WEB BASED INTEGRATION OF MES AND OPERATIONAL BI

Tom Hänel, Marco Pospiech and Carsten Felden

TU Bergakademie Freiberg, Faculty of Business Administration, Lessingstraße 45, 09599, Freiberg, Germany

Keywords: Web Services, Integration, Flexibility, Decision Support.

Abstract: Internet and web-based technologies increase the informal networks within and across organizations. This

implies an acceleration of changing basic conditions and forces the embracement of innovative technologies

to achieve flexible business processes. However, current research indicates a lack of flexibility in enterprise

applications with negative effects on customer satisfaction and service orientation. Hence, the paper’s

arguments build up on the hypothesis that a web service (WS) based integration approach is beneficial for a

conjoint process oriented and flexible decision support oriented infrastructure. A combination of

Manufacturing Execution Systems (MES) and Operational Business Intelligence (OpBI) is discussed,

because both concepts are promising support of process flexibility. In result an architecture scheme

demonstrates a WS oriented interaction of MES and OpBI functions. In conclusion the effort of information

gathering can be reduced. The use of web-based technologies in context of operational decision making

facilitates a comprehensive synchronization of business processes with flexibility-enhancing effects.

1 INTRODUCTION

The design and control of business processes based

on coherent information is a determining

competitive factor. Internet and web-based

technologies influence the business processes of an

organization as well as its relationships to customers

and suppliers. These increasing informal networks

accelerate the changing basic conditions. Companies

are forced to embrace the emerging web

technologies in order to keep their business

processes flexible by corresponding adjustments.

However, research indicates that organizations are

not able to meet flexibility demands. According to a

survey of the Aberdeen Group, 85 percent of

companies do not provide an adequate flexibility

within their applications (Rodriguez, 2007). This

lack of flexibility implies high cost due to delayed

decisions and low productivity associated with

negative effects in terms of customer satisfaction

and service orientation. With respect to the given

issue, the position paper discusses whether a web

service (WS) based integration approach is

beneficial for a conjoint process oriented and

flexible decision support oriented infrastructure.

The range of conformable concepts allowing

efficient support is large and manifold. Recently,

MES and OpBI came into the discussion promising

both support of process flexibility. These concepts

are integrative approaches for operational process

control and analysis, but they come from different

perspectives – the engineering and the decision

support point of view. A combined approach of

MES and OpBI facilitates overarching analyses to

comprehensively coordinate and optimize processes

so that organizations are able to react fast and

flexible on business occurrences (Hänel and Felden,

2011). Considering the state-of-the-art, the

integration potential of WS to combine MES and

OpBI is not investigated, although especially

service-oriented architectures (SOA) are beneficial

to support flexibility (Erl, 2009). Therefore, we

contribute to the research of WS and decision

support by proposing a discussion about

opportunities and potentials of a web-based

integration regarding to engineering and economic

driven systems.

Chapter 2 sheds light on the integration potential

of OpBI and MES. Furthermore, the ability of WS

and SOA in context of a flexible operational

decision making is discussed. Chapter 3 joins the

separately considered aspects and presents an

architecture scheme for a web based integration of

MES and OpBI. Finally, the paper is summarized to

give conclusions and further research perspectives.

195

Hänel T., Pospiech M. and Felden C..

WEB BASED INTEGRATION OF MES AND OPERATIONAL BI.

DOI: 10.5220/0003959701950200

In Proceedings of the 8th International Conference on Web Information Systems and Technologies (WEBIST-2012), pages 195-200

ISBN: 978-989-8565-08-2

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

2 STATUS QUO

The scope of OpBI and MES is the analysis of

processes to recognize weak points, malfunctions or

business interruptions to improve the management

of business processes continuously and to generate

overarching process information. This chapter

explains the concepts of OpBI and MES as well as

its potential of complementation. Thereafter, WS are

put in context to the demonstrated decision support

to support flexible architecture requirements.

2.1 OpBI and MES

OpBI is aiming for an integrated ensemble of

analytical activities and operational processes

(Eckerson, 2007). The main focus is on reducing

times to collect, report, and analyze data as well as

to take appropriate decisions (White, 2006).

Information regarding the process states during

progress is provided (Bauer and Schmid, 2009). Due

to this reason, OpBI analyzes, controls, and

improves organizational core processes in a fast and

flexible manner (Cunningham, 2005). Thereby, a

Corporate Performance Management is facilitated

(Schwingel, 2010) considering the organization as

closed-loop system, where strategic-tactical and

operational management is interrelated (Golfarelli et

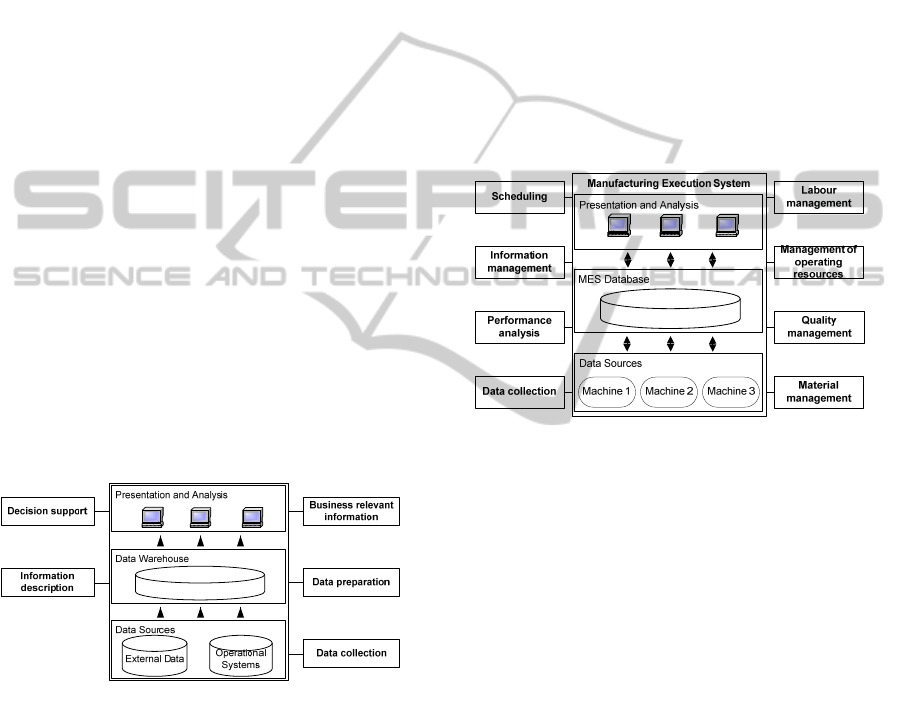

al., 2004). Figure 1 comprises the functionality of

OpBI.

Figure 1: Functions of OpBI.

OpBI provides analytical capabilities in order to

control the organizational value creation in favor of

a continuous improvement of process design and

execution. Thereby, it is a moderator between the

analytical intention and the actual occurrence of a

process. A timely adequate relation between process

performance and states of target achievement get

communicated to the corresponding audience.

A comparable approach to support the decision

making on the shop-floor is the MES (Younus et al.,

2010). It is placed between the layer of Enterprise

Resource Planning (ERP) and the layer of process

execution (ISA, 2000). A vertical integration by

enabling task-oriented compaction, communication

and access of data is realized (Kletti, 2007). The

ERP-system responsible for order and resource

planning communicates desired quantities to the

MES executing a permanently target-performance

comparison and a feedback to ERP. This is to be

done over the full production cycle using real-time

data (MESA, 1997). The MES-architecture consists

of application layer, functional layer, and data

interface layer (Fei, 2010). The data interface layer

enables the access of MES-database on machines

and plants to gather relevant data. The application

layer presents the information generated out of a

MES-database on several clients. Users are able to

send requests and to get desired results. Therefore,

MES are covering eight functions (VDI, 2007):

Figure 2: Functions and architecture of MES.

The functions of OpBI and MES consider an

integrated provision of data as well as its purposive

reporting and analysis. If the MES gets more

complex by including a high number of operational

processes, the similarity to OpBI will grow. This is

associated with a performance lost and limitation of

decision-making in real-time, because an increasing

complexity requires a higher degree of interfaces

(Saenz de Ugarte et al., 2009). Furthermore, the

limited analysis capabilities of the MES (Alpar and

Louis, 2007) question the benefits of such a strategy.

OpBI also forces the decision-making in real-time,

has comprehensive analysis capabilities and

facilitates company-wide process control. But, this

concept is seldom applied in manufacturing

(Eckerson, 2007). A possible reason is that the MES

covers more functions than operational BI, because

it is especially designed for production environments

(Meyer et al., 2009). Hence, OpBI cannot

compensate a MES and vice versa, but they have

beneficial intersections to support enterprise-wide

decision making. Table 1 demonstrates this

functional complementation potential.

WEBIST2012-8thInternationalConferenceonWebInformationSystemsandTechnologies

196

Table 1: Overlapping and complementation possibilities

for MES and OpBI.

OpBI functions

Decision Support

Business relevant information

Data preparation

Data collection

Information description

MES functions

Scheduling

M M

Quality management

M M

Labour Management

M M

Materials management

M M

Management of operating

resources

M M

Data collection

O

Performance analysis

O O

Information management

O O

An integration approach is required to provide a

basis for a conjoint process oriented and flexible

decision support oriented infrastructure using MES

in combination with OpBI. Therefore, the presented

monolithic driven and data warehouse oriented

architecture of the concepts are contradictory.

Flexibility and reduction of complexity is possible

by modularization, which means to structure a

system in semi-autonomous and straightforward

subsystems (Aier and Dogan, 2005). To support

such a modular design Section 2.2 discusses WS to

gain a flexible information architecture.

2.2 Web Services in context of MES

and OpBI

The technology of WS is commonly implemented in

a SOA, representing the current state-of-the-art for

flexible IT structures (Erl, 2009). A SOA can be

understood as „ … a way of designing and

implementing enterprise applications that deals with

the intercommunication of loosely coupled, coarse

grained (business level), reusable artifacts (services).

Determining how to invoke these services should be

through a platform independent service interface …“

(Wilkes and Harby, 2004). It is possible to combine

(orchestration) the existing components depending

on flexibility requirements in consequence of the

loosely coupled services. Thus, business

functionalities are to be abstracted and assembled

according to the process logic. This leads to new

processes, which can be easily redefined or created.

Especially, vendor independent specifications enable

a consistent integration of heterogeneous systems

and an open communication between various

components. A SOA is understood as an abstract

concept, supportable by WS (Erl, 2009). According

to the W3C, a WS is defined as follows:

A Web service is a software system designed

to support interoperable machine-to-machine

interaction over a network. It has an interface

described in a machine-processable format

(specifically WSDL). Other systems interact

with the WS in a manner prescribed by its

description using SOAP-messages, typically

conveyed using HTTP with an XML

serialization in conjunction with other Web-

related standards. (W3C, 2004)

Nowadays, SOAP and WS Description Language

(WSDL) specifications are state-of-the-art based on

Extensible Markup Language (XML) (Melzer,

2010). WSDL describes the WS-interface and

specifies service functionalities, restrictions and

conventions. Furthermore, it refers to an endpoint

that corresponds to a software component. Those

descriptions can be stored in a Universal,

Description, Discovery and Integration (UDDI)

repository. The UDDI is based on XML and serves

as directory service that is responsible for WS

publication and detection. SOAP allows as message

exchange format the discovery, searching, finding

and usage of WS. Thereby, the transport occurs by

an underlying protocol like HTTP or FTP. In this

context, a WS gets described by a WSDL document

and published in a UDDI. A potential service-

consumer will search through SOAP in the UDDI

and retrieves the matching WSDL. Afterwards, the

service consumer will start the communication to the

service provider by the SOAP protocol.

The main concept of a SOA is the encapsulation

of business functionalities. In this context, OpBI and

MES functionalities have to be encapsulated into

WS, so that they act either as service user or service

provider. Performance analysis services provide

analytical business logic and correspond to mature

BI techniques (Martin, 2011). The data collection

services provide the required operational, tactical

and strategic data. They are divided into data access,

transformation and infrastructure services,

corresponding mainly to encapsulate extract,

transform and load (ETL) functionalities (Dinter and

Stroh, 2009). The data access service includes four

basic operations, namely create, read, update and

delete. They allow universal access to all connected

systems and all systems to request demanded

WEBBASEDINTEGRATIONOFMESANDOPERATIONALBI

197

analyses (Vogt et al., 2008). Source and target exist

likewise as service or database e.g. the DWH. If

persistently storing is not required, the data get

promptly accessed by a service from any operational

system on demand and will be used for further

analysis (Dittmar, 2007). Transformation services

represent the encapsulated transformation phase of

ETL. Thus, tasks like aggregation, encoding,

filtering, conversion, join and mapping have be

fulfilled by services. (Martin 2011; Dinter 2008)

There are existing cross-cutting tasks in addition to

the presented services that are realized through

infrastructure services (Dinter and Stroh, 2009)

including data security and data protection features

as well as aspects of data quality, master-data, and

meta-data management (Gordon et al., 2006).

Furthermore, the data collection services provide all

MES relevant data regarding to materials, operators,

machines and processes in real time through specific

decision support services. On this basis, the labour

management service ensures that every shift is

properly organized and recorded. The material

management handles the need driven supply and

disposal with material on schedule, as well as the

management of work in process. Here, quality

information, schedule and material status data are

considered. In this context, the quality management

services sustain the guarantee of the product quality

and the capability of the process, by quality planning

and inspection. The service for management of

operating resources provides a demand-actuated

availability on schedule and functionality of

equipment (machines, operating utilities) in a

historical, current and further view. The scheduling

service plans operational sequences in

manufacturing under consideration of available

resources and capacities. (VDI, 2007)

3 WEB BASED INTEGRATION

PLATFORM

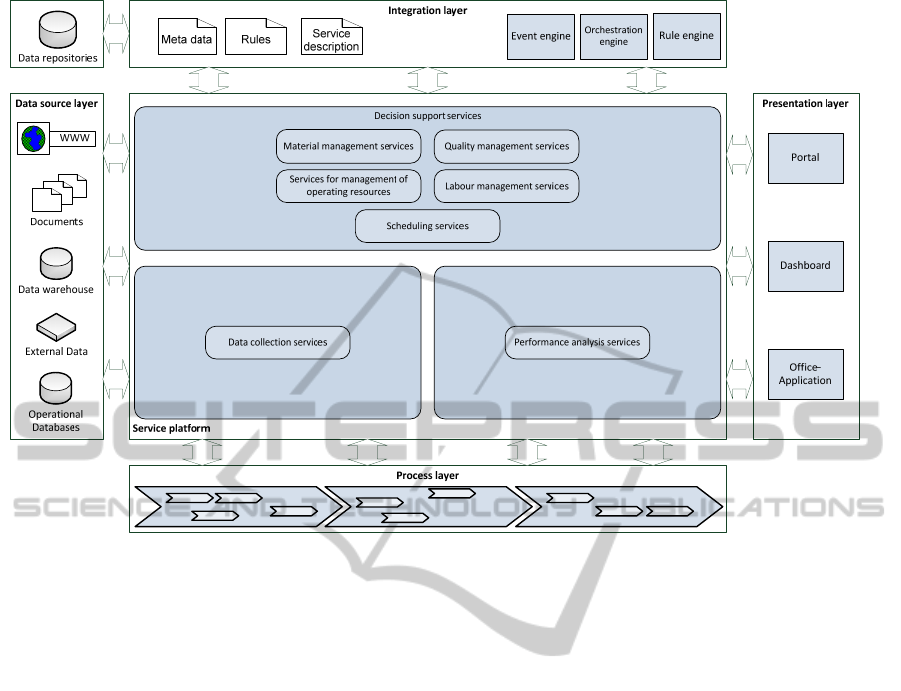

The platform is divided into five components, which

gets successively refined. The data storage

component holds data sources and serves as

fundament for further analyses. Here, process

changes get noticed by the event engine and will be

instantly inserted by orchestrated data collection

services placing the target data into the data source.

In addition, performance analysis and decision

support services accessing the available data through

the same services. The enterprise-wide consolidation

of information exceeds in most of the cases the IT

budget and the manageable complexity (Melzer,

2010). Therefore, it appears adversely to follow the

traditional BI architecture concept, since a DWH

exists no longer in a monolithic pillar, but rather in

an embedded IT infrastructure (Martin, 2011). Thus,

the DWH lose its role as central data storage

component (Dittmar, 2007). The historical data

stored by the DWH are combined and synchronized

with real-time information from the operational

processes. This provides an input flow for decision

support and performance analysis services. There is

the danger that redundant and distributed storage

lead to individual application terminologies ending

in inconsistencies and duplication. Due to this

reason, a central meta data repository is required.

The service platform component reflects all

encapsulated and presented functionalities of OpBI

and MES. In this context, both have to be

implemented in a WS oriented way. Here, OpBI and

MES take the role as service provider or service

consumer. This integrates analytical functions into

processes and operational applications affecting the

operational detailed planning. All services are event-

driven and transfer real time data. Thereby, WS are

endpoints, which react to or produce new events.

(Vogt et al., 2008) In this context, a WS oriented

platform promises the integration of OpBI services

into MES processes and systems, avoids redundant

implementations, enables an unproblematic

integration, improves scalability, and allows an open

communication between all components.

The integration component realizes the

coordination of all services and events in the total

system. The service repository (UDDI) manages and

publishes all service descriptions, which are presented

in form of WSDL. Furthermore, the service repository

selects WS in cooperation with the orchestration

engine. The selection is based on the service

description, which makes the service available for the

orchestration engine. The orchestration executes a

service sequence that can be embedded in other

systems or processes. In addition, the orchestration

engine contains mechanisms that allow state

management, logging and monitoring of sequences.

The orchestration engine is requested by events that

are triggered from the event engine. Here, the event

engine is based on publish-and-subscribe. It receives

and processes events from all components, which are

sent to registered users. Furthermore, the event engine

holds analytical operations.

The analysis is enriched by business process

events (Vogt et al., 2008). Therefore, defined

business rules are required, which are provided by

the corresponding repository. This prevents a

redundant implementation of business rules,

WEBIST2012-8thInternationalConferenceonWebInformationSystemsandTechnologies

198

Figure 3: Web-based integration architecture for OpBI and MES.

increases their reusability and separates the process

logic from the decision logic.

The core of the process component is the

process. Here, the event engine analyzes continually

business process events in real time. The required

process states are received by data collection

services and passed through decision support and

performance analysis WS. Hereby, a timely

adjustment of the manufacturing process in

consequence of unpredictable circumstances can be

established. Complex events or causal, temporal or

spatial relationships are detected by the event engine

and leading to defined reactions in process

execution. Thus, decisions can be automated and

done in shortest time. Consequently, the approach

enables the monitoring of critical process key figures

in MES, OpBI analyses and hereupon tailored

events. A so called closed-loop can be established

that provides reduced decision latency.

The top level is represented by the presentation

component. This enables a flexible integration of

different visualization options. The fundament is

performance analysis and decision support services

which allow graphical representations in portals,

dashboards, or office applications. (Vogt et al.,

2008) The user can be informed about circumstances

by event or send its decision directly to the event

engine.

4 CONCLUSIONS

The position paper discusses an integration platform

to consolidate economic and engineering driven

information across the whole value creation. The

proposed architecture joins the concepts of MES and

OpBI, while their domain specific functions are

conserved. Thereby, during the paper`s discussion

the advantages of WS are evident in favour of a

flexible process oriented decision support. Process

performance indices are enriched by information

from all segments of the value chain as part of

technical-economic analyses. This reduces the effort

of information gathering and provides the ability for

a comprehensive synchronization of business

processes with flexibility-enhancing effects.

Organizations are able to consider changing

requirements of customers and suppliers

contemporary to adjust their production, distribution

and purchase processes. This implies an increased

process transparency so that improvements and

innovations are possible in fields of process and

product design. Next to the introduction of

completely new products, there are for example

opportunities to improve quality characteristics of

products or to tailor the use of resources according

to business needs. Due to the knowledge about the

WEBBASEDINTEGRATIONOFMESANDOPERATIONALBI

199

process performance in all segments of the value

creation, the necessity as well as technical and

economic feasibility of innovation is assessable in

detail. In order to realize the presented benefits of

the integration platform, a practical validation of

these arguments is required. Thereby, the discussed

insights of this position paper serve as guidance and

basis for further research.

REFERENCES

Aier, S., Dogan, T., 2005. Indikatoren zur Bewertung der

Nachhaltigkeit von Unternehmensarchitekturen. In

Wirtschaftsinformatik 2005, 607-626.

Alpar, P., Louis, J.P., 2007. Eine empirische

Untersuchung der Softwareunterstützung bei der

Fertigung und Qualitätssteuerung. Philipps-

Universität Marburg.

Bauer, A., Schmid, T., 2009. Was macht Operational BI

aus? BI-Spektrum, 4 (1), 13-14.

Cunningham, D., 2005. Aligning Business Intelligence

with Business Processes. TDWI, 20, 50-51.

Dinter, B., 2008. Einsatzmöglichkeiten serviceorientierter

Architekturen in der Informationslogistik. In Töpfer, J.

and Winter, R. (Eds.), Active Enterprise Intelligence,

1st Edition. Springer, Berlin.

Dinter, B., Stroh, F. 2009. Design Factors for Service-

oriented Architecture Applied to Analytical

Information Systems: an Explorative Analysis. In

Proceedings of the 17th European Conference on

Information Systems ECIS, Verona.

Dittmar, C., 2007. Latenzzeiten von Business Intelligence-

Systemen. In Gluchowski, P. et al. (Eds.),

Schlaglichter der Wirtschaftsinformatik, 1st Edition.

GUC,Chemnitz, 131-142.

Eckerson, W.W., 2007. Best Practices in Operational BI:

Converging Analytical and Operational Processes.

TDWI Best Practices Report. Renton (WA).

Erl, T., 2009. SOA Design Patterns, 1st Edition, Prentice

Hall, Boston.

Fei, L., 2010. Manufacturing Execution System Design

and Implementation, 2

nd

International Conference on

Education Technology and Computer (ICETC).

Golfarelli, M., Rizzi, S., Cella, I., 2004. Beyond data

warehousing: what's next in business intelligence? In

Proceedings of 7th ACM international workshop on

Data warehousing and OLAP, ACM Press, New York.

Gordon, S. et al., (2006). Service-Oriented Business

Intelligence. In The Architecture Journal. 6, 23-32.

Hänel, T., Felden, C., 2011. Limits or Integration? -

Manufacturing Execution Systems and Operational

Business Intelligence. In Americas Conference on

Information Systems AMCIS 2011, Detroit, USA.

ISA ANSI/ISA-95.00.01-2000, 2000. Enterprise Control

System Integration, Part 1: Models and Terminology,

ISA technical paper.

Martin, W., 2011. Performance Management and

Analytics – Business Intelligence meets Business

Process Management, Retrieved 2011-11-21, from:

http://www.wolfgang-martin-team.net/BI-BPM-

SOA.php.

Melzer, I., 2010. Service-orientierte Architekturen mit

Web Services, 4th Edition, Spektrum Verlag,

Heidelberg.

MESA, 1997. MES Explained: A High Level Vision for

Executives, MESA International – White Paper

Number 6, Pittsburgh.

Meyer, H., Fuchs, F., Thiel K., 2009. Manufacturing

Execution Systems (MES), McGraw Hill, Colum.

Kletti, J., 2007. Manufacturing Execution System – MES,

Springer, Berlin.

Rodriguez, R. A., 2007. Aligning IT to Business

Processes: How BPM is Complementing ERP and

Custom Applications. Aberdeen Group.

Saenz de Ugarte, B., Artiba, A., Pellerin, R., 2009.

Manufacturing execution system – a literature review.

Production Planning and Control, 20, 6, 525-539.

Schwingel, J. (2010). Strategien für Process Performance

Management. BI-Spektrum 4 (3), 14-18.

VDI 5600, 2007. Manufacturing Execution Systems, VDI

Verlag, Duesseldorf, Germany.

Vogt, T. et al., 2008. Business-Intelligence-Konzept auf

Basis einer Event-Driven Service-Oriented

Architecture. In Dinter, B. et al. (Eds.), Synergien

durch Integration und Informationslogistik

Proceedings DW 2008.

Wilkes, S., Harby, J., 2004. A move to drive industry

standardization of SOA. Retrieved 2012-01-21, from:

http://xml.coverpages.org/SOA-

BlueprintsConceptsV05.pdf.

W3C (2004), W3C Web Services Glossary. Retrieved

2012-01-27, from: http://www.w3.org/TR/2004/NOTE-

ws-gloss-20040211.

White, C., 2006. The Next Generation of Business

Intelligence: Operational BI. (White Paper). Retrieved

2012-01-21, from: http://certification. sybase.com.

Younus, M. et al., 2010. MES Development and

Significant Applications in Manufacturing – A

Review, 2

nd

International Conference on Education

Technology and Computer (ICETC).

WEBIST2012-8thInternationalConferenceonWebInformationSystemsandTechnologies

200