An Integrated Replemishment Model under Dynamic Demand

Conditions

He-Yau Kang

1

, Amy H. I. Lee

2

and Chun-Mei Lai

3

1

Department of Industrial Engineering and Management, National Chin-Yi University of Technology,

Chung-Shan Rd., Taichung, Taiwan, R.O.C.

2

Department of Technology Management, Chung Hua University, Wu-Fu Rd., Hsinchu, Taiwan, R.O.C.

3

Department of Marketing and Logistics Management, Far East University, Zhonghua Rd., Tainan, Taiwan, R.O.C.

Keywords: Lot-sizing, Mixed Integer Programming, Multi-objective Programming, Genetic Algorithm (GA), Safety

Stock.

Abstract: This research develops an integrated replenishment model considering supplier selection, procurement lot-

sizing, quantity discounts and safety stocks under dynamic demand conditions. The objectives of the model

are to minimize total costs, which include ordering cost, purchase cost, transportation cost, shortage cost and

holding cost, and to maximize service level of the system over the planning horizon. First, a multi-objective

programming (MOP) model is proposed in the paper. Next, the model is transformed into a mixed integer

programming (MIP) model based on the

ε

-constraint method. Then, the genetic algorithm (GA) model is

constructed to solve a large-scale optimization problem by finding a near-optimal solution. An example of a

bike manufacturer is used to illustrate the practicality of the proposal model. The results demonstrate that

the proposed model is an effective and accurate tool for the integrated replenishment and logistics

management.

1 INTRODUCTION

Good inventory management is essential for a firm

to be cost competitive and to acquire reasonable

profit in the market. How to achieve an outstanding

inventory management has already been a popular

topic in both the academic field and in real practice.

There are two major categories of inventory models:

deterministic and stochastic.

In deterministic models,

all input data are assumed to be deterministic, and a

mathematical programming model is usually

sufficient to obtain the optimal solution.

For example,

Su and Wong (2008) studied a stochastic dynamic

lost-sizing problem under the bullwhip effect. A

framework of two-stage ant colony optimization

(TACO) was proposed, and a mutation operation

was added in the second stage to determine the

replenishment policy. Stochastic models, on the

other hand, are often limited to highly restricted

assumptions, and most current literature is a

variation of the deterministic lot sizing problem

(Şenyiǧit and Erol, 2010).

The contribution of this research can be

summarized as follows. First, a general formulation

of the lot-sizing problem by mixed integer

programming (MIP) is proposed. The model

considers various costs such as ordering cost,

purchase cost, transportation cost, shortage cost and

holding cost. It aims to minimize the total cost in the

system with safety stock while maximizing the

service level for each planning period. Second, a

genetic algorithm (GA) model is constructed to solve

the problem when it becomes too complicated. We

find that the GA model can find solutions that are

very close to the optimal ones.

The remaining of this paper is organized as

follows. Section 2 reviews some related

methodologies and works. In section 3, the problem

under consideration and the assumptions are

described. The formulation of the lot-sizing problem

by MIP and the construction of the GA model are

presented. Case study is carried out in section 4. In

the last section, some conclusion remarks are made.

614

Kang H., H. I. Lee A. and Lai C..

An Integrated Replemishment Model under Dynamic Demand Conditions.

DOI: 10.5220/0004030706140619

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (OMDM-2012), pages 614-619

ISBN: 978-989-8565-22-8

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

2 RELATED METHODOLOGY

AND RESEARCH

Dynamic lot-sizing can be referred back to Wagner

and Whitin (1958), and diverse lot-sizing heuristics

have been adopted in many operations management

works.

For example, Teunter, Bayindir and Van Den

Heuvel (2006) studied the dynamic lot sizing

problem for systems with product returns and

remanufacturing, and proposed modifications of the

Silver Meal (SM), least unit cost and part period

balancing heuristics.

Decision makers may want to optimize two or

more objectives simultaneously under various

constraints, and a MOP can then be applied.

A

complete optimal solution seldom exists, and a

Pareto-optimal solution is used then (Wee et al.,

2009).

There are a few methods to derive a

compromise solution (Rosenthal, 1985). For example,

the weighting method assigns priorities to the

objectives and sets aspiration levels for the

objectives. The

ε

-constraint method is a modified

weight method.

One of the objective functions is

optimized while the other objective functions are

incorporated in the constraint part of the model.

GA, a heuristic search process for optimization,

was first developed by Holland (1975). Based on

Darwin’s survival of the fittest principle, GA mimics

the process of natural selection (Maiti et al., 2006). It

has been widely applied to solve production and

operations management problems (Aytug et al.,

2003). The fundamental concept of GA is to code the

decision variables of the problem as a finite length

array, which is called chromosome, and to calculate

the fitness, the objective function, of each string

(Yang, Chan and Kumar, 2012).

3 PROBLEM DESCRIPTION AND

ASSUMPTIONS

The following assumptions and notations are defined

with the modification of those used in the models of

Kang (2008) and Kang and Lee (2010). The

assumptions are summarized as follows:

• The demand of each period is independent and

follows a normal distribution with a constant

coefficient of variation (

θ

).

• At most one order can be placed from each

supplier in each period.

• The replenishment lead time is of known

duration, and the entire order quantity is delivered at

once in the beginning of a period.

• All-units discount schedule is considered. The

price of each unit is dependent on the order quantity.

• The inventory holding cost for each unit is

known and constant, independent of the price of

each unit.

• Planning horizon is finite and known. There are T

periods in the planning horizon, and the duration of

each period is the same.

• The expected ending inventory level in period t

(i.e., the expected beginning inventory level in

period t+1) is the safety stock level in period t.

• The initial inventory level (X

1

) is zero.

All the required notations in this paper are defined

below.

Notations

Indices:

i Supplier (i = 1,2,…, I ).

k Price break (k = 1,2,…, K ).

t Planning period (t = 1,2,…, T ).

v Integer number for calculating the quantity

purchased (v= 1,2,…, V ).

w Integer number for calculating the time

transported (w= 1,2,…, W ).

Parameters:

E(d

t

) Expected demand in period t.

ˆ

t

σ

Standard deviation of demand in period t.

t

σ

Pool standard deviation of demand in period t.

h Inventory holding cost, per unit per period.

r

i

Transportation cost per time from supplier i.

s Shortage cost, per unit per period.

z

α

Standard normal value of service level α.

()Lz

α

Standardized number of units short with

service level α.

M A large number.

o

i

Ordering cost per replenishment from supplier

i.

p

ik

Unit purchase cost from supplier i with price

break k.

q

ik

The upper bound quantity of supplier i with

price break k.

Decision variables:

()

it

PQ Purchase cost for one unit based on the

discount schedule of supplier

i with order quantity

it

Q in period t.

it

Q Purchase quantity from supplier i in period t.

AnIntegratedReplemishmentModelunderDynamicDemandConditions

615

it i

Qb

⎡⎤

⎢⎥

The smallest integer greater than or equal

to

it i

Qb

.

N

it

Number of transportations from supplier i in

period t.

F

it

A binary variable, set equal to 1 if a purchase

is made from supplier i in period t, and 0 if no

purchase is made from supplier i in period t.

X

t

Expected beginning inventory level in period

t.

Y

t

Expected beginning available inventory level

in period t, and

1

I

t t it it

i

YX FQ

=

=+ ×

∑

.

z

t

Standard normal value of ending inventory

level in period t.

()

t

Lz

Standardized number of units short of ending

inventory level in period t

itv

β

A binary variable for calculating the purchase

quantity from supplier i in period t.

itw

G A binary variable for calculating the time of

transportations from supplier i in period t.

itk

U A binary variable, set equal to 1 if a certain

quantity is purchased, and 0 if no purchase is made,

with price break k supplier i in period t.

The above information is used to develop a MIP

model and a GA model to solve the lot-sizing

problem with multiple suppliers and quantity

discounts so that an appropriate inventory level for

each period can be determined. The total cost for

each period can be calculated by adding up the

relevant costs, including ordering cost, holding cost,

and purchase cost with quantity discounts. The total

cost in a planning horizon includes all the total costs

in each period.

3.1 Relevant Costs

The ordering cost for the system is calculated by

equation (1), where o

t

is the ordering cost per time

from supplier i and F

it

represents whether a quantity

is purchased from supplier i in period t.

11

TI

iit

ti

Ordering cost O o F

==

== ×

∑∑

(1)

Equation (2) calculates the purchase cost, where

P(Q

it

) is the unit purchase cost based on the discount

schedule with the order quantity Q

it

, and F

it

represents whether a quantity is purchased from

supplier i in period t.

(( ) )

TI

it it it

t1i1

Purchase cost P P Q Q F

==

== × ×

∑∑

(2)

Equation (3) calculates the transportation cost of the

system, where r

i

is the transportation cost per time

from supplier i,

it i

Qb

⎡

⎤

⎢

⎥

is the smallest integer

greater than or equal to

it i

Qb

from supplier i in

period t, N

it

is number of transportations from

supplier i in period t and b

i

is the maximum

transportation batch size from supplier i.

11 11

TI TI

iiti iit

ti ti

Transportation cost R r Q b r N

== ==

== × = ×

⎡⎤

⎢⎥

∑∑ ∑∑

(3)

The shortage cost of the system is calculated by

equation (4), where s is the shortage cost per unit per

period,

()

t

Lz

is the standardized number of unit

shortage function, and

t

σ

is the pool standard

deviation in period t.

1

()

T

tt

t

Shortage cost S s L z

σ

=

=

=× ×

∑

(4)

The holding cost in period t is equal to the holding

cost per unit times the ending inventory in period t.

Then, the holding cost for a planning horizon is the

summation of the holding cost for each period, as in

equation (5).

1

1

(()

T

tt t

t

H

olding cost H h X L z

σ

+

=

== × +×

∑

(5)

3.2 Multi-objective Programming

(MOP)

The stochastic lot-sizing problem is formulated into

a MOP model for minimizing total cost and

maximizing service level. Based on the

ε

-constraint

method, we can set the total cost as an objective and

use the service level as a constraint. The proposed

model is formulated as follows:

Min ()TC x

(6)

s.t.

x

E

∈

(7)

()

Z

xz

α

≥

(8)

where

z

α

is the standard normal value of service

level α.

3.3 Mixed Integer Programming (MIP)

Model

The multi-objective programming (MOP) problem

can be transformed into a MIP model to solve the

multi-period inventory problem and to determine an

appropriate replenishment policy for each period.

The proposed model can be formulated as follows:

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

616

Minimize

11 1 1

() ()

TI I I

iit it itit i it t t

ti i i

TC o F P Q Q F r N s L z

σ

== = =

⎡

=×+××+×+××

⎢

⎣

∑∑ ∑ ∑

()

1

()

ttt

hX Lz

σ

+

+× + ×

⎤

⎦

(9)

s.t.

1

()

tt t

X

YEd

+

=−

, for all t

(10)

1

I

t t it it

i

YX QF

=

=+ ×

∑

, for all t

(11)

it it

QMF≤×

, for all t

(12)

1

1

2

it

V

v

it itv

v

Q

β

−

=

=

∑

, for all i, t

(13)

it it

i

NQb=

⎡⎤

⎢⎥

, for all i, t

(14)

1

1

2

W

w

it itw

w

NG

−

=

=

∑

, for all i, t

(15)

()

()

tt tt

zYEd

σ

=−

, for all t

(16)

t

zz

α

≥

, for all t

(17)

()

ˆ

tt

Ed

σθ

=×

, for all t

(18)

2

'

'1

ˆ

t

tt

t

σ

σ

=

=

∑

, for all t

(19)

1

()

K

it ik itk

k

PQ p U

=

=×

∑

, for all i, t

(20)

1

(1) (1)

ik itk it ik itk

qMU QqM U

−

+× −≤ <+×−

, for all i, t, k

(21)

1

1

K

itk

k

U

=

=

∑

, for all i, t

(22)

{}

0,1

it

F ∈

, for all i, t

(23)

{}

0,1

itw

G ∈

, for all i, t,w

(24)

{}

0,1

itv

β

∈

, for all i, t, v

(25)

{}

0,1

itk

U ∈

, for all i, t, k

(26)

and all variables are nonnegative.

3.4 Genetic Algorithm (GA) Model

GA is used next to solve the lot-sizing problem with

quantity discounts and safety stock so that near-

optimal solutions can be produced in a short period

of computation time. The procedures of the GA are

proposed as follows:

Step 1. Coding scheme

Assume that at most one order can be placed in each

period and that a replenishment quantity can serve

for an integer number of periods.

Step 2. Initial population of chromosomes

The initial population is generated randomly, and

there are two types of chromosomes, which are also

determined randomly.

Step 3. Fitness function

The fitness function for each chromosome is Min

TC, where TC is the total cost. Min TC is the

minimum cost among all the chromosomes across

the population.

Step 4. Crossover operation

The standard two-cut-point crossover operator is

applied to the selected pair of parent-individuals by

recombining their genetic codes and producing two

offspring.

Step 5. Mutation operator

A mutation operator is to counteract premature

convergence and to maintain enough diversity in the

population. It is performed by changing a randomly

selected gene in the genetic code (0-1, 1-0). In each

generation, all individuals have a set of given genes

fixed, called frozen genes.

Step 6. Selection of subsequent population

After the mutation and crossover operations in each

generation, a subsequent population is selected for

the next generation.

Step 7. Termination

The processes of crossover, selection and

replacement are repeated until the objective function

of the problem is optimized or the stop criterion is

met.

4 CASE STUDY OF A BIKE

MANUFACTURER

4.1 Stochastic Lot-sizing Problem

A stochastic lot-sizing problem with quantity

discounts and safety stock is solved here. Based on

an interview with the management of a bike

manufacturer in Taiwan, the following assumptions

are made. The ordering cost of supplier A (

o

1

) and

supplier B (

o

2

) per replenishment is set to be $220

and $190, respectively. In addition, we set unit

holding cost per period (

h), which includes the

handling cost, storage cost and capital cost, to be

$0.1. The demand in each period is assumed to be

normal distributed with a mean

()

t

Ed and a

coefficient of variation (

θ

) of 1/3. Table 1 shows

the expected demand

()

t

Ed and its standard

deviation

ˆ

t

σ

in each period t.

AnIntegratedReplemishmentModelunderDynamicDemandConditions

617

The ordering cost per time from supplier A and B

is $220 and $190, respectively. The transportation

cost per time is $21 and $20.5 from supplier A and B,

respectively. The unit shortage cost is $30, required

service level is 95%, and the number of periods is 7.

A quantity can be purchased from supplier A and/or

B using the discount schedules in Table 2 and Table

3, respectively.

Table 1: Demand of each period in a planning horizon.

t 1 2 3 4 5 6 7

()

t

Ed

660 700 560 120 650 510 525

Standard

deviation

(

ˆ

t

σ

)

220 233 187 40 217 170 175

Table 2: Discount schedule for supplier A.

Price break (k)

Purchase quantity (q

1k

)

Price per unit

( p

1

k

)

1 0 – 999 $4.00

2 1000 – 1999 $3.92

3 2000 – 2999 $3.84

4 3000 or more $3.76

Table 3: Discount schedule for supplier B.

Price break (k) Purchase quantity

(q

2k

)

Price per unit

( p

2k

)

1 0 – 1500 $4.02

2 1501 – 3000 $3.89

3 3001 or more $3.75

4.2 Experimental Results

The lot-sizing problem is solved by both the MIP

model and the GA model. The MIP model is

implemented using the software LINGO (2006), and

the GA is implemented using the software

MATLAB (2007).

The solution of the MIP model is shown in Table

4.

Under the MIP model, two purchases are made:

3034 units from supplier B in period 1, 1507 units

from supplier B in period 5.

The total cost is $18983.

The GA model is implemented by using the

software MATLAB. Two-cut-point crossover for

crossover operations is applied, and an inversion

mutation operator is used to avoid a solution being

trapped in a local optimum and to approach the

global optimum. The size of the initial population is

set as 35. The crossover rate is set as 0.75, meaning

that around 75% pairs of individuals take part in the

production of offspring. The mutation rate is set as

0.01, meaning that each gene of a newly created

solution is mutated with the probability 0.01. The

solutions of the case obtained by the MIP model and

by the GA algorithm are the same, and the total cost

is $18983.

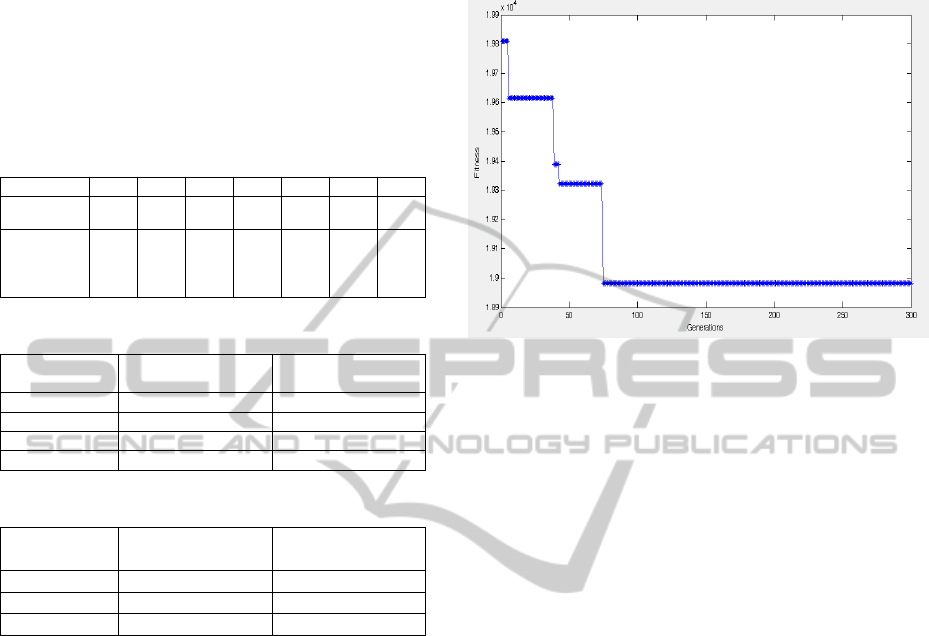

Figure 1: The convergence of GA.

5 CONCLUSIONS

This paper constructs a lot-sizing model with

quantity discounts and safety stock to minimize total

cost over the planning horizon.

A general

formulation of the lot-sizing problem is proposed by

mixed integer programming (MIP) first to devise

appropriate replenishment policies.

An efficient

genetic algorithm (GA) is introduced next for

solving large-scale lot-sizing problem in a very short

time.

Replenishment level and system cost can be

determined after calculating ordering cost, purchase

cost, transportation cost, shortage cost and holding

cost.

The results show that the GA model is effective

in searching for solutions, and it can be very useful

for managers in real practice.

In the future, a more complete case study of

supply chain management can be considered.

A

model that considers issues, such as variable lead

time, probability demand, different priority of

orders, backorder and lost sales, can be developed.

To incorporate these issues, the assumptions will

need to be relaxed by modifying objectives and

constraints.

ACKNOWLEDGEMENTS

This work was supported in part by the National

Science Council in Taiwan under Grant NSC 98-

2410-H-167-008-MY3.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

618

REFERENCES

Aytug, H., Khouja. M., Vergara, F. E., (2003). Use of

genetic algorithms to solve production and operations

management: a review. International Journal of

Production Research, 41(17), 3955-4009.

Kang, H.-Y., (2008). Optimal replenishment policies for

deteriorating control wafers inventory. International

Journal of Advanced Manufacturing Technology, 35

(8), 736-744.

Kang, H.-Y., Lee, A. H. I., (2010). Inventory

replenishment model using fuzzy multiple objective

programming: A case study of a high-tech company in

Taiwan. Applied Soft Computing, 10, 1108-1118.

LINGO, (2006), LINGO user’s manual, version 10.

Chicago: USA LINGO System Inc.

Maiti, A. K., Bhunia, A. K., Maiti, M., (2006). An

application of real-coded genetic algorithm (RCGA)

for mixed integer non-linear programming in two-

storage multi-item inventory model with discount

policy. Applied Mathematics and Computations, 183,

903-915.

MATLAB, (2007). Using MATLAB, version 7.5.

Massachusetts: The Mathworks.

Rosenthal, R.E., (1985). Concepts theory and techniques:

Principles of multi-objective optimization. Decision

Sciences, 16, 133-152.

Şenyiǧit, E., Erol, R. (2010). New lot sizing heuristics for

demand and price uncertainties with service-level

constraint. International Journal of Production

Research, 48(1), 21-44.

Su, C. T., Wong, J. T. (2008). Design of a replenishment

system for a stochastic dynamic production/forecast

lot-sizing problem under bullwhip effect. Expert

Systems with Applications, 34, 173-180.

Teunter, R. H., Bayindir, Z. P., Van Den Heuvel, W.

(2006). Dynamic lot sizing with product returns and

remanufacturing. International Journal of Production

Research, 44 (20), 4377-4400.

Wagner, H. M., Whitin, T. M., (1958). Dynamic version of

the economic lot size model. Management Science, 5,

89-96.

Wee, H. M., Lo, C. C., Hsu, P. H., (2009). A multi-

objective joint replenishment inventory model of

deteriorated items in a fuzzy environment. European

Journal of Operational Research, 197, 620-631.

Yang, W., Chan, F. T. S, Kumar, V., (2012). Optimizing

replenishment polices using genetic algorithm for

single-warehouse multi-retailer system. Expert

Systems with Applications, 39, 3081-3086.

AnIntegratedReplemishmentModelunderDynamicDemandConditions

619