FAST BEAD DETECTION AND INEXACT MICROARRAY PATTERN

MATCHING FOR IN-SITU ENCODED BEAD-BASED ARRAY

Soumita Ghosh

1

, Andreas Schmidt

1

and Dieter Trau

2

1

AyoxxA Living Health Technologies, Singapore, Singapore

2

Department of Bioengineering and Department of Chemical & Biomolecular Engineering,

National University of Singapore, Singapore, Singapore

Keywords:

Fast Inexact Graph Matching, Microarray Bead Detection, In-situ Encoded Bead-based Array, Graph Spectra,

Sequence Alignment.

Abstract:

This paper presents an automatic bead detection and bead array pattern matching technique developed for the

In-situ Encoded Bead-based Array (IEBA) technology. A supervised learning based bead detection technique

robust to irregular illumination variations and noise is developed. An efficient and effective graph matching

technique that combines graph spectral analysis and sequence alignment is used to match bead array patterns.

The matching algorithm proposed is rotation and scale-invariant. The pattern matching algorithm performs

in-exact matching and is capable of handling very large numbers of outliers in the target graph as well as large

number of occlusions in the template graph. The matching algorithm uses dynamic programming and can give

good time performances dependent only on the number of nodes in the template and target graphs, irrespective

of the number of outliers and occlusions. The algorithm can detect and match large number of beads in a few

seconds.

1 INTRODUCTION

With the rapid progress of life sciences in the last

decade various protein and DNA microarray formats

have emerged. All these technologies have the com-

mon goal of detecting and measuring multiple bio-

logical markers in the same sample - so called ”mul-

tiplexing”. They have become the preferred choice

when addressing complex questions in biomedical re-

search as well as when screening clinical blood sam-

ples for multiple infectious disease or cancer markers

at the same time in the same test. The latest gener-

ation of these ”biochips” include microscopic beads

immobilized on silicon chips. These beads are coated

with different biological agents like DNA-sequences

or antibodies that can each detect a distinct marker.

The central problem that remains is how to identify

which microscopic bead is measuring which analyte?

So far all commercial techniques use some kind of

physical label to identify the beads. To provide an

effective solution to multiplexing problem companies

around the world offer beads either in different shades

or colors or sizes or with tiny ”bar codes”. These ap-

proaches however make the process very tedious and

require expensive and bulky equipments such as flow

cytometers. Further using any kind of identifier lim-

its the multiplexing capacity. For example, if color is

used as the identifying marker then the multiplexing

capacity is limited by the available color labels that

can be robustly distinguished from each other.

In (Trau et al., 2008) the In-situ Encoded Bead-

based Array (IEBA) technology was introduced to

resolve the multiplexing issue in an effective way.

The IEBA technology identifies randomly distributed

beads on the biochip by obtaining the unique ”postal

code” of each bead without use of any other marker

on the beads. The postal code of each bead is the

unique spatial address of each bead. In this paper

we devise an algorithm using computer vision tech-

niques to detect the beads and identify them without

the use of any markers. Using such a marker less

method a higher multiplexing capacity (>1000) can

be achieved. The technique is developed using Ay-

oxxa Prokemion biochips. The chips contain multiple

wells, with each well comprising of a complete mul-

tiplex microarray. The detection of analytes on the

chip is based on a fluorescent signal. The quantitative

fluorescent signal can be obtained using a fluorescent

microscope, which is one of the most common equip-

ment in any research laboratory. Additionally vari-

ous high resolution fluorescent readers including au-

tomated high throughput screening lines used in in-

5

Ghosh S., Schmidt A. and Trau D..

FAST BEAD DETECTION AND INEXACT MICROARRAY PATTERN MATCHING FOR IN-SITU ENCODED BEAD-BASED ARRAY.

DOI: 10.5220/0003826800050014

In Proceedings of the International Conference on Computer Vision Theory and Applications (VISAPP-2012), pages 5-14

ISBN: 978-989-8565-04-4

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

dustry can be used to generate the fluorescence pic-

ture files as test read-out. To simplify the whole pro-

cess we use a single fluorescent wavelength as a re-

porter for all analytes and all positive controls.

The analysis process involves finding correspon-

dence between two different kinds of images which

we call the manufacturing and fluorescent images.

The set of images acquired after each batch of bead

deposition during chip manufacturing are the manu-

facturing images and the set of images acquired af-

ter multiplex protein assay are called the fluorescent

images. The measurement and protein quantification

and analysis is carried out on these set of images. The

fluorescent picture shows the beads after reacting with

the different markers in the biological sample. The

beads light up, with their intensity of fluorescence be-

ing directly proportional to the concentration of a cer-

tain analyte. It then remains to uncover the identity of

the bead and find the biomarker it corresponds to.

Figure 1: The Ayoxxa Prokemion biochip. The chip has a

grid of circular wells. Each well is used for a sample.

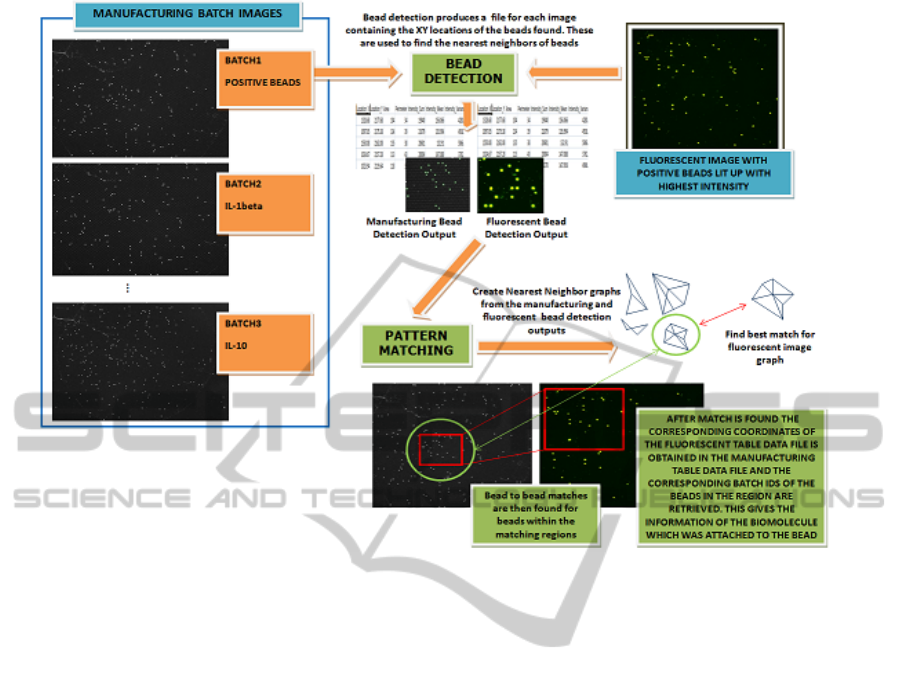

The analysis process involves the following steps:

detecting the beads in the manufacturing and fluores-

cent images, tracing the region of the manufacturing

images that contains the fluorescent images and ob-

taining quantifiable measures like intensity and other

parameters from the fluorescent image to determine

the biomolecule that was attached to each individual

bead. The software developed fully automates this

analysis process. It uses two separate modules; one

for detection of the beads and the other for matching

between manufacturing and fluorescent beads. The

detection is done using a supervised learning tech-

nique while the matching uses spectral properties of

nearest-neighbour graphs and sequence matching al-

gorithms.

In order for the software to be commercially vi-

able both the detection and matching algorithms have

to be very accurate and efficient. Furthermore, the

algorithms have to be very robust to noise and other

external factors. In particular for fluorescent images,

since the environment under which they are captured

cannot be controlled the images produced may vary

in quality. Even slight variations in conditions may

affect the quality by a large amount. Some of the

common challenges involved in developing practical

bead detection algorithms are handling image noise

and irregular illumination. These can be caused by

the human involvement in the imaging process and the

imaging device setup. Further the microarray multi-

plexing technique is also not exact. Contaminations,

dust and excess solution sticking to the surface can in-

troduces impurities and make matching difficult. The

main contributions of this paper are firstly the devel-

opment of a practical and commercially viable bead

detection algorithm for the IEBA technology that can

detect beads of varying intensities and sizes under

heavy noise and non-uniform illumination and sec-

ondly the development of a fast graph matching al-

gorithm that can handle large mismatches and occlu-

sions in the graphs.

Once a match for the fluorescent image is found

in the manufacturing image, we also need to identify

those manufacturing beads which are present within

the matching region but do not have a corresponding

match in the fluorescent image. This is used to extract

information about the beads which were not captured

under fluorescence but were present on the chip sur-

face.

Section 2 gives a brief overview of the existing

commercially used bead detection techniques and the

available state-of-the-art pattern matching techniques.

In Section 3 we present the bead detection techniques

developed for identifying beads in the manufacturing

and fluorescent images. Then in Section 4 we present

the bead pattern matching technique. In Section 5

we present some performance results and in Sections

6 and 7 we draw conclusions and outline future im-

provements.

2 PREVIOUS WORKS

The most widely encountered problem in bead detec-

tion algorithms is that of irregular illumination. The

manufacturing images often have irregular illumina-

tion due to reflection from within the imaging envi-

ronment, due to external lighting or due to lens dis-

tortion. Insufficient drying of the chip surface before

capturing images can also causes solution droplets

to stick onto the surface and obstruct the bead pat-

tern layout beneath it, resulting in loss of valuable

information. Also, dust particles can get very heav-

ily illuminated causing nearby beads to be brighter

than usual. Figure 3 shows an irregularly illuminated

manufacturing image where the beads near the cen-

tre of the well are well focused and are brighter than

VISAPP 2012 - International Conference on Computer Vision Theory and Applications

6

Figure 2: Illustrates the working of the system.

the ones near the edge of the well. Most commer-

cially used automatic bead detection algorithms do

not have to deal with such irregular illumination as

most of the bio chip techniques use complex imaging

devices that produce very high quality images. Fur-

ther, besides using high quality image capturing sys-

tems most other techniques also use expensive read-

ers to decode each bead uniquely. Some of the algo-

rithms that do handle such irregular illumination need

an additional pre-processing step to correct the image.

Other techniques such as (Oliveros and Sotaquir

`

a,

2007) use grids to simplify the detection process but

require pre-processing to handle rotation. Our bead

detection technique on the other hand does not use

any global parameters and performs bead detection

locally for each bead. Consequently the technique is

inherently rotation and scale invariant and very robust

against illumination variations and noise. Further to

allow for robust bead detection we use two different

kind of supervised learning techniques for the manu-

facturing and fluorescent images.

The main challenge in matching the fluorescent

image with the manufacturing image is that the scale

and orientation of the fluorescent image is unknown.

Therefore a scale and rotation invariant matching

technique is needed. Further since the bead detec-

tion algorithm cannot guarantee 100% accuracy there

is always the possibility of a few beads missing or a

few additional beads belonging to other batches be-

ing detected. Also as mentioned previously there is

always the possibility of additional bead like struc-

tures being present in the manufacturing images due

to contamination or dust. Therefore an exact match-

ing is inadequate for the problem. Most computation-

ally tractable point pattern matching algorithms as-

sume that either the template or the query set does not

have any noise. However in our case both the manu-

facturing and fluorescent image will have beads that

are not present in the other. Fig. 2 shows an example

of the bead detection and pattern matching process.

We formulate the problem of matching patterns of

beads as a graph matching problem. The problem

can be formally described as that of identifying the

largest common isometric subgraph that best matches

the template graph G (the manufacturing image bead

pattern) in the query graph G

0

(the fluorescent im-

age bead pattern).The problem of graph matching is

a quadratic assignment problem and is NP-hard. The

focus of graph matching research is therefore to ef-

fectively approximate the exact solution. In a recent

work (J.McAuley and S.Caetano, 2012) developed a

matching algorithm that gives good empirically for-

mulated results under noise. The algorithm however

has a major drawback. The complexity of the algo-

rithm is dependent on the number of missing beads in

the template graph. In our problem matching has to

FAST BEAD DETECTION AND INEXACT MICROARRAY PATTERN MATCHING FOR IN-SITU ENCODED

BEAD-BASED ARRAY

7

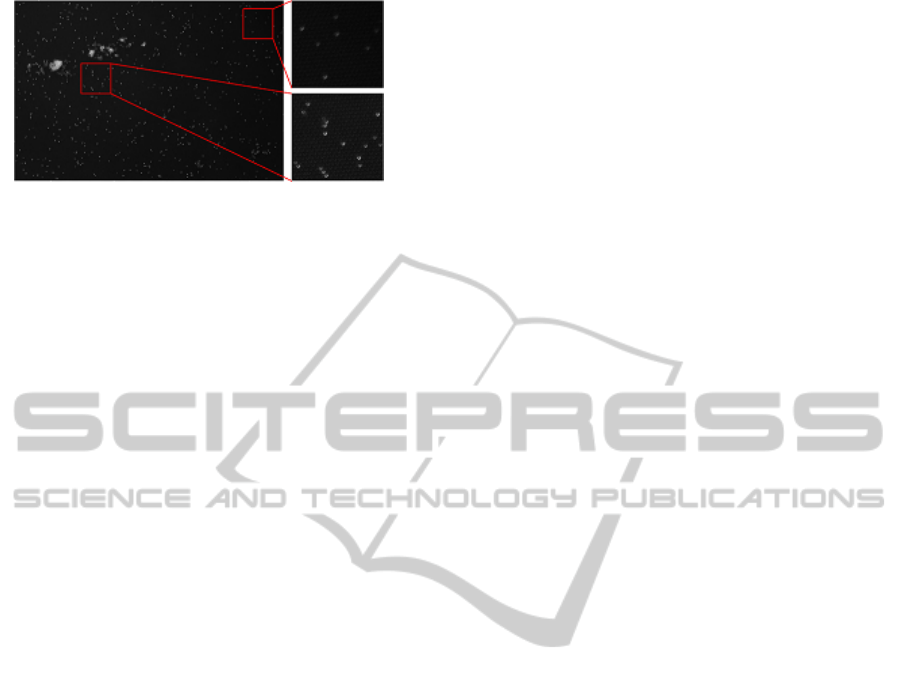

Figure 3: Shows an irregularly illuminated manufacturing

image. The beads close to the top right corner are less bright

due to lens distortion while the beads close to the noise are

brighter than the average beads because of the high lumi-

nance of the dust particles.

work even when as much as 25% of the beads in the

fluorescent image are missing.

Further the manufacturing image has thousands of

beads and an exhaustive search for scale and rotation

invariant match is impractical. Most fast graph match-

ing algorithms either performs only exact matching or

make too many assumptions (H.Alt and L.J.Guibas,

1996) and (Rezende and Lee, 1995). To perform inex-

act matching and still keep the time performance rea-

sonable we take a two step approach. First we use a

fast graph spectra based technique to identify regions

in the manufacturing image that are likely to have a

match for the beads in the fluorescent image. We then

use a more demanding sequence matching technique

to identify the most optimal bead to bead matches be-

tween manufacturing and fluorescent beads as well as

identify beads in each image which are missing in the

other.

Graph spectra is used to identify beads in the man-

ufacturing image which are similar to the beads in the

fluorescent image. Since the development of spectral

matching in (Leordeanu and Heberti, 2005) numerous

other graph spectra based graph matching techniques

such as (Cour et al., 2006) have been developed.

These techniques use the graph spectra of an assign-

ment graph whose nodes represent potential matches

between the template graph (G) and query graph (G

0

)

nodes and whose edge weights represent the potential

agreement between match pairs. The Eigenvalue de-

composition of the assignment graph has a time com-

plexity of O(|G|

3

|G

0

|

3

). This prohibitively high time

complexity restricts the use of spectral techniques to

matching smaller graphs. We avoid this problem by

using graph spectra only as a local descriptor.

The estimation of the location of a bead in both the

fluorescent and the manufacturing images can have

some errors and therefore an error tolerant matching

is necessary. We use the tolerance estimation tech-

nique used in (Evans and Tay, 1995) to estimate the

tolerance values for each spectral feature individually

from a training dataset.

The Smith-Waterman algorithm (Smith and Wa-

terman, 1981) is used in the second step to find the

most optimal set of bead to bead matches. The Smith-

Waterman algorithm was originally developed for

finding common molecular subsequence and there-

fore has to be modified slightly for use in our match-

ing problem. The algorithm is implemented using dy-

namic programming and has a complexity of O(mn)

where the sequences to be matched are of length m

and n. Smith-Waterman algorithm has also been used

previously for shape matching in (Chen et al., 2008)

and (Riedel et al., 2006). It has the nice property that

it produces the optimal local alignment with respect

to the scoring system.

3 BEAD DETECTION

3.1 Manufacturing Bead Detection

In order to overcome the irregular illumination prob-

lem we use a local adaptive thresholding technique.

The thresholding is performed by calculating the in-

tensity distribution of small square patches in the im-

age and thresholding out the highest 5% of the inten-

sities. A sliding window with no overlap is used to

threshold the entire image. The size of the patches is

about 10 times the normal diameter of beads. This al-

lows a very optimistic thresholding i.e. it tries to iden-

tify beads everywhere. Even for large illuminated ar-

eas the algorithm extracts only the brightest regions.

The normal diameter of beads is learnt from the ra-

dius feature described later and the 5% cut-off is esti-

mated empirically. Contour detection is then applied

on the binary images using algorithm developed by

(S.Suzuki and K.Abe, 1985). The regions of the man-

ufacturing image fully enclosed by each closed con-

tour are then extracted. The maximum intensity and

mean location (mean x and y coordinates) of each

region is calculated. The locations are then used as

seeds for region growing while the maximum intensi-

ties are used to estimate the intensity threshold to stop

the region growing.

Small amount of region dilation is then performed

for each region using a circular structuring element of

radius 3 pixels to make the edges smooth.

Following this for each region the following set

of shape, size and intensity features are extracted:

Area, Perimeter, Intensity Sum, Intensity Mean, In-

tensity Variance, Minimum Intensity, Maximum In-

tensity, Radius Mean, Radius Variance, Minimum Ra-

dius, Maximum Radius and Orientation. Where the

area and perimeter features are the number of pixels

inside the region and on the contour respectively. The

VISAPP 2012 - International Conference on Computer Vision Theory and Applications

8

area and perimeter features deal with both size and

shape of the feature. For e.g. a very large perimeter

for a small area is indicative of a rough contour or a

concave region. The Intensity Sum, Intensity Mean,

Intensity Variance, Minimum Intensity, Maximum In-

tensity features deal with the intensity distribution of

the region. The sum of intensities and mean are in-

dicative of the overall brightness of the region. The

intensity variance and minimum and maximum inten-

sities are indicative of the overall change in intensity

from the centre of the region to the edge of the re-

gion. A very high variance in intensity or a large max-

imum intensity to minimum intensity ratio is indica-

tive of an unevenly bright spot. The radius mean, ra-

dius variance, minimum radius, maximum radius are

calculated as the mean, variance, minimum and max-

imum respectively of the distances from the centre of

the region to each contour pixel. The Radius mean

and radius variance features also deal with the overall

shape of the region. True beads tend to show a slightly

oval shape and therefore have a moderate radius vari-

ance and a rather stable minimum to maximum radius

ratio. For any particular manufacturing image, beads

are also found to be oriented in the same way. The

orientation feature is used to encapsulate this prop-

erty. It is calculated as the angle the longest axis of

the region makes with the y-axis.

A binary one-to-one support vector machine is

then trained using the above 12 features to classify

the extracted regions as bead and non-bead regions.

Classification results are presented in Section 5.

3.2 Fluorescent Bead Detection

The same set of features as the ones extracted for de-

tecting manufacturing beads are also extracted for flu-

orescent bead detection. However for the final classi-

fication instead of using a single support vector ma-

chine a number of support vector machine classifiers

are trained. This is necessary because beads of differ-

ent batches in the manufacturing process differ heav-

ily in appearance in both size and intensity. Further

estimating the batch of the bead directly from the

intensity becomes a multi-class classification prob-

lem which can significantly reduce the accuracy, even

when classification is done by max-wins voting strat-

egy. For our particular problem we found that training

a single one-versus-all support vector machine classi-

fier for each batch gave the best results.

4 BEAD PATTERN MATCHING

Once the bead patterns and their respective batches

have been estimated the relative locations of beads is

used to find matches. For a particular batch the inten-

sity, shape, size and orientation of all beads are very

similar and therefore these features cannot be used to

distinguish between them. The only feature that dis-

tinguishes a bead is the relative position of other beads

with respect to that bead. That is the pattern formed

by the neighbours of a bead is the identifier of the

bead.

The bead matching is done in two steps. In the first

step the graph spectra of the fully connected weighted

graph formed using the bead and its 3 nearest neigh-

bours is used to find a region of the manufacturing im-

age that is most likely to have a matching pattern. The

spectrum of the affinity matrix of a graph has the nice

property of being invariant to rotation and labelling.

This allows the first step of the matching to be rota-

tion invariant. Further using the normalized Laplacian

of the graph instead of the adjacency matrix makes

the matching invariant to scale. The edge weights

are simply the Euclidean distance between the bead

centres. The graph spectra is calculated by doing an

Eigen value decomposition of the normalized graph

Laplacian. The graph Laplacian is calculated as fol-

lows:

L(u, v) =

1, if u = v

−w(u,v)

√

d

u

d

v

, if u and v are adjacent

0, otherwise

(1)

where

d

u

=

∑

v

w(u, v) (2)

and w(u, v) is the weight of the edge between nodes u

and v.

The choice of the number of nearest neighbours

depends on the amount of mismatch in the graphs.

For our implementation the value of 3 was chosen em-

pirically. Using 3 nearest neighbours means that in

order to find a correct match there should be at least

one bead in the fluorescent image for which its 3 near-

est neighbour pattern matches the 3 nearest neighbour

pattern of its true corresponding bead in the manufac-

turing image. This is a reasonable assumption partic-

ularly for dense patterns. In case of sparse patterns us-

ing even 2 nearest neighbours produced good results.

Using a small number of nearest neighbours is nec-

essary because in this step we intend to find matches

which are very similar to each other. In particular we

try to find matches where nodes are not missing and

differences in the two graphs are only because of er-

ror in determining the location of the beads during the

detection process. This step however provides many

possible matches and is used to locate the regions

of the manufacturing image that is likely to have the

FAST BEAD DETECTION AND INEXACT MICROARRAY PATTERN MATCHING FOR IN-SITU ENCODED

BEAD-BASED ARRAY

9

matching pattern. Further the matching is extremely

fast because of the small size of the graph Laplacian.

The Eigen decomposition of the 4x4 graph Laplacian

gives 4 Eigen values. The first Eigen values deals with

the scale of the graph and since we are interested in a

scale invariant match it is ignored. The remaining 3

Eigen values are used to find the matches. Matching

the 3-tuple graph spectra of two graphs is done using

a tolerance value for each dimension. The tolerance

value for each dimension is calculated as the standard

deviation of that dimension for true matches and is es-

timated using a training dataset.

The graph spectra based matching produces a set

of possible matches in the manufacturing image for

each fluorescent bead. These possible matches are

then further refined in the second step using a larger

set of nearest neighbours and a sequence matching

technique. The nearest neighbours of a bead in this

step are defined as a set of distance-angle pairs in-

stead of just distances. The angle for the kth nearest

neighbour is calculated as the angle formed between

the line connecting the bead to its first nearest neigh-

bour and the line connecting the bead to its kth nearest

neighbour. This allows the matching to be rotation in-

variant. In order to make the matching scale invariant

the distances are normalised by dividing all distances

by the distance to the first nearest neighbour. The

sequences are finally formed by sorting the distance-

angle pairs first by distance and then by angle.

A slightly modified version of the Smith-

Waterman sequence alignment algorithm is used to

find the match between nearest neighbour sequences

for each fluorescent-manufacturing bead match found

in the first step. Instead of doing exact matches of

characters as in the original Smith-Waterman algo-

rithm an error tolerant matching of distance-angle

pairs is used where some tolerance is allowed for both

the distance and angle values. In this case however

the effect of tolerance is much less significant because

of the use of both the angle and distance. The score

matrix for two sequences a and b of lengths m and n

respectively is defined as:

H(i, j) =

0, if i = 0 or j = 0

max

0,

H(i −1, j −1) +w(a

i

, b

i

),

H(i −1, j) +w(a

i

, −),

H(i, j −1) + w(−, b

i

)

else

(3)

where

w(a

i

, b

i

) =

(

match score, if a

i

= b

i

,

mismatch score, otherwise

(4)

and

w(a

i

, −) = w(−, b

i

) = gap score (5)

The values for gap score, match score and mis-

match score were empirically found to be -9.0, 10.0

and -8.0 respectively. The Smith-Waterman algorithm

however does not guarantee an exact match for each

element of the sequences. For instances for two se-

quences of distance-angle pairs shown in table 1 be-

low:

Table 1: Example sequence.

A 119,7.47 166,7.19 321,5.22 60,4.98

B 127,7.59 166,7.23 35,6.13 60,5.01

Smith-Waterman algorithm can produce an align-

ment as shown below:

Table 2: Example sequence alignment.

119,7.47 -

- 127,7.59

166,7.19 166,7.23

321,5.22 35,6.13

60,4.98 60,5.01

Since we are interested only in finding exact

bead to bead matches an additional correction step is

needed which identifies mismatches in the aligned se-

quences such as the one in the 4th row of table 2 and

changes the sequence alignment to correct them.

The best matching fluorescent and manufacturing

bead pair is identified as the one that gives the high-

est percentage of matching distance-angle pairs. In

case more than one fluorescent and manufacturing

bead pair produces the same percentage of distance-

angle pair matches, the one with the smallest sum

of squared error is defined as the best match. The

sequence matching directly gives the bead to bead

matches for all fluorescent image beads as well as

gives the manufacturing and fluorescent beads for

which matches were not found.

Finally, the scale and rotation of the matching pat-

tern are estimated as the modes in the ratio of dis-

tances and the difference of angles between the flu-

orescent and its corresponding manufacturing bead.

Once the scale and rotation angle have been esti-

mated the missing fluorescent beads are located by

back tracking their location in the manufacturing im-

age.

5 RESULTS

Testing was performed on a set of manually labelled

manufacturing and fluorescent images. For testing

detection performance artefacts in both manufactur-

ing and fluorescent images were manually labelled as

VISAPP 2012 - International Conference on Computer Vision Theory and Applications

10

beads and non-bead artefacts. For quantifying the pat-

tern matching performances the most optimal match

for each fluorescent image’s bead pattern was man-

ually found in a set of manufacturing images and the

exact bead to bead matches were also manually found.

To evaluate the performance of the detection algo-

rithm the specificity, sensitivity, precision and accu-

racy of detection were used.

For testing detection accuracy on fluorescent im-

ages bead detection was performed on a set of 40 fluo-

rescent images acquired under different experimental

conditions over a long period of time. Table 3 shows

the detection results for a 10-fold cross validation on

fluorescent beads. For fluorescent images the detec-

tion algorithm shows high accuracy and precision and

as well as high specificity and sensitivity.

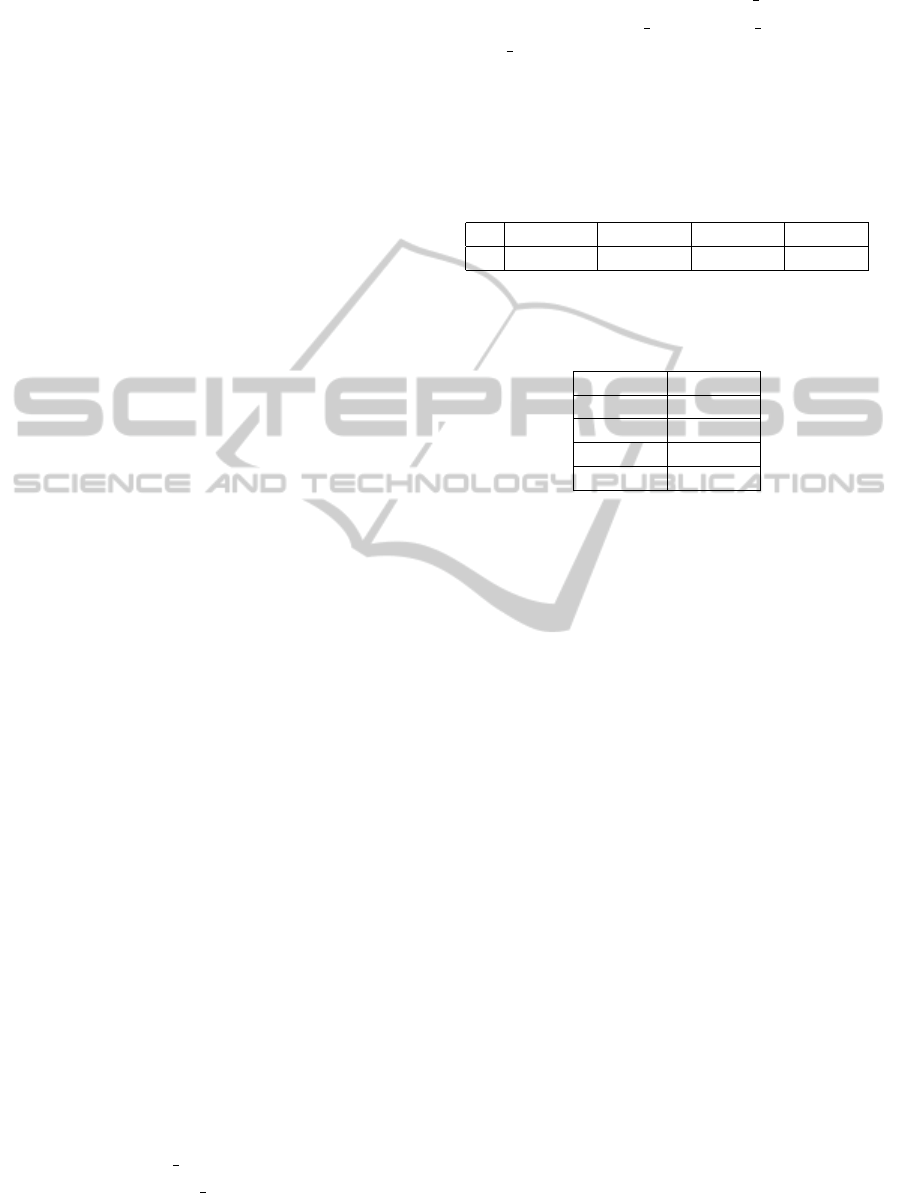

Table 3: 10-fold cross validation results of detection on a

set of 40 fluorescent images.

Performance Measure Mean Standard Deviation

Sensitivity 0.974 0.016

Specificity 0.988 0.015

Accuracy 0.980 0.003

Precision 0.993 0.009

Bead detection was also evaluated on 20 manu-

facturing images. The images were acquired under a

large range of conditions and the dataset was designed

to have images with large variations in noise levels as

well as irregular illumination levels. Typically manu-

facturing images have a very large number of beads

(>500) and therefore manually identifying all pos-

itive and negative beads is extremely tedious. The

data set used here for example contained over 10000

beads. Therefore to generate the labelled data a semi-

supervised technique was used. A naive Bayes classi-

fier was trained to classify the most obvious beads as

true beads. This classifier was trained very conserva-

tively and therefore high confidence could be put on

its positive results. In essence whenever the classifier

found even slight variations in the features with re-

spect to the features of the positive class it classified

the bead as negative. An interface was also devel-

oped that allowed the program to sequentially present

beads identified by the naive Bayes classifier as nega-

tive to the user for manual classification.

Table 4 shows the performance results for manu-

facturing bead detection. The algorithm achieves high

specificity and sensitivity as well as high accuracy and

precision even for manufacturing images. The sensi-

tivity in the case of manufacturing image is however

slightly lower than that of fluorescent images as the

percentage of actual beads to the total number of arte-

facts in the image is much smaller and this bias in-

creases the number of false negatives.

Table 4: 10-fold cross validation results of detection on a

set of 20 manufacturing images.

Performance Measure Mean Standard Deviation

Sensitivity 0.919 0.019

Specificity 0.997 0.003

Accuracy 0.973 0.006

Precision 0.993 0.008

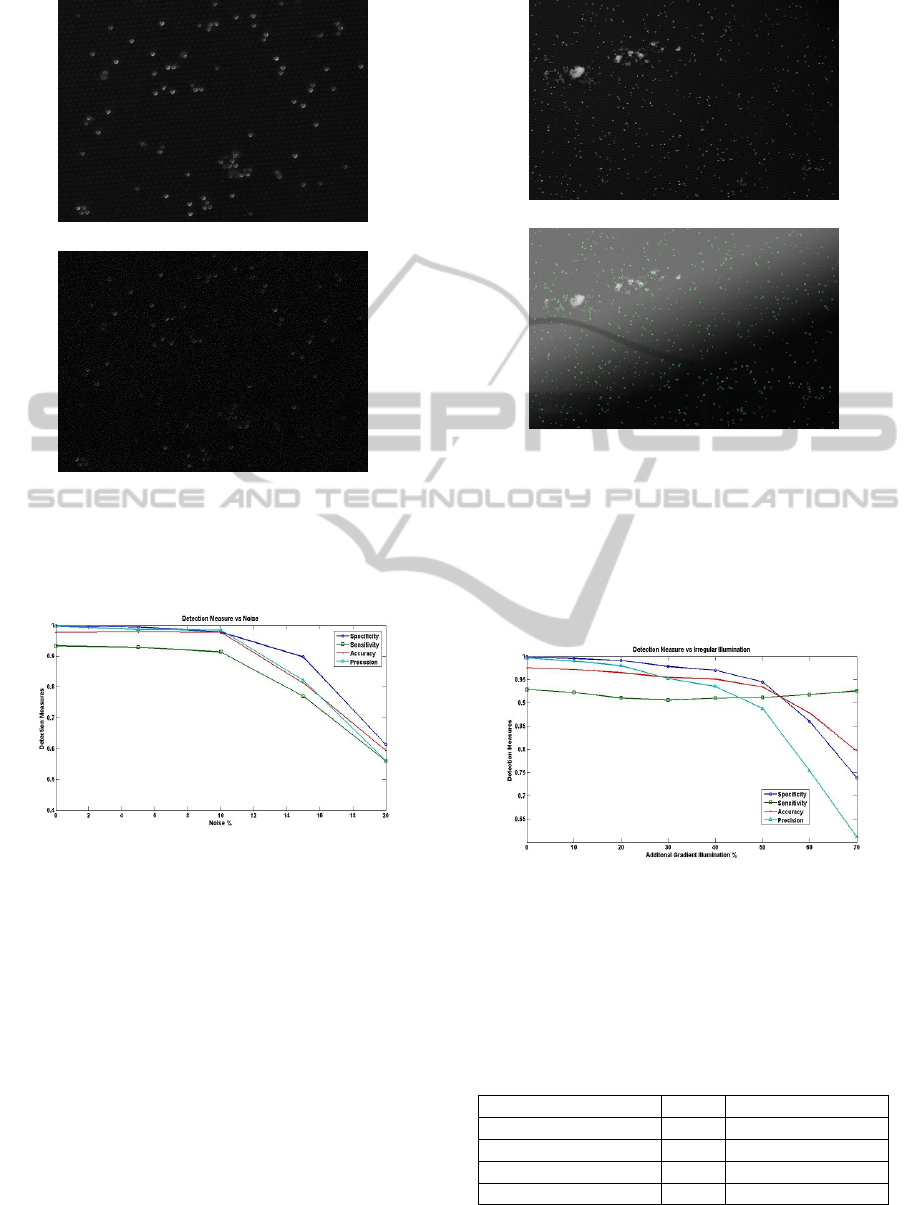

To test the robustness of the algorithm against

noise simulated noisy manufacturing images were

generated by adding Salt and Pepper noise to the orig-

inal images. Adding salt and pepper noise has two

effects, first it arbitrarily changes the shapes of the

true beads and second when large amount of noise

is added, artificial artefacts similar to real noise pat-

terns caused by dust particles are formed. Figure 4(a)

shows a section of a manufacturing image and figure

4(b) shows the same section with 10% noise added

to it. Detection was performed on a set of 5 manu-

facturing images with each image having 6 instances

with different levels of noise added. Figure 5 shows

the detection performance on the set of images with

respect to different levels of noise. The detection al-

gorithm shows good resistance against noise and is

able to handle noise as high as 10%.

To test detection performance against irregular il-

lumination synthetic manufacturing images were cre-

ated from the original images by adding a grayscale

gradient map. Figure 6(a) shows an original manu-

facturing image and figure 6(b) shows the synthetic

image constructed by adding a gradient map with

mean intensity of 128 and 50% opacity to the orig-

inal image. Figure 7 shows the detection perfor-

mance against different levels of irregular illumina-

tion. As can be seen both form the detection out-

put in figure 6(b) and in figure 7 the algorithm is ca-

pable of handling very large amount of illumination

variations. The number of false positives starts to in-

crease sharply at 40% opacity while at the same time

the number of false negatives reduces significantly as

more and more artefacts in the image are extracted

and classified. This effect can be seen in figure 7

where the specificity starts to increase as opacity is

increased beyond 40%.

Pattern matching performance is evaluated on 5

sets of 3 manufacturing and 3 fluorescent images.

For each fluorescent image a match is found in one

of the three manufacturing images giving a total of

15 pattern matches. Together the 15 fluorescent im-

ages contain over 700 beads for which bead to bead

matches were detected. The fluorescent bead patterns

to be matched vary heavily in bead density and in

the number of beads within the pattern actually hav-

ing a match in the manufacturing image. The true

FAST BEAD DETECTION AND INEXACT MICROARRAY PATTERN MATCHING FOR IN-SITU ENCODED

BEAD-BASED ARRAY

11

(a)

(b)

Figure 4: (a) shows the original section of a manufacturing

image and (b) shows the same section with 10% salt and

pepper noise. Here 10% noise means 10% of the pixels

have been randomly set to the mean intensity of beads.

Figure 5: Shows the change in Specificity, Sensitivity, Ac-

curacy and Precision with changing noise levels.

positives in this case are identified as correct bead

to bead matches for all beads within the bounding

region of the matching patterns (for fluorescent im-

age this means the entire image). This includes pre-

dicted matches for manufacturing beads not present

in the fluorescent image that is beads that did not re-

act or were not detected. True negatives are those

beads in the fluorescent image which are missing in

the manufacturing image and for which a match was

not found. These are the beads that were activated

because of contamination. False positives are incor-

rectly identified bead to bead matches while false neg-

atives are fluorescent image beads which do not have

a true match in the manufacturing image but a match

was detected. Once again we use specificity, sensi-

(a)

(b)

Figure 6: (a) shows the original manufacturing image and

(b) shows the bead detection output on the same image with

50% gradient. Here 50% gradient means a gradient map

with mean intensity of 128 and 50% opacity has been ap-

plied to the original image. The detection algorithm output

is evenly distributed irrespective of the illumination level.

However, at this level of irregularity the false positive rate

of detection starts to increase sharply.

Figure 7: Shows the change in Specificity, Sensitivity, Ac-

curacy and Precision with changing levels of irregular illu-

mination.

tivity, precision and accuracy to evaluate the match-

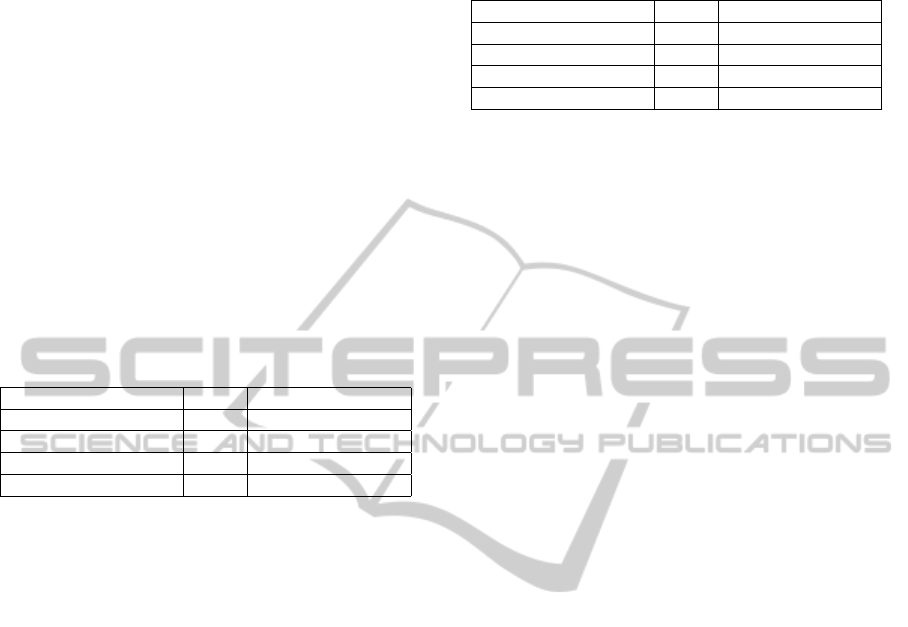

ing performance. Table 5 shows the results for the 15

matches.

Table 5: Bead to bead matching results for 15 fluorescent

image patterns.

Performance Measure Mean Standard Deviation

Sensitivity 0.382 0.185

Specificity 0.988 0.010

Accuracy 0.923 0.021

Precision 0.931 0.022

The results show good sensitivity, accuracy and

VISAPP 2012 - International Conference on Computer Vision Theory and Applications

12

precision but a strikingly low specificity. This is be-

cause of a large bias towards the positive class. Typi-

cally most fluorescent beads have a true match in the

manufacturing image and only very few beads in the

fluorescent image are those which reacted and bright-

ened up due to contamination. Therefore although the

Precision is high the number of false positives is com-

parable to the number of true negatives and false neg-

atives.

Fluorescent images of higher batches tend to have

very high bead densities and a larger mismatch can be

found between the fluorescent image beads and the

actual matching manufacturing beads. Beads that lit

up due contamination and beads that did not react or

were not detected can together cause the true match-

ing regions in the two images to have less than 30%

of the matching beads. Matching under such heavy

occlusion conditions and with outliers is one of the

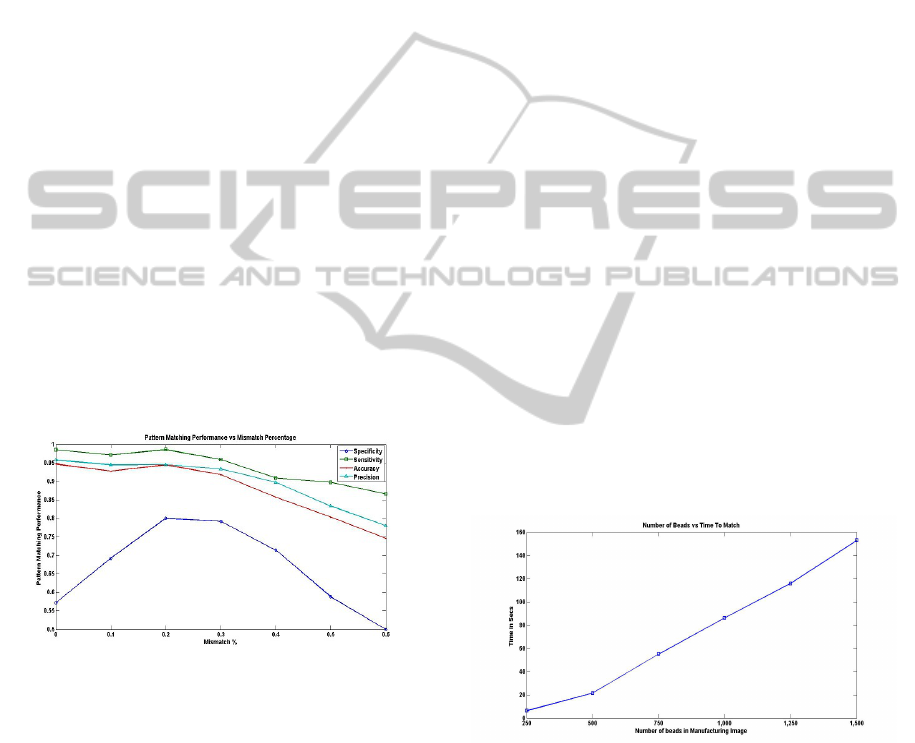

strengths of this algorithm. To evaluate the matching

performance under such conditions simulated data is

created by adding and removing beads to the fluores-

cent images and to the region of the manufacturing

image containing the true match. The results of test-

ing on a set of 15 fluorescent manufacturing image

pairs is shown in figure 8. The amount of mismatch

is quantified as the ratio of synthetic beads added and

original beads removed to the number of total match-

ing beads.

Figure 8: Shows the change in Specificity, Sensitivity, Ac-

curacy and Precision with changing levels of mismatch be-

tween the fluorescent bead pattern and the manufacturing

bead pattern. Here the amount of mismatch is quantified as

the ratio of the sum of synthetic beads added to the fluores-

cent image and manufacturing beads removed to the number

of total manufacturing beads with true bead to bead match

in the fluorescent image.

Similar to the results in table 3 the specificity is

low in figure 8 as well. However as the amount of

mismatch increases initially the specificity also in-

creases as more instances of the negative class are

added to the data and therefore the bias towards the

positive class decreases. However after a certain level

of mismatch all the performance measures start de-

clining sharply. This is due to the cases where overall

matching fails all together. The matching algorithm

requires at least one bead with similar 3-NN struc-

ture in both the fluorescent and manufacturing image.

As the mismatch exceeds 30% this is not satisfied in

some cases. Similarly even at very high mismatches

such as 60% in some cases true matches are found.

In general however when the 3-NN criterion is satis-

fied very high sensitivity, precision and accuracy are

achieved.

Another major strength of this algorithm is that

it is fast and scales well with increasing size of

the graphs. State-of-the-art graph matching algo-

rithms that can deal with occlusions and outliers have

quadratic or quasi-quadratic complexity. Our algo-

rithm on the other hand has almost linear complex-

ity. The time performance of the algorithm was evalu-

ated on a manufacturing data set with 6 images where

each subsequent image had greater number of beads.

Matching was performed for 5 fluorescent images

with number of beads ranging from 70 to 80. Test-

ing was done on a workstation with Pentium Core 2

duo 2.1 GHz processor with 2.0 GB RAM. Figure 9

shows that the time taken to match increases almost

linearly with the number of beads in the manufactur-

ing images. This is because most of the matching is

done using graph spectra and calculating the spectra

of a 4x4 matrix is extremely fast. The number of pos-

sible matches identified using graph spectra also does

not increase rapidly with increasing number of nodes.

When the number of beads range from 250 to 500,

which is the most significant range for us the time

taken to match is between 6 to 20 seconds.

Figure 9: Shows the time taken to find a match with increas-

ing graph sizes.

6 CONCLUSIONS

The future of the healthcare lies in ’Personalized

Medicine’ which tailors the medical treatment of an

individual based on his/her profile characteristics (Pri-

orities for Personalized Medicine, 2008). This is ben-

eficial in many ways as treating all patients in the

same way not only ignores the individual conditions

FAST BEAD DETECTION AND INEXACT MICROARRAY PATTERN MATCHING FOR IN-SITU ENCODED

BEAD-BASED ARRAY

13

and specific therapy requirements of each individual

but also incurs excess cost to the healthcare system.

Improvement in healthcare system requires

closer collaboration with technologies from multi-

disciplinary background. Use of advanced computer

vision and machine learning techniques are of

vital importance to resolve many issues in medical

applications. In present days no technology can be

isolated from the other in creation of a successful

commercially viable product. The bead detection

and pattern matching algorithm developed here

specifically solves some of the problems such as

handling noisy image data, irregular illumination

and occlusion and outlier resistant pattern matching

involved in the IEBA technology. The IEBA technol-

ogy together with automated fast bead detection and

inexact microarray pattern matching effectively uses

computer vision and machine learning algorithms

and promises to be an excellent platform for protein

multiplexing and take medical diagnostics to the next

level.

REFERENCES

Chen, L., Feris, R., and Turk, M. (2008). Efficient partial

shape matching using smith-waterman algorithm. In

In CVPR workshop on Non-Rigid Shape Analysis and

Deformable Image.

Cour, T., Srinivasan, P., and Shi, J. (2006). Balanced graph

matching. In NIPS.

Evans, D. J. and Tay, L. P. (1995). Fast learning artificial

neural networks for continuous input applications. In

Kybernetes.

H.Alt and L.J.Guibas (1996). Discrete geometric

shapes:matching,interpolation,and approximation: A

survey. In Technical Report, Handbook of Computa-

tional Geometry.

J.McAuley, J. and S.Caetano, T. (2012). Fast matching of

large point sets under occlusions. In Pattern Recogni-

tion 45 (2012). Elsevier.

Leordeanu, M. and Heberti, M. (2005). A spectral tech-

nique for correspondence problems using pairwise

constraints. In ICCV.

Ng, J. K., Selamat, E. S., and Liu, W.-T. (2008). A spatially

addressable bead-based biosensor for simple and rapid

dna detection. In Biosensors & Bioelectronics. Else-

vier.

Oliveros, A. and Sotaquir

`

a, M. (2007). An automatic grid-

ding and contour based segmentation approach ap-

plied to dna microarray image analysis. In Interna-

tional Journal of Biological and Life Sciences.

Priorities for Personalized Medicine (2008). (PCAST

2008). Technical report, Presidents Council of Ad-

visors on Science and Technology.

Rezende, P. and Lee, D. (1995). Point set pattern matching

in d-dimensions. In Algorithmica 13(1995).

Riedel, D. E., Venkatesh, S., and Liu, W. (2006). A smith-

waterman local alignment approach for spatial activity

recognition. In In Proceedings of AVSS’2006.

Smith, T. F. and Waterman, M. S. (1981). Identification

of common molecular subsequences. In Journal of

Molecular Biology.

S.Suzuki and K.Abe (1985). Topological structural analysis

of digital binary image by border following. In Com-

puter Vision, Graphics, and Image Processing, Vol.

30, No. 1.

Trau, D., Liu, W.-T., and Ng, J. K. K. (2008). A microarray

system and a process for producing microarrays. In

International Publication Number WO 2008/016335

A1.

VISAPP 2012 - International Conference on Computer Vision Theory and Applications

14