NITRITE BIOSENSING WITH DISPOSABLE

ELECTRODE STRIPS

A Preliminary Study

Marcelo Rodrigues

1

, Cátia Correia

1

, Célia M. Silveira

1

, José. J. G. Moura

1

, Estibaliz Ochoteco

2

,

Elena Jubete

2

and M. Gabriela Almeida

1,3

1

REQUIMTE — Dept. de Química, Faculdade de Ciências e Tecnologia,

Universidade Nova de Lisboa, 2829-516 Monte de Caparica, Caparica, Portugal

2

CIDETEC-IK4 — Sensors and Photonics Unit, Parque Tecnológico de San Sebastián, Pº Miramon, 196,

20009 Donostia — San Sebastián, Spain

3

Escola Superior de Saúde Egas Moniz, Monte de Caparica, 2829-511 Caparica, Portugal

Keywords: Nitrite, Cytochrome c nitrite reductase, Electrochemical biosensors, Screen printed electrodes.

Abstract: This paper presents the results of a preliminary study on the construction of miniaturized biosensing devices

for nitrite analysis in clinical samples. Following our previous works regarding the development of

amperometric nitrite biosensors using the nitrite reducing enzyme (ccNiR) from Desulfovibrio desulfuricans

ATCC 27774, now we aim to reduce the size of the experimental set-up according to the specific needs of

biomedical applications. For this, thick-film strip electrodes made of carbon conductive inks deposited on

plastic supports were modified with ccNiR previously mixed with the conductive graphite ink, in the

presence of propanone or methylethylketone. Then, the enzyme electrodes were dried at 40°C or 60°C, to

simulate the curing procedure typically done after screen-printing. In this way, the biocompatibility of

ccNiR with these organic solvents and thermal treatments was evaluated and the composition of the mix

enzyme/conductive ink was optimized. The analytical performance of these electrodes was satisfactory,

with a sensitivity of 52 A.μM

-1

.cm

-2

within a linear range of 0.001 - 1 mM.

1 INTRODUCTION

The detection of nitrites in physiological fluids such

as plasma and urine is commonly used for clinical

diagnosis and has gained an increasing importance

in biomedical research. In fact, the nitrate-nitrite-NO

pathway is emerging as an important mediator of

blood flow regulation, cell signaling, energetics and

tissue responses to hypoxia (Bryan, 2005; Lundberg,

2009; Hord, 2009). Most of the strategies used for

analytical determination of NO

3

-

and NO converge

to the quantification of NO

2

-

. However, the classical

protocols for nitrite assessment lack the sensitivity

and selectivity needed for the analysis of

physiological samples (Almeida, 2010). For

example, urine test strips are routinely used for

screening nitrites in patients with infection, but

results are just qualitative as they are obtained by

visual comparison to a color chart. Plasma analysis

is much less frequent, owing to limitations of the

analytical methods, including blood sampling and

processing (Ellis, 1998). As a consequence, there is

a growing demand for improved analytical tools,

increasingly sensitive, reliable and, preferentially,

easy-to-use and inexpensive.

An alternative approach relies on the

construction of biosensing devices using stable

enzymes with high catalytic activity and specificity

for nitrite. Due to its high selectivity, turnover and

stability, the multihemic cytochrome c nitrite

reductase (ccNiR) from the sulphate reducing

bacterium Desulfovibrio desulfuricans ATCC

27774, which performs the six electron reduction of

nitrite to ammonia (Almeida, 2003), has proven to

be a promising candidate for the development of an

electrochemical nitrite biosensor (Almeida, 2007;

Chen, 2007; da Silva, 2004; Silveira 2010a,b;

Zhang, 2009).

Miniaturization is critical for both health care

and physiological studies. The screen-printing

technology has been widely used for the large-scale

32

Rodrigues M., Correia C., M. Silveira C., J. G. Moura J., Ochoteco E., Jubete E. and Gabriela Almeida M..

NITRITE BIOSENSING WITH DISPOSABLE ELECTRODE STRIPS - A Preliminary Study.

DOI: 10.5220/0003757700320036

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2012), pages 32-36

ISBN: 978-989-8425-91-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

fabrication of disposable biosensors. Besides the

portable dimensions, screen-printed electrodes

(SPEs) are low-cost and versatile in terms of formats

and materials (Jubete, 2009).

In this work, thick-film strip electrodes were

fabricated using carbon based conductive pastes

printed on plastic supports. The working electrodes

were later modified with an extra layer of the carbon

ink, previously diluted with either propanone or

methyl ethyl ketone (MEK) and mixed in different

proportions with ccNiR. The activity of ccNiR

towards nitrite after immobilization in this harsh

environment (solvents exposure and heat dry) was

evaluated by cyclic voltammetry, and has proved to

be highly satisfactory.

2 MATERIALS AND METHODS

2.1 Reagents

Acetone (propanone; 99%; b.p. 56°C) and

propanone (methylethylketone, MEK; 99%, b.p.

79°C) were from Pronalab. The remaining chemicals

were analytical grade and were used without further

purification. Solutions were prepared with deionized

(DI) water (18 MΩcm) from a Millipore MilliQ

purification system.

The graphite conductive ink was obtained from

Acheson. Alumina slurries (0.05 and 1.0 µm) were

from Buehler.

ccNiR was purified from Desulfovibrio

desulfuricans ATCC 27774 cells grown in nitrate, as

previously described by Almeida and co-workers

(Almeida, 2003).

2.2 Electrochemical Measurements

For the optimization studies, a conventional three-

electrode electrochemical cell was used, with an

Ag/AgCl reference electrode, a Pt counter electrode

(both from Radiometer) and a home-made working

electrode made of pyrolytic graphite disks (4 mm

diameter) and modified with the enzyme/ink layer.

The characterization of the optimized electrode

was performed after replacing the previous system

by carbon paste screen-printed electrodes (CPSPEs)

with a three electrode configuration (Figure 1),

including an Ag/AgCl pseudo-reference, a graphite

paste counter electrode and a graphite paste working

electrode (3.1 mm diameter). The CPSPEs were

fabricated at CIDETEC facilities, as described by

Ochoteco and co-workers (Ochoteco, 2009).

Figure 1: A screen-printed three-electrode system. (1)

working electrode; (2) reference electrode; (3)

counter-electrode.

The one-compartment electrochemical cell

containing 0.1 M KCl in 0.05 M Tris-HCl buffer, pH

7.6 as supporting electrolyte, was thoroughly purged

with Argon before each experiment. Measurements

were performed with a potentiostat Autolab PSTAT

12 (Eco-Chemie) monitored by the control and data

acquisition software GPES 4.9. The cyclic

voltammograms (CV) were plotted at room

temperature (22 ± 2°C), with a scan rate of 20 mV/s,

in the potential window [0.0; -0.8] V (vs reference

system). To evaluate the biosensors response to the

analyte (0.001 - 7 mM), the cell was successively

spiked with standard solutions of nitrite. After each

addition, the electrochemical cell was deoxygenated

and the CV was registered. The catalytic currents

(I

cat

) were measured at the inversion potential; all

values were subtracted from the non-catalytic

current recorded in the absence of nitrite (I

c

). Each

experiment was replicated two times.

2.3 Bioelectrodes Preparation

Prior to coating, the pyrolytic graphite electrodes

(PGEs) were polished with alumina slurry in cloth

pads. Then, the electrodes were thoroughly washed

with DI water and ethanol and ultrasonicated in

water for 5 min. The electrodes’ surface was further

washed with DI water and dried with compressed

air.

CPSPEs were used as produced, with no pre-

activation.

The conductive carbon inks were previously

diluted with an organic solvent (acetone or MEK) in

a 1:1 ratio and homogenised with the help of an

ultrasound bath. The inks’ suspensions were then

mixed with ccNiR in different proportions (4:1, 2:1,

1:1 and 1:2 ink/enzyme). Finally, a 5 μL drop was

placed on the surface of the working electrodes

which were cured for 20 min. inside an oven set at

40°C or 60°C. Control experiments were carried out

with no curing treatment and/or no carbon ink; in

such cases, the ccNiR layer was dried at room

1

2

3

NITRITE BIOSENSING WITH DISPOSABLE ELECTRODE STRIPS - A Preliminary Study

33

temperature.

3 RESULTS

3.1 Response to Nitrite

Regardless of the composition of the electrode

material and enzyme modifying layer, the CVs

displayed a sigmoidal shape in the presence of nitrite

(not shown), as previously observed in bare PGEs

and carbon nanotubes modified electrodes (Silveira

2010a,b). This reflects the electrocatalytic reduction

of nitrite into ammonium as a consequence of the

direct electron transfer between the electrode and

ccNiR.

In general, the plots catalytic current (I

cat

) vs

nitrite concentration could be fitted to a hyperbolic

equation, denoting a Michaelis-Menten profile. The

assessment of the analytical performance of each

bioelectrode was based on the measurement of the

following parameters: catalytic efficiency (I

max

/I

c

),

sensitivity of detection (slope of the linear range),

correlation coefficient (r

2

) and quantification range.

3.2 Temperature and Solvent Effects

Preliminary experiments were carried out in order to

check if the chemicals (organic solvents) and the

thermal treatment (curing) required for printing the

working electrode component in CPSPEs were

compatible with nitrite reductase activity. In this

regard, three different PG electrodes were modified

with i) ccNiR only, ii) ccNiR mixed with carbon ink

diluted in acetone and iii) the same as (ii) but with

an extra curing step at 60°C. As seen in Figure 2, the

maximum catalytic current (I

max

) has increased about

three times in the presence of the carbon ink. This

should be related with the resultant enlargement of

the electroactive area. Apparently, the carbon

ink/acetone composite had no critical effect on

catalytic activity.

When comparing the response profiles obtained

with or without electrode curing (both in the

presence of conductive ink), one can see that the

thermal treatment does not have a strong influence

on I

max

. On the other hand, the sensitivity of the

sensor, as given by the slope of the linear range of

the plot, decreased about 55%. This indicates that

partial protein denaturation has occurred.

3.3 Electrode Optimization

3.3.1 Enzyme/Carbon Ink Ratio

Different proportions of enzyme and carbon ink

suspended in acetone were early tested in order to

choose the best composition. The one using the

highest amount of protein (1:2 ratio, corresponding

to 3.3 μg of ccNiR) displayed the best results (not

shown) without relevant loss of ink, and was

selected for further studies.

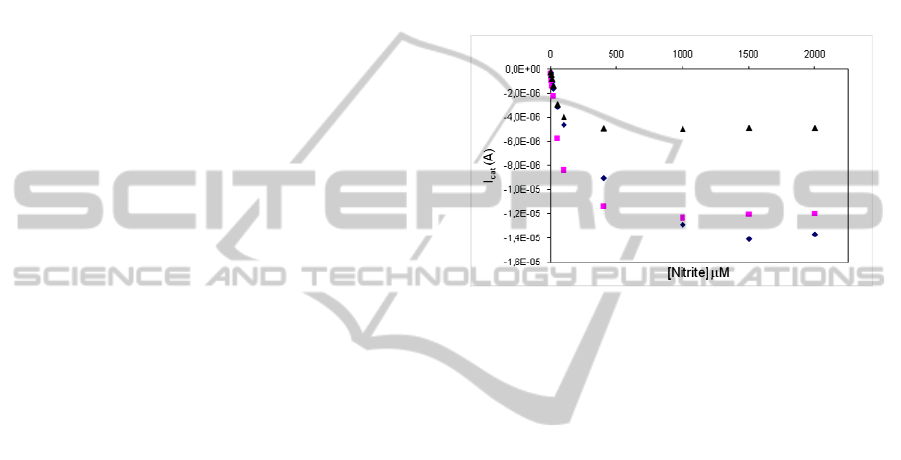

Figure 2: Electrocatalytic response to nitrite of ccNiR

(3.3 μg) modified PG electrodes: (S) without carbon

conductive ink and thermal treatment (sensitivity:

32x10

-8

A.μM

-1

.cm

-1

); () pre-mixed with the carbon

conductive ink diluted in acetone (sensitivity:

73x10

-8

A.μM

-1

.cm

-1

); (¡) pre-mixed with the carbon

conductive ink diluted in acetone and cured at 60°C

(sensitivity: 33x10

-8

A.μM

-1

.cm

-1

).

3.3.2 Selection of Organic Solvent and

Curing Temperature

Normally, inks for screen printing contain organic

solvents that are later evaporated by heating. If other

ingredients like ccNiR need to be included, it is

highly recommended to lower the viscosity of the

paint in order to facilitate the mixing process. For

this reason, prior to enzyme incorporation, the

carbon ink used in this work was diluted with two

different organic solvents - MEK or acetone. It is

worth noting that acetone is less commonly used for

inks dilution than MEK, although it has a lower

boiling point that could permit the use of lower

curing temperatures. Actually, the response to nitrite

was much higher when this solvent was used instead

of MEK (Figure 3) and, accordingly, the linear range

was also wider. Therefore, acetone has proved to be

less harmful to the protein.

In order to evaporate residual organic solvents,

most CPSPEs have to be dried thermally. Although a

temperature of 60°C is normally selected for the

curing process of those used in the present work, due

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

34

to the presence of the biocatalyst, we have also

tested the lowest permitted heating temperature, i.e.,

40°C. Interestingly, the differences on nitrite

reducing activity were generally small, except when

MEK was used for ink dilution, which generated

much lower catalytic currents. Most likely, this

solvent did not evaporate completely at 40°C,

enhancing its detrimental effect on enzyme activity.

Figure 3: Electrocatalytic response to nitrite of ccNiR

(3.3 μg) modified PG electrodes, pre-mixed with the

carbon conductive ink, prepared and treated in the

following ways: (U) diluted in MEK and cured at 40°C;

(S) diluted in MEK and cured at 60°C; ({) diluted in

acetone and cured at 60°C. (z) diluted in acetone and

cured at 40°C.

In accordance to the results obtained in this

combined study, we have selected acetone for ink

solubilization and a curing temperature of 40°C.

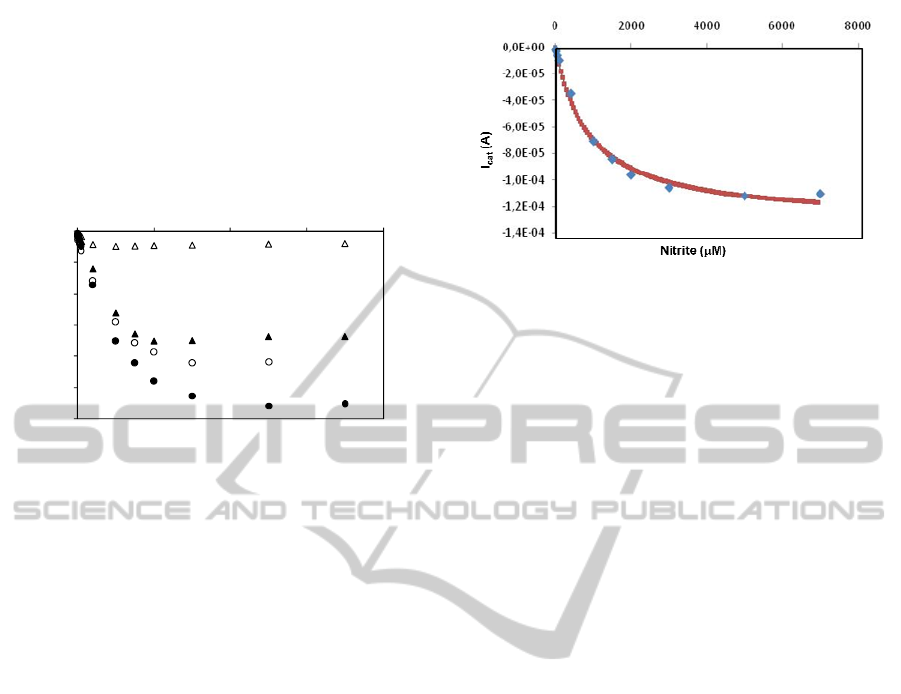

3.4 Application of Carbon Paste Screen

Printed Electrodes (CPSPEs)

Following the optimization of the ccNiR containing

conductive paints, the enzyme/carbon inks were

deposited on CPSPEs. The CVs displayed higher

background currents (not shown), which is most

likely related to the roughness of the SPEs surfaces,

generating higher capacitive currents. Nevertheless,

the analytical parameters (sensitivity: 52 A.μM

-1

.cm

-2

;

linear range: 0.001 - 1 mM) remained similar (Figure

4). The data were fitted to the Michaelis-Menten

kinetic model using the software GraphPad Prism

4.0. Accordingly, the K

m

app

is 0.9 ± 0.1 mM, which

is about 250 times higher than the value previously

determined by protein film voltammetry (Silveira,

2010c). This means that the diffusion of nitrite

within the carbon ink is a very slow process and

should be responsible for the wide linear range of

the calibration curves.

Figure 4: Nitrite response of CPSPEs modified with ccNiR

in accordance with the optimized procedure

(3.3 μg enzyme in a 1:1 mix of acetone:graphite ink;

curing temperature = 40°C). Sensitivity: 52 A.μM

-1

.cm

-2

;

linear range: 0.001 - 1 mM. The calibration curve was

fitted to a hyperbolic equation according to the Michaelis-

Menten using the GraphPad Prism program

(K

m

app

= 0.9 ± 0.1 mM; I

max

= 1.32 x 10

-4

± 0.04 x 10

-4

A;

r

2

= 9.94 x 10

-1

).

4 CONCLUSIONS

This R&D project was designed to address a critical

and growing need for real-time monitoring of nitrites

and to provide better analytical tools for its clinical

diagnosis. Our previous results have demonstrated

the feasibility of using ccNiR in the construction of

bioelectrodes for a selective nitrite analysis

(Almeida, 2007; Chen, 2007; da Silva, 2004;

Silveira 2010 a,b; Zhang, 2009). Herein we have

shown the biocompatibility of the painting materials

and the electrode curing procedure with ccNiR

activity. The success of this preliminary work opens

up the possibility of including the enzyme directly in

the printing paste used for the fabrication of thick-

film electrodes, facilitating the mass production of

easy-to-use nitrite biosensors. If coupled to a

portable potentiostat, these enzyme containing

disposable electrode strips will turn a long and

elaborated laboratory protocol into a simple task,

quickly executed onsite.

ACKNOWLEDGEMENTS

The authors thank the financial support from

Associated Laboratory REQUIMTE.

REFERENCES

Almeida, M. G., Serra, A. S., Silveira, C., Moura, J. J. G.,

2010. “Nitrite Biosensing Via Selective Enzymes – A

‐1,2E‐04

‐1,0E‐04

‐8,0E‐05

‐6,0E‐05

‐4,0E‐05

‐2,0E‐05

0,0E+00

0 2000 4000 6000 8000

I

cat

(A)

[Nitrite]μM

NITRITE BIOSENSING WITH DISPOSABLE ELECTRODE STRIPS - A Preliminary Study

35

Long But Promising Route” Sensors, 10(12) 11530-

11555; doi:10.3390/s101211530.

Almeida, M. G., Macieira, S., Gonçalves, L. L., Huber, R.,

Cunha, C. A., Romão, M. J., Costa, C., Lampreia, J.,

Moura, J. J. G., Moura I., 2003. “The Isolation and

characterization of Cytochrome c Nitrite Reductase

Subunits (NrfA and NrfH) from Desulfovibrio

desulfuricans ATCC 27774. Re-evaluation of the

spectroscopic data and redox properties”, Eur. J.

Biochem. 270, 3904-3915.

Almeida, M. G., Silveira, C. M., Moura, J. J. G., 2007.

“Biosensing Nitrite Using the System Nitrite

Redutase/Nafion/Methyl Viologen - A Voltammetric

Study” Biosens. Bioelectron. 22, 2485-2492.

Bryan, N. S., Fernandez, B. O., Bauer, S. M., Garcia-

Saura, M. F., Milsom, A. B., Rassaf, T., Maloney, R.

E., Bharti, A., Rodriguez, J., Feelisch, M., 2005.

“Nitrite is a signaling molecule and regulator of gene

expression in mammalian tissues” Nat. Chem. Biol. 1,

290-297.

Chen, H., Mousty, C., Cosnier, S., Silveira, C. Moura, J. J.

G., Almeida, M. G., 2007. “Highly Sensitive ccNiR

Biosensor Electrical-Wired by [ZnCrAQS

2

] for Nitrite

Determination” Electrochem. Comm. 9, 2240-2245.

da Silva, S., Cosnier, S., Almeida, M. G., Moura, J. J. G.,

2004. “An Efficient Poly(pyrrole)-Nitrite Reductase

Biosensor for the Mediated Detection of Nitrite”

Electrochem. Comm. 6, 404-408.

Ellis, G., Adatia, I., Yazdanpanah, M., Makela, S. K,

1998. “Nitrite and nitrate analyses: A clinical bioche-

mistry perspective”. Clin. Biochem. 31, 195-220.

Hord, N. G., Tang, Y., Bryan N. S., 2009. “Food sources

of nitrates and nitrites: The physiologic context for

potential health benefits” Am. J. Clin. Nutr. 90, 1-10.

Jubete, E., Loaiza, O. A., Ochoteco, E., Pomposo, J. A.,

Grande, H., Rodrıguez, J., 2009. “Nanotechnology: A

Tool for Improved Performance on Electrochemical

Screen-Printed (Bio)Sensors” J. Sensors, Article ID

842575, 13 pages, doi:10.1155/2009/842575.

Lundberg, J. O. et al., 2009. “Nitrate and nitrite in biology,

nutrition and therapeutics” Nature, 12, 865-869.

Ochoteco, E., Jubete, E., Pomposo, J. A., Grande, H. et al.

2009 Patent Application Number E200930539.

Silveira, C. M., Gomes, S. P., Araújo, A. N., Couto, C. M.

C. M., Montenegro, M. C. B. S. M., Silva, R., Viana,

A. S., Todorovic, S., Moura, J. J. G., Almeida, M. G.,

2010a. “An Efficient Mediatorless Biosensor for

Nitrite Determination” Biosens. Bioelectron. 25, 2026-

2032.

Silveira, C., Baur, J., Cosnier, S., Moura, J. J. G.,

Holzinger, M., Cosnier, S., Almeida, M. G., 2010b.

"Enhanced direct electron transfer of a multihemic

nitrite reductase on SWCNT modified electrodes"

Electroanalysis, 22, 2973–2978.

Silveira, C. M., Besson, S., Moura, I., Moura, J. J. G.,

Almeida, M. G., 2010c. ”Measuring the Cytochrome c

Nitrite Reductase Activity – Practical considerations

on the enzyme assays”, Bioinorg. Chem. Applic.,

Volume 2010, Article ID 634597, 8 pages,

doi:10.1155/2010/634597

Zhang, Z., Xia, S., Leonard, D., Jaffrezic-Renault, N.,

Zhang, J., Bessueille, F., Goepfert, Y. S, Wang, X.,

Chen, L., Zhu, Z., Zhao, J., Almeida, M. G., Silveira,

C. M., 2009. “A novel nitrite biosensor based on

conductometric electrode modified with cytochrome c

nitrite reductase composite membrane” Biosens.

Bioelectron. 24, 1574–1579.

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

36