Design and Implementation of a Service-based Scheduling

Component for Complex Manufacturing Systems

Lars Mönch

Department of Mathematics and Computer Science, University of Hagen, Universitätsstraße 1, 58097, Hagen, Germany

Keywords: Service-oriented Computing, Scheduling, MES, Complex Manufacturing Systems.

Abstract: Scheduling is highly desirable in complex manufacturing systems. However, there is still a mismatch

between academic scheduling research, the scheduling solutions offered by software vendors, and the

requirements of real-world scheduling applications. In this paper, we describe the design and the develop-

ment of a scheduling component prototype that is based on web services. It exploits the idea of a

hierarchical decomposition of the overall scheduling problem allowing the integration of different problem-

specific scheduling algorithms for sub-problems. We discuss how appropriate services can be identified and

implemented and how the resulting scheduling component can be used to extend the functionality offered by

manufacturing execution systems (MESs).

1 INTRODUCTION

This research is motivated by scheduling problems

that are found in complex manufacturing systems, as

for example, semiconductor wafer fabrication

facilities (wafer fabs). Complex manufacturing sys-

tems are characterized by a diverse product mix,

many machines, a large number of jobs, sequence-

dependent setup times, and batching. Here, batching

means that several jobs can be processed at the same

time on the same machine. Scheduling is chal-

lenging in such an environment. However, it is

highly desirable because of the increasing automa-

tion pressure. In contrast to previous papers (cf.

Mönch and Driessel, 2005), we are not interested in

proposing a new scheduling technique. Instead of

this, we deal with the question of how to design

scheduling components from a functional and also

from a software technical point of view. It turns out

that the data available in Enterprise Resource

Planning (ERP) systems and Advanced Planning

Systems (APS) are not fine-grained enough to allow

for making detailed scheduling decisions.

Furthermore, their actuality with respect to time is

not appropriate. MESs are a natural carrier of

scheduling functionality (McClellan, 1997; Meyer et

al., 2009). However, the scheduling capabilities of

packaged MESs are often not appropriate because

they are too generic (cf. Pfund et al., 2006 for the

results of a survey of the acceptance of packaged

scheduling solutions in the semiconductor

manufacturing industry). In this paper, we research

the problem of designing a scheduling component

that can be used by an MES. In a certain sense, this

paper extends previous work carried out for the ERP

domain (cf. Mönch and Zimmermann, 2009). The

design of the component is derived taking an

appropriate hierarchical decomposition of the overall

scheduling problem into account. After identifying

appropriate services, we implement a prototype

based on web services. Such questions are rarely

discussed in the literature so far (cf. Framinan and

Ruiz, 2010 for a recent survey of the architecture of

scheduling systems).

The paper is organized as follows. In the next

section, we describe the problem and discuss related

literature. We present the hierarchical decomposition

of the overall scheduling problem in Section 3.

Furthermore, we describe how appropriate services

can be indentified. The implementation of the proto-

type is described in Section 4. We discuss also some

limitations of the proposed approach and future

research needs.

2 PROBLEM DESCRIPTION

2.1 Problem

In current MESs for complex manufacturing systems,

284

Mönch L..

Design and Implementation of a Service-based Scheduling Component for Complex Manufacturing Systems.

DOI: 10.5220/0004002702840290

In Proceedings of the 14th International Conference on Enterprise Information Systems (ICEIS-2012), pages 284-290

ISBN: 978-989-8565-10-5

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

dispatching functionality often is offered instead of

the more sophisticated scheduling functionality.

Optimization kernels are typically based on genetic

algorithms or on generic commercial constraint

programming and mixed integer programming

libraries (cf. Fordyce et al., 2008). Scheduling

systems are mainly developed only for parts of the

manufacturing system, for example for the leading

bottleneck machine group. There is only little

interaction of software vendors and academic

research (cf. Kellogg and Walczak, 2008). There are

several reasons for this situation.

1. Scheduling of production jobs is often

combined with transportation scheduling,

process planning, staff scheduling, and finally

advanced process control decision-making.

2. Global scheduling systems fail because humans

on the shop floor are not involved in the resul-

tant scheduling decisions. It seems that often the

notion of reasonable automation is not taken

into account.

3. Scheduling algorithms depend to a large extent

on the objectives and constraints taken into

account. That means that slight changes in the

objectives and the constraints might lead to

totally different algorithms. Dispatching rules

strongly support this behavior by its inherent

myopic view. Generic scheduling solutions have

some limitations with respect to dealing with

this situation. They are often not well accepted

by people on the shop floor.

4. The data for scheduling decisions is located in

different operative application systems. MES-

and Material Control System (MCS)-related

data are very important in this context.

5. Supplying appropriate data to the scheduling

algorithms is important. However, scheduling

algorithms that take many details into account

require at the same time data that is fine-grained.

Analyzing these insights results in the conclusion

that striving for a more detailed modeling is in-

applicable because a more detailed consideration of

constraints leads to sophisticated algorithms and also

to a more difficult data supply. Therefore, it seems

important to focus on the quintessence of

scheduling, i.e., considering the finite capacity of the

manufacturing system is more important. However,

it is possible to deal with the finite capacity on a

more aggregated level.

In this paper, we address the question of how a

scheduling component has to be organized to take

this vision into account. Therefore, the design of a

service-based scheduling component is discussed

that is based on an appropriate distributed

hierarchical decomposition of the overall scheduling

problem. The resultant design is validated by a

prototypical implementation of such a component.

2.2 Related Work

A web service-based specification and implemen-

tation of ERP components is described, for example,

by Brehm and Marx Gomez (2007) and Tarantilis et

al. (2008). However, a direct application of these

ideas to scheduling is not possible because of the

different level of detail. A conceptual proposal for

an MES based on web services that can be used in

small- and medium-size enterprises in Mexico is

discussed by Gaxiola et al. (2003). But again, no

specific details of possible scheduling functionality

are included in this paper. This is also true for the

recent survey paper by Framinan and Ruiz (2010),

where the usage of web services is only mentioned,

but not further elaborated.

A service-oriented integration framework for

complex manufacturing systems is presented by Qiu

et al. (2007). A certain portion of a traditional MES,

especially with respect to feedback from the shop

floor, is implemented within the framework, but

again, scheduling functionality is not covered.

There is some work done for the identification of

services (cf. Winkler and Buhl, 2007 for the finan-

cial domain and Mönch and Zimmermann, 2009 for

ERP-related services). However, to the best of our

knowledge, there is no work available that addresses

this question for scheduling services in complex

manufacturing systems. A distributed scheduling

system for complex job shops based on software

agents is presented in Mönch et al. (2006). But in

contrast to web services, software agents and multi-

agent-systems are still not widely accepted in

applications on the shop floor. In this paper, we will

show that some of the scheduling functionality

described by Mönch et al. (2006) can be provided

using principles of service-oriented computing.

3 IDENTIFICATION OF

APPROPRIATE SERVICES

3.1 Distributed Hierarchical

Decomposition

As discussed in Subsection 2.1, we are interested in

making manufacturing system-wide scheduling

decisions without increasing the level of detail for

modeling. This goal is mainly reached by an appro-

priate hierarchical approach.

DesignandImplementationofaService-basedSchedulingComponentforComplexManufacturingSystems

285

We start by describing the assumed physical

decomposition of the base system of the

manufacturing system. The routing of the jobs, the

dynamic entities in the system, takes place between

different groups of parallel machines. Parallel

machines offer the same functionality in a

manufacturing system. A single group of parallel

machines is called a work center. The work centers

that are located in the same area of the

manufacturing system are aggregated into work

areas. On the highest level, we find the entire

manufacturing system, i.e., the different work areas

form the base system. In order to solve the overall

scheduling problem, often hierarchical decompo-

sition approaches have been applied.

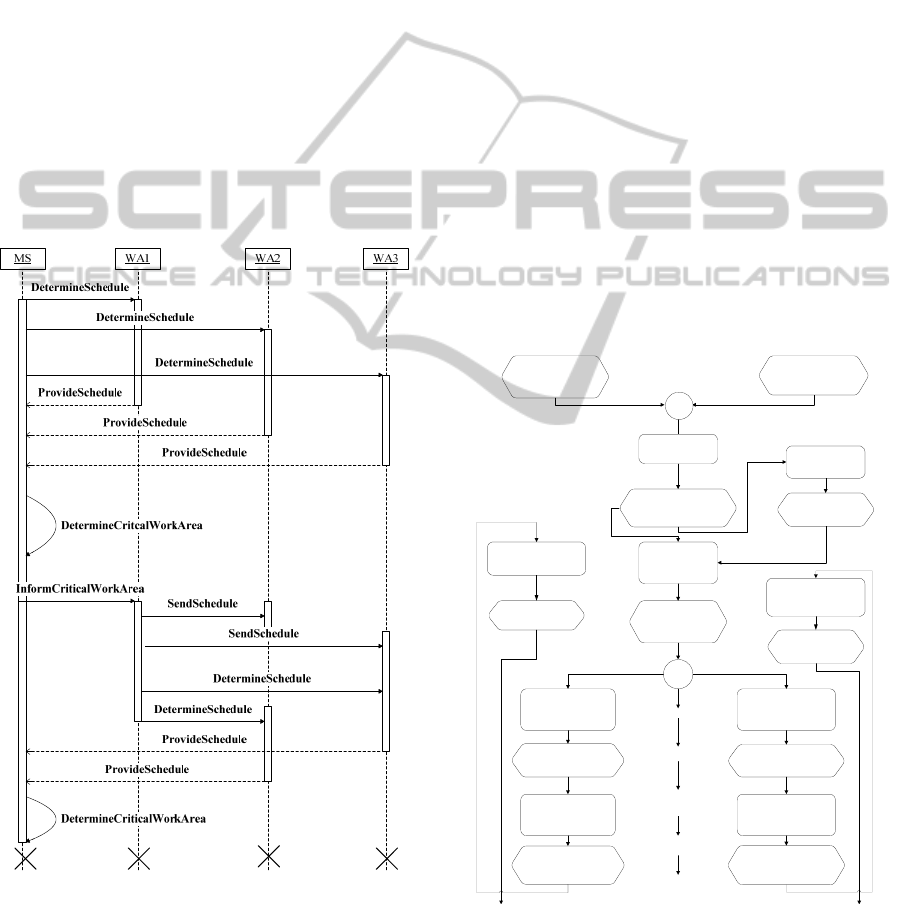

In this paper, we consider a two-layer hierarchi-

cal approach. The resulting scheduling scenario is

shown in Figure 1 as a Unified Modeling Language

(UML) sequence diagram and will be explained in

more detail below.

Figure 1: Sequence diagram for distributed scheduling.

In complex manufacturing systems, planned start

dates and completion dates are determined with

respect to a fixed work area (cf. Mönch and Driessel,

2005 and Mönch et al., 2006) on the top-layer. Here,

an aggregated model is used taking the capacity only

on the work center level into account. Consecutive

operations that are related to one work area are

combined into macro operations. This results in

aggregated routes that consist of these macro

operations. The resulting start and completion dates

can be used to set production goals for each

decision-making entity, i.e., a scheduling unit, on a

certain work area. This approach is called job

planning to differentiate it from the more detailed

scheduling. In Figure 1, we denote the decision-ma-

king entity of the entire manufacturing system by

MS. The base-layer is formed by the different work

area decision-making entities. We can see three

work areas, denoted by WA, in Figure 1. This layer

results in schedules for each single work area. Then,

it determines a critical work area with respect to a

criticality measure, for example, the tardiness of the

jobs with respect to the work area where they are

scheduled. Based on the schedule for the critical

work area, updated ready dates and due dates are

sent to the non-critical work areas and used to

determine new schedules. This procedure is repeated

for the next most critical work area in a recursive

manner until the last work area is reached.

Rescheduling

(time driven)

Rescheduling

(event driven)

Read data for job

planning

Data for job planning

are read

Job planning

performed

Perform job

planning

V

Transfer job plan to

work area 1

Transfer job plan to

work area n

Job plan transfered

Job plan transfered

.....

....

Determine data for

scheduling in work

area 1

Determine data for

scheduling in work

area n

Data for scheduling

in work area 1

determined

Data for scheduling

in work area n

determined

....

Select

parameters for

job planning

Parameters

selected

Select parameters for

scheduling in work

area 1

Parameters

selected

Select parameters for

scheduling in work

area n

Parameters

selected

....

V

Figure 2: Functionality of the top- and base-layer (Part 1).

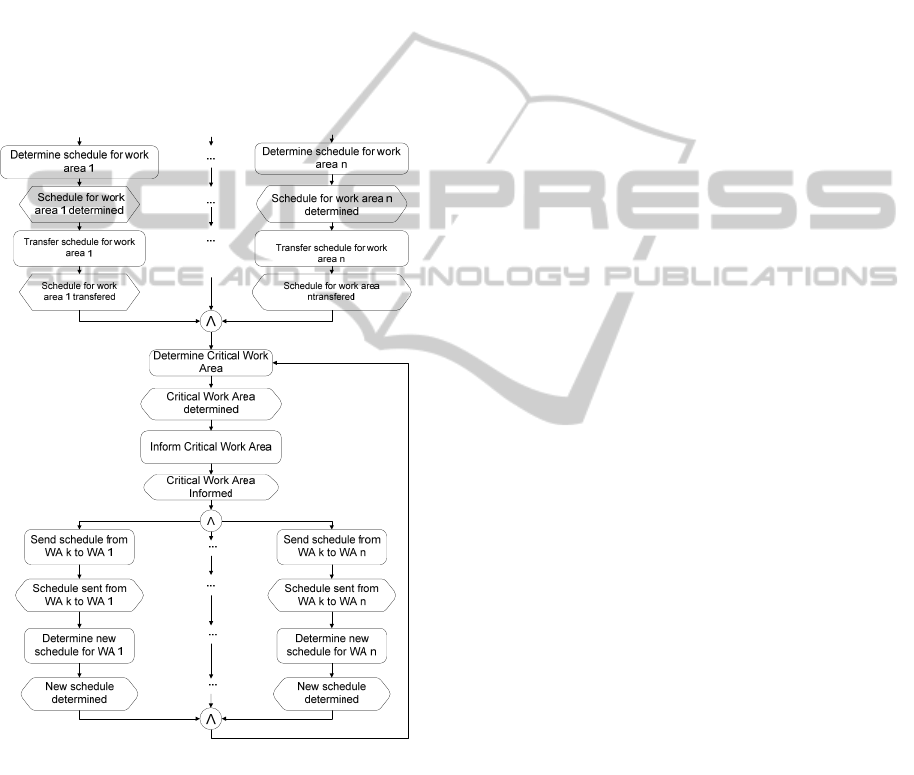

Figure 1 does not provide enough information

from a process modeling point of view. Therefore,

we provide event-driven process chains (EPC) for

ICEIS2012-14thInternationalConferenceonEnterpriseInformationSystems

286

the researched scheduling scenario in Figure 2 and

Figure 3.

These process models can be used as a starting

point for identifying appropriate services, because

service-oriented architectures (SOAs) usually

distinguish between process, service, and technology

models (cf. Siedersleben, 2007). Figure 2 shows the

job planning step and major parts of the preparation

phase for the scheduling activities on the base-layer.

The iterative procedure that corresponds to the

decisions on the base-layer is shown by continuing

the EPC from Figure 2 in Figure 3. Only a single

iteration is depicted in this figure for the sake of

simplicity. Note that a simple process model is

provided by the EPC in Figure 2 and Figure 3.

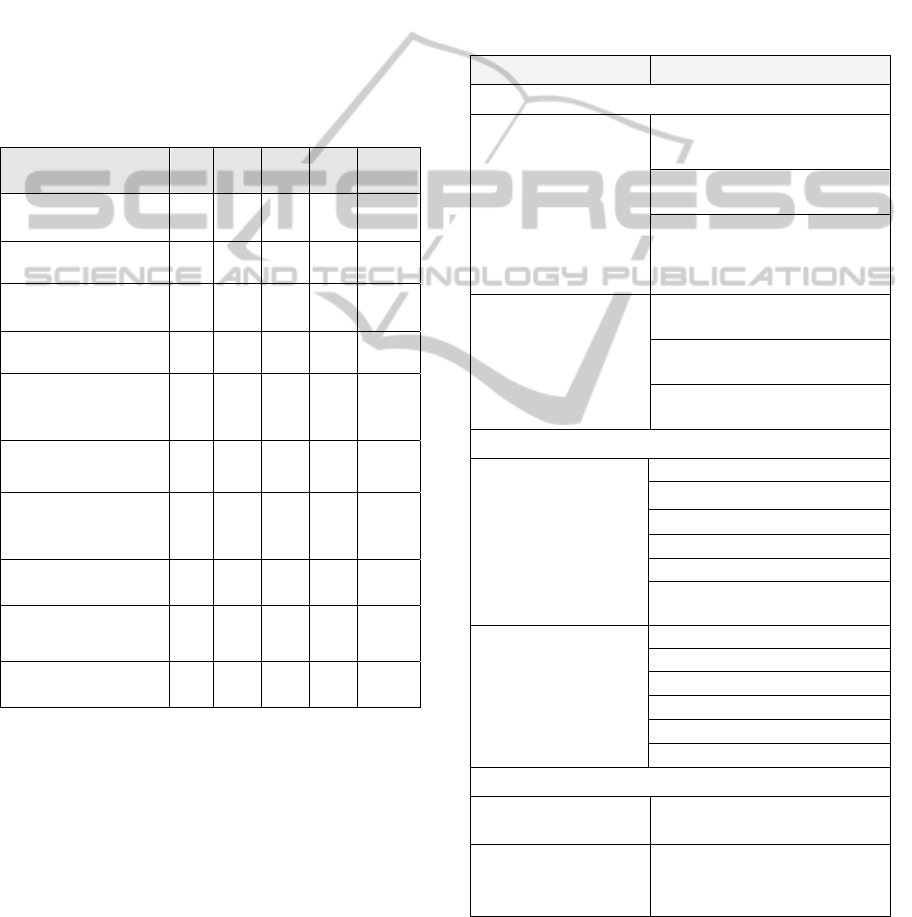

Figure 3: Functionality of the top- and base-layer (Part 2).

3.2 Identification of Services

Next, we are interested in deriving a concrete service

model for the researched scenario. The basic idea for

identifying services consists in determining for each

function within an EPC or activity within an activity

diagram, respectively whether it has to be

implemented as an operation of a service or not. We

use the following five criteria to make this decision:

1. Degree of Automation (DA): If no manual

intervention is required between two consecu-

tive functions then the two functions can be

pooled together into one operation, otherwise,

the two functions have to be represented by

different operations.

2. Atomicity (A): When sub-functions of a certain

function can be used within different business

processes then it makes sense to implement the

sub-functions using different operations. When

the entire function can be re-used then a service

might be implemented by orchestrating the

services that correspond to the sub-functions.

3. Modularity (M): Functions are often carriers of

an algorithm. When different algorithms are

available to solve a problem, a situation-depen-

dent selection of one algorithm is often benefi-

cial. When such a selection is required, then an

implementation of the function within a service

is useful.

4. Reusability (R): When a function is applied in

different business processes, then the function

has to be implemented within a service.

5. Number of Users (NU): When a function is

used by different humans, a certain degree of

reusability is given. This function has to be

implemented within a service.

Note that some of these criteria are also

contained in (Kohlborn et al., 2009 and Mönch and

Zimmermann, 2009).

Applying these five criteria, we obtain a set of

operations that can be grouped into different

services. We differentiate between different types of

services according to Kohlborn et al. (2009). Object-

centric services are given by a set of operations that

are used to access business objects. Task-centric

services are formed by a set of operations that can be

carried out without a specific business object.

Hybrid services are somewhere between object- and

task-centric services, because they consist of

operations that are used to access data and perform

tasks. Finally, process-centric services are used to

support business processes using operations of other

services by means of service composition. The first

three service types correspond to basic operations

that cannot be further decomposed. The resultant

services are shown in Table 1. Here, we use the ab-

breviations PPC and PM for production planning

and control and preventative maintenance, respec-

tively.

Determining the necessary data for the job

planning functionality is important. Therefore, we

decompose the corresponding function into several

sub-functions that are implemented as operations of

DesignandImplementationofaService-basedSchedulingComponentforComplexManufacturingSystems

287

a service that is related to data management for job

planning. Several algorithms can be used to find

appropriate parameters for the algorithms used for

job planning. Therefore, this function is identified as

an own operation of a job planning-related service.

Because different job planning algorithms are

possible, we also identify the function that

determines job plans as an operation of the job

planning service. The function that transfers job

plans to work areas is only important in the context

of work area scheduling. However, within the flow

control, the job plans are available. Therefore, this

function is not identified as an operation of the job

planning service.

Table 1: Applying the criteria to the scheduling functions.

Criterion

DA A M R NU

Data Gathering

Job Planning

0 X 0 X None

Parameter Setting Job

Planning

X 0 X X PPC

Calculate Job Plans X 0 X X PPC

Transfer Job Plans to

Work Areas

0 X 0 0 None

Data Gathering for

Scheduling a Work

Area

0 X 0 X None

Parameter Setting

Job Planning

X 0 X X PC

Determine

Schedule for Work

Area

X 0 X X

PC,

PM

Transfer Schedule

to Top-Layer

0 X 0 0 None

Determine Critical

Work Area

X 0 X X PPC

Inform Critical

Work Area

0 X 0 0 None

The data management service for work area-

related scheduling is justified in a similar manner as

the data management service for job planning. Again,

a refinement into several sub-functions is performed.

Due to different possible algorithms for parameter

setting within work area scheduling algorithms, we

identify a corresponding parameter setting operation

for the work area scheduling service. Different

scheduling algorithms, e.g., decomposition- or local-

search-based approaches, can be used to determine

schedules for jobs in each single work area.

Therefore, this function is represented by an operation

of the work area-related scheduling service. Because

the work area schedules are available within the flow

control, we do not identify a separate operation to

transfer schedules to the top-layer of the hierarchy.

Several methods are available to determine a critical

work area. Therefore, this function is identified as an

operation of the job planning-related service. It is

reasonable to inform the decision-making entity of a

critical work area. Therefore, we include this

functionality into the operation that determines the

critical work area.

Table 2: Identified services for the scheduling process.

Service

/

Operation

Object-centric

DataManagement-

JobPlanning

ReadCapacityMS()/

ChangeCapacityMS()

ReadJobsMS()/

AddJobsMS()

ReadAggregatedRoutes-

MS()/AddAggregated

RoutesMS()

DataManagement-

SchedulingWork-

Area

ReadMachinesWA()/

AddMachinesWA()

ReadJobsWA()/

AddJobsWA()

ReadPartialRouteWA()/

AddPartialRoute()

hybrid

JobPlanning

InitializeJP()

SetParametersJP()

ReadDataJP()

DetermineJP()

EvaluateJP()

DetermineCriticalWA()

SchedulingWA

InitializeSWA()

SetParameterSWA()

ReadDataSWA()

DetermineScheduleWA()

EvaluateScheduleWA()

IsWACritical()

process-centric

Data Manage-

mentScheduling

DetermineAggregatedCapa-

cities()

AutomatedSche-

dulingManufacturing

System

StartProcess()

After the identification of operations, they have

to be grouped into appropriate services as discussed

before. We show the results of this second step in

Table 2.

ICEIS2012-14thInternationalConferenceonEnterpriseInformationSystems

288

Note that two process-centric services are

described in Table 2. The first service is related to

data management issues of an automated scheduling

process. This service is based on operations of the

DataManagementSchedulingWorkArea service. For

example, the single machine capacities are determi-

ned using the ReadMachinesWA() operation. They

are aggregated to capacities of certain work centers

that are used within the job planning approach. The

second process-centric service represents the auto-

mated hierarchical scheduling process. It contains

only a single operation to launch this process. Note

that the SchedulingWA service allows for the in-

tegration of problem specific scheduling approaches

for different work areas.

4 IMPLEMENTATION OF THE

PROTOTYPE

4.1 Implementation Issues

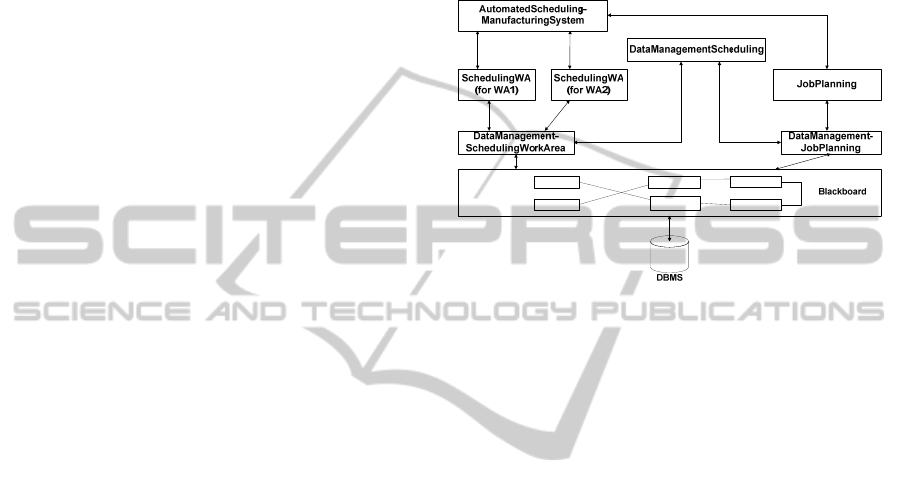

In this section, we will discuss our technology

model. A prototype is designed and coded to check

the feasibility of the proposed component. A client

application implemented in the C# programming

language provides a graphical user interface for

calling the services and therefore, serves as a test

driver. Web services, implemented in C#, are run on

an ASP .NET development server. They implement

the services described in Section 3.

We do not use a real MES for our prototype

because we do not have access to an MES. Instead

of that, the MES is simulated by a so called black-

board service, basically a SQL Server database.

Within the prototype, we implement the Automated-

SchedulingManufacturingSystem service and the

DataManagementScheduling service.

However, we are not interested in evaluating

concrete scheduling algorithms for the scheduling

scenario in this paper because this was done in

previous research (cf. Mönch and Driessel, 2005 and

Mönch et al., 2006). Our main interest is related to

the process flow. The architecture of the prototype is

depicted in Figure 4.

4.2 Orchestration of the Services

An orchestration is required to implement the process-

centric services. Orchestration of the services is

performed using the BPEL engine of the Oracle

BPEL process manager. The Oracle BPEL process

manager runs on a J2EE application server. The

decision to use Oracle BPEL is based on the fact that

we used this tool for several previous prototypes.

Because web services are stateless, we compose

them into a BPEL process that owns state variables

that can be used to manage the state of the system.

We can see from Figure 4 that the AutomatedSche-

dulingManufacturingSystem and the DataManage-

mentScheduling services are implemented as BPEL

processes.

Figure 4: Architecture of the Prototype.

SOAP messages are used to exchange data between

the different web services. This approach requires

that appropriate XML data structures for routes,

aggregated routes, job plans, and work area

schedules are defined because SOAP is XML-based.

Because we also have to write data, we use SOAP-

and not REST-based web services.

4.3 Limitations of the Approach

There are some limitations of the proposed

approach. Task objects, goals, and solution methods

are the main building blocks of an enterprise task

(cf. Ferstl and Sinz, 2006). Business processes work

on task objects and change the attributes of these

objects. Therefore, we can conclude that business

processes are always related to persistency issues.

Many object-centric services are the consequence

(see Table 2). A tight coupling using joint master

data is typical for scheduling and more generally for

the production planning and control domain.

This may lead to undesirable side effects of

services, such as problems with the global state

consistency of the distributed application. The state

of the art master data management in MESs has to

be extended to fulfill the SOA requirements. We can

see this requirement from Figure 4, where the

blackboard service is used to represent the master

data from the MES.

The second limitation is also related to data

management in the service-based prototype. A certain

DesignandImplementationofaService-basedSchedulingComponentforComplexManufacturingSystems

289

number of XML-based SOAP messages have to be

exchanged between the different operations of the

services that form the scheduling component. A loss

of performance might be the result of this situation.

5 CONCLUSIONS

In this paper, we described a scheduling component

for complex manufacturing systems that is based on a

hierarchical decomposition of the overall scheduling

problem. We discussed the identification of

appropriate services. The orchestration of these servi-

ces is shown. The implementation of a prototype for

such a component based on web services is also

discussed.

There are some directions for future work. While

it is possible to design and implement such a

component, there is still much more effort required to

integrate the resultant component into a real-world

MES. A rigor assessment of the performance of the

overall application, especially with respect to compu-

ting time, is also necessary.

Furthermore, it seems fruitful to combine software

agents with service-oriented computing techniques as

proposed by Huhns (2008). It is highly desirable to

enrich the multi-agent-system FABMAS (cf. Mönch

et al., 2006) that implements a similar hierarchical

scheduling approach as described in the present paper

by web services. It is differentiated between decision-

making and staff agents in FABMAS. Staff agents

support the decision-making agents. It seems possible

to replace the staff agents by web services as

discussed in the present paper. The decision-making

agents can be used to carry out a more sophisticated

orchestration of these services.

ACKNOWLEDGEMENTS

The author would like to thank Daniel Kaiser for

implementing the prototype and for interesting dis-

cussions on the topic of this paper.

REFERENCES

Brehm, N., Marx Gomez, J., 2007. Web service-based

specification and implementation of functional compo-

nents in federated ERP-systems. In Proceedings Busi-

ness Information Systems (BIS) 2007, LNCS 4439, 133-

146.

Ferstl, O., Sinz, E. J., 2006. Grundlagen der Wirtschafts-

informatik. Oldenbourg, München, Wien, 5th Edition.

Fordyce, K., Bixby, R., Burda, R., 2008. Technology that

upsets the social order - a paradigm shift in assigning

lots to tools in a wafer fabricator - the transition from

rules to optimization. In Proceedings of the 2008

Winter Simulation Conference, 2277-2285.

Framinan, J., Ruiz, R., 2010. Architecture of

manufacturing scheduling systems: literature review

and an integrated proposal. European Journal of

Operational Research, 295, 237-246.

Gaxiola, L., Ramirez, M. D. J., Jimenez, G., Molina, A.,

2003. Proposal of holonic manufacturing execution

systems based on web service technologies for

Mexican SMEs. In Proceedings HoloMAS 2003,

LNAI 2744, 156-166.

Huhns, M. H., 2008. Services must become more agent-

like. WIRTSCHAFTSINFORMATIK, 50(1), 74-75.

Kellogg, D., Walczak, S. 2008. Nurse scheduling: from

academia to implementation or not? INTERFACES,

37, 355-369.

Kohlborn, T., Korthaus, A., Chan, T., Rosemann, T.,

2009. Identification and analysis of business and

software services – a consolidated approach. IEEE

Transactions on Services Computing, 2(1), 50-64.

McClellan, M., 1997. Applying Manufacturing Execution

Systems. St. Lucie Press, Boca Raton.

Meyer, H., Fuchs, F., Thiel, K., 2009. Manufacturing

Execution Systems: Optimal Design, Planning, and

Deployment. McGraw-Hill.

Mönch, L., Driessel, R., 2005. A distributed shifting

bottleneck heuristic for complex job shops. Computers

& Industrial Engineering, 49, 673-680.

Mönch, L., Zimmermann, J., 2009. Providing production

planning and control functionality by web services:

state of the art and experiences with prototypes. In

Proceedings of the 5th Annual IEEE Conference on

Automation Science and Engineering, 495-500.

Mönch, L., Stehli, M., Zimmermann, J., Habenicht, I.,

2006. The FABMAS multi-agent-system prototype for

production control of wafer fabs: design, implement-

tation, and performance assessment. Production Plan-

ning & Control, 17(7), 701-716.

Pfund, M., Mason, S. J., Fowler, J. W., 2006. Semi-

conductor manufacturing scheduling and dispatching.

Chapter 9 in Handbook of Production Scheduling,

Herrmann, J.W. (ed.), Springer, New York, 213-241.

Qiu, R. G., 2007. A service-oriented integration frame-

work for semiconductor manufacturing systems. Inter-

national Journal Manufacturing Technology and

Management, 10(2-3), 177-191.

Siedersleben, J., 2007. SOA revisited: Komponenten-

orientierung bei Systemlandschaften. WIRTSCHAFTS-

INFORMATIK, 49, 110-117.

Tarantilis, C. D., Kiranoudis, C. T., Theodoadoakopoulos,

N. D., 2008. A web-based ERP system for business

services and supply chain management: application to

real-world process scheduling. European Journal of

Operational Research, 187, 1310-1326.

Winkler, V., Buhl, H. U., 2007. Identifikation und Gestal-

tung von Services: Vorgehen und beispielhafte An-

wendung im Finanzdienstleistungsbereich. WIRT-

SCHAFTSINFORMATIK, 49, 257-266.

ICEIS2012-14thInternationalConferenceonEnterpriseInformationSystems

290