AUTONOMOUS SENTINELS

FOR THE DETECTION OF INVASIVE PATHOGENS

Howard Clyde Wikle III, Suiqiong Li, Aleksandr Simonian and Bryan A. Chin

Materials Research & Education Center, Auburn University, Auburn, AL, U.S.A.

Keywords: Pathogen Detection, Biosensor, Bio-inspired, Phage, Magnetoelastic, Wireless Sensor.

Abstract: This paper describes the results of a research project to investigate and develop an autonomous pathogen

detection and capture system that mimics the function of naturally occurring biological defensive systems,

such as white blood cells. The autonomous sentinel system is envisioned to have the capability of seeking

out invasive pathogens in liquid environments, detecting and capturing them. Once detected and captured

the invasive pathogens can be removed, by retrieving the sentinels using a magnetic field. The sentinels are

composed of two main parts: a magnetoelastic resonator whose motion and detection functions is actuated

and monitored using magnetic fields; and a bio-probe that is immobilized onto the resonator surface and

captures specific target pathogens. The freestanding sentinels require no on-board power for motion or to

signal detection of a target pathogen. Upon contact with the target pathogen, the bio-molecular recognition

element on the sentinel will bind with the target cell. This will cause a mass change of the sentinel, which

results in a change in the sentinel's resonant frequency and the instantaneous detection of the target

pathogen. Similar to white blood cells, the autonomous sentinels when placed in a liquid analyte will move

through the analyte, capture and disable the target pathogens and signal their detection. The objective of

this paper is to demonstrate proof-in-principal of the concept of autonomous sentinels.

1 INTRODUCTION

For centuries, humankind has attempted to mimic

the designs of Nature to develop new engineering

materials and systems. The human blood system is

an excellent example of one of Nature’s amazing

creations that inspires us in this work. The human

blood contains many components that work

synergistically to keep us healthy. As part of the

immune system, white blood cells are the main

defensive mechanism against pathogenic invaders.

There are a variety of white blood cell types

(neutrophil, eosinophil, lymphocytes, etc.) that target

different pathogens. This capability serves as the

model for a bio-inspired system of autonomous

sentinels for the capture and detection of invasive

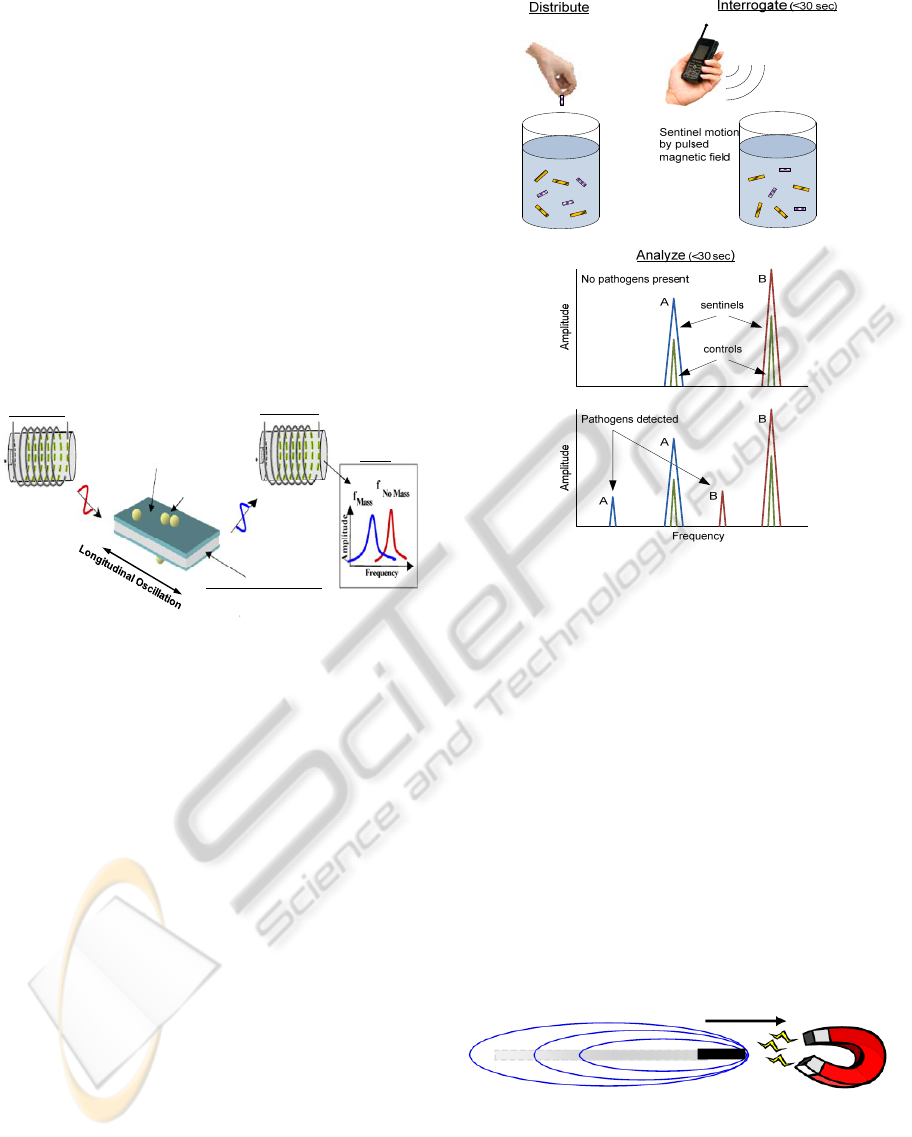

pathogens described in this paper (Figure 1). To

provide proof-in-principal of the concept, research

results for autonomous sentinel detection in liquid

analytes are presented in this paper. Potential short

term applications include the capture and detection

of bacteria in urine and liquid food products such as

water, juices and milk.

Figure 1: Bio-inspired sentinels will target different types

of bacteria (E. coli, Salmonella Typhimurium, etc.)

mimicking white blood cells that target different invasive

pathogens (Wetzel and Schaefer, 1982).

2 THEORY OF THE SENTINEL

A biosentinel is constructed of a freestanding

magnetoelastic (ME) resonator (transducer platform)

that is coated with a biorecognition layer

(bacteriophage) that specifically captures or binds a

single type of pathogen. The magnetoelastic

resonator investigated in the paper is strip-shaped, a

rectangular, flat piece of material. The resonator is

constructed from an iron-based, amorphous alloy

Nature

Bioinspired Sentinels

47

Wikle III H., Li S., Simonian A. and A. Chin B. (2012).

AUTONOMOUS SENTINELS FOR THE DETECTION OF INVASIVE PATHOGENS.

In Proceedings of the International Conference on Biomedical Electronics and Devices, pages 47-52

DOI: 10.5220/0003775200470052

Copyright

c

SciTePress

with magnetostrictive properties. Magnetostrictive

materials undergo a change in shape when subjected

to an applied magnetic field. If the magnetic field is

varied at the proper frequency aligned along the

length direction of the resonator, the structure can

achieve resonance. The detection principle of the

ME sentinels is shown in Figure 2. The freestanding

ME resonator serves as the transduction platform,

actuated into resonance by the application of an

alternating magnetic field. Upon contact with the

specific target bacteria, the bio-molecular

recognition element on the sentinel's surface

captures the target bacterial cells, causing the overall

sensor mass to increase which results in a decrease

in the resonant frequency. The resonant frequency is

remotely and wirelessly measured using a pick-up

coil. No onboard power is required by a sentinel.

Biorecognition Layer

Target

Pathogens

Apply Varying

Magnetic Field

ME Biosentinel

Resulting Field

Magnetoelastic Platform

nm to µm sized resonator

Result

Pick-Up Coil

Driving Coil

Figure 2: Detection principle of a magnetoelastic (ME)

biosentinel. A driving coil generates a modulated magnetic

field that drives the ME resonator into vibrational

resonance. Binding of the target bacteria to the bio-

molecular recognition layer immobilized onto the

resonator increases the mass of the sensor resulting in a

decrease in resonant frequency.

ME sentinels have unique advantages that stem

from both the magnetoelastic resonator platform and

the phage biorecognition layer. The sentinels are

wireless devices, enabling in-situ remote detection

of multiple target pathogens (Figure 3). Due to its

wireless nature, a large number of sentinels can be

deployed simultaneously, which significantly

enhances the probability of binding with a target

pathogen. More importantly, the binding of target

pathogens on only one out of many sentinels can be

easily detected. By taking advantage of these

properties and capabilities of phage-coated ME

resonators, a system of sentinels that mimics the

functions of white blood cells can be built and

deployed for enhanced medical diagnostics, food

safety, or water quality applications.

One of the key parameters of these Fe based, bio-

sentinels is the minimum detection limit. At low

bacterial concentrations, the odds of detection are

Figure 3: A large number of sentinels targeting different

pathogens may be mixed together and interrogated

simultaneously for pathogen detection. Different

pathogens may be detected simultaneously since the

sentinels for different pathogens are designed to operate in

different frequency ranges.

improved either by increasing the number of ME

sentinels deployed or by exposing the sentinels to a

dynamic environment. For detection in liquid media,

dynamic exposure can be achieved by flowing the

media past the immobilized sentinels or by moving

the sentinels around within the media. While flow

cells are a viable option, a simpler approach to

achieve greater exposure is to harness the magnetic

field that is currently used only for pathogen

detection to provide the forces for sentinel motion

(Figure 4). A nonuniform magnetic field can be used

to propel and steer the sentinels.

Figure 4: ME sentinel motion. A nonuniform magnetic

field generated by the detection system can be used to

induce movement in strip shaped sentinels.

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

48

2.1 The Resonator Platform

Acoustic resonators as sensor platforms have been

widely investigated (Ballantine et al., 1997). Quartz

crystal microbalances, microcantilevers, surface

acoustic wave devices, and magnetoelastic particles

are all examples of acoustic resonators. Acoustic

resonators are mass sensitive devices where a

change in the mass load on the sensor surface causes

a change in the sensor’s resonant frequency.

Acoustic resonators are characterized by two

important parameters: 1) the sensitivity (S

m

) which

represents the shift in the initial resonant frequency

(Δf = f − f

0

) due to the attachment of a unit mass

load (Δm =m − m

0

) as shown in Equation 1 (Grimes

et al., 1999); and 2) the resonance performance (Q

factor), which is defined as the ratio of the energy

stored in the resonant structure to the total energy

losses per oscillation cycle. In an amplitude-

frequency spectrum, a measure of the Q factor is

given by the resonant frequency f divided by the 3

dB frequency bandwidth. A higher Q factor means a

sharper resonant peak and thus better resolution in

determining the resonant frequency. The minimum

detectable mass (

Δ

m

min

) for an acoustic sensor

platform depends on the ability to resolve resonant

frequency shifts as a result of the mass loading.

0

0

2

1

m

f

m

f

S

m

−≈

Δ

Δ

= (Δm << m

0

) (1)

For biological detection, the surface of the ME

sentinels is coated with a biorecognition element,

such as an antibody or phage. This biorecognition

element is designed to specifically bind the target of

interest. When the ME biosentinel comes into

contact with the target pathogens, the biorecognition

element will capture/bind the target pathogen

creating an additional mass load on the sentinel

resulting in a decrease in the resonant frequency.

Therefore, the presence and concentration of any

target pathogens can be identified by monitoring the

resonant frequency shifts of the sentinel. For a thin

strip-shaped ME resonator of length L, the largest

vibrations will occur along the length direction. The

fundamental resonant frequency of this longitudinal

oscillation is given as (Landau and Lifshitz, 1986,

Liang et al., 2007):

)1(2

1

0

υρ

−

=

E

L

f

(2)

where E, ρ, and υ are the Young’s modulus, density,

and Poisson ratio of the material respectively.

The sensitivity of the ME biosentinel is

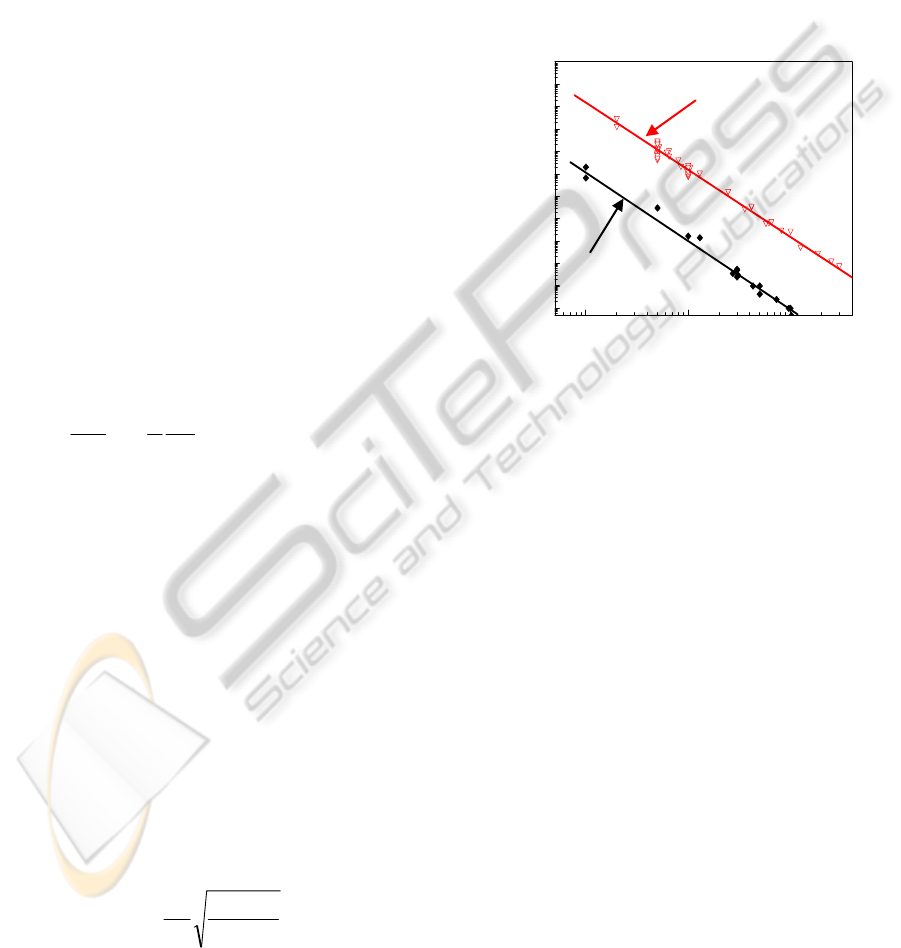

compared with cantilevers in Figure 5. For ME

biosentinels and cantilevers fabricated from the

same material and of the same size, the ME sensor

exhibits an S

m

about 100 times better than the

cantilever. Advanced microfabrication processes

will enable the optimization of the resonance

performance of the ME sentinels which will lead to

improved pathogen detection capabilities. Different

shapes, structures, and/or material compositions are

parameters that affect sentinel motion, sensitivity

and resonance performance.

1x10

2

1x10

3

1x10

4

1x10

-6

1x10

-4

1x10

-2

1x10

0

1x10

2

1x10

4

Sensitivity (Hz/pg)

Len

g

th

(

um

)

Sentinels

Cantilevers

Figure 5: Sensitivity vs. length for cantilever and sentinels.

Sentinels are 100 times more sensitive.

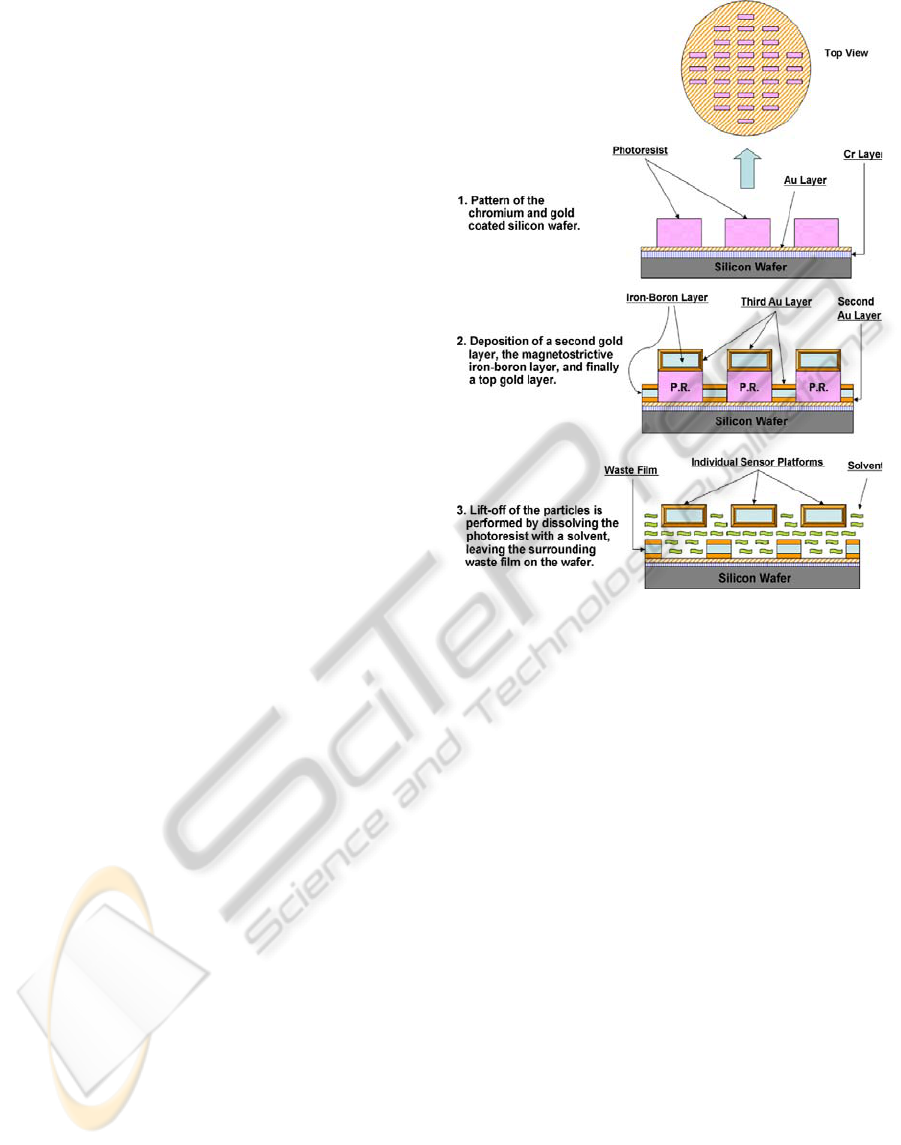

2.2 Fabrication of ME Resonators

The ME resonators were fabricated using standard

microelectronic fabrication techniques of

photolithography and physical vapor deposition

(sputtering). The process used to fabricate the

resonators is shown schematically in Figure 6.

Binary alloy magnetoelastic resonators are

fabricated on a patterned wafer by co-depositing iron

and boron at controlled rates under vacuum. The

resonators are coated with gold that provides

oxidation protection for the alloy and a bioactive

surface to immobilize the phage. The resonators are

freed from the wafer by lift-off using an acetone

rinse and collected using a magnet. Fabrication of

the sensor platform begins by coating a 100 mm

plain silicon test wafer with a layer of chromium,

and then gold, each at a thickness of 30−40 nm. This

is accomplished using a Denton Vacuum Discovery-

18™ magnetron sputtering system, which employs

three cathodes (each holding a 3 inch diameter

target) aimed off-axis at a circular, rotating substrate

platform, along with DC and RF power supplies.

The gold layer is needed to adhere the next

deposited film (also gold) to the wafer, while the

AUTONOMOUS SENTINELS FOR THE DETECTION OF INVASIVE PATHOGENS

49

chromium merely serves to act as a bond between

the silicon and the gold. Next, a layer of photoresist

is applied to the gold surface of the wafer by spin

coating such that the resultant thickness is at least

twice that of the desired magnetoelastic film to be

deposited later. This photoresist is then UV exposed

using a positive mask comprised of evenly-spaced

rectangles, which are the desired length and width of

the magnetoelastic sentinels. The wafer is then

developed in a 2:1 solution of de-ionized water and

AZ-400K developer, rinsed, dried, and then

inspected for pattern integrity and thickness.

The magnetoelastic film is then deposited onto

the patterned wafer using the same sputtering system

as before. First, the wafer is loaded into the

deposition chamber, along with a gold, iron, and

boron target for each of the three cathodes, and then

the chamber is pumped down to 7×10

-7

Torr in order

to minimize residual oxygen in the film. Next, a gold

layer is deposited onto the patterned wafer to a

thickness of about 30–40 nm. The magnetoelastic

layer is formed by co-depositing iron (DC) and

boron (RF) simultaneously using a dual-cathode

method. This method differs somewhat from the

usual procedure for co-sputtering iron and boron,

which typically involves using a specially made

composite target. The advantage here is that the

power of each cathode can be tuned separately such

that the film has the desired composition at a

reasonable deposition rate. Thickness of this film

depends on process conditions, and is generally

limited by the thickness of the photoresist layer, but

highly magnetostrictive films of up to about 7 µm

have been obtained using this dual-cathode method.

Finally, another gold layer, using the same

processing conditions as before, is applied on top of

the iron-boron film, such that the magnetostrictive

particles will be completely enclosed in gold. From

an 8" wafer, approximately 40,000 sentinels can be

fabricated. The cost of fabrication of a single 8"

silicon wafer of sentinels is approximately $28.00.

Hence the cost of a single ME sensor is less than

1/1000 of a cent.

2.3 Immobilization of the

Bio-molecular Recognition Layer

To form functional sentinels, a bio-molecular

recognition element must be immobilized onto a

transducing platform to bind the specific target

pathogenic species. Other investigators typically use

traditional antibodies as the biorecognition element.

The strengths and weaknesses of antibody binding

are well known. An antibody is a relatively fragile

Figure 6: The ME resonator fabrication process.

species and subject to denaturation with

consequential loss of sensitivity and other binding

characteristics when exposed to unfavorable

environments. Moreover, the quality of antibodies

can vary with different animals and production

variables. To be used in sentinels, antibodies require

affinity purification and stabilization, which

dramatically increases their cost. Monoclonal

antibodies are more standard and selective, but their

application in the field is hindered by their stability.

The use of phage as substitute antibodies offers a

stable, reproducible and inexpensive alternative

(Petrenko, 2008, Petrenko and Smith, 2000). In

contrast to antibodies, the phage structure is

extraordinarily robust, being resistant to: heat (up to

80 °C) (Brigati and Petrenko, 2005); organic

solvents (e.g., acetonitrile) (Olofsson et al., 2001),

urea (up to 6 M), acid, alkali and other chemicals.

Purified phage can be stored indefinitely at moderate

temperatures without losing infectivity and probe-

binding activity. Three major factors contribute to

the high affinity binding of landscape phage to their

targets: a) constrained conformation of foreign

peptides; b) their multivalent display—thousands of

binding sites per phage filament; and c) extremely

high local concentration of binding sites. The

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

50

surface area density of the phage is 300 to 400 m

2

/g,

exceeding even the best-known absorbents and

catalysts. The genetically engineered amino acids

that form the “active receptors” of a landscape phage

comprise up to 25% by weight of the phage and up

to 50% of its surface area—an extraordinarily high

fraction compared to natural proteins, including

antibodies.

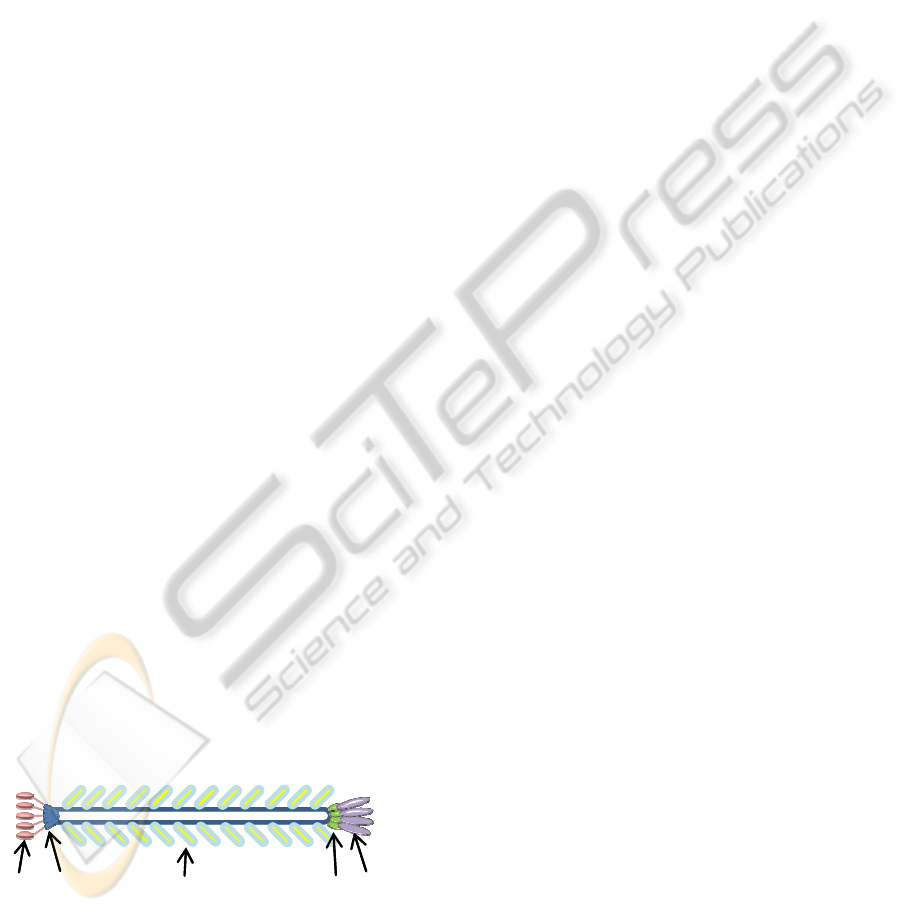

Our research team has genetically engineered

filamentous phage (Figure 7), to serve as a

replacement for current antibody technology. The

filamentous E2 phage for binding to Salmonella

enterica serovar Typhimurium was affinity selected

from a landscape f8/8 phage library and provided by

the Department of Biological Sciences at Auburn

University (Petrenko and Sorokulova, 2004). The

clone E2 phage used in this work has been studied

and verified to be highly specific and selective

towards S. Typhimurium (Sorokulova et al., 2005).

The phage was immobilized on the ME sensor

surface using physical adsorption. Each ME sensor

platform was placed in a vial containing 300 μL of

phage E2 suspension (5×10

11

vir/mL in 1 x Tris-

Buffered Saline (TBS)). These vials were then

rotated and incubated on a rotor (running at 8 rpm)

for 1 hour. After the immobilization process, the

sensors were washed three times with 1 x TBS

solution and two times with sterile distilled water in

order to remove salt and any unbound or loosely

bound phage.

In order to reduce nonspecific binding, Bovine

Serum Albumin (BSA) solution was then

immobilized on the sensor surfaces to serve as a

blocking agent. The ME sentinels were immersed

into 1 mg/mL BSA solution for at least 1 hour,

followed by a distilled water rinse. In this study,

control sensors were fabricated and used to calibrate

the effects of environmental changes, such as

temperature and non-specific binding. The control

sensor is identical to the measurement biosensor

except it lacks the E2 phage coating. The control

sensors were also treated with BSA to block

nonspecific binding.

Major coat protein: pVIII

pVIpIII

pIXpVII

Major coat protein: pVIII

pVIpIII

pIXpVII

Figure 7: Filamentous Phage.

3 CHARACTERIZATION OF ME

SENTINEL PERFORMANCE

3.1 Detection of Pathogens by the ME

Sentinels

The S. Typhimurium culture (ATCC 13311) used in

this work was provided by the Department of

Biological Sciences at Auburn University, Auburn,

AL. These cultures were provided in the form of a

suspension at a concentration of 5×10

8

CFU/mL.

The suspensions were serially diluted in water to

prepare bacterial suspensions with the

concentrations ranging from 5×10

1

to 5×10

7

CFU/mL. All test solutions were prepared on the

same day as the biosentinel testing. The test

solutions were stored at 4 °C (during transfer and

storage) and equilibrated to room temperature in a

water bath prior to the experiments.

The resonant frequency of the sentinels was

measured using an HP 8751A network analyzer with

S-parameter test set. The ME sentinels (control and

measurement) were placed in a tube containing pure

water and the resonant frequency of the sentinel

measured. The network analyzer scanned, measured

and recorded the resonant frequency spectrum of the

ME sensor as a function of time. After each 30

minute exposure the analyte was changed to the next

highest dilution. Figure 8 shows the frequency shift

measurements for ME sentinels 500 × 100 × 4 µm in

size. Note that the control sensor shows a nearly

constant frequency (no frequency shift), while the

measurement sensor undergoes a frequency shift of

nearly 120,000 Hz. As can be seen from the plot, the

detection limit of the sentinel is better than 50

CFU/mL of S. Typhimurium in water.

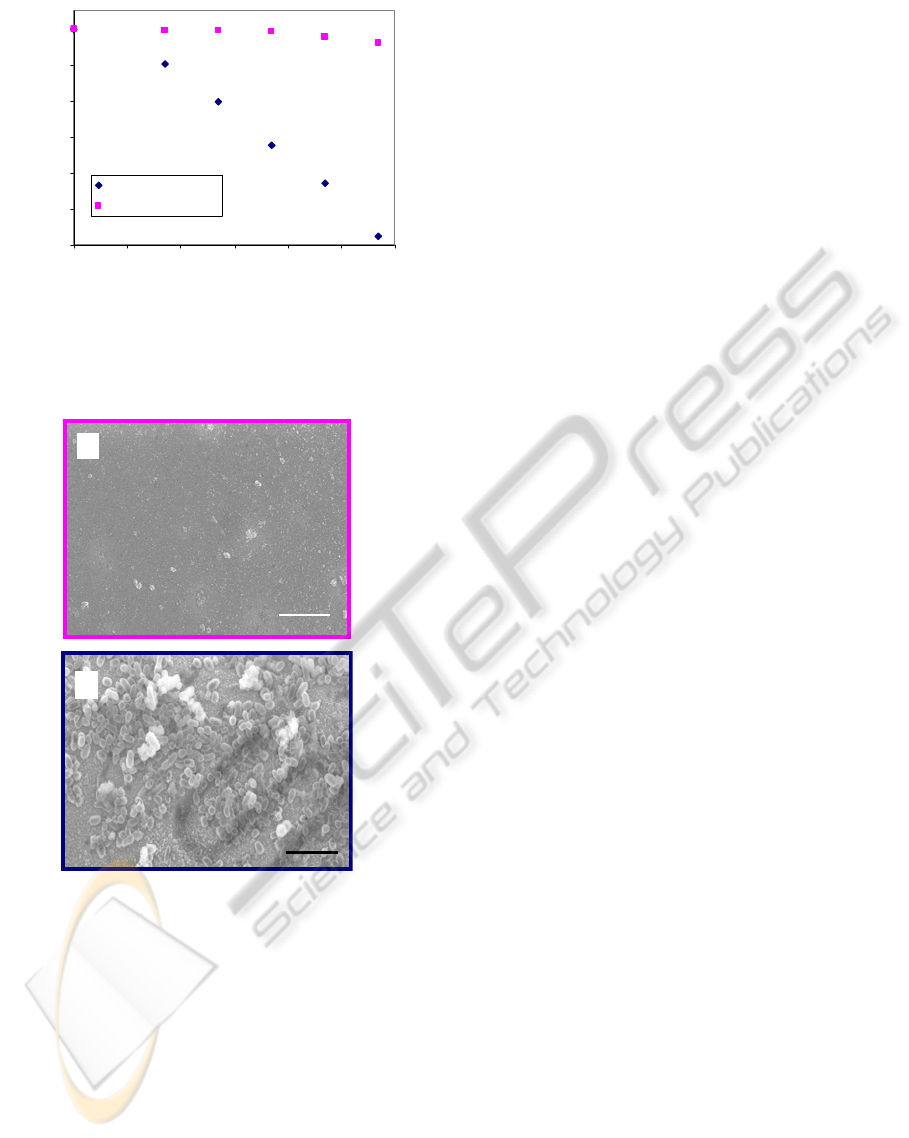

A JEOL-7000F scanning electron microscope

(SEM) was used to confirm and compare the binding

of S. Typhimurium on the phage-coated

measurement and control sentinels. After the

detection, the ME sentinels were exposed to osmium

tetroxide (OsO

4

) vapour for 45 minutes. The sensors

were then mounted onto aluminum stubs and

examined using the SEM. Figure 9 shows the SEM

micrographs for the measurement and control

sentinels. The control sentinel shows only a few

cells are bound to the surface while the measurement

sentinel is nearly completely covered with bound S.

Typhimurium bacteria.

AUTONOMOUS SENTINELS FOR THE DETECTION OF INVASIVE PATHOGENS

51

-120000

-100000

-80000

-60000

-40000

-20000

0

1.E+00 1.E+01 1.E+02 1.E+03 1.E+04 1.E+05 1.E+06

Concentration of Salmonella Solution (CFU/ml)

Shift in the Resonance Frequency (Hz)

Measurement Sensor

Control Sensor

Figure 8: Response of 500 µm long biosensor exposed to

increasingly higher concentrations of S. Typhimurium.

The detection limit is less than 50 CFU/mL. The response

of the control sensor (devoid of phage) is also shown.

10µm

(a

10µm

(b

Figure 9: The SEM images show near zero binding of

Salmonella cells to the control sentinel (a) and a large

number of bound Salmonella cells to the measurement

sentinel (b).

4 CONCLUSIONS

Proof-in-principle of the concept of autonomous

sentinels for the detection of invasive pathogens has

been established. Magnetoelastic strip-shaped

resonators coated with a bio-molecular recognition

layer can moved through a liquid using a non-

uniform magnetic field and then measured remotely

and wirelessly to detect the binding and capture of

specific pathogenic bacteria. Because the

magnetoelastic sentinels investigated in this research

are iron based, they can be retrieved with a magnet

and hence captured pathogenic bacteria can be

removed from the system.

REFERENCES

Ballantine, D. S. Jr, White, R. M., Martin, S. J., Ricco, A.

J., Zellers, T., Frye, G. C., Wohltjen, H., 1997.

Acoustic wave sensors: Theory, design, & physio-

chemical applications, Academic Press. San Diego,

CA.

Brigati, J. R., Petrenko, V. A., 2005. Thermostability of

landscape phage probes. Analytical and Bioanalytical

Chemistry, 382, pp.1346-50.

Grimes, C. A., Stoyanov, P. G., Kouzoudis, D., Ong, K.

G., 1999. Remote query pressure measurement using

magnetoelastic sensors. Review of Scientific

Instruments, 70, pp.4711-14.

Landau, L. D., Lifshitz, E. M., 1986. Theory of elasticity,

Pergamon Press. Oxford, 3

rd

edition.

Liang, C., Morshed, S., Prorok, B. C., 2007. Correction

for longitudinal mode vibration in thin slender beams.

Applied Physics Letters, 90, pp.221912.

Olofsson, L., Ankarloo, J., Andersson, P. O., Nicholls, I.

A., 2001. Filamentous bacteriophage stability in non-

aqueous media. Chemistry & Biology, 8, pp.661-71.

Petrenko, V. A., 2008. Evolution of phage display: from

bioactive peptides to bioselective nanomaterials.

Expert Opinion on Drug Delivery, 5, pp.825-36.

Petrenko, V. A., Smith, G. P., 2000. Phages from

landscape libraries as substitute antibodies. Protein

Engineering, 13, pp.589-92.

Petrenko, V. A., Sorokulova, I. B., 2004. Detection of

biological threats. A challenge for directed molecular

evolution. Journal of Microbiological Methods, 58,

pp.147-68.

Sorokulova, I. B., Olsen, E. V., Chen, I. H., Fiebor, B.,

Barbaree, J. M., Vodyanoy, V. J., Chin, B. A.,

Petrenko, V. A., 2005. Landscape phage probes for

Salmonella typhimurium. Journal of Microbiological

Methods, 63, pp.55-72.

Wetzel, B., Schaefer, H., 1982. National Cancer Institute.

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

52