Rotor Speed Sensor Fault Detection in Induction Motors

Riccardo Marino, Stefano Scalzi, Patrizio Tomei and Cristiano Maria Verrelli

Department of Electronic Engineering, University of Rome “Tor Vergata”, Via del Politecnico 1, 00133 Rome, Italy

Keywords:

Fault Detection, Speed Sensor Faults, Induction Motors.

Abstract:

The problem of detecting a speed sensor fault in induction motor applications with load torque and rotor/stator

resistances uncertainties is addressed. It is shown that in typical operating conditions involving constant

rotor speed and flux modulus and non-zero load torque, a constant non-zero (sufficiently large) difference

between the measured speed and the actual speed may be on-line identified by an adaptive flux observer

which incorporates a convergent rotor resistance identifier and relies on the measured rotor speed and stator

currents/voltages.

1 INTRODUCTION

Three-phase induction motors are widely used for

electric railway and automotive traction (Hill, 1994)

since they offer several advantages such as no com-

mutator, no brushes, no rotor windings in squirrel

cage motors, simple rugged structure, inherent regen-

erative braking capability, ability of tolerating heavy

overloading and of producing high torques with low

weights, small sizes, and low rotating masses. In high

impact automotive applications (see Rehman, 2008)

such as electrical and hybrid electrical vehicles, the

operation continuity is a key feature and high relia-

bility of the drive system should be guaranteed (see

Benbouzid et al., 2007). On the other hand, traction

main drives are often equipped with rotor speed sen-

sors (Guzinski et al., 2009) which are used by clas-

sical induction motor control schemes such as direct

or indirect field oriented controls (see Marino et al.,

2010b) for recent adaptive results). In the case of ro-

tor speed sensor fault, a proper and prompt fault de-

tection is required so that an effective action can be

performed and the fault effect is not widely propa-

gated with a resulting hard system failure.

The idea underlying a model-based approach to

fault diagnosis (see for instance (Isermann, 2011) and

(Ding, 2008)) relies on the assumption that certain

process signals carry information about the faults of

interest. The gist of the approach is then to gener-

ate, on the basis of measurements from (and knowl-

edge of) the system, a set of ”residual signals” which

are zero when no fault is present and non-zero when

faults occur (Bennet et al., 1999). However sev-

eral difficulties naturally arise for the specific applica-

tion to induction motors: induction motor dynamics

are nonlinear; flux measurements are not available;

three critical parameters, namely rotor and stator re-

sistances (which vary during operations due to motor

heating) and load torque (which depends on applica-

tions), are typically uncertain and are required to be

on-line estimated.

A first intuitive solution (I S ) to speed sensor fault

detection problems relies on designing an adaptive

flux/speed observer which does not use the measured

speed but only stator currents and voltages measure-

ments (see (Guzinski et al., 2010) and (Guzinski et al.,

2009)). The gist of the above design is then to com-

pare the measured speed with the estimated one with

the aim of identifying the possibly occurring speed

sensor fault. Since suitable identifiers for the uncer-

tain parameters are to be incorporated in the adaptive

observer in order to avoid false fault detections, the

drawback of the above approach is then constituted

by the well-known identifiability and observability is-

sues which arise when only stator currents and volt-

ages are measured. It is in fact well-established

that when the motor operates at constant rotor speed

and flux modulus with non-zero load torque to mini-

mize power losses and maximize power efficiency at

steady-state (see Marinoet al., 2010b), the simultane-

ous estimation of rotor speed and rotor resistance can-

not be achieved (see (Ha and Lee, 2000), (Marino et

al., 2008), as well as (Marino et al., 2010a)) and ref-

erences therein) since only a linear combination

L = R

r

+ γω

of the rotor resistance R

r

and speed ω (along with

the real γ) can be on-line identified by stator currents

59

Marino R., Scalzi S., Tomei P. and Maria Verrelli C..

Rotor Speed Sensor Fault Detection in Induction Motors.

DOI: 10.5220/0004026500590066

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 59-66

ISBN: 978-989-8565-21-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

and voltages measurements. This structural difficulty

may be used to our advantage by noting that when the

(constant) measured speed ω

m

is used by a suitable

adaptive flux observer AF O, the identifiable linear

combination becomes

L

e

= R

r

+ γ(ω −ω

m

).

If the rotor speed is measured and no speed sensor

fault fault occurs, i.e. ω ≡ ω

m

, estimating L

e

coin-

cides with estimating R

r

; on the other hand, in the

presence of speed sensor failures, estimating L

e

coin-

cides with estimating a quantity which, depending on

(ω −ω

m

), may be larger or smaller than any admissi-

ble R

r

∈ [R

rm

,R

rM

] for the specific motor in consider-

ation, that is

R

r

+ γ(ω −ω

m

) < R

rm

or

R

r

+ γ(ω −ω

m

) > R

rM

.

In this case a speed sensor fault may be on-line

identified by designing a speed measurement-based

adaptive observer and by monitoring the estimate of

L

e

on the basis of the boundary values R

rm

and R

rM

.

The aim of this paper is to show that an adaptive

flux observer A F O which incorporates a convergent

rotor resistance identifier and relies on the measured

rotor speed and stator currents/voltages may be ef-

fectively used to on-line identify a constant non-zero

(sufficiently large) difference ω − ω

m

in typical oper-

ating conditions involving non-zero load torque and

constant rotor speed and flux modulus. In particular,

denoting by α ∈ [α

m

,α

M

] (α

m

= L

r

R

rm

, α

M

= L

r

R

rM

)

the ratio between the rotor resistance R

r

and the ro-

tor inductance L

r

and by

ˆ

α its estimate (provided by

the AF O), we will show that a residual signal for

the speed sensor fault detection may be chosen as

the steady-state distance of

ˆ

α(t) from the compact set

[α

m

,α

M

], i.e.

lim

t→+∞

dist(

ˆ

α(t); [α

m

,α

M

]).

A similar idea (though not analytically motivated)

has been also recently presented in Najafabadi et al.

(2011) even though it relies on an observer which is

adaptive with respect to the rotor resistance only. In

contrast to Najafabadi et al. (2011), we propose a

candidate adaptive flux observer belonging to the set

of all adaptive flux observers which provide conver-

gent estimates of the rotor resistance despite uncer-

tainties in critical parameters such as load torque and

stator resistance. This is to avoid false fault detections

which may be related to uncertainties in those criti-

cal parameters. With this respect, among the adap-

tive observers which have been proposed in the lit-

erature since 1978 (see for instance (Castaldi et al.,

2005), (Hasan and Husain, 2009), (Jeon et al., 2002),

(Kenn

´

e et al., 2010), (Marino et al., 2000), (Marino

et al., 2011), (Najafabadi et al., 2011), (T¸ iclea and

Besanc¸on, 2006) and references therein), we con-

sider in this paper the one presented in Marino et al.

(2011) which is simultaneously characterized by: i)

an overall structural simplicity with no use of sign

functions, high gains or output time derivatives which

lead to well-known implementation difficulties and

high noise sensitivity; ii) persistency of excitation

conditions which are naturally related to motor ob-

servability and parameter identifiability and are guar-

anteed to be satisfied in the typical case of constant

motor speed and flux modulus and non-zero electro-

magnetic torque; iii) exponential convergence prop-

erties guaranteeing a certain degree of robustness. It

is constituted by an adaptive flux observer which is

able to estimate the motor fluxes and to identify the

rotor resistance and by a stator resistance identifier

whose design is performed on a different time scale

in order to isolate its estimation from the estimation

of motor fluxes and rotor resistance (see also (Jadot

et al., 2009), (Marino et al., 2010c)) for a similar ap-

proach to parameter estimation in induction motors).

Simulation and experimental results illustrate the ef-

fectiveness of the proposed solution and show satis-

factory fault detection performances. Such a speed

sensor fault detector constitutes a first step toward the

design of effective fault-tolerant control architectures

which involve output feedback adaptive tracking con-

trols (Marino et al., 2010b) minimizing power losses

in conjunction with sensorless adaptive tracking con-

trols (Marino et al., 2010c) imposing rotor speed ob-

servability and resistance identifiability. Those fault-

tolerant architectures may be of special interest for

speed-controlled traction applications in which induc-

tion motor controls are required to tolerate rotor speed

sensor faults (see (Benbouzid et al., 2007), (Guzinski

et al., 2010), (Guzinski et al., 2009)) and to main-

tain at the same time high power efficiency at every

speed (see (Bennet et al., 1999), (Diallo et al., 2004),

(Lee and Ryu, 2003), (Romero et al., 2010), (Wang et

al., 2006) for the general problem of designing fault-

tolerant induction motor controls).

2 PHYSICAL MODELING

Assuming linear magnetic circuits, the dynamics of a

balanced non-saturated induction motor with one pole

pair in a fixed reference frame attached to the stator

are given by the well known fifth-order model (see for

instance (Marino et al., 2010a) and references therein)

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

60

dω

dt

= µ(ψ

ra

i

sb

− ψ

rb

i

sa

) −

T

L

J

dψ

ra

dt

= −αψ

ra

− ωψ

rb

+ αMi

sa

dψ

rb

dt

= −αψ

rb

+ ωψ

ra

+ αMi

sb

(1)

di

sa

dt

= −

R

s

σ

+ βαM

i

sa

+

1

σ

u

sa

+ βαψ

ra

+ βωψ

rb

di

sb

dt

= −

R

s

σ

+ βαM

i

sb

+

1

σ

u

sb

+ βαψ

rb

− βωψ

ra

in which: ω is the rotor speed, (ψ

ra

,ψ

rb

) are the ro-

tor fluxes, (i

sa

,i

sb

) are the stator currents, (u

sa

,u

sb

)

are the stator voltages in a fixed reference attached

to the stator. The constant model parameters are:

load torque T

L

; motor moment of inertia J; rotor and

stator windings resistances (R

r

,R

s

) and inductances

(L

r

,L

s

); mutual inductance M. To simplify nota-

tions we use the reparameterization: α =

R

r

L

r

, β =

M

σL

r

,

µ =

M

JL

r

, σ = L

s

(1 −

M

2

L

s

Lr

). The rotor fluxes (ψ

ra

,ψ

rb

)

are unmeasured variables since flux sensors are usu-

ally not available while the parameters T

L

, α and R

s

are typically uncertain owing to load torque depen-

dence on applications and owing to resistance varia-

tions which depend on motor heating. We will only

assume, in the following, the boundedness of state

and input variables while any restriction concerning

the boundedness of stator currents integrals, which

has been proposed for the design of similar adaptive

flux observers in Jeon et al. (2002), (Marino et al.

(2000), is not required.

3 OBSERVER DESIGN

The first idea in Marino et al. (2011) is to introduce

the variables z

a

= i

sa

+ βψ

ra

, z

b

= i

sb

+ βψ

rb

so that

the motor electro-magnetic equations in (1) become

˙z

a

= −

R

s

σ

i

sa

+

1

σ

u

sa

˙z

b

= −

R

s

σ

i

sb

+

1

σ

u

sb

di

sa

dt

= −

R

s

σ

i

sa

− α(1 +βM)i

sa

− ωi

sb

+ αz

a

+ωz

b

+

1

σ

u

sa

(2)

di

sb

dt

= −

R

s

σ

i

sb

− α(1 +βM)i

sb

+ ωi

sa

+ αz

b

−ωz

a

+

1

σ

u

sb

.

The advantage of using the (z

a

,z

b

) variables,

which are physically related to the stator fluxes, is that

their dynamics depend neither on the unmeasured ro-

tor fluxes nor on the uncertain rotor resistance. On the

basis of model (2), the following observer is designed

(k

i

is a positive design parameter):

˙

ˆ

i

sa

= −

ˆ

R

s

σ

i

sa

−

ˆ

α(1 + βM)i

sa

− ω

ˆ

i

sb

+

ˆ

αˆz

a

+ωˆz

b

+

u

sa

σ

+ k

i

(i

sa

−

ˆ

i

sa

)

˙

ˆ

i

sb

= −

ˆ

R

s

σ

i

sb

−

ˆ

α(1 + βM)i

sb

+ ω

ˆ

i

sa

+

ˆ

αˆz

b

−ωˆz

a

+

u

sb

σ

+ k

i

(i

sb

−

ˆ

i

sb

) (3)

˙

ˆz

a

= −

ˆ

R

s

σ

i

sa

+

u

sa

σ

+ v

a

˙

ˆz

b

= −

ˆ

R

s

σ

i

sb

+

u

sb

σ

+ v

b

which is a copy of system (2) with: i) the estimates

(ˆz

a

, ˆz

b

,

ˆ

α,

ˆ

R

s

) in place of the unmeasured/uncertain

(z

a

,z

b

, α, R

s

); ii) stabilizing terms on the current esti-

mation errors (i

sa

−

ˆ

i

sa

), (i

sb

−

ˆ

i

sb

); iii) the compensat-

ing terms v

a

,v

b

yet to be designed. According to the

stability analysis in Marino et al. (2011), the estima-

tion laws for

ˆ

α and

ˆ

R

s

and the feedback terms v

a

,v

b

are chosen as

˙

ˆ

α = −k

α

h

[(1 + βM)i

sa

− ˆz

a

]

˜

i

sa

+ [(1 +βM)i

sb

− ˆz

b

]

˜

i

sb

i

˙

ˆ

R

s

= −k

R

(v

a

i

sa

+ v

b

i

sb

)

v

a

= −k

z

ω

˜

i

sb

−

ˆ

α

˜

i

sa

v

b

= k

z

ω

˜

i

sa

+

ˆ

α

˜

i

sb

(4)

in which

˜

i

sa

= i

sa

−

ˆ

i

sa

,

˜

i

sb

= i

sb

−

ˆ

i

sb

are the stator

current estimation errors, k

z

and k

α

are positive design

parameters, k

R

is a sufficiently small positive design

parameter.

The two-time-scale arguments in Marino et al.

(2011), under certain identifiability assumptions at

steady-state, allow for isolating the estimation of the

stator resistance from the estimation of motor fluxes

(achieved through the estimation of (z

a

,z

b

)) and rotor

resistance so that the following persistency of excita-

tion condition:

P

e

: there exist two positive reals t

p

and k

p

such that

the persistency of excitation condition (I

3

is the

3 × 3 identity matrix)

Z

t+t

p

t

Γ

T

(τ)Γ(τ)dτ ≥ k

p

I

3

, ∀ t ≥ 0 (5)

holds with

Γ =

α ω β(ψ

ra

− Mi

sa

)

−ω α β (ψ

rb

− Mi

sb

)

is obtained. Inequality (5) is naturally related to mo-

tor observability and parameter identifiability: when

the rotor speed and the rotor flux modulus are con-

stant and the load torque is zero so that ψ

ra

= Mi

sa

RotorSpeedSensorFaultDetectioninInductionMotors

61

and ψ

rb

= Mi

sb

, it cannot be satisfied; when a positive

load torque is applied and when the rotor speed and

the rotor flux modulus are constant with ψ

2

ra

+ ψ

2

rb

=

c

ψ

> 0, it is satisfied.

The gist of the estimation design in Marino et al.

(2011) and the required assumptions can be simply

explained in the following terms: if the adaptive ob-

server (3)-(4) (with no stator resistance identifier) is

used with a constant value of the stator resistance that

is slightly different from its actual value, then a non-

zero steady-state solution appears that causes a suit-

able measured output function s

π

= v

a

i

sa

+v

b

i

sb

to be,

in first approximation, monotone with respect to the

R

s

-estimation error

˜

R

s

= R

s

−

ˆ

R

s

; thus, by adjusting

the R

s

-estimate

ˆ

R

s

on the basis of this output func-

tion (slowly, in order not to deviate too much from

the steady-state solution) one can obtain the correct

estimation of R

s

and the consequent exponential con-

vergence to zero of all the estimation errors

˜

i

sa

,

˜

i

sb

,

z

a

− ˆz

a

, z

b

− ˆz

b

, α −

ˆ

α,

˜

R

s

. Exponential rotor flux re-

covering can be finally obtained by

ˆ

ψ

ra

ˆ

ψ

rb

= −

1

β

ˆ

i

sa

− ˆz

a

ˆ

i

sb

− ˆz

b

where the filtered estimates (

ˆ

i

sa

,

ˆ

i

sb

) are preferred to

the measured (i

sa

,i

sb

) for practical implementation is-

sues. The following second-order load torque identi-

fier (k

ω

and k

T

are positive design parameters):

˙

ˆ

ω = µ(

ˆ

ψ

ra

i

sb

−

ˆ

ψ

rb

i

sa

) −

ˆ

T

L

J

+ k

ω

(ω −

ˆ

ω)

˙

ˆ

T

L

= −k

T

(ω −

ˆ

ω)

is finally proposed in Marino et al. (2011). It can be

used in conjunction with the adaptive observer (3)-(4)

to provide an exponentially convergent estimate of the

load torque once convergent estimates of rotor fluxes

have been obtained. The proof, which is reported in

Marino et al. (2010a), is based on the quadratic func-

tion

V

T

=

1

2k

T

J

˜

T

2

L

+

1

2

˜

ω

2

+ ε

˜

ω

˜

T

L

in which

˜

ω = ω −

ˆ

ω,

˜

T

L

= T

L

−

ˆ

T

L

and ε > 0 is a suf-

ficiently small positive real.

4 SENSOR FAULT DETECTION

The aim of this section is to prove that a constant non-

zero (sufficiently large) difference between the mea-

sured speed and the actual speed may be on-line iden-

tified by the adaptive flux observer (3)-(4) (in which

the measured speed ω

m

replaces the actual speed ω) in

typical operating conditions involving non-zero load

torque and constant rotor speed and flux modulus. To

this purpose, we preliminarly note that in those con-

ditions we have

˙

z }| {

ψ

2

ra

+ ψ

2

rb

≡ 0

˙

ω ≡ 0,

from which we obtain

Mi

sa

= ψ

ra

− cψ

rb

Mi

sb

= ψ

rb

+ cψ

ra

(6)

with (ω

s

is the slip speed [see (Marino et al., 2010a)])

c =

T

L

M

Jµc

ψ

=

T

L

L

r

c

ψ

= ω

s

/α.

By adding and subtracting in (2) suitable terms

proportional to ω

e

= ω − ω

m

and by using (6), equa-

tions (2) can be equivalently rewritten as

˙z

a

= −

R

s

σ

i

sa

+

1

σ

u

sa

˙z

b

= −

R

s

σ

i

sb

+

1

σ

u

sb

di

sa

dt

= −

R

s

σ

i

sa

− ω

m

i

sb

+ ω

m

z

b

+

1

σ

u

sa

+α[z

a

− (1 +βM)i

sa

] + ω

e

(z

b

− i

sb

)

di

sb

dt

= −

R

s

σ

i

sb

+ ω

m

i

sa

− ω

m

z

a

+

1

σ

u

sb

+α[z

b

− (1 +βM)i

sb

] − ω

e

(z

a

− i

sa

)

with the last two equations reading

di

sa

dt

= −

R

s

σ

i

sa

− ω

m

i

sb

+ ω

m

z

b

+

1

σ

u

sa

+

α +

ω

e

c

(z

a

− (1 +βM)i

sa

)

di

sb

dt

= −

R

s

σ

i

sb

+ ω

m

i

sa

− ω

m

z

a

+

1

σ

u

sb

+

α +

ω

e

c

(z

b

− (1 +βM)i

sb

).

In other terms, in typical operating conditions in-

volving non-zero load torque and constant rotor flux

modulus and (measured and actual) speeds, an equiv-

alent constant α

e

= α + ω

e

/c appears in the motor

model (with ω

m

in place of ω): it incorporates any

possibly non-zero difference between the measured

speed and the actual speed.

By virtue of the same analysis presented in Marino

et al. (2011) and discussed in Section 3 (with ω

m

in

place of ω), the adaptive observer (3)-(4) is able to

guarantee exponential convergence to zero of all the

estimation errors

˜

i

sa

,

˜

i

sb

, z

a

− ˆz

a

, z

b

− ˆz

b

, α

e

−

ˆ

α,

˜

R

s

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

62

(provided that initial errors belong to the region of at-

traction of the origin for the error system dynamics).

Exponential estimation of motor fluxes, equivalent α

and stator resistance are therefore achieved. In par-

ticular, lim

t→+∞

dist(

ˆ

α(t);[α

m

,α

M

]) may be used as a

residual signal for speed sensor fault detection since

when rotor speed ω and flux modulus

q

ψ

2

ra

+ ψ

2

rb

are

constant along with the measured speed ω

m

, the α-

estimate

ˆ

α(t) is guaranteed to exponentially converge

to α

e

. It is clear that only the speed sensor faults that

lead to a value of α

e

outside the compact set [α

m

,α

M

]

can be in this way identified. An estimate of ω

e

(and

therefore of the sensor failure magnitude) can be fi-

nally obtained according to

T

L

L

r

c

ψ

(α

e

− α) = ω

e

once the load torque (through the load torque identi-

fier) and the rotor fluxes have been estimated.

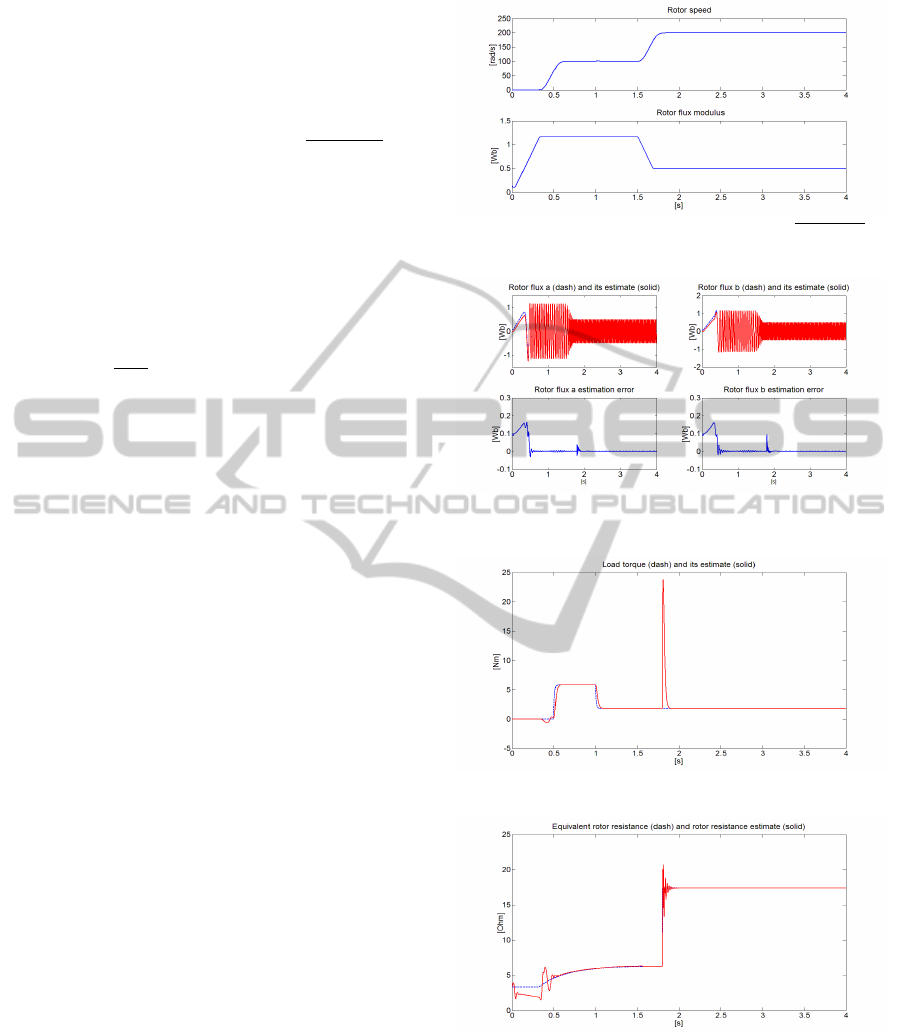

5 SIMULATION RESULTS

The aim of this section is to illustrate the previ-

ously presented results even in the presence of time-

varying perturbations of the motor resistances and

step-wise variations of the load torque. To this pur-

pose, the nonlinear adaptive observer (3)-(4) and the

load torque identifier are simulated for the three-phase

single pole pair 0.6-kW induction motor OE-MER

7-80/C in Marino et al. (2010a) whose parameters

are: J = 0.0075 kgm

2

, R

s

= 5.3 Ohm, R

r

= 3.3 Ohm,

L

s

= 0.365 H, L

r

= 0.375 H, M = 0.34 H. The motor

(with initial conditions ψ

ra

(0) = ψ

rb

(0) = 0.1 Wb) is

illustratively controlled by the input-output feedback

linearizing control reported in Section 2.4 of Marino

et al. (2010a) (which relies on exact rotor speed

and stator current measurements and on the perfect

knowledge of all motor parameters). The rotor speed

and the flux modulus are reported in Figure 1. The de-

sign parameters are chosen as (all the values are in SI

units): k

i

= 120, k

z

= 3, k

α

= 450, k

R

= 0.1, k

ω

= 200,

k

T

= 100

2

J. All the observer initial conditions are set

to zero excepting for

ˆ

α(0) = 9 s

−1

and

ˆ

R

s

(0) = 5.4

Ohm. For t < 1.8 s the measured speed is equal to the

actual one (ω ≡ ω

m

) while for t ≥ 1.8 s a speed sensor

fault occurs leading to ω − ω

m

= 0.4ω. The equiva-

lent rotor resistance R

e

= L

r

α

e

is thus equal to R

r

for

t < 1.8 s and equal to R

r

+ω

e

c

ψ

/T

L

for t ≥ 1.8 s. The

rotor fluxes, the load torque, the equivalent rotor resis-

tance, the stator resistance along with the correspond-

ing converging estimates are reported in Figures 2-5.

Fast estimation is obtained: the speed sensor fault can

be promptly identified by monitoring the estimated

Figure 1: Rotor speed ω and flux modulus

q

ψ

2

ra

+ ψ

2

rb

.

Figure 2: Rotor fluxes ψ

ra

,ψ

rb

(dash) and their estimates

ˆ

ψ

ra

,

ˆ

ψ

rb

(solid); rotor fluxes ψ

ra

,ψ

rb

estimation errors.

Figure 3: Load torque T

L

(dash) and its estimate

ˆ

T

L

(solid).

Figure 4: Equivalent rotor resistance R

re

(dash) and its esti-

mate

ˆ

R

r

(solid).

rotor resistance on the basis of the available bound-

ing values R

rm

= L

r

α

m

= 2.8 Ohm, R

rM

= L

r

α

M

= 6.9

Ohm. In order to illustrate the possibility of detecting

false faults by using adaptive observers with no stator

resistance identifier (as in (Najafabadiet al., 2011)),

the same simulation is carried out in the presence of

no speed sensor fault for the adaptive observer (3)-

RotorSpeedSensorFaultDetectioninInductionMotors

63

Figure 5: Stator resistance R

s

(dash) and its estimate

ˆ

R

s

(solid).

Figure 6: Observer with no R

s

-adaptation: rotor resistance

R

r

(dash) and its estimate

ˆ

R

r

(solid).

Figure 7: First experimental test (ω

m

= 70 rad/s, ω = 88

rad/s).

(4) with the stator resistance value 5.4 Ohm in place

of

ˆ

R

s

. As illustrated by Figure 6, a non-zero resid-

ual results even in the case of no speed sensor fault:

this is only due to stator resistance uncertainties and

motivates the use of adaptive observers which provide

convergent rotor resistance estimates despite stator re-

sistance uncertainties.

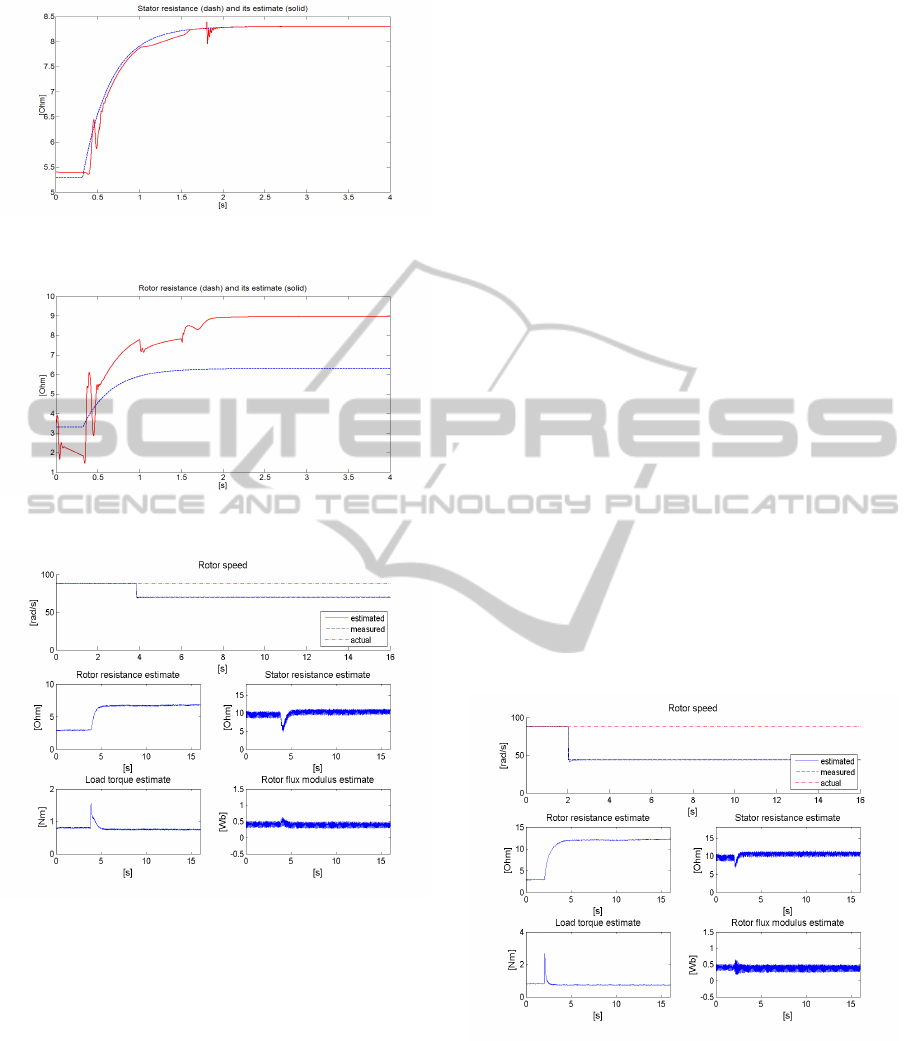

6 EXPERIMENTAL RESULTS

In this section we present the results of three exper-

imental tests which have been carried out with ref-

erence to a 0.25 kW C4T34FB5B Leeson induction

motor driven by a 20 kHz PWM-based open loop

voltage/frequency control (61 V, 16.7 Hz). The ap-

plied load torque, which is proportional to the induc-

tion motor speed, is provided by the WSM-3-32-1

Sangalli Servomotori DC permanent magnet motor

directly connected to the shaft of the induction mo-

tor. The nonlinear adaptive observer (3)-(4) and the

load torque identifier are executed (at 12.5 kHz) when

the motor has reached its steady-state. The nomi-

nal values of the parameters (provided by the man-

ufacturer) L

s

= 0.268 H, L

r

= 0.298 H, M = 0.258

H, J = 0.005 kgm

2

are used, the control gains (all

the values are in SI units) k

i

= 600, k

z

= 3, k

α

= 10,

k

R

= 0.65, k

ω

= 100, k

T

= 5 are chosen while zero ini-

tial conditions, excepting for

ˆ

α(0) and

ˆ

R

s

(0) (equal

to 12.75 s

−1

and 10.45 Ohm) are set. The first test,

whose steady-state results are reported in Figure 7,

involves a partial speed sensor fault (ω

m

= 70 rad/s,

ω = 88 rad/s) occurring at t = 3.84 s. The second

test, whose steady-state results are reported in Figure

8, involves a larger partial speed sensor fault (ω

m

= 44

rad/s, ω = 88 rad/s) occurring at t = 2.02 s. The third

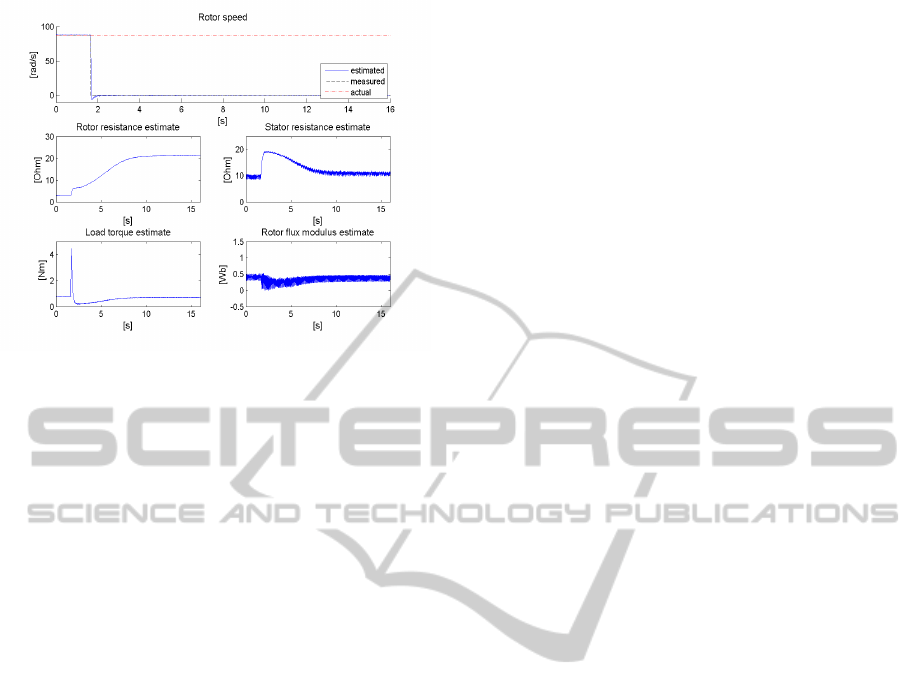

test, whose steady-state results are reported in Figure

9, finally involves a full speed sensor fault (ω

m

= 0

rad/s, ω = 88 rad/s) occurring at t = 1.66 s. All the

three tests confirm the theoretical results presented in

the paper: as expected, the speed sensor fault can be

promptly identified (R

rM

= 6 Ohm) by monitoring the

estimated rotor resistance which converges to α

e

.

Figure 8: Second experimental test (ω

m

= 44 rad/s, ω = 88

rad/s).

7 CONCLUSIONS

A constant non-zero (sufficiently large) difference be-

tween the measured speed and the actual speed may

be on-line identified, even in the presence of uncer-

tainties in load torque and rotor/stator resistances, in

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

64

Figure 9: Third experimental test (ω

m

= 0 rad/s, ω = 88

rad/s).

typical operating conditions involving non-zero load

torque, constant rotor speed and flux modulus. An

adaptive flux observer which incorporates a conver-

gent rotor resistance identifier and relies on the mea-

sured rotor speed and stator currents/voltages is used

to this purpose. A relevant consequence of the pre-

sented analysis is that rotor fluxes (and therefore mo-

tor torque), load torque and stator resistance can be

actually estimated even in the presence of speed sen-

sor faults.

REFERENCES

M. E. H. Benbouzid, D. Diallo, and M. Zeraoulia (2007).

Advanced fault-tolerant control of induction-motor

drives for EV/HEV traction applications: from con-

ventional to modern and intelligent control tech-

niques. IEEE Transactions on Vehicular Technology,

56(2), 519-528.

S. M. Bennet, R. J. Patton, and S. Daley (1999). Sensor

fault-tolerant control of a rail traction drive. Control

Engineering Practice, 7, 217-225.

P. Castaldi, W. Geri, M. Montanari, and A. Tilli (2005). A

new adaptive approach for on-line parameter and state

estimation of induction motors. Control Engineering

Practice, 13(1), 81-94.

D. Diallo, M. E. H. Benbouzid, and A. Makouf (2004). A

fault-tolerant control architecture for induction motor

drives in automotive applications. IEEE Transactions

on Vehicular Technology, 53(6), 1847-1855.

S. X. Ding (2008). Model-based Fault Diagnosis Tech-

niques. Springer, Berlin.

J. Guzinski, H. Abu-Rub, M. Diguet, Z. Krzeminski, and A.

Lewicki (2010). Speed and load torque observer appli-

cation in high-speed train electric drive. IEEE Trans-

actions on Industrial Electronics, 57(2), 565-574.

J. Guzinski, M. Diguet, Z. Krzeminski, A. Lewicki, and

H. Abu-Rub (2009). Application of speed and load

torque observers in high-speed train drive for diagnos-

tic purposes. IEEE Transactions on Industrial Elec-

tronics, 56(1), 248-256.

I.-J. Ha and S.-H. Lee (2000). An online identification

method for both stator and rotor resistances of in-

duction motors without rotational transducers. IEEE

Transactions on Industrial Electronics, 47(4), 842-

853.

S. M. N. Hasan and I. Husain. A Luenberger-sliding mode

observer for online parameter estimation and adap-

tation in high-performance induction motor drives

(2009). IEEE Transactions on Industry Applications,

45(2), 772-781.

R. J. Hill (1994). Electric railway traction. Power Engineer-

ing Journal, 8(3), 143-152.

R. Isermann (2011). . Fault-Diagnosis Applications.

Springer, Berlin.

F. Jadot, F. Malrait, J. Moreno-Valenzuela, and R. Sepul-

chre (2009). Adaptive regulation of vector-controlled

induction motors. IEEE Transactions on Control Sys-

tems Technology, 17(3), 646-657.

S. H. Jeon, K. K. Oh, and J. Y. Choi (2002). Flux ob-

server with online tuning of stator and rotor resis-

tances for induction motors. IEEE Transactions on In-

dustrial Electronics, 49(3), 653-664.

G. Kenn

´

e, R. S. Simo, F. Lamnabhi-Lagarrigue, A.

Arzand

´

e, and J.C. Vannier (2010). An online simpli-

fied rotor resistance estimator for induction motors.

IEEE Transactions on Control Systems Technology,

18(5), 1188-1194.

K.-S. Lee and J.-S. Ryu (2003). Instrument fault detection

and compensation scheme for direct torque controlled

induction motor drives. IEE Proceedings on Control

Theory and Applications, 150(4), 376-382.

R. Marino, S. Peresada, and P. Tomei (2000). On-line sta-

tor and rotor resistance estimation for induction mo-

tors. IEEE Transactions on Control Systems Technol-

ogy, 8(3), 570-579.

R. Marino, P. Tomei, and C. M. Verrelli (2010a). Induction

Motor Control Design. Springer, London.

R. Marino, P. Tomei, and C. M. Verrelli (2008). An adap-

tive tracking control from current measurements for

induction motors with uncertain load torque and rotor

resistance. Automatica, 44(10), 2593-2599.

R. Marino, P. Tomei, and C. M. Verrelli (2010b). Adaptive

output feedback tracking control for induction mo-

tors with uncertain load torque and resistances. Inter-

national Symposium on Power Electronics, Electrical

Drives, Automation and Motion, 419-424, Pisa, June

14-16.

R. Marino, P. Tomei, and C. M. Verrelli (2010c). Tracking

control for sensorless induction motors with uncertain

load torque and resistances. 8

th

IFAC Symposium on

Nonlinear Control Systems, Bologna, September 1-3.

R. Marino, P. Tomei, and C. M. Verrelli (2011). A new flux

observer for induction motors with on-line identifica-

tion of load torque and resistances. 18

th

IFAC World

Congress, 18, Milano, 28 August-2 September.

T. A. Najafabadi, F. R. Salmasi, and P. Jabehdar-Maralani

(2011). Detection and isolation of speed-, DC-link

RotorSpeedSensorFaultDetectioninInductionMotors

65

voltage-, and current-sensor faults based on an adap-

tive observer in induction-motor drives. IEEE Trans-

actions on Industrial Electronics, 58(5), 1662-1672.

H. U. Rehman (2008). An integrated starter-alternator and

low-cost high-performance drive for vehicular appli-

cations. IEEE Transactions on Vehicular Technology,

57(3), 1454-1465.

M. E. Romero, M. M. Seron, and J. A. De Don

´

a (2010).

Sensor fault-tolerant vector control of induction mo-

tors. IET Control Theory and Applications, 4(9),

1707-1724.

A. T¸ iclea and G. Besanc¸on (2006). Observer scheme for

state and parameter estimation in asynchronous mo-

tors with application to speed control. European Jour-

nal of Control, 12(4), 400-412.

H. Wang, S. Pekarek, and B. Fahimi (2006). Multilayer

control of an induction motor drive: a strategic step for

automotive applications. IEEE Transactions on Power

Electronics, 21(3), 676-686.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

66