from the heat effects. With the deposited heat,

thus increased temperature, the gain of quantum

wells (QWs) will decrease sharply, and the laser

wavelength will redshift so the periodic resonant

gain structure will be detuned (Corzine,1989).What

is more, the nonradiative recombination will become

dominant and the temperature rise will be further

accelerated. All of the above factors are

compounded until finally the thermal rollover of the

laser occurs.

Numerical analysis can give an overall pattern

of the generation, deposition and dissipation of heat

in a SDLs, and therefore bring forward advanced

thermal management to improve the thermal

properties and upgrade the output power of the laser.

A finite element analysis was used by Kemp et al. to

study the heatspreader approach; the required

properties of a heatspreader were examined and the

effect on heat flow and thermal lens effects were

discussed.

Here we present a numerical analysis of

thermal effect in InGaAs system SDL. We

discovered the heat spread affected by the thickness

of the substrate and found the outstanding heat

spread result of the diamond chip.

2 NUMERICAL METHODS

2.1 Model for Thermal Simulation

Figure 1: The epitaxial structure of the simulated

semiconductor wafer.

The epitaxial structure of the simulated

semiconductor wafer is shown in Fig. 1. We divide

231

Song Y., Yu Z., Zhang P. and Li Z..

Simulation of the Thermal Management of the Semiconductor Disk Laser.

DOI: 10.5220/0004056902310233

In Proceedings of the 2nd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2012),

pages 231-233

ISBN: 978-989-8565-20-4

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

the whole structure into four parts: the window

layer, the multiple QWs, the DBR and the substrate.

The total thermal conductivity in axial and radial

direction of each part including multiple layers can

be written as

i

ii

t

tk

k

(1)

And the total absorption coefficient of each

part is obtained by

i

ii

t

t

(2)

where

i

k

and

i

are the thermal conductivity

and absorption coefficient of the ith layer, and

i

t

is

the thickness. In the computation, the wavelengths

of pump and laser are 808 and 1040 nm; the value of

0.475µm

-1

for the absorption coefficient of GaAs

layer and 1µm

-1

for the absorption coefficient of

In0.2Ga0.8As/Al0.05Ga0.95As QWs are used.

Then, the temperature, the heat flux and the

gradient of temperature can be obtained by solving

the standard heat equation (steady state):

QTk

(3)

where k is the thermal conductivity and T is the

temperature.

The heat loading density Q is calculated by

www

ww

w

zz

r

P

Q

0

2

2

2

exp

2

exp

2

(4)

where

w

is the fraction of absorbed pump

power that goes to heating, andη=1-λ

pump

/λ

laser

in

MQWs part and η=1 in other parts. α is the

absorption coefficient of each part, r is the

coordinate in radial direction and z is the coordinate

in axial direction. The start position z0 of each part is

different and the start position of window layer is

chosen to be zero. In this paper, the pump power and

the pump spot radius are assumed to be 10W and 50

mm unless there is a special explanation.

Table 1: Parameters of some materials.

Material

k (Wm

-1

K

-1

)

α (µm

-1

)

GaAs

44

0.457

AlAs

91

0

Al

0.6

GaAs

11

0

Al

0.05

GaAs

27

1.000

In

0.2

GaAs

7

1.000

Diamond

2000

0

2.2 Results of the Simulation

We used the finite-element analysis method to

simulate the heat distribution of the semiconductor

chip when the heat sink temperature was 300 k. The

parameters used is in table 1. We could discovery

the heat spread affected by the thickness of the

substrate illustrated in Fig.2. and Fig.3. We also can

find the outstanding heat spread result of the

diamond chip from Fig.3. and Fig. 4.

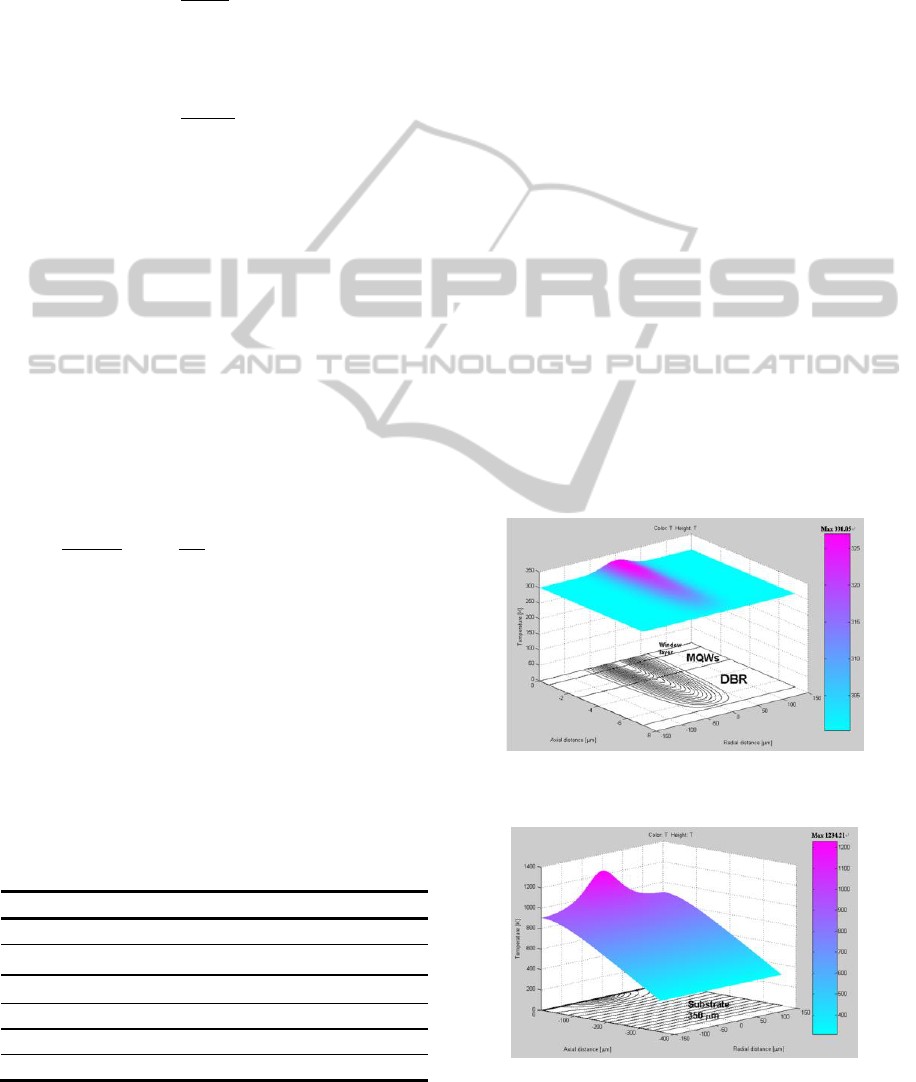

The Fig.2 described the temperature variation

when the thickness of the gain chip substrate is 0

µm, the maximum temperature rise is 30.05 K,

compare to the 934.21 K of the max temperature rise

represented in Fig.3. when the thickness of the gain

chip is 350 µm. So the substrate removal is an

effective method to improve the heat spread of gain

chip.

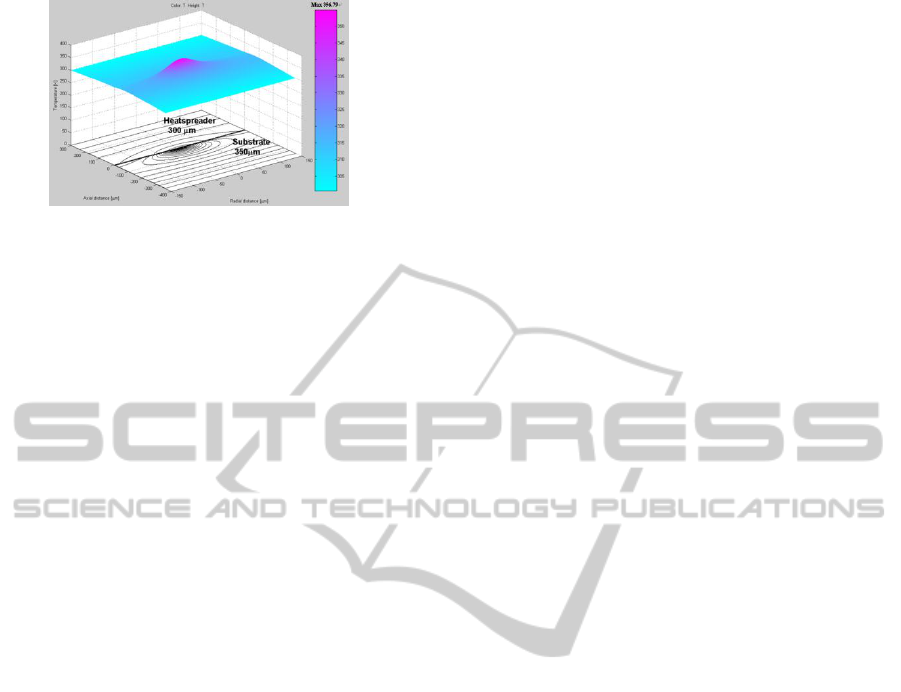

At the same time, a 300µm-thick diamond chip

was bonded on the gain chip with 350 µm substrate,

as shown in Fig. 4. The maximum temperature rise

is 56.79 K, which is much lower than the 934.21 K

shown in Fig.3. Therefore, the diamond has

outstanding heat spread results. Whilst using

heatspreader has superior heat spread effect, and

we’ll try to bonding the diamond on the gain chip to

obtain higher fundamental power so as to get higher

harmonic power in our next work.

Figure 2: Heat distribution of the semiconductor chip

without substrate.

Figure 3: Heat distribution of the semiconductor chip

when its substrate is 350 µm-thick.

SIMULTECH 2012 - 2nd International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

232

Figure 4: Heat distribution of the semiconductor chip with

its 350 µm-thick substrate which is bonded a 300µm-thick

diamond heatspreader.

3 CONCLUSIONS

In this papser, the thermal distribution has been

discussed and the simulation results has been

demonstrated by finite-element analysis method.

Using the model, we could optimize the SDL and

obtain higher output power.

ACKNOWLEDGEMENTS

This work is supported by the National Natural

Science Foundation of China ( Grant No

61177047).

REFERENCES

M. Kuznetsov. F. Hakimi, R. Sprague, and A. Mooradian,

IEEE J. Sel. Top. Quantum Electron, 5. 516-573, 1999,

“Design and characteristics of high-power (>0.5-

WCW) diode-pumped vertical –external-cavity

surface-emitting semiconductor lasers with circular

TEM00 beams”.

A J. Maclean, Alan J. Kemp, Stephane Calvez, IEEE

44,3,2008, “Continuous Tuning and Efficient

Intracavity Second-Harmonic Generation in a

Semiconducot Disk Laser With an Intracavity

Diamond Heaterspreader”

P. Daukantas, Opt. Photon, News. 18, pp. 20-27,2007

“Optics in forensics: Separating science from fiction”.

W. P. Risk, T. R. Gosnell, and A. V. Nurmikko, 2003,

“Compact blue-green lasers” (Cambridge University

Press, UK)

A. Garnache, A. Liu, L.Cerutti, and A. Campargue, Chem.

Phys. Lett., 416, 22-27, 2005, “Intracavity laser

absorption spectroscopy with a vertical external cavity

surface emitting laser at 2.3µm: Application to water

and carbon dioxide”.

A. Richter, H. Scheife, E. Heumannn, G. Huber, W.

Seelert, and A. Diening, Electron. Lett., 41, 794-795,

2005, “Semiconductor laser pumping of continuous-

wave Pr3+-doped zblan fibre laser”.

S. W. Corzine, R. S. Geels, J. W. Scott, R. H. Yan, and L.

A. Coldren: IEEE J. Quantum Electron. 25,1513. 1989

Simulation of the Thermal Management of the Semiconductor Disk Laser

233