DEVELOPMENT OF A MULTI-AGENT PLATFORM

FOR SUPPLY CHAIN-WIDE ORDER FULFILMENT

Roberto Domínguez Cañizares and Jose M. Framiñán

Industrial Management, School of Engineering, University of Seville,

Camino de los Descubrimientos, s/n, Isla de la Cartuja, 41092, Sevilla, Spain

Keywords: Supply Chain Management, Order Fulfilment Process, Multi-Agent System, Simulation.

Abstract: In this paper we describe an agent-based framework for modelling and simulating different processes taking

place in supply networks, resulting in a supply chain simulator called SCOPE (Sistemas COoperativos para

la Programación y Ejecución de pedidos). The framework is composed of reusable elements (agents and

objects) allowing easy modelling of real-scale supply chains, with different companies and products. Each

company in the model can use different policies and parameters for the different business functions. The

framework is implemented using Swarm. Furthermore, its generic and modular structure allows to easily

adding new and more complex functions for the agents. The final aim of SCOPE is to serve as a testbed to

implement and analyse the effects of different management decisions related to order fulfilment over real-

scale supply chains. SCOPE has been validated using different supply chains described in the literature.

1 INTRODUCTION

In today's dynamic and complex manufacturing

environment, an important enabler in gaining

competitiveness is the ability of a company to

respond quickly and effectively to satisfy customers

(Framinan, 2009) via an effective Order Fulfilment

Process (OFP), which starts with receiving orders

from the customers and ends with having the

finished goods delivered (Lin et al., 1998).

OFP is a complex process because it is usually

composed of several activities, executed by different

functional entities heavily interdependent among the

tasks, resources, and agents involved in the process

(Lin and Shaw, 1998). Furthermore, manufacturing

practice is shifting towards the outsourcing

paradigm, so OFP activities may take place across

different companies, thus hindering the centralized

planning and scheduling (Lin and Lin, 2006).

Therefore, OFP is likely to be executed over a

Supply Chain Network (SCN).

Available-To-Promise (ATP) systems refer to a

variety of methods and tools to enhance the

responsiveness of order promising and the reliability

of order fulfillment (Framinan, 2009). It is difficult

to predict the effects of new management policies

and strategies to improve OFP on a real SCN, but at

the same time this may be of great benefit for

companies. One of the most popular approaches is

using analytic models, like linear programming,

integer/mixed integer programming to analyze the

performance of a SCN. However, a SCN involves

stochasticity and uncertainty features not suited for

these analytical models. In addition, analytical

models may not be solved due to their complexity

and nonlinearity. Simulation, especially the multi-

agent-based distributed simulation, turns out to be

one of the most effective tools to model and analyze

SCNs (Long et al., 2011).

Because of its ease for modeling and

comprehensive description of complex systems

(particularly its capability of handling their

dynamics and stochastic behaviour), simulation has

been widely used in SCN management. There is a

great interest in modeling SCNs as Agent-Based

Systems (ABS) because there is a natural

correspondence between SCN participants and

agents in a simulation model. In addition, SCNs tend

to be decentralized systems with the participants

acting independently, according to their own

interests and policies (Long et al., 2011). Thus, the

use of an agent-based approach is suitable to model

and simulate SCNs (Chatfield et al., 2007).

The rest of this paper is summarized as follows:

Section 2 describes the framework, Section 3

describes the implementation of the framework,

203

Domínguez Cañizares R. and M. Framiñán J..

DEVELOPMENT OF A MULTI-AGENT PLATFORM FOR SUPPLY CHAIN-WIDE ORDER FULFILMENT.

DOI: 10.5220/0003747802030208

In Proceedings of the 4th International Conference on Agents and Artificial Intelligence (ICAART-2012), pages 203-208

ISBN: 978-989-8425-96-6

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

Section 4 is validation of the simulation platform

obtained (SCOPE) and Section 5 is the conclusion.

2 FRAMEWORK

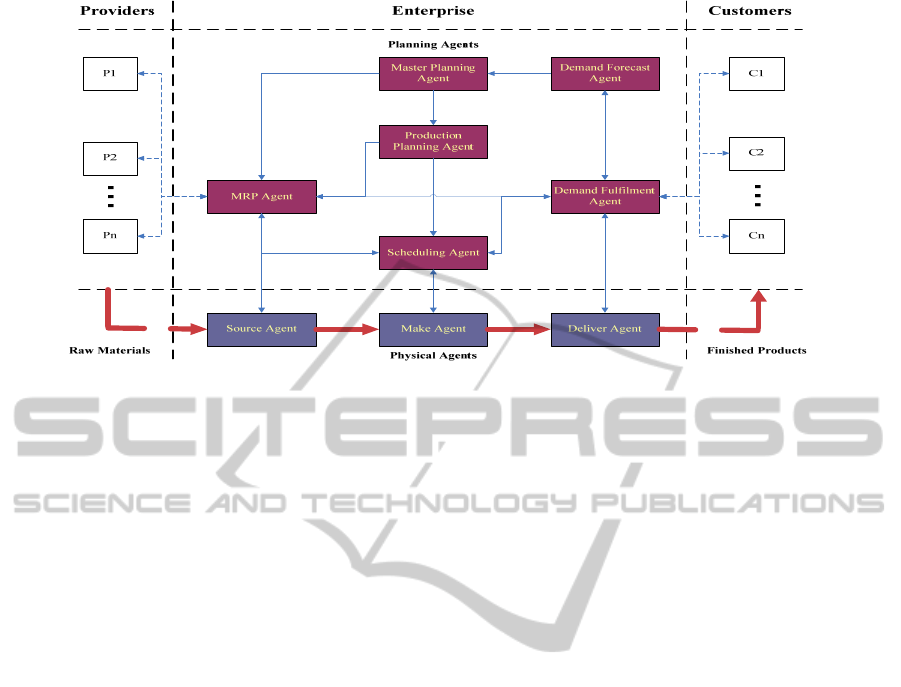

Real SCNs have multiple layers of abstraction (Lin

et al., 2002), as they can be studied in different

levels of details. Thus, we model two different

layers: an Enterprise Layer containing all enterprises

in the SCN, and a Functional Layer, including the

main functions/departments of the enterprises. This

structure will allow studying inter-enterprises

relationships and intra-enterprises relationships.

The Enterprise Layer is modelled by one generic

and reusable agent (Enterprise Agent) composed of

several functional agents modelling physical and

planning tasks. By doing this, every department in

the enterprise is encapsulated in one agent, with its

characteristics of independency and autonomy, and

being able to take its own decisions.

A central feature of ABS is the bottom-up

methodology to construct a model. In this

methodology the user assumes that he/she cannot

understand the whole phenomenon of interest but

can observe, at a micro level, specific activities and

processes, and tries to understand their behaviour

and their objectives. These agents interact and

communicate with other agents and they join to form

a coherent whole on a macro level (Nilsson and

Darley, 2006). This whole is the emergent

behaviour, which cannot be predicted in advance.

In accordance with the bottom-up methodology,

SCN and the Enterprise Agent are not explicitly

modelled. Instead, the Enterprise Agent behaviour

emerges from its components’ behaviours (i.e.,

functional agents), which are easier to understand

and model. Similarly, the global SCN behaviour

emerges from that of its components enterprises.

2.1 Enterprise Agent

The Enterprise Agent is able to model any kind of

company in the SCN. The composition of their

functional agents determines its behaviour. To

simplify the Enterprise Agent configuration we

identify four roles of the companies in the SCN.

Companies with similar functions (in terms of

functional agents) belong to the same category.

These four role categories and their main

characteristics are summarized in the Table 1.

To model a new company, it is enough to select

one of the roles from Table 1 for the Enterprise

Agent and automatically the required functional

agents are assigned to it. The basic agents always

belong to the Enterprise Agent for the selected role,

while the optional agents are selected depending on

the enterprise characteristics.

2.2 Functional Agents

A good design of the functional agents is crucial

because they must capture the internal dynamic of a

real enterprise and should model the key aspects of

enterprise management. We base our choice in the

level 1 of the SCOR model (SCC, 2006) and the

literature revised.

Level 1 of the SCOR model summarises business

operations in five main activities: Plan, Source,

Make, Deliver and Return. Activities are divided in

two groups: Physical activities (Source, Make,

Deliver and Return) to manage the physical

resources of the enterprise, and planning activities

(Plan) to make decisions. Each one of the physical

activities (with the exception of Return) is modelled

by one agent, so there are three physical agents:

Table 1: Roles of the Enterprise Agent.

Roles in

Framework

Description Examples types Basic Agents Optional Agents

Manufacturer

The enterprise is in the SCN and

has manufacturing or assembly

capacity

Manufacturer,

Assembler

Demand Fulfillment, MRP,

Scheduling, Source, Make,

Deliver

Demand Forecast,

Master Planning,

Production Planning

Intermediate

The enterprise is in the SCN and

has not manufacturing or

assembly capacity

Distributor,

Wholesaler,

Retailer

Demand Fulfillment, MRP,

Deliver

Demand Forecast

External

Provider

Any enterprise who provide

something to the SCN, but it’s

out of the SCN

Provider

Demand Fulfillment,

Deliver

No

External

Customer

Any enterprise who demand

something to the SCN, but it’s

out of the SCN

Customer MRP, Source No

ICAART 2012 - International Conference on Agents and Artificial Intelligence

204

Figure 1: Multi-Agent Framework: general configuration of the Enterprise Agent.

Source Agent, Make Agent and Deliver Agent. The

Return activity is implicitly implemented by

allowing the Deliver Agent to return products or

receive returned products. According to the Supply

Chain Planning Matrix in Stadtler (2005), the Plan

activity has been divided into six planning functions,

being each of these functions carried out by a

different agent: Demand Fulfilment Agent, Demand

Forecast Agent, Master Planning Agent, Production

Planning Agent, MRP (Material Resource Planning)

Agent and Scheduling Agent.

The enterprise is then modelled as a mix of

planning agents and physical agents. Planning agents

store management policies and take the main

decisions. Physical agents control the physical

resources of the enterprise and share information

with planning agents. The overall configuration of

the Enterprise Agent, with all its functional agents is

shown in Figure 1. A brief description of the agents

is presented below:

Source Agent, to handle the arrival and

storage of raw materials, and its delivery to

the manufacturing process when needed.

Make Agent, to monitor the manufacturing

process by controlling machines and the flow

of jobs in the shop floor.

Deliver Agent, to handle the arrival and

storage of finished products, and the

delivering of orders to customers.

Demand Fulfillment Agent, in charge of

demand management and inventory control. It

checks incoming RFQs (Request for

Quotations) from customers and quotes the

due dates. If the order is accepted, it tries to

fulfill them from inventory, if available. If

inventory is not enough, it sends a production

order (a Job) to the Scheduling Agent if the

enterprise is a manufacturer. Otherwise it

sends a purchase order to the MRP Agent.

Demand Forecast Agent: This agent requests

the enterprise demand historical data to the

Demand Fulfillment Agent in every forecast

period. Then it forecasts the demand for each

product in the next periods using a forecasting

rule (like Simple Moving Average, etc.).

Master Planning Agent: In every planning

period, this agent uses forecast information

from the Demand Forecast Agent and

generates an aggregate Master Plan for the

products concepts defined by the company by

solving a linear programming model (that

includes capacity and inventory restrictions, as

well as production and inventory holding

costs), obtaining the production needs per

product concept for each period.

Production Planning Agent: It receives the

Master Plan and takes only the production

needs for the first planning period. Then it

generates a detailed Production Plan solving

one model for each product concept and

obtaining the production needs for the final

products to accomplish the Master Plan.

MRP Agent: It creates a detailed material plan

to fulfil the Master Plan. If there is no Master

Plan, it takes control of the raw material

inventory levels by using some inventory

policy. This agent is the one in charge of the

purchasing functionality in the enterprise.

Scheduling Agent: This agent schedules

production orders (Jobs) coming from the

Production Planning/Demand Fulfillment

DEVELOPMENT OF A MULTI-AGENT PLATFORM FOR SUPPLY CHAIN-WIDE ORDER FULFILMENT

205

Agent by using first some priority rule to

create an initial solution, and then a heuristic

to improve the initial solution according to

certain objective. It also calculates starting and

ending times for each job (so it can help the

Demand Fulfillment Agent for due date

calculation), generating a detailed schedule.

According to this schedule, at the starting time

of each job it sends the job information to the

Make Agent to start its production.

3 IMPLEMENTATION

SCOPE has been implemented in Swarm (Java

version) and NetBeans IDE 6.7 as implementation

framework. Swarm is a multi-agent software

platform for the simulation of complex adaptive

systems (Minar et al., 1996). It provides object

oriented libraries of reusable components for

building models and analyzing, displaying, and

controlling experiments on those models. Swarm is

suitable for modeling SCN (Lin et al., 1998). In Lin

et al., (2002) we can see a comparison between

SCN’s features and Swarm. Furthermore, models are

coded in Java, so low-level functions can be added.

We have considered other platforms for the

implementation of our framework, such as NetLogo

or Repast. NetLogo stands out for its ease of use, but

it is basically designed for mobile agents acting

concurrently on a grid space with behaviour

dominated by local interactions over short times, and

that are not extremely complex (Railsback et al.,

2006). Repast was initially conceived for

implementing Swarm in Java. However, it does not

implement swarms, which are very helpful for

organizing models. Furthermore the schedule

executes top-level actions in randomized order

(which is not desirable), while Swarm allows a

precise control of the sequence of actions.

In our model we have four different types of

objects, nine agents and three swarms. Objects are

information containers created by the agents, who

use them and send them to other agents. A typical

object is represented by a java class, where all

variables and methods are defined. The objects

available are: RFQ, Job, Product and Machine.

Agents are the basic elements in the simulation

model. They represent the main functions in the

enterprise (functional agents in the framework).

Their behavior is modeled by writing methods.

Information is passed by arguments, which makes

easy to add new capabilities to the agents, by simply

adding new methods, or overwriting existing ones. A

typical agent in our model is represented by a java

class that extends the Agent class in Swarm. A

pseudo code example is shown below:

Public class AgentName extends

SwarmObjectImpl {

//Internal Variables

Private Type name1;

Private Type name2;

...

//Constructor

Public AgentName (Type name1, Type

name2,...) {

this.name1=name1;

this.name2=name2;

...

}

/*Methods: define behaviours and

abilities of the agent*/

Public Type behaviour1 (Type name3) {...}

Public void behaviour2 () {...}

...

}

Swarms are agent’s containers with schedules of

actions. The three swarms in the model are the

following:

Enterprise: this is the main swarm, and it

serves to model an entire enterprise. It is

formed by a combination of the nine types of

agents described before and contains the

schedules for all these agents, controlling their

actions. The behaviour of the enterprise

swarm is defined by the emergent phenomena

of the agents inside themselves.

Model: it models the SCN environment, and it

contains all the enterprises.

Observer: it contains the model swarm and

special methods to present all relevant

information from the agents in the model

swarm, for a post-simulation analysis.

For solving the planning models included in the

Master Planning and Production Planning agents,

SCOPE can be connected with Gurobi solver

through a special library for Java. Gurobi is a

commercial software package for solving large-scale

mixed-integer linear optimization problems.

4 VALIDATION

In order to validate SCOPE we have looked into the

literature for SCNs modeled and simulated by other

authors and have compared their results with those

provided by our platform. Particularly, in Chatfield

et al. (2004) their Simulator for Integrated Supply

Chain Operations (SISCO) is validated by

comparing their results with those by Chen et al.

(2000) and Dejonckheere et al. (2003). Therefore,

ICAART 2012 - International Conference on Agents and Artificial Intelligence

206

we validate SCOPE using the same two scenarios as

in Chatfield et al. (2004), and simulate a third

scenario reproducing some of the experiments

conducted in Chatfield et al. (2004) after the

validation of SISCO.

The SCN’s structure is the same for the first two

scenarios: Only one product, and SCN structured by

a serial formation of customer, retailer, wholesaler,

distributor, and factory levels. The lower node

places orders with the next upper node and this node

fills these orders. The customer does not fill orders

and the factory places orders with an outside

supplier. There are other features that remain

identical for both scenarios, like the use of a fixed

lead time, or the forecast rule and inventory policy.

For more details see Chatfield et al. (2004).

4.1 Scenario 1: Chen et al. (2000)

Chen et al. calculated a statistical lower bound for

the variance amplification in the SCN described

above, and obtained the result shown in equation (1).

(

)

()

≥1+

2

+

2

,∀

(1)

We have obtained very similar results to those

offered by SISCO, although we found a greater

amplification at upper SCN stages than in Chen et

al. (2000). Chatfield et al. justify these results

arguing that the bounds provided by Chen et al. do

not account for interactions and interdependencies

present in a multi-stage system. To test this, they

perform a “sequential pairs execution” simulation, in

which they broke the supply chain into four two-

node sub-chains (customer-retailer, retailer-

wholesaler, wholesaler - distributor, distributor -

factory). Then, they simulate each sub-chain using

the ordering mean and standard deviation obtained

from the simulation of the previous sub-chain. We

reproduced this new scenario, obtaining the results

in Table 2, which are extremely close to those

predicted by Chen et al., and SISCO.

Table 2: Amplification Ratio for Chen et al. (2000),

“sequential pairs execution” experiment. Parameters:

demand rate =N (50,20

2

); protection time = L+R = 4+1

= 5; MA(15) forecasting; simulation time = 5200 time

periods (200 for warm-up).

Enterprise Chen et al. SISCO SCOPE

Retailer

1.89

1.90

1.90

Wholesaler

3.57 3.59 3.53

Distributor 6.74

6.70 6.66

Factory 12.73

12.84 12.58

4.2 Scenario 2: Dejonckheere et al.

(2003)

These authors used a Control Engineering

methodology to study the variance amplification in

the SCN described before, and obtained the result

shown in equation (2). The results for this scenario

are summarized in Table 3, where it is possible to

notice that SCOPE performs very similar to SISCO

and to Dejonckheere et al. (2003).

=

−2−+2

+

+

(2)

Table 3: Amplification Ratio for Dejonckheere et al.

(2003). Parameters: demand rate =

N

(100,10

2

);

protection time = L+R = 3+2 = 5; MA(19) forecasting;

simulation time = 5200 time periods (200 for warm-up).

Enterprise Dejonckheere

et al.

SISCO SCOPE

Retailer

1.67

1.67

1.71

Wholesaler

2.99 2.99 3.10

Distributor 5.72

5.72 5.96

Factory 11.43

11.43 11.93

4.3 Scenario 3: Chatfield et al. (2004)

After the validation of SISCO these authors studied

the impact of information sharing and different

degrees of information quality on the Bullwhip

Effect when the lead time between companies is

stochastic. The SCN used is similar to the one used

in the previous scenarios, with only some

differences like the mentioned stochastic lead time

or the inventory policy used (see Chatfield et al.

2004 for more details). We have used SCOPE to

reproduce two of these experiments. The first

experiment analyzes the influence of different

information quality levels on the Bullwhip Effect for

a lead time c.v. = 0.50. The results obtained by

SCOPE (Figure 2) are identical to the results

obtained by SISCO in Chatfield et al. (2004). A

second experiment analyzes the impact of the

variance of the lead time on the standard deviation

of orders for a given information quality level.

Again the results obtained by SCOPE were identical

to those by SISCO. Therefore we can conclude that

the validation of SCOPE is successful.

DEVELOPMENT OF A MULTI-AGENT PLATFORM FOR SUPPLY CHAIN-WIDE ORDER FULFILMENT

207

Figure 2: SCOPE results for Scenario 3.

5 CONCLUSIONS

We have developed SCOPE, a framework with a

modular design for SCN simulation and analysis.

This tool may help SCN managers and researchers

to better understand how a given SCN configuration

performs in the presence of external and/or internal

disturbances. SCOPE is completely open for

improvement, which can be done in several ways:

New functions, i.e. more policies, planning

models, heuristics methods, priority rules,

forecast methods, etc.

New behaviours in order to have agents more

proactive and with negotiation abilities.

Including a User Interface.

Future work includes the following lines:

Studying the Bullwhip Effect and optimizing

inventory policies when there are multiple

Providers, each one providing different raw

materials with different stochastic lead times.

Testing up-to-date heuristic rules for

scheduling. Simulation of full-scale SCNs and

analysis of the impact that these have on lead

times and customer satisfaction when they are

implemented at different levels of the SCN.

Studying different policies for purchase

selection, giving to the agents the ability of

selecting the best offer in each purchase and

analyzing their individual and global benefits.

REFERENCES

Chatfield, D., Kim, J., Harrison, T., Hayya, J., 2004. The

Bullwhip Effect—Impact of Stochastic Lead Time, In-

formation Quality, and Information Sharing: A Simu-

lation Study. Production and Operations Management,

Vol. 13(4), pp. 340-353.

Chatfield, D., Hayya, J., Harrison, T., 2007. A multi-for-

malism architecture for agent-based, order-centric

supply chain simulation. Simulation Modelling Pra-

ctice and Theory, Vol. 15(2), pp. 153-174.

Chen, F., Drezner, Z., Ryan, J., Simchi-Levi, D., 2000.

Quantifying the bullwhip effect in a simple supply

chain: the impact of forecasting, lead times, and infor-

mation. Management Science, Vol. 46(3), pp. 436-

443.

Dejonckheere, J., Disney, S., Lambrecht, M., Towill, D.,

2003. The impact of information enrichment on the

Bullwhip effect in supply chains: A control enginee-

ring perspective. European Journal of Operational Re-

search, Vol. 153, pp. 727-750.

Framinan, J. M, 2009. Managing resources for order pro-

mising in Available-To-Promise (ATP) systems: A

simulation study. International Conference on Indus-

trial Engineering and Systems Management.

Lin, F.-R., Tan, G. W., Shaw, M. J., 1998. Modeling

Supply-Chain Networks by a Multi-Agent System. Pro-

ceedings of the Hawaii International Conference on

System Sciences, Vol. 5, pp. 105-114.

Lin, F.-R., Shaw, M., 1998. Reengineering the Order Ful-

fillment Process in Supply Chain Networks. Interna-

tional Journal of Flexible Manufacturing Systems,

Vol. 10 (3), pp. 197-229.

Lin, F.-R., Huang, S.-H., Lin, S.-C, 2002. Effects of Infor-

mation Sharing on Supply Chain Performance in Ele-

ctronic Commerce. IEEE Transactions on Enginee-

ring Management, Vol. 49 (3), pp. 258-268.

Lin, F.-r., Lin, Y., 2006. Integrating multi-agent nego-

tiation to resolve constraints in fulfilling supply chain

orders. Electronic Commerce Research and Appli-

cations, Vol. 5(4), pp. 313-322.

Long, Q., Lin, J., Sun, Z., 2011. Modeling and distributed

simulation of supply chain with a multi-agent plat-

form. International Journal of Advanced Manufactu-

ring Technology, pp. 1-12.

Minar, N., Burkhart, R., Langton, C., Askenazi, M., 1996.

The Swarm simulation system: A toolkit for building

multi-agent simulations. Working Paper 96-06-042,

Santa Fe Institute, Santa Fe.

Nilsson, F., Darley, V., 2006. On complex adaptive sys-

tems and agent-based modelling for improving deci-

sion-making in manufacturing and logistics settings:

Experiences from a packaging company. International

Journal of Operations and Production Management,

Vol. 26 (12), pp. 1351-1373.

Railsback, S., Lytinen, S., Jackson, S., 2006. Agent-based

Simulation Platforms: Review and Development Reco-

mmendations. Simulation, Vol. 82(9), pp. 609-623.

SCC, 2006. SCOR v8.0. Supply Chain Council, Inc,

Washington.

Stadtler, H., 2005. Supply chain management and advan-

ced planning - Basics, overview and challenges. Euro-

pean Journal of Operational Research, Vol. 163 (3),

pp. 575-588.

ICAART 2012 - International Conference on Agents and Artificial Intelligence

208