VELOCITY VECTOR FIELD VISUALIZATION OF FLOW IN

LIQUID ACQUISITION DEVICE CHANNEL

John B. McQuillen

1

, David F. Chao

1

, Nancy R. Hall

1

and Nengli Zhang

2 †

1

NASA Glenn Research Center, Cleveland, OH 44135, U.S.A.

2

Ohio Aerospace Institute at NASA Glenn Research Center, Cleveland, OH 44135, U.S.A.

Keywords: Velocity Vector, Liquid Acquisition Device (LAD), Flow Pattern, CFD Simulation, Vertically Submerged

Screen Channel, Gravity Effects.

Abstract: A capillary flow liquid acquisition device (LAD) for cryogenic propellants has been developed and tested in

NASA Glenn Research Center to meet the requirements of transferring cryogenic liquid propellants from

storage tanks to an engine in reduced gravity environments. The prototypical mesh screen channel LAD was

fabricated with a mesh screen, covering a rectangular flow channel with a cylindrical outlet tube, and was

tested with liquid oxygen (LOX). In order to better understand the performance in various gravity

environments and orientations at different liquid submersion depths of the screen channel LAD, a series of

computational fluid dynamics (CFD) simulations of LOX flow through the LAD screen channel was

undertaken. The resulting velocity vector field visualization for the flow in the channel has been used to

reveal the gravity effects on the flow in the screen channel.

1 INTRODUCTION

As is well known for a space mission, liquid

propellants have to be delivered from their storage

tanks to an engine in a liquid state. It is easy to

realize the delivery on earth using gravity to position

liquid above the tank outlet that is located at the tank

bottom. However, it is impossible to ensure the

propellant drainage from the tank without vapor or

pressurant gas entrainment in the low gravity

environment of space, because of the uncertainty in

the ullage position. One type of propellant

management device, a liquid acquisition device

(LAD), uses capillary flow and surface tension to

acquire liquid has been developed and well

characterized for storable (noncryogenic)

propellants. Many of LADs have been built, tested

and used for hypergolic propellants, such as nitrogen

tetroxide (N

2

O

4

) and monomethyl hydrazine

(MMH), but the development for use with cryogenic

propellants has been lagging. LADs are custom

designed to fulfill a unique set of requirements under

the appropriate environmental mission conditions

and demands; consequently, there is no universal

design that satisfies all applications (Fester et al,

1976). Future space vehicles will require the use of

non-toxic, cryogenic propellants, because of the

performance advantages over the toxic hypergolic

propellants and also because of the environmental

and handling concerns (Kudlac and Jurns, 2006).

Capillary-flow LADs have been well characterized

for storable toxic propellants (Chato and M.T.

Kudlac, 2002; Kudlac and Jurns, 2006), but there

have been only a few LAD experiments with

cryogenic propellants, including liquid oxygen

(LOX). Recently, Zhang et al (2009) performed a

CFD simulation for sub-cooled LOX flow in LAD

channel test assembly in normal gravity

environment. McQuillen et al (2012) conducted a

series of CFD simulations of the LOX flows in LAD

channel in different gravity environments for various

flow rates. All of these simulations are for a

“horizontally” submerged LAD channel in the LOX.

This paper reports the CFD simulation results for

“vertically” submerged in the LOX at normal gravity

environment, revealing the gravity effects on the

flow in the screen channel through velocity vector

field visualizations produced by the simulation.

†

Corresponding author, Tel: 216-433-8750, Fax: 216-

433-8050

743

B. McQuillen J., F. Chao D., R. Hall N. and Zhang N..

VELOCITY VECTOR FIELD VISUALIZATION OF FLOW IN LIQUID ACQUISITION DEVICE CHANNEL.

DOI: 10.5220/0003909807430748

In Proceedings of the International Conference on Computer Graphics Theory and Applications (IVAPP-2012), pages 743-748

ISBN: 978-989-8565-02-0

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

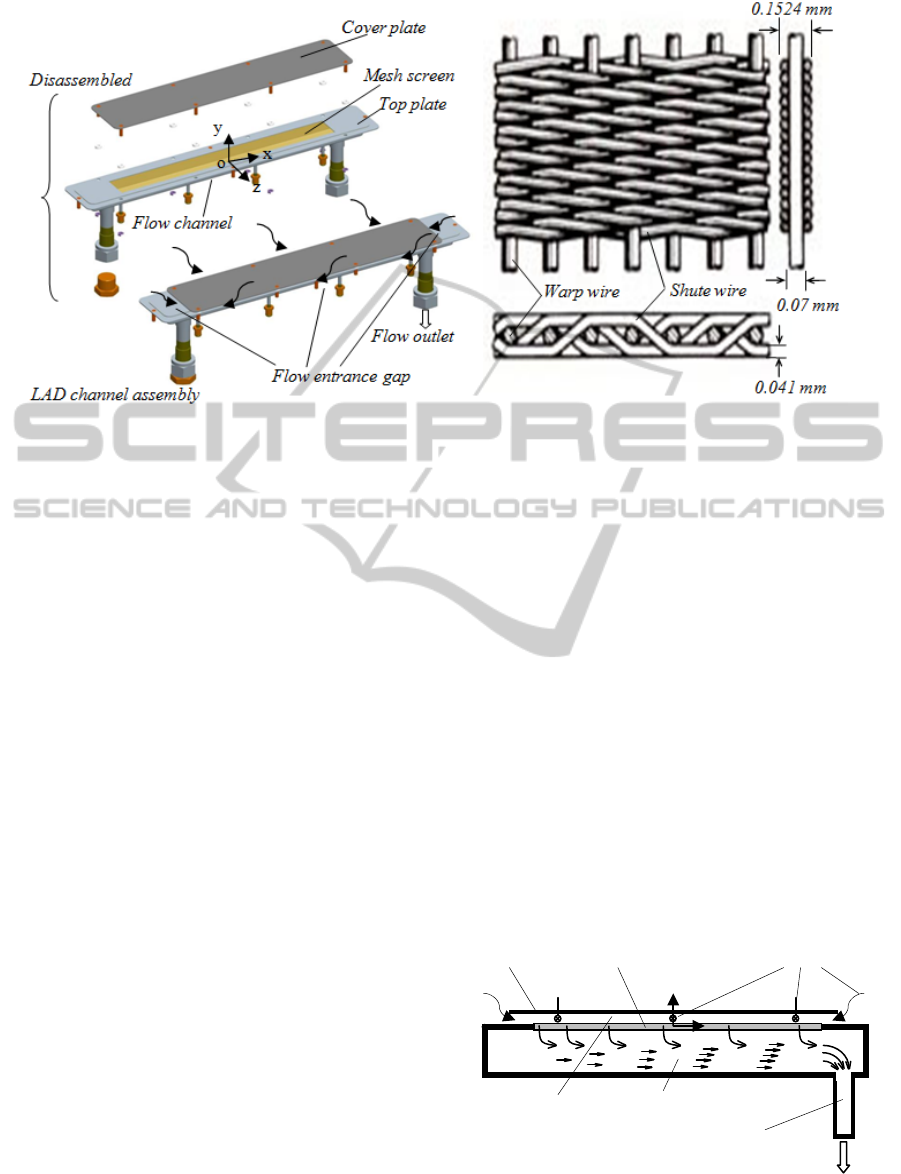

Figure 1: Prototypical LAD screen channel assembly and Geometry of Dutch Twill mesh.

2 LAD CHANNEL ASSEMBLY

Under NASA’s continuing Cryogenic Fluid

Management (CFM) development program, a

prototypical LAD screen channel assembly was

designed and tested using LOX in NASA Glenn

Research Center, as shown in Figure 1 left. The

LOX flows into the channel assembly via the gap

between the cover plate and the mesh screen, so

called entrance gap, from all directions, and then

passes through the fine mesh screen to flow down of

the channel assembly and then goes out. The mesh

screen consists of stainless steel wires arranged in a

200x1400 Dutch Twill weave mesh. This geometry

is shown in Figure 1 right. The LOX flow path is

shown schematically in Figure 2. Since most liquids,

including LOX, perfectly wet stainless steel

surfaces, the liquid wets the entire screen when the

screen partially contacts the liquid pool, thus

effectively blocking gas passage through the porous

screen unless a critical pressure differential across

the screen, is exceeded. This pressure differential is

called the bubble point. The procedure for bubble-

point test is described in American Society for

Testing and Materials Standard (ASTM) Method

F316

.

3 CFD SIMULATION SETTINGS

Since the Dutch Twill mesh screen is very thin

compared to the LAD channel dimensions, the

screen is approximated to a porous sheet and is

handled as porous-jump in the CFD simulations of

the LAD channel flow using FLUENT. Two primary

parameters, the face permeability,

α,

and the

pressure jump coefficient, C

2

, define the porous-

jump in FLUENT, which can be determined

experimentally. The relevant reviews and calculation

methods have been given by Zhang et al. (2009) and

McQuillen et al. (2012).

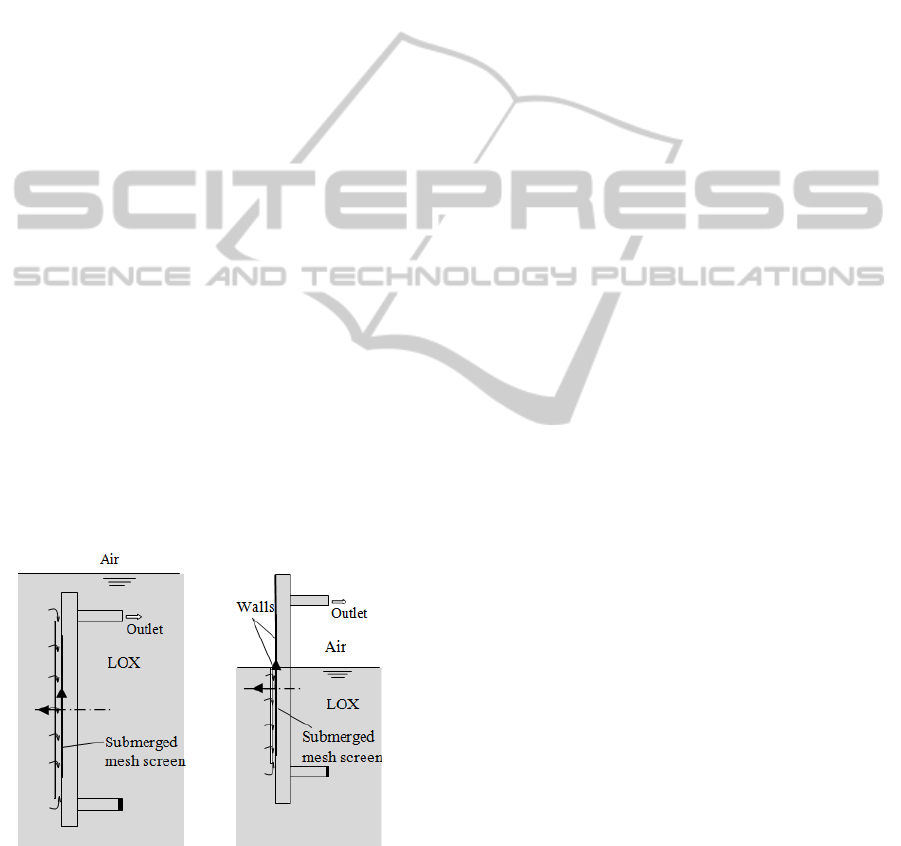

In order to simulate the cases of vertically partial

submersions of the LAD channel in LOX, several

geometry models have been established, including

full submersion and partial submersion depths of the

mesh screen, such as 1/3, 1/2, and 2/3 of the screen

length submerged. For the partially submerged cases,

the exposed portion of the mesh screen was taken as

a solid wall, as shown in Figure 3. This is reasonable

because no liquid or vapor can flow through this

portion of the screen provided that the local pressure

Figure 2: Fluid flow route in the LAD channel assembly.

Cover plate

Flow entrance

Outlet-tube

L

AD

f

low channel

Flow outlet

Fine mesh Screen

Entrance channel

y

x

IVAPP 2012 - International Conference on Information Visualization Theory and Applications

744

drop between the vapor and the LOX does not

exceed the bubble point.

The pressure-based solver was used, with a

steady implicit formulation. The three-dimensional

simulations used the Green-Gauss cell based

gradient and the standard k-epsilon model for the

turbulent flow with the following constants: The

coefficient of first order turbulent dissipation rate in

the dissipation rate equation, C

1

ε

= 1.44; the

coefficient of second order turbulent dissipation rate

in the dissipation rate equation C

2

ε

= 1.92; the

turbulent viscosity coefficient C

μ

= 0.09; the

turbulent Prandtl number for turbulent kinetic

energy,

σ

k

= 1.0; and the turbulent Prandtl number

for dissipation rate of turbulent kinetic energy,

σ

ε

=

1.3.

The operating conditions were set to a system

pressure = 1620269 Pa, T= 89 K, and gravitational

acceleration vectors were set at g

x

= g

z

= 0.0 m/s

2

,

and g

y

= -9.81 m/s

2

for the horizontally-oriented

completely submersion cases, while g

y

= g

z

= 0.0

m/s

2

, and g

x

= -9.81 m/s

2

for vertically-oriented

completely and partially submerged cases.

The ‘pressure-outlet’ type was selected as the

boundary condition at the flow outlet, and set to a

gauge pressure of 0 Pa with a backflow modified

turbulent viscosity of 0.001 m

2

/s. The ‘pressure-inlet’

type boundary condition was selected at the flow

inlet surface with corresponding values of total

gauge pressure and modified turbulent viscosity of

0.001 m

2

/s to obtain a mass flow rates within the

range of 0.0455 kg/s (0.1 lbs/s) ~ 0.1818 kg/s (0.4

lbs/s). It

should be noted that all the gauge pressures

are relative to the operating pressure.

Figure 3: Vertically submerged LAD channel assembly.

4 SIMULATION RESULTS

Twenty four cases of vertically-oriented submerged

LAD channel, including six complete submerged,

seven 2/3 submerged screen length, five 1/2

submerged screen length, and six 1/3 submerged

screen length cases, were simulated. Two cases of

horizontally-oriented submerged LAD channel were

simulated for comparison with the corresponding

vertically-oriented completely submerged cases. The

simulation results show that for the completely

submerged cases, the mass flow rate passing through

the LAD channel is not affected by the orientation of

the channel. In fact, the total static pressure drop

between the inlets and outlet,

Δ

p

i-o

, and submerged

portion of the screen determines the flow rate. For

example, at the cases of completely submerged

channel, the value of

Δ

p

i-o

is proportional to the

mass flow rate and independent of channel

orientation However, as more of the screen becomes

exposed in the vertically-oriented submerged cases,

a larger

Δ

p

i-o

is needed to achieve the same mass

flow rate. As is well known, the flow pattern in the

channel directly reflects the effects of gravity on the

channel performance. In order to ascertain the

effects of the channel orientation or gravity on the

LAD channel performance, the velocity vector fields

are visualized and compared to reveal the flow

pattern characteristics.

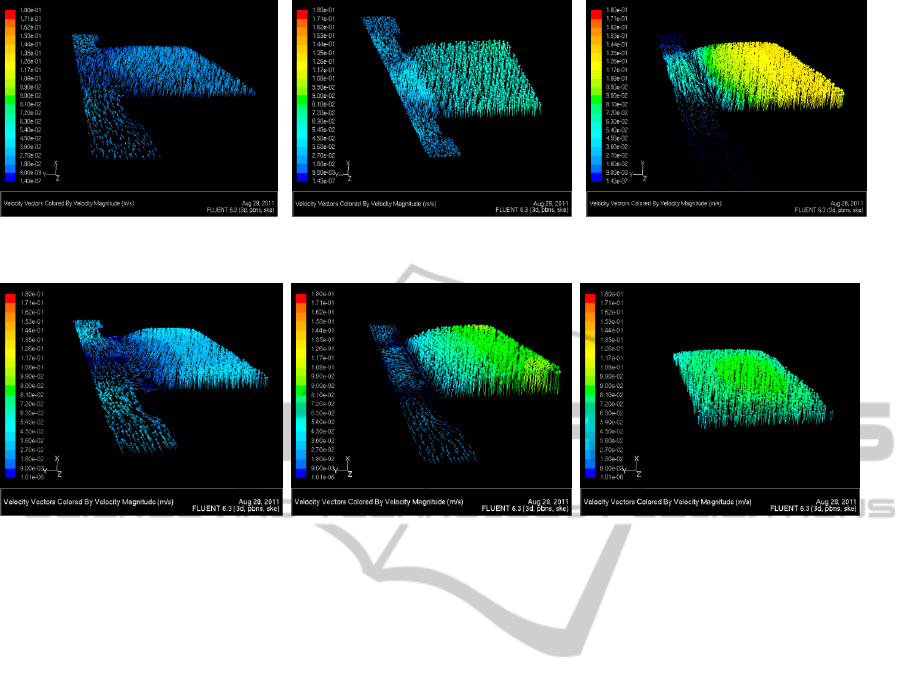

4.1 Velocity Vector Field Visualization

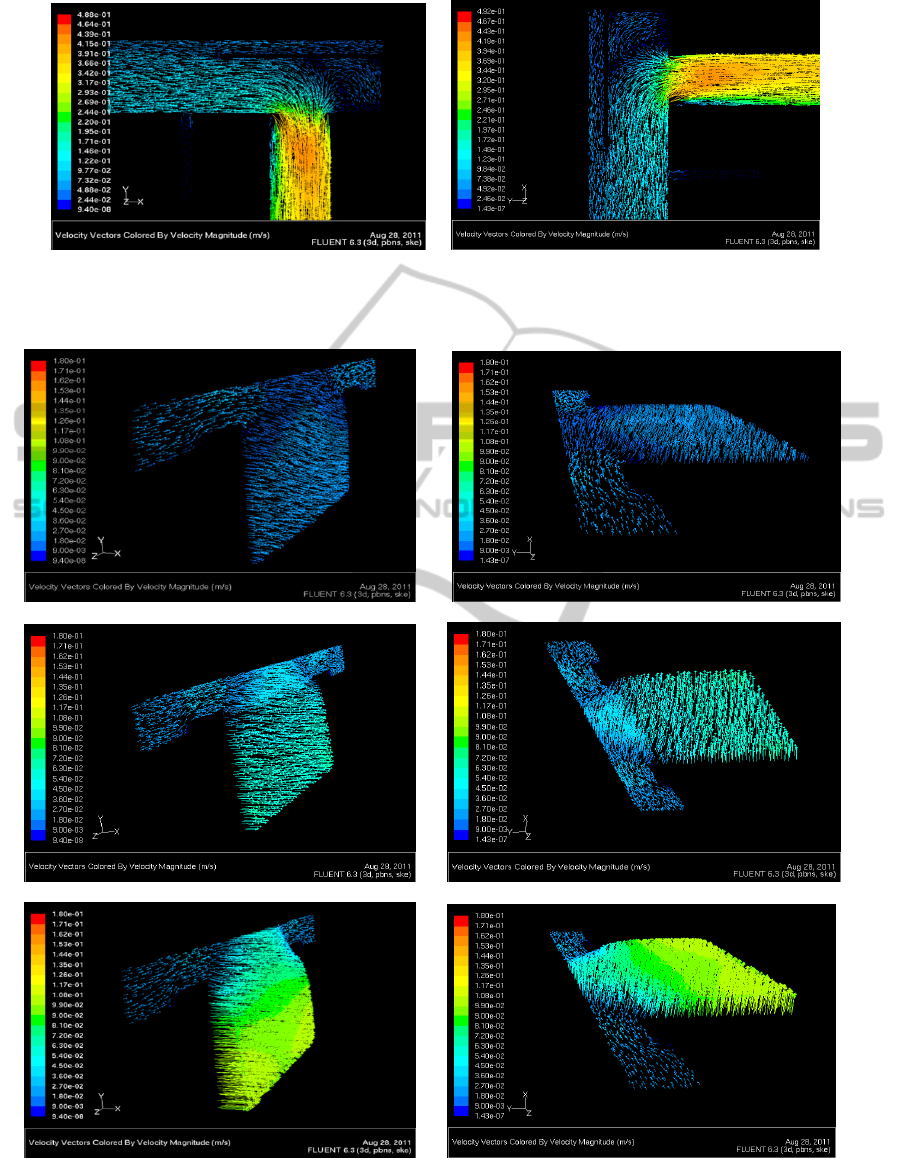

For the case of vertically-oriented, completely

submerged channel, the hydrostatic pressures in both

entrance gap and LAD flow channel are the same;

therefore, gravity has no effect on the flow in the

channel. The flow pattern in the channel is no

different between the completely submerged cases

horizontally and vertically oriented channels. For

example, the velocity vectors near the outlet tube for

both cases are almost identical, as shown in Figure 4.

The velocity vectors for completely submerged

channels along the channel length at the sections of

axial distance of x = -0.16 m, x = 0 m, and x = 0.16

m, are also identical for horizontally and vertically

oriented channels, respectively, as shown in Figures

5a, 45b, and 5c, in which the left ones are for

horizontal orientation while the right ones for

vertical orientation. However, gravity affects the

flow pattern in the flow channel when a portion of

the screen is exposed. At the same

Δ

p

i-o

, the amount

of exposed screen length is proportional to the

hydrostatic pressure drop between the entrance gap

and the LAD flow channel; consequently, when the

screen exposed portion increases, the resistance of

the flow passing through the flow channel becomes

larger. As a result, the flow in the flow channel by

VELOCITY VECTOR FIELD VISUALIZATION OF FLOW IN LIQUID ACQUISITION DEVICE CHANNEL

745

a) b)

Figure 4: Velocity vectors in the completely submerged channel near the outlet tube: a) horizontally oriented; b) vertically

oriented channel.

a) At section of x = -0.16 m.

b) At section of x = 0.0 m.

c) At section of x = 0.16 m.

Figure 5: Velocity vectors at different sections.

IVAPP 2012 - International Conference on Information Visualization Theory and Applications

746

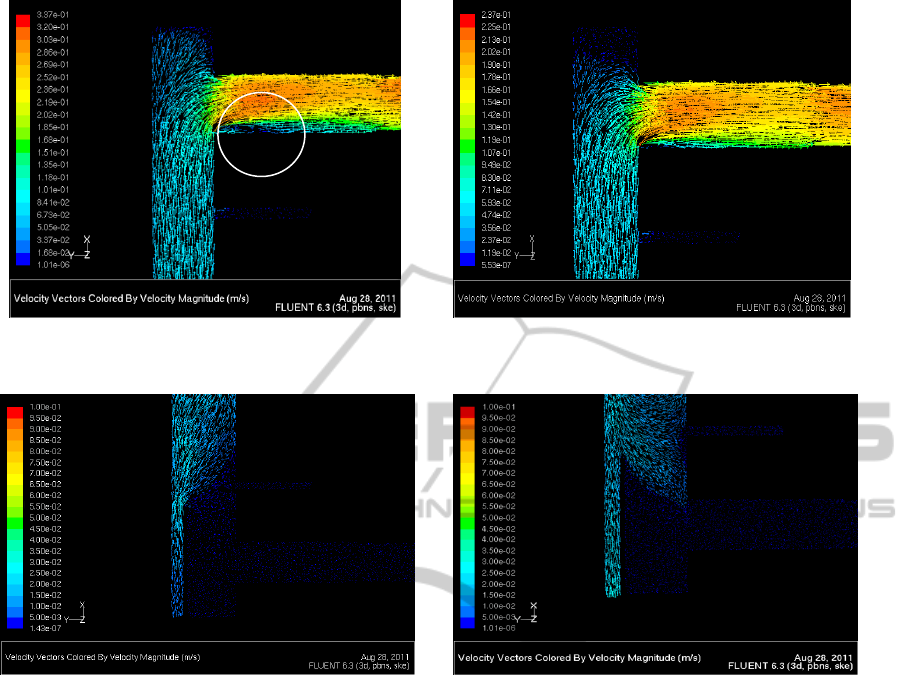

a) In case of vertically full submersion b) In case of vertically half screen submersion

Figure 6: Velocity vectors in the channel near the outlet tube for cases of vertically submerged.

In case of vertically full submersion In case of vertically half screen submersion

Figure 7: Velocity vectors in the channel at bottom end for the cases of vertically submerged.

the outlet tube is different for the cases of various

screen exposures. For the case of vertically-oriented,

completely submerged channel, the flow has higher

velocity in the channel and a vortex occurs at the

flow channel end by the outlet tube, as shown in

Figure 6a, while for the cases of vertically-oriented

exposed screen half length, the flow enters into the

outlet tube without generating a vortex, because the

higher hydrostatic pressure drop reduces the flow

velocity in the flow channel, as shown in Figure 6b.

It should also be noted that for cases of completely

submerged channel and half submerged screen

length, the

flow direction passing though the screen

is different at the bottom end of the flow channel, as

shown in Figure 7.

4.2 Velocity and Mass Flow Rate

Change

The CFD simulation results show that the flow

velocity and mass flow rate in the channel are

continuously augmented along the submerged

channel length (x-axis direction) when the LOX

passes through the screen and then flows toward the

outlet tube in the flow channel. The typical velocity

vectors distributions at different sections for the

cases of completely submerged and half submerged

screen length are shown in Figure 8. It is noted that

when the LOX flows in the exposed screen portion

of the channel, the flow rate maintains constant

because no LOX is added into the channel through

the screen anymore.

5 CONCLUSIONS

In virtue of the velocity vector field visualization,

the flow pattern characteristics in the capillary flow

LAD channel are revealed and the performance of

the LAD channel at different submersion cases in

normal gravity can be evaluated.

Vertex zone

VELOCITY VECTOR FIELD VISUALIZATION OF FLOW IN LIQUID ACQUISITION DEVICE CHANNEL

747

At section of x = -0.16 m At section of x = 0 m At section of x = 0.24 m

a) In case of vertically full submersion

At section of x = -0.16 m At section of x = 0 m At section of x = 0.24 m

b) In case of vertically half screen submersion.

Figure 8: Velocity vectors distributions in the channel assembly at Δp

i-o

= 400 Pa.

1. The flow patterns in the completely

submerged LAD channel are identical between the

cases of horizontal and vertically-oriented channels.

2. The gravity effects flow pattern in the flow

channel when as of the amount of exposed screen

length is varied. At the bottom end of the channel,

far away from the outlet tube, the hydrostatic

pressure drop reverses the flow direction of the LOX

passing the screen, while at the top end of the

channel, the flow smoothly enters into the outlet

tube without vortex, which is contrary to one in the

completely submerged channel.

3. The flow velocity and mass flow rate in

the channel are continuously augmented along the

channel length (x-axis direction) when the LOX

passes through the screen and then flows toward the

outlet tube in the flow channel. However, when the

LOX flows in the exposed screen portion of the

channel, the flow rate is constant.

REFERENCES

Chato, D. J. and Kudlac, M. T., 2002. In: 38

th

AIAA/ASME/SAE/ASEE Joint Propulsion Conference

& Exhibit, Indianapolis, IN, see also Paper AIAA

2002-3983.

Fester, D. A., Villars, A. J. and Uney, P.E., 1976. Journal

of Spacecraft and Rocket ,13: 522-527.

Kudlac, M. T. and Jurns, J. M., 2006. In: 42

nd

AIAA/ASME/SAE/ASEE Joint Propulsion Conference &

Exhibit, Sacramento, CA, see also Paper AIAA 2006-

5054.

McQuillen, J. B., Chato, D. J., Motil, B. J., Doherty, M.

P., Chao, D. F. and Zhang, N., 2012. Journal of

Porous Media (in print).

Zhang, N., Chato, D. J., . McQuillen, J. B., Motil, B. J.

and Chao, D. F., 2009. World Academy of Science,

Engineering and Technology, 58: 1180-1185.

IVAPP 2012 - International Conference on Information Visualization Theory and Applications

748