Support Vector Machines for Identification of HCCI Combustion

Dynamics

Vijay Manikandan Janakiraman

1

, Jeff Sterniak

2

and Dennis Assanis

3

1

Department of Mechanical Engineering, University of Michigan, Ann Arbor, MI, U.S.A.

2

Robert Bosch LLC, Farmington Hills, MI, USA

3

Stony Brook University, Stony Brook, NY, U.S.A.

Keywords:

Support Vector, Identification, Combustion, Homogeneous Charge Compression Ignition, HCCI, Neural

Networks, Nonlinear Regression, Engine Model, Control Model.

Abstract:

Homogeneous charge compression ignition (HCCI) is a promising technology for Internal Combustion En-

gines to improve efficiency and reduce nitrogen oxides emissions. Control of HCCI combustion is often

model-based, and it is vital to have a good model of the engine to make control decisions. The HCCI engine is

characterized by complex chemical kinetics whose physical modeling is difficult and laborious. Identification

is an effective alternative to quickly develop control oriented models for such systems. This paper formulates

a Support Vector Regression (SVR) methodology for developing identification models capturing HCCI com-

bustion behavior. Measurable quantities from the engine such as net mean effective pressure (NMEP) and

crank angle at 50% mass fraction burned (CA50) can be used to characterize and control the HCCI engine and

are considered for identification in this study. The selected input variables include injected fuel mass (FM)

and valve events {intake valve opening (IVO), exhaust valve closing (EVC)}. Transient data from a gasoline

HCCI engine recorded at stable HCCI conditions is used for training, validating and testing the SVR models.

Comparisons with the experimental results show that SVR with Gaussian kernels can be a powerful approach

for identification of a complex combustion system like the HCCI engine.

1 INTRODUCTION

In recent years, the requirements on automotive per-

formance, emissions and safety have become increas-

ingly stringent. In spite of advanced concepts enter-

ing the industry, achieving fuel economy, emission

and cost targets simultaneously still remains an ar-

duous task. HCCI engines gained the spotlight from

traditional spark ignited and compression ignited en-

gines owing to its ability to reduce emissions and fuel

consumption significantly (Thring, 1989; Christensen

and Johansson, 1997; Aoyama and Sato, 1996). In

spite of its known advantages, HCCI combustion

poses several challenges for implementation. A ma-

jor challenge is achieving stable combustion over a

wide operating range. HCCI control is a hard prob-

lem and a predictive model is typically used to make

decisions (Chiang and Chen, 2010; Bengtsson, 2010;

Ravi and Gerdes, 2009). Hence it becomes extremely

important to develop accurate HCCI models that can

operate with less computational demand so that it can

be implemented on-board for controls and diagnos-

tics purposes. HCCI combustion is characterized by

complex nonlinear chemical and thermal dynamics,

which are extremely laborious and tedious to model

using physics. Also, the model may be required to

predict the nonlinear dynamic behavior of the engine

for several steps ahead of time for analysis and op-

timization. Hence a key requirement is to develop a

model quickly that can capture the required dynamics

for control purposes and has the potential to be imple-

mented on-board.

For the HCCI identification problem, Support

Vector Machine based regression was selected for its

fast operation and good approximation capabilities to

fit nonlinear systems (Hammer and Gersmann, 2003;

Clarke and Simpson, 2005). Also, when SVR is

trained on real-world data, it represents the real sys-

tem and makes no simplifying assumptions of the un-

derlying process. The dynamics of sensors, actua-

tors and other complex processes, which are usually

overlooked/hard to model using physics, can be cap-

tured using the identification method. In addition,

for a system like the combustion engine, prototype

hardware is typically available, and sufficient exper-

imental data can be collected. The application of

385

Janakiraman V., Sterniak J. and Assanis D..

Support Vector Machines for Identification of HCCI Combustion Dynamics.

DOI: 10.5220/0004035903850393

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 385-393

ISBN: 978-989-8565-21-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

SVR to system identification (Gretton and Scholkop,

2001; Drezet and Harrison, 1998; Trejo, 2006; Ra-

mon, 2006; Wang and Pan, 2009; Chitralekha, 2010),

time series modeling (Mller and Vapnik, 1997; Kim,

2003) and predicting chaotic behavior (Sun and Luo,

2006) has been reported in the literature though major

practical implementations were less abundant (Wang

and Pan, 2009; Chitralekha, 2010). Identification of

HCCI combustion is not common owing to its com-

plex and unstable behavior. A subspace based iden-

tification was the only reported approach (Bengtsson

and Johansson, 2006) where linear models were de-

veloped for HCCI model predictive control. A non-

linear system identification for HCCI has not been

reported in the literature to the best of the authors’

knowledge. This paper aims to be the first applica-

tion of support vector machines for nonlinear identi-

fication of the HCCI combustion which is the main

contribution of this paper. A gasoline homogeneous

charge compression ignition engine is considered in

this paper. This paper is organized as follows. The

basic idea and formulation of the SVR model is pre-

sented, followed by experiment design for collecting

stable HCCI data from the engine. Tuning of hyper-

parameters of the SVR model using cross-validation

is demonstrated, followed by validation of the model

using predictions based on unseen data.

2 SUPPORT VECTOR

REGRESSION

The Support Vector Regression (Vapnik and Smola,

1996; Drucker, 1996; Schlkopf and Williamson,

1998) was developed as an extension to the Sup-

port Vector Machines (SVM) originally developed for

classification. The SVR model car approximates the

given input-output data by forming an error bound-

ary (error tube) (Drucker, 1996) around the data by

solving a convex constrained optimization problem.

The kernel trick is typically used for nonlinear sys-

tems where a kernel function transforms the input

variables to a high dimensional feature space so that

the input-output relationship can be approximated as

a linear function in this transformed space. An im-

portant property of the SVR method is that the ob-

tained model could be a sparse representation of the

nonlinear system which can have benefits in terms of

storage.

In general, the non-linear time-invariant dynamic

model of the HCCI combustion system can be repre-

sented as

˙z(t) = g(z(t), u(t)) + v

1

(1)

y(t) = h(z(t), u(t)) + v

2

(2)

where t represents time, z(t) ∈ R

z

d

, y(t) ∈ R

y

d

and

u(t) ∈ R

u

d

represent the system states, outputs and in-

put respectively while v

1

and v

2

represent the distur-

bance on state and measurements respectively. The

terms z

d

, y

d

and u

d

represent the dimensions of the

state, output and input respectively. In an identifi-

cation approach, the functions g(.) and h(.) are un-

known nonlinear mappings and it may not be al-

ways possible to have state measurements. Hence a

generic nonlinear identification model using the non-

linear auto regressive model with exogenous input

(NARX) is considered as follows

y(k) = f[u(k), u(k − 1), ..

.., u(k− n

u

), y(k− 1), .., y(k− n

y

)] (3)

where u = [FM NVO]

T

, y = [NMEP CA50]

T

, k

represents the discrete time index, f(.) represents the

nonlinear function mapping by the model and n

u

, n

y

represent the number of past input and output sam-

ples required (order of the system). Let x represent

the augmented input vector

x = [u(k), u(k − 1), ..

.., u(k− n

u

), y(k− 1), .., y(k− n

y

)]

T

(4)

Consider the independent and identically dis-

tributed training data {(x

1

, y

1

), ..., (x

n

, y

n

)} ∈ X × Y ,

where X denotes the space of the input features (Here

X = R

u

d

(n

u

+1)+y

d

n

y

and Y = R).The goal of SVR is

to approximate the underlying input-output function

mapping f(.) by minimizing a risk functional with re-

spect to the model parameters

R(w) =

1

n

n

∑

i=1

L(y

i

− ˆy

i

(x, w)) +

1

2

w

T

w (5)

where ˆy(x, w) represents the model prediction given

by

ˆy(x, w) = hw, φ(x)i + b (6)

Here, w ∈ R

u

d

(n

u

+1)+y

d

n

y

and b ∈ R represents the

model parameters, φ is a function that transforms the

input variables to a higher dimension feature space

H and h., .i represents inner product. The first term

of equation (5) represents the error minimizing term

while the second term accounts for regularization.

The SVR model deals only with the inner products

of φ and a kernel function can be defined that takes

into account the inner products implicitly as

K(x

i

, x

j

) = hφ(x

i

), φ(x

j

)i (7)

The function φ is not required to be known but any

kernel function that satisfies the Mercer’s condition

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

386

(Vapnik, 1995) such as radial basis functions, poly-

nomial and sigmoidal functions can be used. In this

study, a gaussian kernel function is used. The ker-

nel transforms the input variables to a high dimension

space H and aids in converting a nonlinear map in

the X − Y space to a linear map in H space. This is

known as kernel trick in the literature.

There are two different formulations for SVR

based on accuracy control such as ε-SVR (Vapnik and

Smola, 1996; Smola and Schlkopf, 2003) and ν-SVR

(Schlkopf and Williamson, 1998). In ε-SVR, the ob-

jective is to find a function f(x) that has at most ε

deviation from the actual targets y for the training

data while in ν-SVR the ε is automatically tuned in

the algorithm. The ν-SVR is considered in this study,

as the tradeoff between model complexity and accu-

racy (controlled by ν) can be tuned to the required

accuracy and sparseness. Also, the ε-insensitive loss

function (8) can be used. Other loss functions can be

used if specific information about the noise model is

known (Scholkopf and Smola, 2001). For instance, it

is known that a quadratic loss function performs well

for gaussian distributed noise (Hastie and Friedman,

1995) while a huber loss function can be used if the

density describing the noise is smooth is the only in-

formation that is available. For the ν-SVR considered

in this paper, the following ε-insensitive loss function

is used for achievingmodel sparseness. The loss func-

tion (8) is defined to be zero when the predicted out-

put falls within the error tube and the magnitude of the

distance away from the error tube when the prediction

falls outside the tube.

L(y− ˆy)

ε

=

(

0 if | y− ˆy |≤ ε

ε− | y− ˆy | otherwise

(8)

The goal of SVR training is to determine the op-

timal model parameters (w

∗

, b

∗

) that minimizes the

risk function (5). However, solving (5) involves min-

imization of the loss function L in (8) for every data

point. Since L is minimum for the points lying in-

side the error tube, this translates to minimizing L

for points that lie outside the error tube. If a slack

variable is assigned to every data point such that the

slack variable is the measure of discrepancy between

the predicted output and the error tube, the problem

reduces to minimizing the slack variables ζ and ζ

∗

which leads into the following optimization problem

min

w,b,ε,ζ

i

,ζ

∗

i

1

2

w

T

w+C(νε+

1

n

n

∑

i=1

(ζ

i

+ ζ

∗

i

)) (9)

subjected to

y

i

− (hw, φ(x

i

)i + b) ≤ ε+ ζ

i

(hw, φ(x

i

)i + b) − y

i

≤ ε+ ζ

∗

i

ζ

i

, ζ

∗

i

, ε ≥ 0

(10)

for i = 1, .., n.

It should be noted that the slack variables take val-

ues of zero when the points lie inside the error tube.

Also, separate slack variables ζ and ζ

∗

are assigned

for points lying outside the error tube on either side

of the function. The above optimization problem is

usually referred as the primal problem and the vari-

ables w, b, ζ, ζ

∗

and ε are the primal variables. In

the above formulation (9), ε is considered as a vari-

able to be optimized along with the model parame-

ters. This allows ν to set a lower bound on the frac-

tion of data points used in parameterizing the model

(Schlkopf and Bartlett, 2000) and hence by tuning ν

one can achieve a tradeoff between model complex-

ity (sparseness) and accuracy. A value of ν close to

one will try to shrink the ε tube and reduce sparse-

ness (all data points become support vectors) while

reducing ν close to zero will result in a sparse model

(very few data points are used in model parametriza-

tion) with possible under-fitting. This flexibility is the

prime reason for selecting the ν-SVR algorithm for

this study.

The lagrangian can be formulated as follows

L(w, b, ζ, ζ

∗

, ε, α, α

∗

, β, β

∗

, γ) =

1

2

w

T

w+C(νε+

1

n

n

∑

i=1

(ζ

i

+ ζ

∗

i

))

+

n

∑

i=1

α

i

(y

i

− (hw, φ(x

i

)i + b) − ε − ζ

i

)

+

n

∑

i=1

α

∗

1

((hw, φ(x

i

)i + b) − y

i

− ε− ζ

∗

i

)

−

n

∑

i=1

(β

i

ζ

i

+ β

∗

i

ζ

∗

i

) −

n

∑

i=1

γε (11)

where α, α

∗

, β, β

∗

, γ are the lagrange multipliers or the

dual variables. The derivatives of (11) with respect to

the primal variables w, b, ζ

i

, ζ

∗

i

, ε yields

n

∑

i=1

(α

∗

i

− α

i

)φ(x

i

) = w (12)

n

∑

i=1

(α

∗

i

− α

i

) = 0 (13)

C

n

− α

i

− β

i

= 0, i = 1, .., n (14)

C

n

− α

∗

i

− β

∗

i

= 0, i = 1, .., n (15)

Cν −

n

∑

i=1

(α

∗

i

+ α

i

) − β = 0 (16)

The other KKT conditions are given by

α

i

(y

i

− (hw, φ(x

i

)i + b) − ε − ζ

i

) = 0 (17)

SupportVectorMachinesforIdentificationofHCCICombustionDynamics

387

α

∗

1

((hw, φ(x

i

)i + b) − y

i

− ε− ζ

∗

i

) = 0 (18)

β

i

ζ

i

= 0 (19)

β

∗

i

ζ

∗

i

= 0 (20)

γε = 0 (21)

for every i = 1, 2, ..., n. Also, since every data obser-

vation cannot lie on both sides of the function simul-

taneously,

αα

∗

= 0 (22)

ββ

∗

= 0 (23)

Substituting the above equations in (11), we get

the following dual optimization problem

max

α

i

,α

∗

i

n

∑

i=1

(α

∗

i

− α

i

)y

i

−

1

2

n

∑

i=1

n

∑

j=1

(α

∗

i

− α

i

)(α

∗

j

− α

j

)K(x

i

, x

j

) (24)

subjected to

∑

n

i=1

(α

∗

i

− α

i

) = 0

∑

n

i=1

(α

∗

i

+ α

i

) ≤ νC

0 ≤ α

i

≤

C

n

0 ≤ α

∗

i

≤

C

n

(25)

for i = 1, .., n. The SVR model is given by

f(x) =

n

∑

i=1

(α

∗

i

− α

i

)K(x

i

, x) + b (26)

where ε and b can be determined using (10). This

is the well known SVR model and the following are

some known properties. The parameter w can be com-

pletely described as a linear combination of functions

of the training data (x

i

). The model is independent of

the dimensionality of X and the sample size n and the

model can be described by dot products between the

data.

3 EXPERIMENT DESIGN

The data for system identification is collected from

a variable valve timing gasoline HCCI engine whose

specifications are listed in Table 1. For identifica-

tion of the HCCI combustion, an amplitude modu-

lated pseudo-random binary sequence (A-PRBS) has

been used to design input signals. The A-PRBS signal

excites the system at several different amplitudes and

frequencies so that rich data about the system dynam-

ics can be obtained (Agashe and Agashe, 2007). The

steps of a PRBS data set can be tuned to remain con-

stant for a specified time. This determines if the exci-

tation is dominantly transient or steady state. For the

HCCI system, the step signal was held constant for

at least 25 cycles so that the data captures both tran-

sient and steady state behavior fairly equally. The data

is sampled using the AVL Indiset acquisition system

where in-cylinder pressure is sensed every crank an-

gle while NMEP and CA50 are determined on a com-

bustion cycle basis. The input signals are designed

off-line and loaded into the rapid prototyping hard-

ware that provides commands to the engine controller.

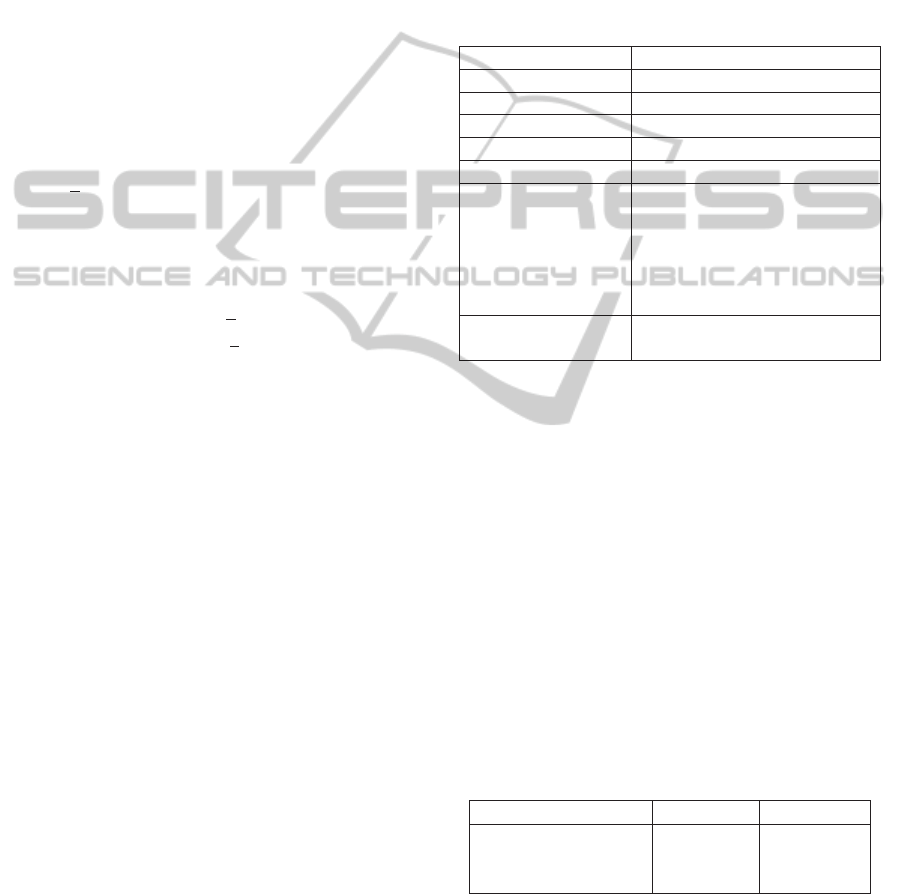

Table 1: Specifications of the experimental HCCI engine.

Engine Type 4-stroke In-line

Fuel Gasoline

Displacement 2.0 L

Bore/Stroke 86/86

Compression Ratio 11.25:1

Injection Type Direct Injection

Valvetrain Variable Valve Timing

with hydraulic cam phaser

(0.25mm constant lift,

119 degree constant duration

and 50 degree crank angle

phasing authority)

HCCI strategy Exhaust recompression

using negative valve overlap

HCCI is unstable beyond certain operating con-

ditions and hence large input steps close to unstable

regimes tend to misfire the engine or operate on limit

cycles. For this purpose, the input excitations are

required to be filtered using prior knowledge about

the system. As a first check, a design of experi-

ments model (DOE) (Kruse and Lang, 2010) using

a set of steady state experiments is used to eliminate

the unstable input combinations. The feasible lim-

its of inputs at a speed of 2500 RPM as given by the

DOE model are shown in Table 2. The feasible HCCI

load range is shown in Figure 1, and the stable HCCI

boundary for different fueling inputs is shown in Fig-

ure 2.

Table 2: Actuator Extremes for stable HCCI (from the

steady state DOE model). The valve events are measured

in degrees after top dead center (deg aTDC).

Input Min Limit Max Limit

Fuel Mass (mg/cyc) 7.0437 12.9161

IVO (deg aTDC) 78 128

EVC (deg aTDC) -119 -69

The A-PRBS sequence is designed to excite the

engine within this stable HCCI region defined by the

DOE model. It should be noted that the DOE filtered

input limits are valid only for steady state conditions

and a large step near the boundary of stable HCCI can

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

388

1500 2000 2500 3000

1

1.5

2

2.5

3

3.5

4

4.5

5

Engine Speed [RPM]

Net Mean Effective Pressure [bar]

Naturally Aspirated Load Range

Upper Load Limit

Lower Load Limit

(2500, 3.27)

(2500, 1.925)

Figure 1: Load range (in NMEP) of naturally aspirated

HCCI engine.

80 90 100 110 120

−130

−120

−110

−100

−90

−80

−70

IVO (deg aTDC)

EVC (deg aTDC)

Fuel Mass − 7.29945 mg/cyc

80 90 100 110 120

−130

−120

−110

−100

−90

−80

−70

IVO (deg aTDC)

EVC (deg aTDC)

Fuel Mass − 7.90625 mg/cyc

80 90 100 110 120

−130

−120

−110

−100

−90

−80

−70

IVO (deg aTDC)

EVC (deg aTDC)

Fuel Mass − 8.59449 mg/cyc

80 90 100 110 120

−130

−120

−110

−100

−90

−80

−70

IVO (deg aTDC)

EVC (deg aTDC)

Fuel Mass − 9.33501 mg/cyc

Figure 2: Stable HCCI operating region at given actuator

settings of IVO, EVC and Fueling.

lead to instabilities. Hence as a means of precaution

against running the engine in an unstable manner and

to save time during experiments, a simple feedback

was created, which attempts a particular input com-

bination and if found to be unstable, quickly skips to

the next combination in the A-PRBS sequence. As

a first attempt, the CA50 was considered the feed-

back signal. During a small time window, any input

combination that resulted in a CA50 above 21 (found

by observing the CA50 during several misfires) is im-

mediately skipped, and the engine is run on the next

combination in the sequence. Finally, post-processing

was performedon the data to removemisfire and post-

misfire data.

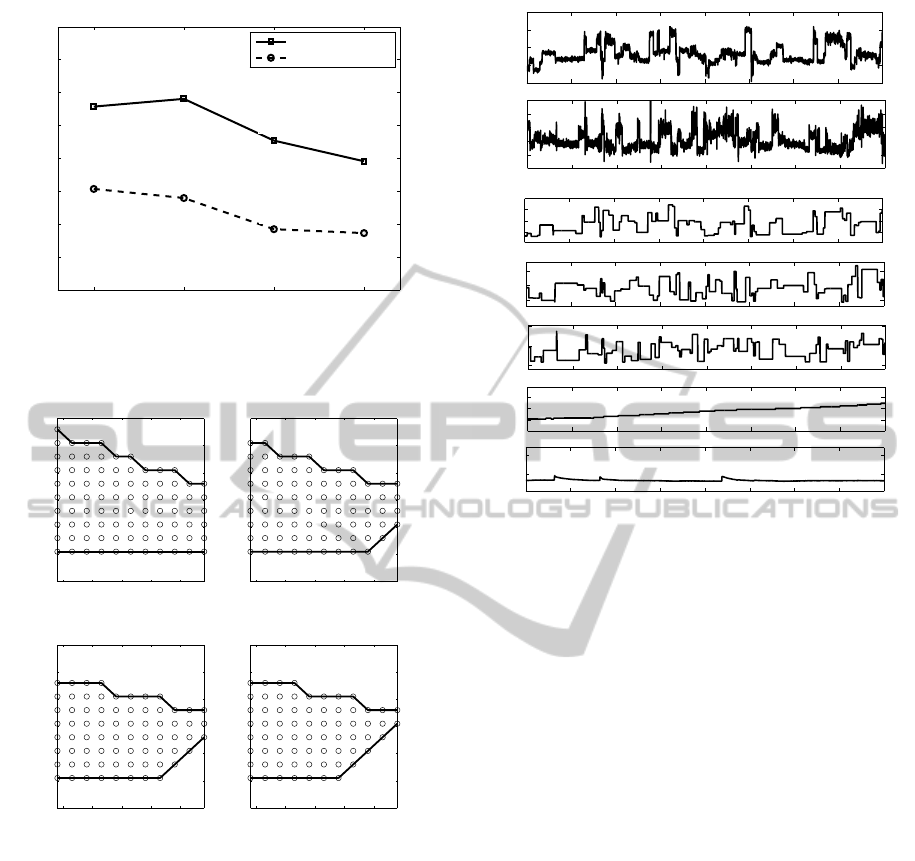

A subset of the bounded input signals and the

1000 1500 2000 2500 3000 3500 4000 4500 5000

2

2.5

3

3.5

4

NMEP

(bar)

1000 1500 2000 2500 3000 3500 4000 4500 5000

−5

0

5

10

15

20

CA50

(deg aTDC)

1000 1500 2000 2500 3000 3500 4000 4500 5000

8

10

12

Fuel Mass

(mg/cyc)

1000 1500 2000 2500 3000 3500 4000 4500 5000

80

100

120

IVO

(deg aTDC)

1000 1500 2000 2500 3000 3500 4000 4500 5000

−120

−100

−80

EVC

(deg aTDC)

1000 1500 2000 2500 3000 3500 4000 4500 5000

80

90

100

Coolant

Temp

(deg C)

1000 1500 2000 2500 3000 3500 4000 4500 5000

60

80

cycles

Intake Air

Temp

(deg C)

Figure 3: A-PRBS input-output sequence.

recorded outputs from the engine are shown in Figure

3. It has to be noted that the engine coolant tempera-

ture and the intake air temperature varies slightly dur-

ing the experiment and their variations are recorded

and considered inputs to the model. Nearly 30000

cycles of data were collected, which corresponds to

about 25 minutes of engine testing. About 30% of the

data were found to be arising from unstable operation

and were removed.

4 SVR TRAINING

This section details the training procedure using the

SVR method described in section 2. The SVR is

coded in Matlab using LIBSVM package (Chang and

Lin, 2011). For each output, the model has four

hyper-parametersnamely the system order (n

u

and n

y

,

assumed to be the same), the cost parameter C, ker-

nel parameter ω and SVR parameter ν. To obtain a

model that generalizes well and captures the right or-

der of dynamics, the above hyper-parameters need to

be optimized based on cross-validation.

4.1 Tuning Hyper-parameters

The data set comprising of (x, y) is divided into a

training set that constitutes 80% of the data while

the remaining 20% is separated out for testing. Fur-

SupportVectorMachinesforIdentificationofHCCICombustionDynamics

389

thermore, the training data is divided into validation

training and validation testing data sets for tuning the

model hyper-parameters. The testing data set is never

seen by the model during the training and validation

phases. The parameter ν determines the tradeoff be-

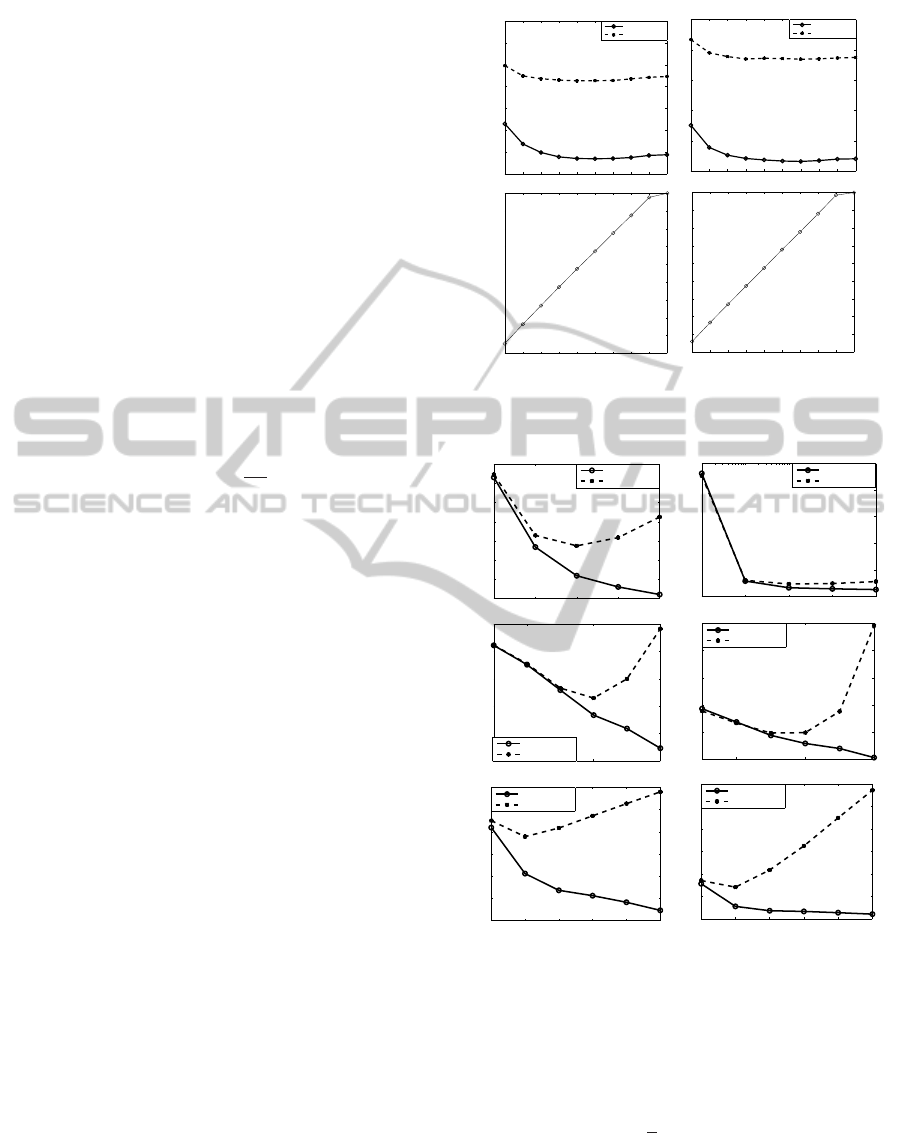

tween the spareness and accuracy of the models. An

optimal value of ν results in the minimum model pa-

rameters required for the given accuracy level. It can

be seen using Figure 4 that the knee of the curve

is located at ν of 0.2 and increasing ν beyond this

value doesn’t improve the the prediction accuracy

even though more parameters are used to fit the data

(increase in sparseness). Hence the knee of the valida-

tion error curve is chosen the optimal ν. However for

the case of NMEP, the desired accuracy level has been

achievedwith the minimum value of ν of 0.1. In order

to have a simple model (minimum sparseness), this

value is taken as the optimal ν. In this study, sparse-

ness is defined as follows

sparseness =

n

sv

n

(27)

where n

sv

is the total number of support vectors.

The cost parameter C determines the relative im-

portance given to the outliers and hence the sensitiv-

ity to measurement noise. A large value of C tries to

fit the model for outliers thereby over-fitting the data.

The kernel parameter ω is required to be tuned for

the same reason of having good generalization. The

system order determines the number of previous mea-

surements required to predict the future output. An

optimal value of the order represents the system dy-

namics correctly and a large value not only makes

the model complex by increasing the dimension of

x but also gives a bad prediction of the system’s re-

sponse. It can be seen from Figure 5 that the valida-

tion error increases beyond the optimal values of C,

ω and system order even though training error con-

tinues to decrease. Hence it is important to tune the

hyper-parameters in combination. A full grid search

is performed where the validation training data set

is used to train the model with all combinations of

the considered hyper-parameter values and validation

error found by testing the models on the validation

test data set. Table 3 lists the best combination of

hyper-parametersfor NMEP and CA50 which had the

minimum validation errors. Furthermore the optimal

hyper-parameters are used for retraining with the full

training data set before which it is used for testing.

4.2 SVR Prediction Results

The SVR models with the optimized hyper-

parameters are then trained with the entire training

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

0.007

0.008

0.009

0.01

0.011

0.012

0.013

0.014

ν

Error

Training Error

Validation Error

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

ν

Sparsity

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

2.5

3

3.5

4

4.5

5

x 10

−3

ν

Error

Training Error

Validation Error

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

ν

Sparsity

CA50

NMEP

Figure 4: Tuning the accuracy vs sparsity tradeoff parame-

ter ν using cross-validation.

10

−2

10

−1

10

0

10

1

10

2

0.006

0.008

0.01

0.012

0.014

0.016

0.018

0.02

C

Error

Training Error

Validation Error

10

−2

10

−1

10

0

10

1

10

2

0

0.01

0.02

0.03

0.04

0.05

C

Error

Training Error

Validation Error

10

−2

10

0

10

2

0

0.005

0.01

0.015

0.02

0.025

ω

Error

Training Error

Validation Error

10

−2

10

0

10

2

0

0.005

0.01

0.015

0.02

0.025

ω

Error

Training Error

Validation Error

0 1 2 3 4 5

0.004

0.006

0.008

0.01

0.012

0.014

0.016

System Order

Error

Training Error

Validation Error

0 1 2 3 4 5

2

4

6

8

10

12

14

x 10

−3

System Order

Error

Training Error

Validation Error

CA50

NMEP

Figure 5: Tuning cost parameter C, kernel parameter ω and

system order using cross-validation.

data set. The models are then simulated with the un-

seen test data and performance of the models are mea-

sured using mean squared error (MSE) given by

MSE =

1

n

n

∑

i=1

(y

i

− ˆy

i

)

2

(28)

Note that the MSE is different from the loss func-

tion (8) used in SVR modeling. The MSE for the

NMEP and CA50 models during training and testing

are given in Table 4.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

390

Table 3: Optimal combination of model hyper-parameters.

NMEP CA50

C 1 1

ω 1 1

System Order 1 1

ν 0.1 0.2

Table 4: SVR performance.

NMEP CA50

Training MSE 0.0031 0.0085

Testing MSE 0.0042 0.0103

Model Sparseness 0.1261 0.2283

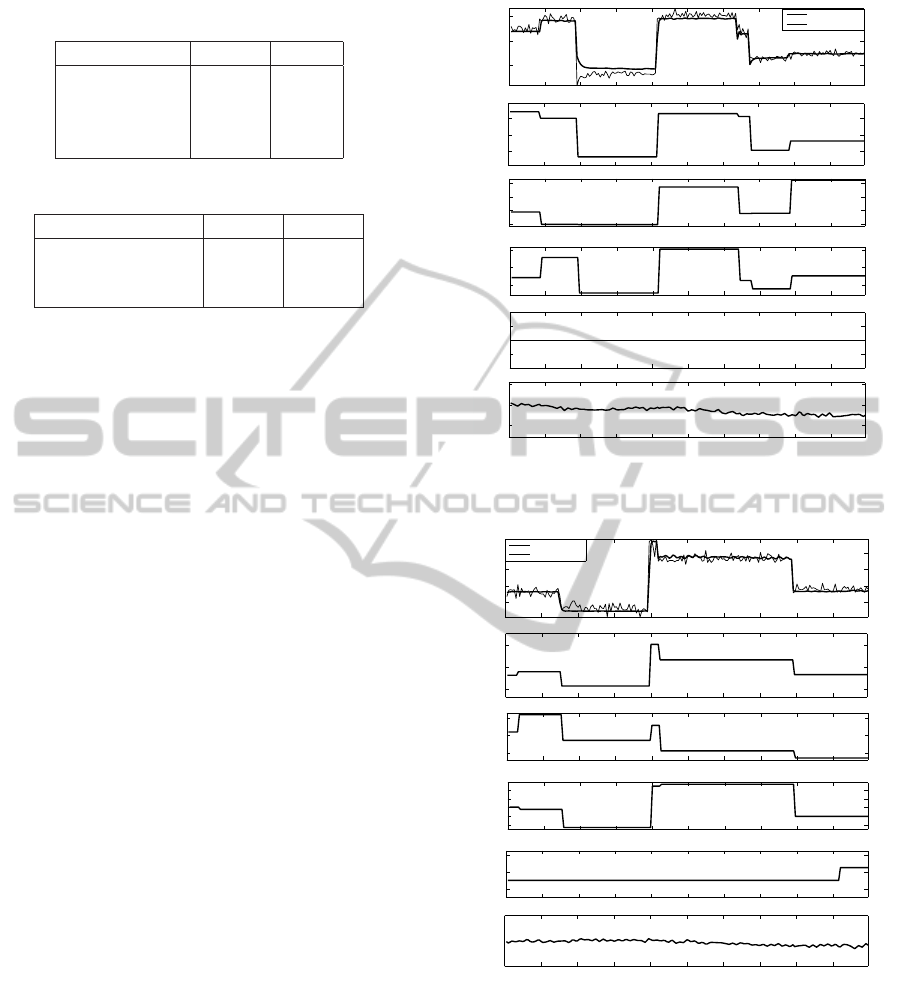

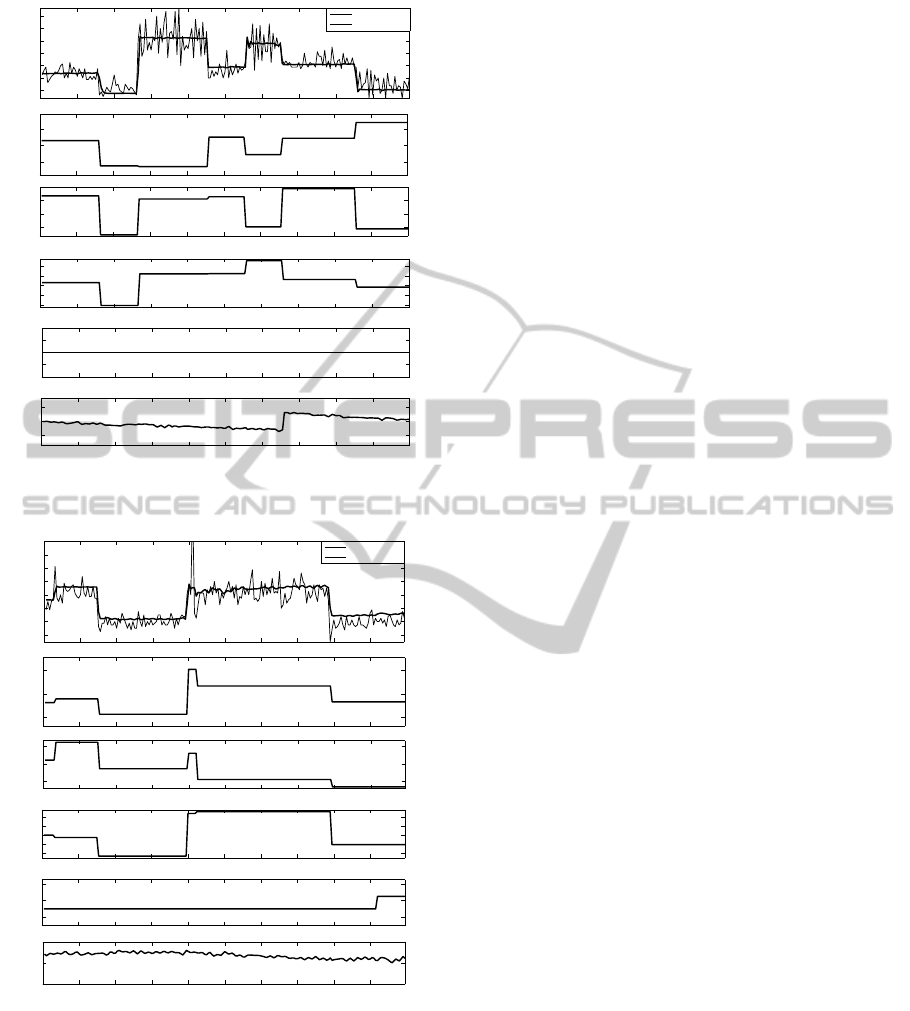

In order to observe the multi-step-ahead predic-

tions, a completely separate data set is used from

which only the inputs are given to the model along

with the initial conditions of the outputs (delay ini-

tial conditions). Figure 6 and Figure 7 show the pre-

dictions of NMEP by SVR model compared against

the engine’s measured NMEP. Figure 8 and Figure 9

show the predictions of CA50 by SVR model com-

pared against the engine’s measured CA50. It can

be observed that the model predictions match with

the engine’s actual response. It should be noted that

the model’s predictions are based on computer com-

manded step input sequences. The wiggly behavior

in the model’s predictions are due to the variations

in the intake air temperature measurements which are

uncontrollable parameters. HCCI combustion is very

sensitive to the intake air temperature which can be

considered as an independent control input. However

practical realization of such a control system can be

difficult in automotive applications and hence consid-

ered only as a disturbance in the identification model-

ing. It can also be observed that both the steady state

values and the transients are sufficiently captured by

the models except for some regions where there is a

bias offset owing to poor approximations. Lack of

excitations near such input combinations could be a

reason for the bad predictions of the model.

Model sparseness in Table 4 shows that only a

small fraction of the training data set (1892 parame-

ters for NMEP model and 3425 parameters for CA50

model) is used to represent the model efficiently and

these data observations constitute the support vectors

in this method.

5 CONCLUSIONS AND FUTURE

WORK

Support Vector Machines are one of the state of the art

methods for nonlinear regression and the application

0 20 40 60 80 100 120 140 160 180

2.5

3

3.5

NMEP

(bar)

Actual Response

SVR Prediction

0 20 40 60 80 100 120 140 160 180

80

90

100

110

IVO

(deg aTDC)

0 20 40 60 80 100 120 140 160 180

−110

−100

−90

EVC

(deg aTDC)

0 20 40 60 80 100 120 140 160 180

96.5

97

97.5

98

98.5

Coolant Temp

(deg C)

0 20 40 60 80 100 120 140 160 180

52

53

54

Intake Air Temp

(deg C)

Cycles

0 20 40 60 80 100 120 140 160 180

8

10

12

Fuel Mass

(mg/cyc)

Figure 6: Comparison of NMEP (engine output and SVR

prediction).

0 20 40 60 80 100 120 140 160 180

2.6

2.8

3

3.2

NMEP

(bar)

Actual Response

SVR Prediction

0 20 40 60 80 100 120 140 160 180

100

110

120

IVO

(deg aTDC)

0 20 40 60 80 100 120 140 160 180

−115

−110

−105

−100

−95

EVC

(deg aTDC)

0 20 40 60 80 100 120 140 160 180

97

98

99

Coolant Temp

(deg C)

0 20 40 60 80 100 120 140 160 180

51

54

Cycles

Intake Air Temp

(deg C)

0 20 40 60 80 100 120 140 160 180

8

10

12

Fuel Mass

(mg/cyc)

Figure 7: Comparison of NMEP (engine output and SVR

prediction).

of SVR to nonlinear system identification is not abun-

dant in spite of its attractive properties. In this paper a

complex nonlinear dynamic system such as the HCCI

engine is identified using ν-SVR method. Data col-

lection within the stable boundary of HCCI combus-

tion has been accomplished by pre-screening the in-

put sequence using the steady state DOE model of the

engine and by using a closed loop control to avoid un-

SupportVectorMachinesforIdentificationofHCCICombustionDynamics

391

0 20 40 60 80 100 120 140 160 180 200

2

4

6

8

10

12

14

CA50

(deg aTDC)

Actual Response

SVR Prediction

0 20 40 60 80 100 120 140 160 180 200

90

100

110

IVO

(deg aTDC)

0 20 40 60 80 100 120 140 160 180 200

−115

−110

−105

−100

−95

EVC

(deg aTDC)

0 20 40 60 80 100 120 140 160 180 200

96.5

97

97.5

98

98.5

Cooland Temp

(deg C)

0 20 40 60 80 100 120 140 160 180 200

52

53

54

Cycles

Intake Air Temp

(degC)

0 20 40 60 80 100 120 140 160 180 200

8

10

12

Fuel Mass

(mg/cyc)

Figure 8: Comparison of CA50 (engine output and SVR

prediction).

0 20 40 60 80 100 120 140 160 180

0

2

4

6

8

10

12

14

CA50

(deg aTDC)

Actual Response

SVR Prediction

0 20 40 60 80 100 120 140 160 180

100

110

120

IVO

(deg aTDC)

0 20 40 60 80 100 120 140 160 180

−115

−110

−105

−100

−95

EVC

(deg aTDC)

0 20 40 60 80 100 120 140 160 180

97

98

99

Coolant Temp

(deg C)

0 20 40 60 80 100 120 140 160 180

51

52

53

Cycles

Intake Air Temp

(degC)

0 20 40 60 80 100 120 140 160 180

8

10

12

Fuel Mass

(mg/cyc)

Figure 9: Comparison of CA50 (engine output and SVR

prediction).

stable excitations. The dynamics of NMEP and CA50

of naturally aspirated HCCI combustion at constant

speed is modeled using SVR to a good accuracy. Dis-

tinguishing features of ν-SVR including global opti-

mality and sparseness make the method very attrac-

tive compared to traditional neural networks based

identification. Future research would focus on con-

troller development using the SVR models to analyze

the suitability and effectiveness compared to existing

neural network controllers.

ACKNOWLEDGEMENTS

This material is based upon work supported by

the Department of Energy [National Energy Tech-

nology Laboratory] under Award Number(s) DE-

EE0003533. This work is performed as a part of

the ACCESS project consortium (Robert Bosch LLC,

AVL Inc., Emitec Inc.) under the direction of PI

Hakan Yilmaz, Robert Bosch, LLC.

DISCLAIMER

This report was prepared as an account of work spon-

sored by an agency of the United States Government.

Neither the United States Government nor any agency

thereof, nor any of their employees, makes any war-

ranty, express or implied, or assumes any legal liabil-

ity or responsibility for the accuracy, completeness,

or usefulness of any information, apparatus, prod-

uct, or process disclosed, or represents that its use

would not infringe privately owned rights. Reference

herein to any specific commercial product, process,

or service by trade name, trademark, manufacturer,

or otherwise does not necessarily constitute or imply

its endorsement, recommendation, or favoring by the

United States Governmentor any agency thereof. The

views and opinions of authors expressed herein do not

necessarily state or reflect those of the United States

Government or any agency thereof.

REFERENCES

Agashe, S., Ghatol A. and Agashe, S. (2007). Automa-

tion of heat exchanger using neural network. In Inter-

national Journal of Mathematical and Computer Sci-

ences.

Aoyama, T., Hattori Y. Mizuta J. and Sato, Y. (1996). An

experimental study on premixed-charge compression

ignition gasoline engine. In SAE Technical Paper

960081.

Bengtsson, J., Strandh P. Johansson R. Tunestal P. and Jo-

hansson, B. (2006). Model predictive control of ho-

mogeneous charge compression ignition (hcci) engine

dynamics. In 2006 IEEE International Conference on

Control Applications.

Bengtsson, J., Strandh P. Johansson R. Tunestl P. Johans-

son B. (2010). Hybrid control of homogeneous charge

compression ignition (hcci) engine dynamics. In In-

ternational Journal of Control. Taylor & Francis.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

392

Chang, Chih-Chung and Lin, Chih-Jen (2011). Libsvm: A

library for support vector machines. In ACM Transac-

tions on Intelligent Systems and Technology. Software

available at http://www.csie.ntu.edu.tw/ cjlin/libsvm.

Chiang, C. J. and Chen, C. L. (2010). Constrained control

of homogeneous charge compression ignition (hcci)

engines. In 5th IEEE Conference on Industrial Elec-

tronics and Applications (ICIEA).

Chitralekha, S. B., Shah S. L. (2010). Application of sup-

port vector regression for developing soft sensors for

nonlinear processes. In The Canadian Journal of

Chemical Engineering. Wiley.

Christensen, M., Einewall P. and Johansson, B. (1997). Ho-

mogeneous charge compression ignition (hcci) using

iso-octane, ethanol and natural gas- a comparison to

spark ignition operation. In SAE Technical Paper

972874.

Clarke, S. M., Griebsch J. H. and Simpson, T. W. (2005).

Analysis of support vector regression for approxima-

tion of complex engineering analyses. In Journal of

Mechanical Design.

Drezet, P. M. L. and Harrison, R. F. (1998). Support vector

machines for system identification. In UKACC Inter-

national Conference on Control.

Drucker, H., Burges C. J. C. Kaufman L. Smola A. Vap-

nik V. (1996). Support vector regression machines.

Gretton, A., Douce A. Herbrich R. Rayner P. J. W. and

Scholkop, B. (2001). Support vector regression for

black-box system identification. In Proceedings of the

11th IEEE Signal Processing Workshop on Statistical

Signal Processing.

Hammer, B. and Gersmann, K. (2003). A note on the uni-

versal approximation capability of support vector ma-

chines. In Neural Processing Letters. Kluwer Aca-

demic Publishers.

Hastie, Tibshirani and Friedman (1995). The Elements

of Statistical Learning: Data Mining, Inference, and

Prediction. Springer, 2 edition.

Kim, K. J. (2003). Financial time series forecasting using

support vector machines. In Neurocomputing. Else-

vier.

Kruse, T., Kurz S. and Lang, T. (2010). Modern statistical

modelling and evolutionary optimisation methods for

the broad use in ecu calibration. In 6th IFAC Sympo-

sium Advances in Automotive Control.

Mller, K. R., Smola A. J. Ratsch G. Scholkopf B. Kohlmor-

gen J. and Vapnik, V. (1997). Predicting time series

with support vector machines. In Artificial Neural

Networks ICANN’97. Springer Berlin / Heidelberg.

Ramon, M. M., Alvarez J. L. R. Valls G. C. Mari J. M.

Vazquez A. N. Olivas E. S. Vidal A. R. F. (2006). Sup-

port vector machines for nonlinear kernel arma system

identification. In IEEE Transactions on Neural Net-

works.

Ravi, N., Roelle M. J. Liao H. H. Jungkunz A. F. Chang

C. F. Park S. and Gerdes, J. C. (2009). Model-based

control of hcci engines using exhaust recompression.

In IEEE Transactions on Control Systems Technology.

Schlkopf, B., Bartlett P. Smola A. and Williamson, R.

(1998). Support vector regression with automatic ac-

curacy control. In Proceedings of ICANN’98, Perspec-

tives in Neural Computing.

Schlkopf, B., Smola A. J. Williamson R. C. and Bartlett,

P. L. (2000). New support vector algorithms. In Neu-

ral Computation. MIT Press.

Scholkopf, B. and Smola, A. J. (2001). Learning with Ker-

nels: Support Vector Machines, Regularization, Opti-

mization, and Beyond. MIT Press, Cambridge, MA,

USA.

Smola, A. J. and Schlkopf, B. (2003). A tutorial on sup-

port vector regression. Technical report, Statistics and

Computing.

Sun, J., Zhou Y. Bai Y. and Luo, J. (2006). Nonlin-

ear noise reduction of chaotic time series based on

multi-dimensional recurrent least squares support vec-

tor machines. In Neural Information Processing, Lec-

ture Notes in Computer Science. Springer Berlin / Hei-

delberg.

Thring, R. (1989). Homogeneous-charge compression-

ignition (hcci) engines. In SAE Technical Paper

892068.

Trejo, J. A. R., Yu W. Li X. (2006). Support vector ma-

chine for nonlinear system on-line identification. In

2006 3rd International Conference on Electrical and

Electronics Engineering.

Vapnik, V., Golowich S. E. and Smola, A. (1996). Support

vector method for function approximation, regression

estimation, and signal processing. In Advances in

Neural Information Processing Systems.

Vapnik, V. (1995). The Nature of Statistical Learning The-

ory. Springer, New York.

Wang, X., Du Z. Chen J. and Pan, F. (2009). Dynamic mod-

eling of biotechnical process based on online support

vector machine. In Journal of Computers. Academy

Publisher.

SupportVectorMachinesforIdentificationofHCCICombustionDynamics

393