Sigmapoint Approach for Robust Optimization

of Nonlinear Dynamic Systems

Sebastian Recker

1

, Peter K

¨

uhl

2

, Moritz Diehl

3

and Hans Georg Bock

4

1

Aachener Verfahrenstechnik, RWTH Aachen University, Aachen, Germany

2

BASF SE, Ludwigshafen, Germany

3

Optimization in Engineering Center, KU Leuven, Leuven, Belgium

4

Interdisciplinary Center for Scientific Computing, University of Heidelberg, Heidelberg, Germany

Keywords:

Parametric Uncertainty, Optimal Control, Batch Process, Unscented Transformation.

Abstract:

Mathematical models describing dynamic processes contain parametric uncertainties. Robust model-based

optimization thus becomes a challenging task in process engineering. Current approaches either require high

computational effort or they make use of oversimplified approximations that do not capture changes in the

solution structure due to nonlinear effects of the uncertain parameters on the states of the process. In this paper

we propose an improved optimization approach that uses sigmapoints to characterize the space of uncertain

parameters. Propagating sigmapoints through the process model and directly using them in the optimization

problem allows to capture relevant nonlinearities for the uncertain parameters. Main advantages of this simple

yet elegant approach are the relatively low computational burden and the independence from the optimizer, as

no further derivatives are needed. The approach is applied to two examples from process engineering, a batch

distillation and a semibatch reactor.

1 INTRODUCTION

In this paper we consider constrained optimization

problems of the form

min

u∈R

n

u

Φ(x,z,u) (1)

with

Φ :=

Z

T

0

L(x(t),z(t),u(t), p) dt + M(x(T ),z(T ))

(2)

subject to the DAE system

˙x(t) = f (x(t),z(t),u(t), p), t ∈ [0,T ], (3)

0 = g(x(t),z(t), u(t), p), t ∈ [0, T ], (4)

the initial value constraint

x(0) −x

0

= 0, (5)

as well as control and path constraints

h(x(t),z(t),u(t), p) ≤ 0, t ∈ [0,T ]. (6)

In this formulation x(t) ∈ R

n

x

denotes the differential

states, z(t) ∈ R

n

z

the algebraic states, u(t) ∈ R

n

u

the

available controls, and p ∈ R

n

p

the parameters. Such

problems often arise from the model-based optimiza-

tion of technical processes, e.g. in the chemical pro-

cess industry.

The above formulation is based on a process

model with exact parameters p. This is an idealiza-

tion, which is referred to as the nominal problem in

this paper. In most real-world problems, at least some

of the parameters will not be known exactly. Rather,

a set P ⊂R

n

p

that is likely to contain p will be known

or can at least be assumed. For a robust solution of the

optimization problem the constraints shall be fulfilled

for all parameters within this set and thus

h(x(t),z(t), u(t), p) ≤ 0 ∀ p ∈P (7)

has to hold. Due to its then infinite number of con-

straints, this formulation is called a semi-infinite pro-

gram (Blankenship and Falk, 1976). In order to solve

this problem, the number of constraints has to be re-

duced. For this purpose we focus on the general con-

cept of local reduction methods (Hettich and Kor-

tanek, 1993) in this paper. Note that we do not con-

sider the case when the model structure is not entirely

known. In some cases, however, such a problem can

be reformulated into one with parametric uncertainty.

A common idea to solve robust optimization prob-

199

Recker S., Kühl P., Diehl M. and Georg Bock H..

Sigmapoint Approach for Robust Optimization of Nonlinear Dynamic Systems.

DOI: 10.5220/0004026401990207

In Proceedings of the 2nd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2012),

pages 199-207

ISBN: 978-989-8565-20-4

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

lems is to see the uncertain parameters as adverse

players (Ben-Tal and Nemirovski, 1999) that try to

disturb any constraint enforcement effort as strongly

as possible. The task is to still meet the constraints

for the worst parameter realization. This leads to min-

imizing the maximum negative effect of possible un-

certainty realizations with respect to the constraints

and results in the worst-case problem

min

u∈U

Φ(x,z,u, p) (8)

s.t. max

p∈P

h(x,z,u, p) ≤ 0.

Due to its bi-level structure, this optimization prob-

lem is still difficult to solve numerically for general

nonlinear functions.

1.1 Min-max Approximative Worst-case

Reformulation

(Diehl et al., 2006) suggest an approximation for this

kind of optimization problem. If the constraint func-

tions are monotone within the parameter set and can

be approximated by a Taylor expansion, the max-

term of the optimization problem (8) for normally dis-

tributed parameters

P :=

p ∈ R

n

p

|

1

γ

Σ

−

1

2

(p − ˜p)

2

≤ 1

(9)

with the covariance matrix Σ and the confidence level

γ can be restated as:

max

p∈P

h(x,z,u, p)

≈ h(x,z,u, ˜p) + γ

Σ

1

2

∇

p

h(x,z,u, ˜p)

2

≤ 0 (10)

This robust optimization problem can efficiently be

solved by dynamic optimization algorithms. For non-

linear DAE systems this linear approximation may

lead to approximation errors and the robust enforce-

ment of constraints will fail. A remedy is to use

higher order approximations. In (Heine et al., 2006)

a second order approximation of the mean and vari-

ance is suggested that can efficiently be computed by

an unscented transformation.

In this article we assume all uncertain parameters to

be normally distributed. Other parameter distribu-

tions can be treated within the same framework. For a

derivation of robust reformulations of the optimiza-

tion problem for different distributions see (Diehl

et al., 2006).

While we focus on robust enforcement of con-

straints, note that the approach also allows to robustly

treat the cost functional Φ(x,z,u, p).

1.2 Min-max Reformulation with

Sufficient Condition

(Moennigmann and Marquardt, 2002) and (Diehl

et al., 2008) present another approach to handle the bi-

level structure of the optimization problem (8). The

inner maximization problem is replaced by its suf-

ficient condition. Due to the additional equations

this extended optimization problem can be difficult to

solve and results in a higher computational effort, but

overcomes the problems associated with the lineariza-

tion approach.

1.3 Chance-constrainted Programming

Another approach to solve optimization problems ro-

bustly, which avoids the bi-level structure caused by

the worst case min-max formulation of the constraint,

is the chance constrained optimization (Arellano-

Garcia et al., 2003). The general constraint (7) is re-

placed by a probability constraint

P

{

h(x,z,u, p) ≤ 0

}

≥ 1 −α. (11)

This approach requires efficient algorithms for realiz-

ing the mapping from the uncertain parameters to the

uncertain constraints. As this mapping only holds for

the actual set of inputs u, it has to be recalculated in

each iteration of the optimization. Even if derivatives

are used to avoid the computation of the mapping in

each iteration (Li et al., 2008), this approach results

in high computational effort.

2 A MODIFIED SIGMAPOINT

APPROACH

The presented approaches either only hold for mildly

nonlinear problems that can be approximated by

linearization, or they result in high computational

time. To combine the low computational effort of

the worst-case approximation with the higher accu-

racy of the other two methods, we modify the usage

of the unscented transformation suggested in (Heine

et al., 2006). Before optimizing, modified constraints

˜

h(x,z,u, p) shall be identified such that satisfying the

new constraints results in satisfying the original con-

straints for all parameters inside the critical subspace

with a desired probability:

˜

h(x,z,u, p) ≤ 0 ⇒P{h(x,z,u, p) ≤ 0} ≥ 1 −α (12)

A possible choice of the modified constraints could

be the principal axis endpoints of the constraint dis-

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

200

tribution, which correspond to the 1 −α interval

1

, if

the constraints are monotone within the parameter set.

For constraints with moderate curvatures, this choice

of the modified constraints results in an approxima-

tion that might allow to meet the original constraints

for all parameters inside the uncertainty ellipsoid with

nearly the desired probability. In order to identify

these endpoints, the mapping of the parameter distri-

bution onto the constraints has to be described.

An appealing method for propagating distribu-

tions through nonlinear models is the Unscented

Transformation ((Julier and Uhlmann, 1996)). By

choosing so called sigmapoints and weights and prop-

agating these sigmapoints through the model, one

can approximate the distribution of the constraints

˜

h(x,z,u, p), if the weighted sigmapoints approximate

the distribution of the parameters. The first two mo-

ments of the constraint distribution (the mean and the

covariance) are matched exactly and the method can

be extended to match additional moments (Julier and

Uhlmann, 1997).

Using these moments, a possible choice of the

modified constraints for normally distributed parame-

ters is

˜

h := h(x,z,u, ˜p) + γ

h(x,z,u, ˜p) −h(x, z, u, p

UT

i

)

2

,

i = 0,...,2n

p

(13)

with the sigmapoints of the Unscented Transforma-

tion

p

UT

0

= ˜p (14)

p

UT

i

= ˜p +

p

Σ

i

,i = 1, . . . , n

p

p

UT

i+n

p

= ˜p −

p

Σ

i

,i = 1, . . . , n

p

,

where

√

Σ

i

is the ith row or column of the matrix

square root of the covariance matrix Σ. ˜p denotes the

set of nominal parameters. As the first two moments

of the distribution are matched exactly, the endpoints

are matched exactly, if the constraints are normally

distributed. For not normally distributed constraints

the endpoints can be mismatched dramatically, as the

first two moments but not the 1−α intervals are prop-

agated.

Applying the Unscented Transformation to in-

dustrial relevant examples has shown, that modified

sigmapoints are a good approximation for the corre-

sponding 1 −α intervals, even for not normally dis-

tributed constraints. Thus, choosing the modified

1

1 −α denotes the probability of values to lie inside the

symmetric confidence interval with less then γ ·σ from the

mean, with σ representing the standard deviation (e.g. for

normal distributions γ = 1 ⇒ 1 −α ≈ 68.3%, γ = 3 ⇒ 1 −

α ≈99.7%).

constraints as

˜

h := h(x,z,u, p

i

) ≤ 0, i = 0,...,2n

p

(15)

results in satisfying the constraints for all parameters

inside the critical subspace with nearly the desired

probability (1 −α), if the modified sigmapoints are

chosen by

p

0

= ˜p (16)

p

i

= ˜p + γ

p

Σ

i

,i = 1, . . . , n

p

p

i+n

p

= ˜p −γ

p

Σ

i

,i = 1, . . . , n

p

.

Hence, the robust optimization problem results in

min

u∈U

Φ(x,z,u, ˜p) (17)

s.t. h(x,z,u, p

i

) ≤ 0, i = 0,...,2n

p

and can easily be solved by a standard dynamic op-

timizer. For normally distributed and monotone con-

straints the 1 −α intervals are mapped exactly. Ap-

plying this approach to industrially relevant examples

has shown that also for non-normally distributed con-

straints the desired probability is nearly achieved.

3 APPLICATION EXAMPLE:

BATCH DISTILLATION

In the following section we will revisit an example

that has already been studied in previous publications

of (Diehl et al., 2006; Diehl et al., 2008). We will

briefly review the optimization method with the lin-

earization of the max-term and compare their results

to our new approach.

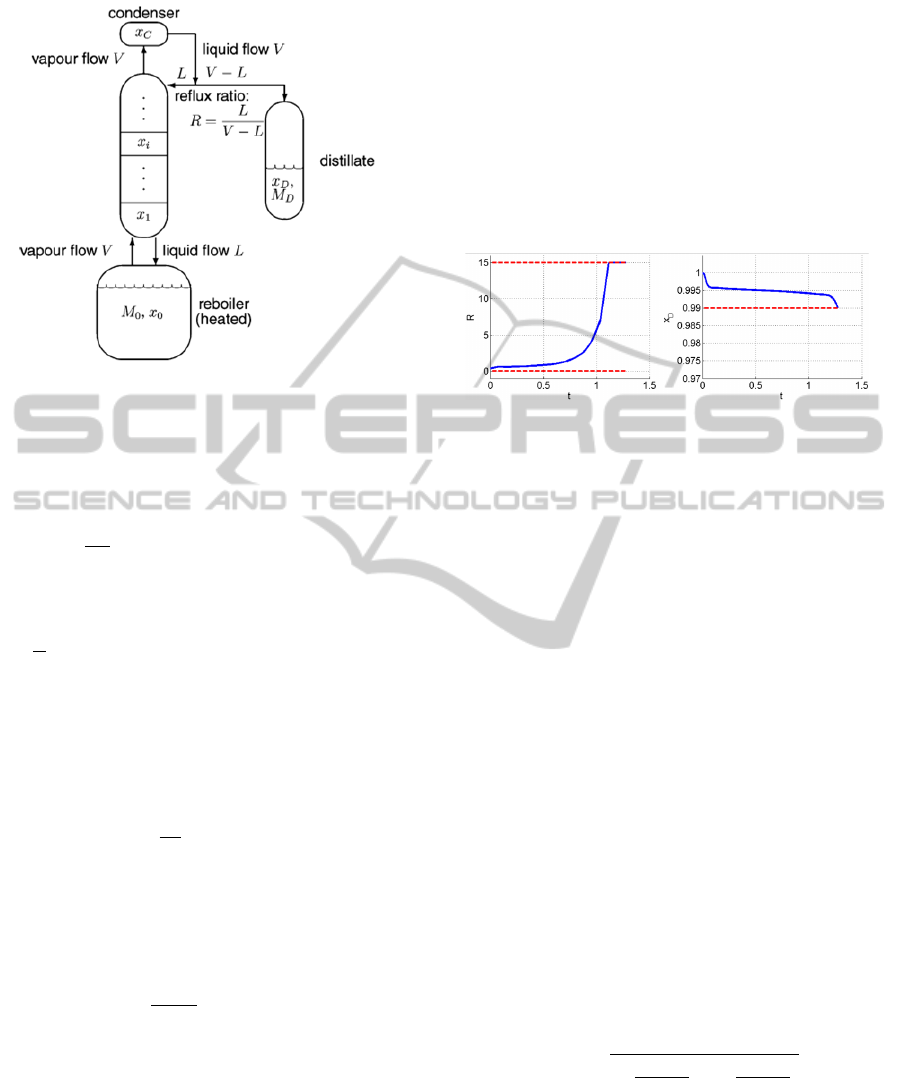

The aim of the process sketched in Figure 1 is the

separation of a binary mixture and to obtain distillate

with a purity of at least 99%. In the following we

briefly summarize the process model.

3.1 Process Model

The content of the reboiler M

0

, with x

0

the molar per-

centage of the lighter component, is heated, so that

vapor with and equilibrium composition y(x) and a

constant molar flux V = 100 kmol/h is produced over

all trays. The vapor equilibrium is expressed by the

simple function y(x) :=

x(1+α)

x+α

. Input to the process

is the controlled reflux ratio R and a liquid molar

flux L =

R

1+R

V , which is also assumed to be constant

throughout the column, is fed back into the column.

The remainder of the condensed liquid flux V −L,

with composition x

C

is collected within the distillate

tank with molar holdup M

D

and composition x

D

. For

SigmapointApproachforRobustOptimizationofNonlinearDynamicSystems

201

Figure 1: Sketch of the batch distillation column ((Diehl

et al., 2006)).

the reboiler, we get the following ordinary differential

equations:

˙

M

0

= −V + L (18)

˙x

0

=

1

M

0

(Lx

1

−V y(x

0

) + (V −L)x

0

) (19)

and

˙x

i

=

1

m

(Lx

x

i

+1

−V y(x

i

) +V y(x

i−1

) −Lx

i

) i = 1,... ,N

(20)

for the tray concentrations, where m = 0.1 kmol

(the molar holdup of each tray) is assumed to be con-

stant, and the number of trays is N = 5. For the con-

denser concentration x

N+1

we obtain

˙x

N+1

=

V

m

c

(y(x

N

) −x

N+1

) (21)

where m

C

= 0.1kmol is the constant molar holdup of

the condenser, and for the distillate container we ob-

tain

˙

M

D

= V −L (22)

˙x

D

=

V −L

M

D

(x

N+1

−x

D

). (23)

3.2 Nominal Optimization Problem

We summarize the states in x = (M

0

,x

0

,x

1

,...,x

N+1

,

M

D

,x

D

)

T

and set the control variable u = R. The ob-

jective is given by Φ := T −M

D

(T ) and reflects the

two objectives of minimizing the batch time and max-

imizing the produced distillate. The only inequality

constraint is h := 0.99 −x

D

(T ) ≤ 0, i.e. the purity

at the end of the batch shall exceed or equal 99%.

Nominal initial values are M

0

= 100, x

0

= 0.5, x

1

=

... = x

N+1

= x

D

= 1,M

D

= 0.1, and the nominal value

of the equilibrium parameter is α = 0.2. In addi-

tion there are bounds on the controlled reflux ratio,

0 ≤ R ≤ 15. Figure 2 shows the solution for the

nominal optimization problem, which has been solved

with the software package MUSCOD-II ((Leinewe-

ber et al., 2003a; Leineweber et al., 2003b)) based on

the direct multiple shooting approach introduced in

(Bock and Plitt, 1984).

Figure 2: Nominal solution of the batch distillation prob-

lem.

3.3 Uncertain Optimization Problem

For practical problems, the aim of a robust optimiza-

tion is to still meet the constraints despite the un-

certainties. For this model uncertainty is certainly

present in the parameter p

1

= α as well as in the ini-

tial feed composition p

2

= x

0

(0). We assume the set

of the uncertain parameters to be characterized by the

covariance matrix

Σ =

0.0278 0

0 2.5e

−5

. (24)

3.4 Robust Optimization by

Linearization of the Max-term

In order to robustify the optimization with respect to

the critical quality specification, we reformulate the

respective constraint as

max

p∈P

0.99 −x

D

(T, p) ≤ 0 (25)

and approximate the solution of the inner maximiza-

tion problem by

0.99 −x

D

(T, ˜p) −γ

s

Σ

1,1

∂x

D

(T, ˜p)

∂α

2

+ Σ

2,2

∂x

D

(T, ˜p)

∂x

0

(0)

2

≤ 0. (26)

Here, ˜p denotes the nominal parameters and γ is set

to 3, to meet the constraint with aa approximate prob-

ability of ≈ 99.7%. The results for this optimization

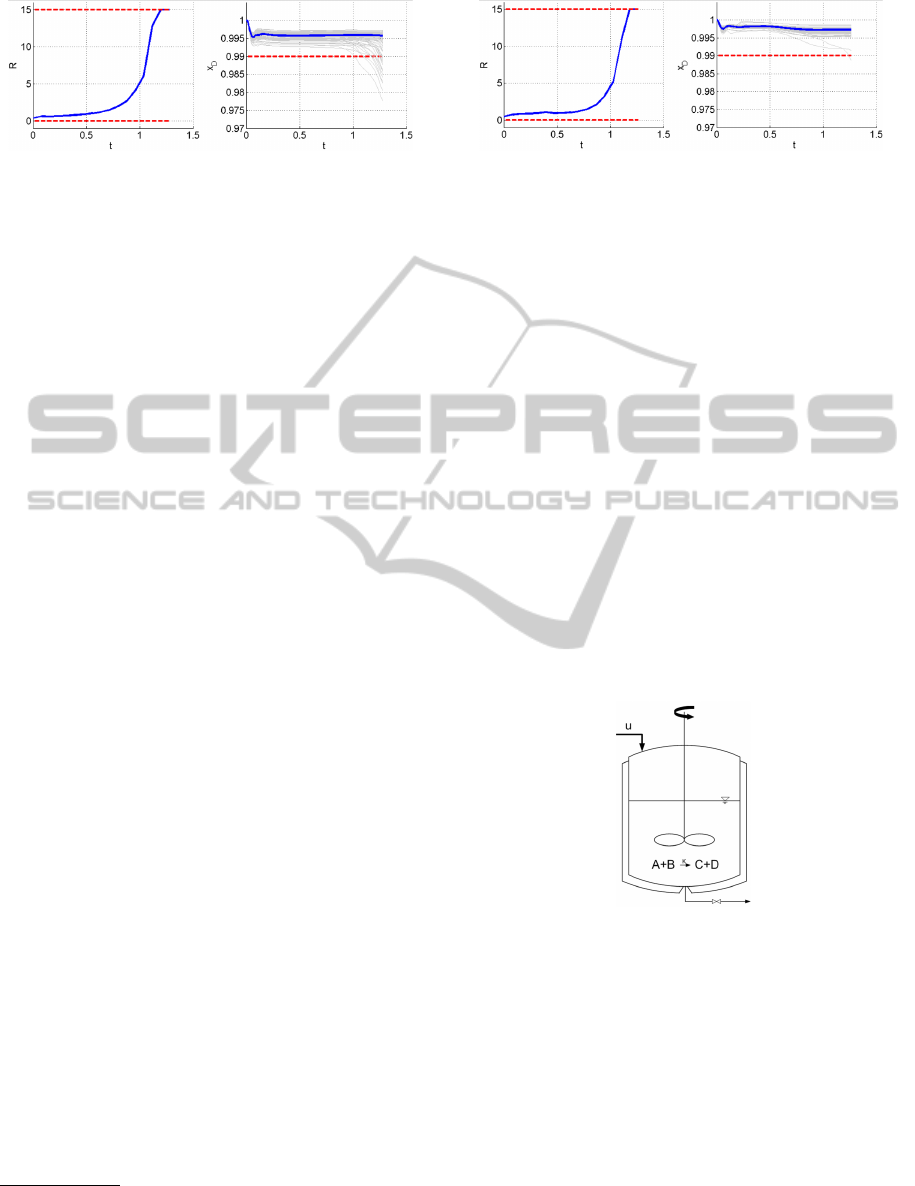

are shown in Figure 3.

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

202

Figure 3: Robust solution of the batch distillation prob-

lem for the linearization of the max-term. Light gray lines

show MonteCarlo simulations with random parameter real-

izations p ∈P .

Although the robust constraint (26) is active, a

MonteCarlo simulation

2

of the robust profile (gray

lines) shows that the desired purity at the end of the

batch is not achieved with the desired probability. Ob-

viously the linearization of the constraint function is

not a sufficient approximation, as shown by (Diehl

et al., 2008). Due to the special properties of this con-

straint function (structural changes of the constraint

function for small changes in the uncertain parameter

x

0

(0)), increasing the order of the Taylor expansion

would not improve the approximation with respect to

the aim of staying above the desired final composi-

tion.

3.5 Robust Optimization by Sigmapoint

Approach

For the sigmapoint approach, the critical constraint

for the nominal parameters ˜p is amended by addi-

tional constraints with the sigmapoints p

i

as argu-

ments. Thus, the robust optimization problem formu-

lation results in

min

u

T −M

D

(T, ˜p) (27)

s.t. 0.99 −x

d

(T, p

0

) ≤ 0

0.99 −x

d

(T, p

1

) ≤ 0

0.99 −x

d

(T, p

2

) ≤ 0

0.99 −x

d

(T, p

3

) ≤ 0

0.99 −x

d

(T, p

4

) ≤ 0

with the sigmapoints (cf. eq. 16)

p

0

= ˜p = (6,0.5)

T

, p

1

= (6.5,0.5)

T

,

p

2

= (6,0.516)

T

, p

3

= (5.5,0.5)

T

, p

4

= (6,0.484)

T

.

The results of the optimization are shown in Fig-

ure 4.

2

For the MonteCarlo simulation the trajectories for 100

normally distributed parameter realizations with mean ˜p

and covariance matrix Σ have been computed.

Figure 4: Robust solution of the batch distillation prob-

lem for the sigmapoint approach. Light gray lines show

MonteCarlo simulations with random parameter realiza-

tions p ∈P .

A MonteCarlo simulation of this profile (gray lines)

shows, that the compliance with the constraint is

achieved with the desired probability.

4 APPLICATION EXAMPLE:

SEMIBATCH PROCESS

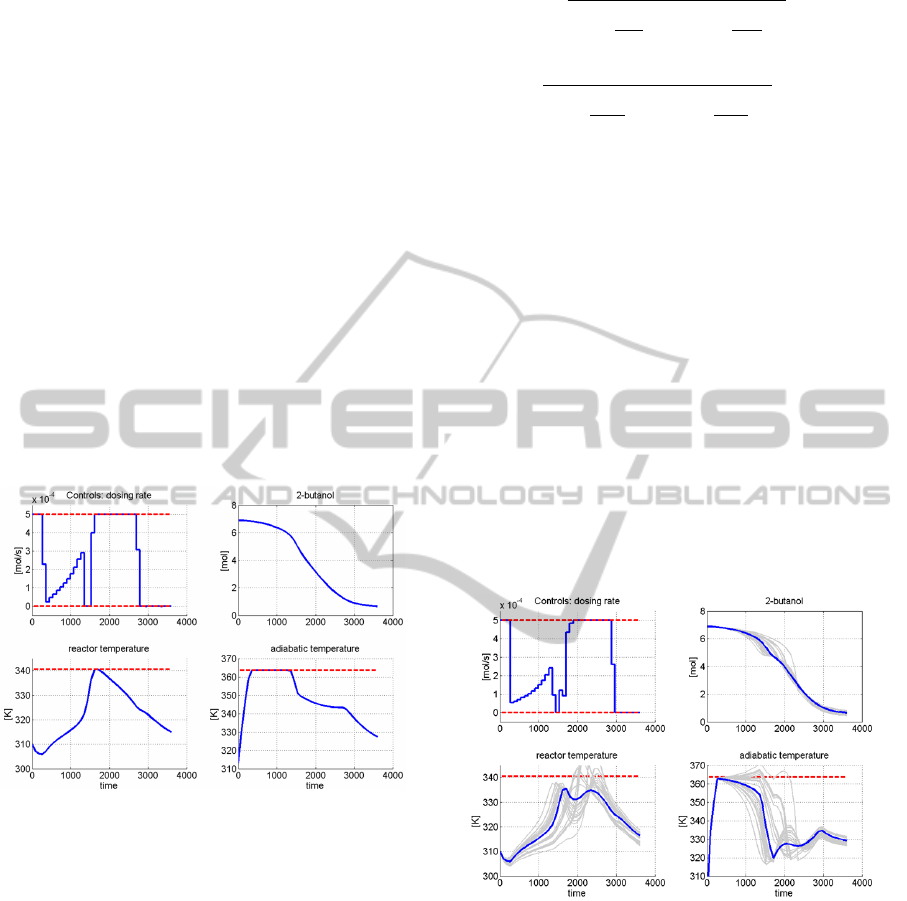

The second application example is an exothermic

semibatch process that been considered for optimiza-

tion purposes in a previous publication of (Kuehl

et al., 2005). A sketch of the process is shown in

Figure 5. It describes the esterification of 2-butanol

(B) with propionic anhydride (A) to 2-butyl propi-

onate (D) and propionic acid (C). This homogeneous

reaction is moderately exothermic and is catalyzed by

sulphuric acid (K).

Figure 5: Sketch of the semibatch process.

The reaction is assumed to take place in a semi-batch

reactor under isoperibolic conditions (e.g. constant

jacket temperature). The reactor is initially charged

with B and K. During the process, A is dosed to the

reactor until the dosed amount of substance A is equal

to the initial amount of substance B. The batch is fin-

ished once almost all B has been consumed. A model

of the process can be found in the Appendix. It was

originally developed by (Milewska, 2006).

SigmapointApproachforRobustOptimizationofNonlinearDynamicSystems

203

4.1 Nominal Optimization Problem

Following the case study in (Kuehl et al., 2005)

the objective is chosen as Φ :=

R

t

f

0

n

B

(τ)

2

dτ. The

inequality constraints are h

1

(t) := T

R

(t) −340.5 ≤ 0

and h

2

(t) := T

ad

(t) −363.65 ≤ 0.

The complete optimization problem is summa-

rized as

min

u

Z

t

f

0

n

B

(τ)

2

dτ (28)

s.t. 0 mol/s ≤ u(t) ≤ 0.005 mol/s,

Z

t

f

t

0

=0

u(τ) dτ ≤6.89396 mol,

T

R

(t) −340.5 K ≤ 0,

T

ad

(t) −363.65 K ≤ 0.

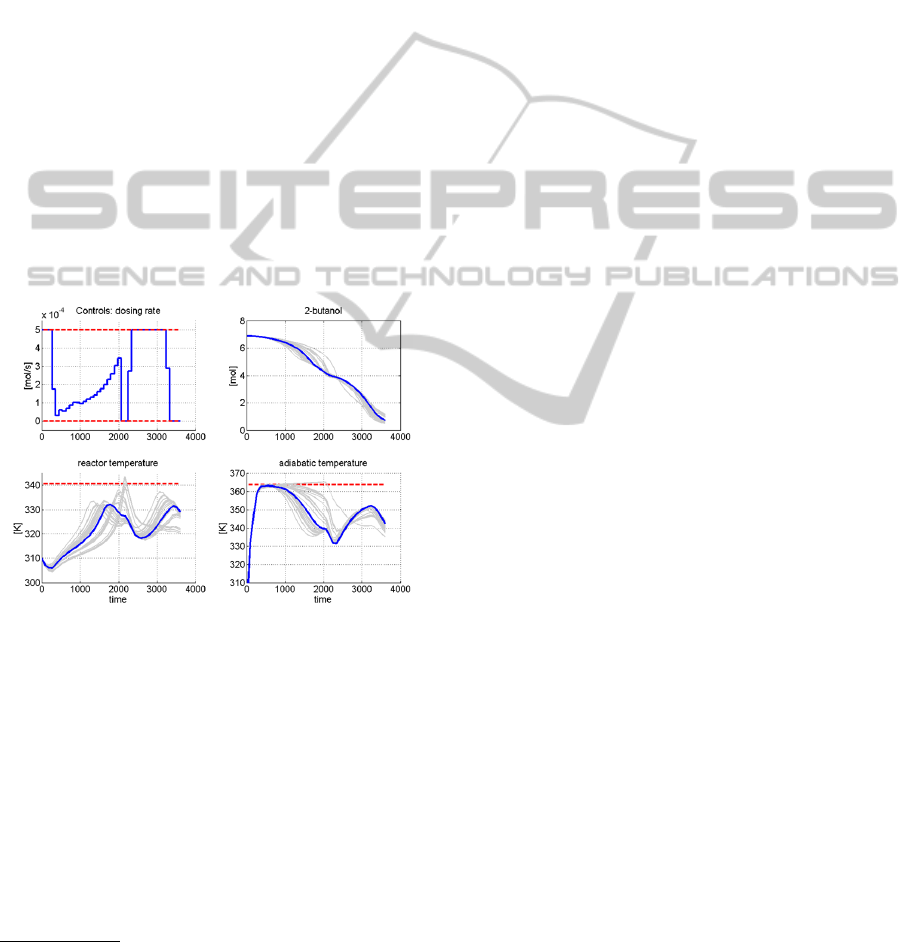

The second constraint ensures, that the maximum

amount of A is not exceeded. Figure 6 shows the so-

lution of the nominal optimization problem.

Figure 6: Nominal solution of the exothermic semibatch

problem with safety constraints on reactor temperature and

worst-case adiabatic temperature in case of a runaway reac-

tion.

4.2 Uncertain Optimization Problem

Uncertainty is assumed to be present in the jacket

temperature p

1

= T

j

, due to imperfect control action

and in the initial amount of catalyst p

2

= n

K

. The

covariance of the uncertain parameter space is

Σ =

1.2469 0

0 2.8747e

−4

. (29)

4.3 Robust Optimization by

Linearization of the Max-term

To meet the constraints for all p ∈ P the approxima-

tion of the inner worst-case problem reads as

T

R

−γ

s

Σ

1,1

dT

R

dT

j

2

+ Σ

2,2

dT

R

dn

K

2

−340.5 ≤0

(30)

T

ad

−γ

s

Σ

1,1

dT

ad

dT

j

2

+ Σ

2,2

dT

ad

dn

K

2

−363.65 ≤0.

(31)

Figure 7 displays the results for the robust optimiza-

tion for γ = 3. Although this profile results in a safety

margin to the maximal reactor temperature, a Mon-

teCarlo simulation (gray lines) reveals, that the con-

straints are violated more often than allowed.

As the linearization of the uncertain constraints is

computed for each iteration of the optimization, this

approach is suitable for the approximation of uncer-

tainties if the structure of the state trajectories does

not change. This example shows, that even for small

uncertainties (here 1% of the jacket temperatur) the

structure of the trajectories can change dramatically.

This strucutral change caused by the intrinsic dynam-

ics of the system (e.g. accumulation of propionic

acid) is not well approximated by the linearization.

As a consequence, the solution fails to meet the con-

straints for the desired range of uncertain parameter.

Figure 7: Robust solution of the exothermic semibatch

problem for the linearization of the max-term. Light gray

lines show MonteCarlo simulations with random parameter

realizations p ∈P .

4.4 Robust Optimization by Sigmapoint

Approach

As the sigmapoint approach tracks critical points in-

stead of locally approximating the transformed dis-

tribution, the differing trajectories are captured in a

broader range. The robust optimization problem for a

desired probability level of γ = 3 results in

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

204

min

u

Z

t

f

0

n

B

(τ)

2

dτ (32)

s.t. 0 mol/s ≤ u(t) ≤ 0.005 mol/s,

Z

t

f

t

0

=0

u(τ) dτ ≤6.89396 mol,

T

R

(t, p

i

) −340.5 K ≤0, i = 0,...,4

T

ad

(t, p

i

) −363.65 K ≤0, i = 0,...,4

with the sigmapoints (16)

p

0

= ˜p = (313.15,0.0511)

T

, p

1

= (314.65,0.0511)

T

p

2

= (311.65,0.0511)

T

, p

3

= (313.15,0.0562)

T

p

4

= (313.15,0.046)

T

.

The optimization results are shown in Figure 8.

In contrast to the robust solution presented above,

even for the trajectories of the MonteCarlo simula-

tion

3

(grey lines) compliance with the constraints is

achieved with higher probability.

Figure 8: Robust solution of exothermic semibatch prob-

lem for the sigmapoint approach. Light gray lines show

MonteCarlo simulations with random parameter realiza-

tions p ∈P .

5 CONCLUSIONS AND

OUTLOOK

An improved approach for the approximative solu-

tion of robust optimization problems with paramet-

ric uncertainties has been introduced in this paper.

The simple but effective idea relies on propagating

3

To guarantee the comparability for both MonteCarlo

simulations even for the small number (25) of realizations

used in this example, both simulations use the same set of

normally distributed parameters for the trajectories.

sigmapoints through the nonlinear process and ensur-

ing that these sigmapoint trajectories also meet the re-

quired constraints as part of the optimization problem.

This approach does not change the original optimiza-

tion problem apart from adding additional path con-

straints. In particular, no higher-order derivatives are

required. The approach takes advantage of the benefi-

cial properties of the unscented transformation, which

allows to better track the nonlinear effect that uncer-

tain parameters have on the constraints. This proves

particularly important in cases where the structure of

the optimal control problem solution changes. Exam-

ples from process engineering illustrate that even for

small uncertainties these structural changes may oc-

cur and that approaches based on local linearization

of the nominal trajectories may not be well suited.

In practical applications, robustly meeting critical

constraints may not be the only concern. As the ob-

jective function increases with increasing robustness

requirements, one typically wishes to find a compro-

mise between robustness and the costs associated with

it. Within the discussed framework, we see two ap-

proaches to adequately balance robustness and costs.

One solution is to simply price constraint violations

and include these costs in the objective function. The

sigmapoint approach nicely supports this solution as

the requested degree of robustness γ corresponds to

a probability of constraint violation α. We have not

yet investigated whether it is possible to directly in-

clude γ (or α respectively) as a free variable into the

optimization problem.

A second solution for a balanced trade-off be-

tween robustness and performance is a robust refor-

mulation of the objective function itself. For normally

distributed parameters the reformulation of the objec-

tive functions is equivalent to that of 13 seems suit-

able. This has not yet been thoroughly investigated

either.

Even though the sigmapoint approach has per-

formed well on the examples shown, no performance

guarantees have been established so far. There cer-

tainly exist optimization problems where the modified

sigmapoints do not approximate the 1−α interval for

the constraints well enough. In this case a possible

remedy could be the propagation of additional sigma-

points at the expense of higher computational cost.

ACKNOWLEDGEMENTS

The research leading to these results has received

funding from the European Union Seventh Frame-

work Programme FP7/2007-2013 for SYNFLOW and

EMBOCON under grant agreement number NMP2-

SigmapointApproachforRobustOptimizationofNonlinearDynamicSystems

205

LA-2010-246461 and FP7-ICT-2009-4248940.

REFERENCES

Arellano-Garcia, H., Martini, W., Wendt, M., Li, P., and

Wozny, G. (2003). Chance constrained batch distil-

lation process optimization under uncertainty. In IE

Grossmann, CM McDonald (Eds.): Proc. FOCAPO

2003, pages 609–612.

Ben-Tal, A. and Nemirovski, A. (1999). Robust solutions of

uncertain linear programs. Operations Research Let-

ters, 25(1):1–14.

Blankenship, J. and Falk, J. (1976). Infinitely constrained

optimization problems. Journal of Optimization The-

ory and Applications, 19(2):261–281.

Bock, H. and Plitt, K. (1984). A Multiple Shooting algo-

rithm for direct solution of optimal control problems.

In Proceedings of the 9th IFAC World Congress, pages

243–247. Pergamon Press.

Diehl, M., Bock, H., and Kostina, E. (2006). An approx-

imation technique for robust nonlinear optimization.

Mathematical Programming, 107(1):213–230.

Diehl, M., Gerhard, J., Marquardt, W., and Mnnigmann,

M. (2008). Numerical solution approaches for robust

nonlinear optimal control problems. Computers and

Chemical Engineering, 32(6):1287–1300.

Heine, T., Kawohl, M., and King, R. (2006). Robust model

predictive control using the unscented transformation.

In Control Applications CCA, pages 224–230. Perga-

mon Press.

Hettich, R. and Kortanek, K. O. (1993). Semi-Infinite Pro-

gramming: Theory, Methods, and Applications. SIAM

Review, 35(3):380–429.

Julier, S. and Uhlmann, J. (1996). A general method for ap-

proximating nonlinear transformations of probability

distributions. Dept. of Engineering Science, Univer-

sity of Oxford, Tech. Rep.

Julier, S. and Uhlmann, J. (1997). A new extension of

the Kalman filter to nonlinear systems. In Int. Symp.

Aerospace/Defense Sensing, Simul. and Controls, vol-

ume 3, page 26. Citeseer.

Kuehl, P., Milewska, A., Diehl, M., Molga, E., and Bock,

H. (2005). NMPC for runaway-safe fed-batch reac-

tors. In Proc. Int. Workshop on Assessment and Future

Directions of NMPC, pages 467–474.

Leineweber, D., Bauer, I., Bock, H., and Schlder, J. (2003a).

An efficient multiple shooting based reduced SQP

strategy for large-scale dynamic process optimization.

Part 1: theoretical aspects. Computers and chemical

engineering, 27(2):157–166.

Leineweber, D., Schfer, A., Bock, H., and Schlder, J.

(2003b). An efficient multiple shooting based reduced

SQP strategy for large-scale dynamic process opti-

mization. Part II: Software aspects and applications.

Computers and chemical engineering, 27(2):167 –

174.

Li, P., Arellano-Garcia, H., and Wozny, G. (2008). Chance

constrained programming approach to process opti-

mization under uncertainty. Computers & Chemical

Engineering, 32(1-2):25–45.

Milewska, A. (2006). Modelling of batch and semibatch

chemical reactors - safety aspects. Ph.d. thesis, War-

saw University of Technology.

Moennigmann, M. and Marquardt, W. (2002). Normal vec-

tors on manifolds of critical points for parametric ro-

bustness of equilibrium solutions of ODE systems.

Journal of Nonlinear Science, 12(2):85–112.

APPENDIX

The model of the semibatch process (as used in

(Kuehl et al., 2005)) reads as follows:

dn

A

dt

=

u

M

A

−r ·V (33)

dn

B

dt

= −r ·V (34)

dn

C

dt

=r ·V (35)

(C

p,I

+C

p

) ·

dT

R

dt

=r ·(−∆H

r

) ·V −q

dil

−U ·Ω(T

R

−T

J

)

−α ·(T

R

−T

a

) −

u

M

A

·c

p,A

·(T

R

−T

d

)

(36)

where n

i

denotes the molar amount of components

i = A,B,C,D and V the volume. T

R

,T

J

,T

a

and T

d

stand for the reactor, jacket, ambient and dosing tem-

peratures. The reaction rate is denoted by r, (−∆H

r

)

is the reaction enthalpy and Q

dil

the dilution’s heat.

U is an overall heat transfer coefficient and Ω the

heat exchanger area. The approximated heat capac-

ity of solid inserts (stirrer, baffles) is C

p,I

. C

p

denotes

the approximated heat capacity of the entire reaction

mixture and c

p,i

is the specific molar heat capacity of

component i. As the number of moles of D always

equals the number of moles of C, the equation for D

has been omitted. The molar concentrations c

i

are cal-

culated as c

i

= n

i

/V . The molar dosing rate u of A to

the batch reactor serves as control input. The defining

algebraic equations are:

ρ

i

=M

i

P

i

·Q

1−

T

R

T

c,i

0.2857

i

−1

, i = A,B,C,D

(37)

c

i

=

n

i

V

, i = A,B,C,D,K (38)

c

p,i

=a

i

+ b

i

·T

R

+ c

i

·T

2

R

+ d

i

·T

3

R

, i = A,B,C,D

(39)

c

p

=

∑

i=A,B,C,D

c

p,i

·n

i

(40)

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

206

Table 1: List of process parameters and initial conditions.

name value name value

Ω

min

0.0113 n

1

1.58

V

min

0.124 n

2

0.76

d 0.155 E

a

9.17·10

4

V

1

0.8 A

1

9.35·10

10

V

2

1.6 A

2

9.22·10

10

C

p,I1

117.3 A

3

9.78·10

10

C

p,I2

198.4 A

4

1.40·10

8

U

1

195 R 8.314

U

2

155 (−∆H

r

) 59458

α 0.1 T

R

(0) 310

T

J

313.15 n

A

(0) 0.0

T

d

298.15 n

B

(0) 6.894

T

a

298.85 n

C

(0) 0.0

m

A,total

890.00 n

K

0.0511

q

0

1.6 ·10

4

i A B C D

M

i

0.13014 0.07412 0.07408 0.13011

a

i

683.73 242.57 94.84 206.16

b

i

-3.701 -2.313 -0.243 0.199

c

i

9.6·10

−3

1.07·10

−2

2.2·10

−3

-3.56·10

−4

d

i

-7.46·10

−6

-1.16·10

−5

-2.51·10

−6

1.04·10

−6

P

i

0.462 0.320 0.285 0.508

Q

i

0.2166 0.2088 0.1993 0.2265

T

c,i

630 536 611 578

C

p,I

=C

p,I1

+

C

p,I2

−C

p,I1

V

2

−V

1

(V −V

1

) (41)

V =

n

A

M

A

ρ

A

+

n

B

·M

B

ρ

B

+

n

C

M

C

ρ

C

+

n

C

·M

D

ρ

D

(42)

Ω = Ω

min

+ 4 ·

V −V

min

d

1m

3

1000 ·l

(43)

U =U

1

+

U

2

−U

1

V

2

−V

1

(V −V

1

) (44)

x

A

=

n

A

(t)

n

A

(t) + n

B

(t) + 2n

C

(t) + n

K

(0)

(45)

q

dil

=q

0

·e

−x

A

0.14

dn

A

dt

(46)

r =

A

1

+ A

2

·c

n

1

C

(t) + A

3

·c

n

2

K

e

−E

a

R·T

R

(t)

·c

A

·c

B

(47)

T

ad

=T

R

+

n

A

·∆H

900 ·c

p

·V

1000

(48)

In these equations, M

i

, ρ

i

, c

i

denote the molar weight,

density and molar concentration of component i. V

1

,

V

2

, U

1

, U

2

are geometry-dependent parameters and

d is the scaled reactor diameter. The rate of heat

loss to the environment is modeled by a constant α

of appropriate dimension derived from a constant

heat transfer coefficient and an average heat transfer

surface area. The reaction rate is calculated following

an Arrhenius approach; the parameters A

i

and n

i

are

estimated from experimental data and give very good

results for the semi-batch operation mode.

SigmapointApproachforRobustOptimizationofNonlinearDynamicSystems

207