ENGINE CALIBRATION PROCESS OPTIMIZATION

Erica Klampfl, Jenny Lee, David Dronzkowski and Kacie Theisen

Ford Research & Advanced Engineering, 2101 Village Road, Dearborn, MI, U.S.A.

Keywords:

Set-covering, Binary integer programming, Engine calibration.

Abstract:

Before an engine can be scheduled in the Product Development cycle for inclusion in a vehicle, it must be

calibrated in such a way that it satisfies a variety of regulatory tests over a range of conditions. The current

engine calibration process involves conducting a design of experiments at a representative number of steady

state points in order to satisfy all required regulatory tests: test engineers use a standard 16 × 16 grid with

standard grid spacing and then conduct a design of experiments on a subset of those points - about 120 of

them. This work explores how to reduce the engine calibration process time by finding the best 16× 16 grid

choice (i.e. the best spacing on both the engine speed and torque axes) and the minimum number of points

on the grid to test in order to satisfy regulatory constraints around NO

X

, particulate matter, noise, and fuel

consumption. Our proposed method models the problem as a Binary Integer Program that simultaneously

selects the best grid spacing and optimized number of points to test, while guaranteeing that all specified

constraints hold. We present an example that demonstrates how we can reduce the number of necessary test

points by approximately 56%.

1 INTRODUCTION

As vehicle emission and fuel economy standards con-

tinue to tighten, manufacturers respond by develop-

ing increasingly more complex engine systems with

advanced control strategies. The process of calibrat-

ing such an engine (i.e. assigning the desired val-

ues to control parameters) quickly becomes a daunt-

ing task for calibration engineers. In the case of a

modern internal combustion engine that may have

six or more inputs (e.g. injection timings, injec-

tion quantities, intake manifold pressure, and ex-

haust gas recirculation rate), generating data for the

calibration task is a time consuming and costly en-

deavor. If we consider the simple case where the re-

sponse of the engine could be reasonably modeled

with a quadratic function (i.e. each control factor

can be understood by using three settings), and the

engine speed and load regime (i.e. the range of en-

gine rotational speed and available output torque) are

each segmented by 16 grid quadrants, then the cal-

ibration engineer would be need to run 16

2

× 6

3

=

256×4,096= 55,296 test points: this is derived from

the (number of quadrants)

engine speed×torque

× (number

of inputs)

number of settings

. At roughly 5 minutes per

test point, data collection alone would take over six

months! Confound this with the fact that calibrations

must be developed for different operating conditions

and engine operation modes, and the product devel-

opment timeline quickly becomes uncompetitive.

There has been significant work using design

of experiment (DoE) and mathematical optimization

techniques to minimize the amount of input data

needed for every given speed and load combina-

tion (e.g. (Yoshida et al., 2011), (Maloney, 2009),

(Castagn´e et al., 2008), and (Langou¨et et al., 2008)):

the goal is to reduce the number of inputcombinations

to some fraction of the possible combination of in-

puts and settings (e.g. 6

3

= 4, 096 combinations when

there are six inputs and three settings). However, this

work does not address on which of the 16

2

= 256

speed and load combinations (i.e. test points) a cali-

bration engineer should focus their efforts, as it is not

feasible to consider every combination. This selection

of test points needs to be determined in such a way to

satisfy testing of typical transient drive cycles needed

to pass certification (i.e. the Environmental Protec-

tion Agency (EPA) Federal Test Procedure (FTP) 75

test cycle (EPA, 1977)).

Steady state (SS) engine development consists of

maintaining constant speed and load for prolonged

periods of time (e.g. five minutes or more). This is

not, however, typical of how most vehicle owners op-

erate their vehicles. Vehicles are usually driven in

335

Klampfl E., Lee J., Dronzkowski D. and Theisen K..

ENGINE CALIBRATION PROCESS OPTIMIZATION.

DOI: 10.5220/0003695603350341

In Proceedings of the 1st International Conference on Operations Research and Enterprise Systems (ICORES-2012), pages 335-341

ISBN: 978-989-8425-97-3

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

a transient manner with engine speed and load con-

stantly changing with pedal position. The transient

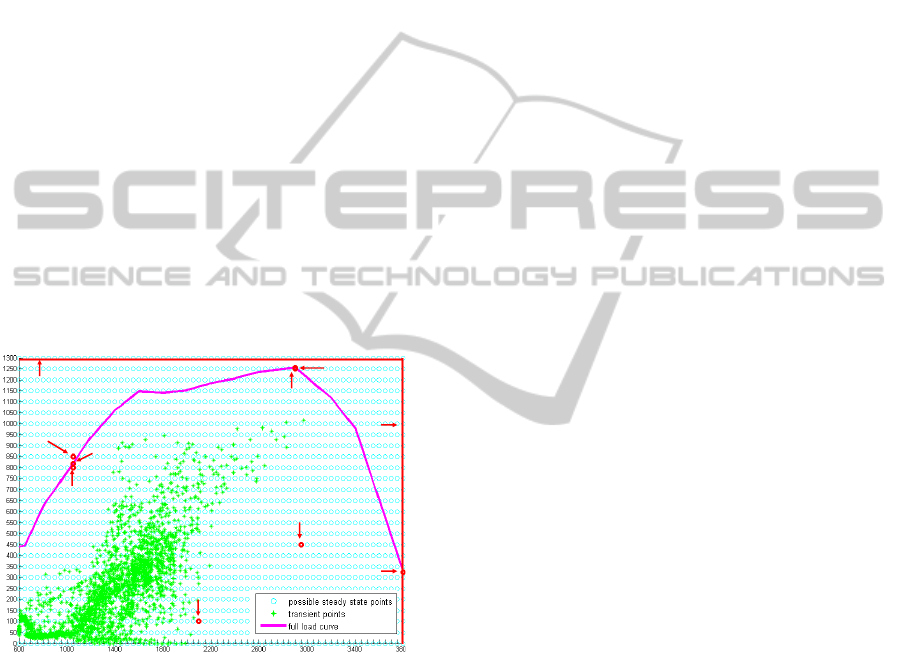

test in Figure 1 is a discretized version of an FTP test,

but note that the time spent at any of these points is

less than one second.

Figure 1 illustrates a conventional 16 × 16 grid

(calibration table points), a discretized representation

of a transient drive cycle (FTP74 Test Points), typi-

cal engine calibration test points, and an engine’s full

load curve (FLC). The transient drive cycle, usually

mandated by a regulatory agency such as the EPA,

is intended to represent a “typical” vehicle’s driving

pattern. The engine calibration test points are usually

a subset of the 256 possible speed and load combina-

tions discussed above. The FLC essentially represents

the output capability of the engine. The typical engine

test points denoted by circles in Figure 1 include all

points directly above and below the FLC, all points on

the zero axis, and every other grid point. The current

process involves performing some level of calibration

work: in-vehicle idle validation for zero load points

for idle and off-idle performance, set point mapping

at the FLC to ensure hardware limits are maintained,

and a DoE at selected points to ensure emissions com-

pliance and minimize fuel consumption. The work

included in this paper is an attempt to minimize the

number of speed/load points to test and to find the

best grid location for these points instead of always

considering a fixed subset of points as demonstrated

by the calibration test points in Figure 1. The goal

is to expedite the product development life-cycle and

significantly reduce testing costs.

400 800 1200 1600 2000 2400 2800 3200 3600 4000

Engine Speed [RPM]

Torque [Nm]

0

200

400

600

800

1000

1200

1400

Full Load Curve

FTP74 Test Points

Calibration Table Points

Calibration Test Points

Figure 1: Typical engine operating regime.

2 PROBLEM FORMULATION

We model this problem as an Binary Integer Pro-

gram (BIP), where all functions are linear, and all

decision variables are binary. This problem is re-

lated to set-covering problems (Balas and Padberg,

1972), (Wolsey, 1998), where we find the minimum-

cost cover. However, in the traditional set covering

problems, the points from which to determine the

cover are pre-defined. In our problem, we have to

simultaneously determine both the points from which

to select the cover (i.e. which SS points will be in the

grid) and the best cover (i.e. which SS points we will

test). We consider that a transient point or SS point

not selected in the grid is covered by a selected SS

point if it is within a certain distance to any selected

SS point.

2.1 Inputs

The inputs below describe the necessary information

to run the model: several are illustrated in Figure 2.

E

s

= engine speed starting point = min

k

{FLE

k

}.

E

e

= engine speed ending point = max

k

{FLE

k

}.

T

s

= torque starting point.

T

e

= torque ending point = max

k

{FLTU

k

}.

p = length/width dimensions of final grid.

GX

min

= minimum allowed for the grid to be spaced

in the engine speed direction.

GY

min

= minimum allowed for the grid to be spaced

in the torque direction.

q = number of possible grid points on x-axis

r = number of possible grid points on y-axis

n = q×r number of possible SS points.

m = number of transient points.

K = {1,.. . ,q} : set of grid point indices on x-axis.

R = {1,.. . ,r} : set of grid point indices on y-axis.

S = {1,.. . ,n} : set of possible SS points.

I = {1,.. . ,m} : set of transient points.

dt

ij

= distance between transient point i ∈ I and

possible SS point j ∈ S.

ds

j

1

j

2

= distance between two SS points j

1

, j

2

∈ S.

DT

max

= max distance allowed between a transient

point and its closest selected SS point.

DS

max

= max distance allowed between a SS point

and its closest selected SS point.

DX

max

= max grid spacing in x direction.

DY

max

= max grid spacing in y direction.

E

j

= engine speed j ∈ S.

T

j

= torque j ∈ S.

FE

max

= max engine speed value of FLC.

FT

max

= max torque value of FLC.

FLE

k

= FLC engine speed value ∀ k ∈ K.

FLT

k

= FLC torque value ∀ k ∈ K.

FLTU

k

= FLC torque upper value ∀ k ∈ K.

FLTD

k

= FLC torque lower value ∀ k ∈ K.

We define the m× n incidence matrix A and n× n

incidence matrix B as follows

a

ij

=

1 if dt

ij

≤ DT

max

0 otherwise

∀ i ∈ I and j ∈ S

ICORES 2012 - 1st International Conference on Operations Research and Enterprise Systems

336

b

j

1

j

2

=

1 if ds

j

1

j

2

≤ DS

max

0 otherwise

∀ i, j ∈ S

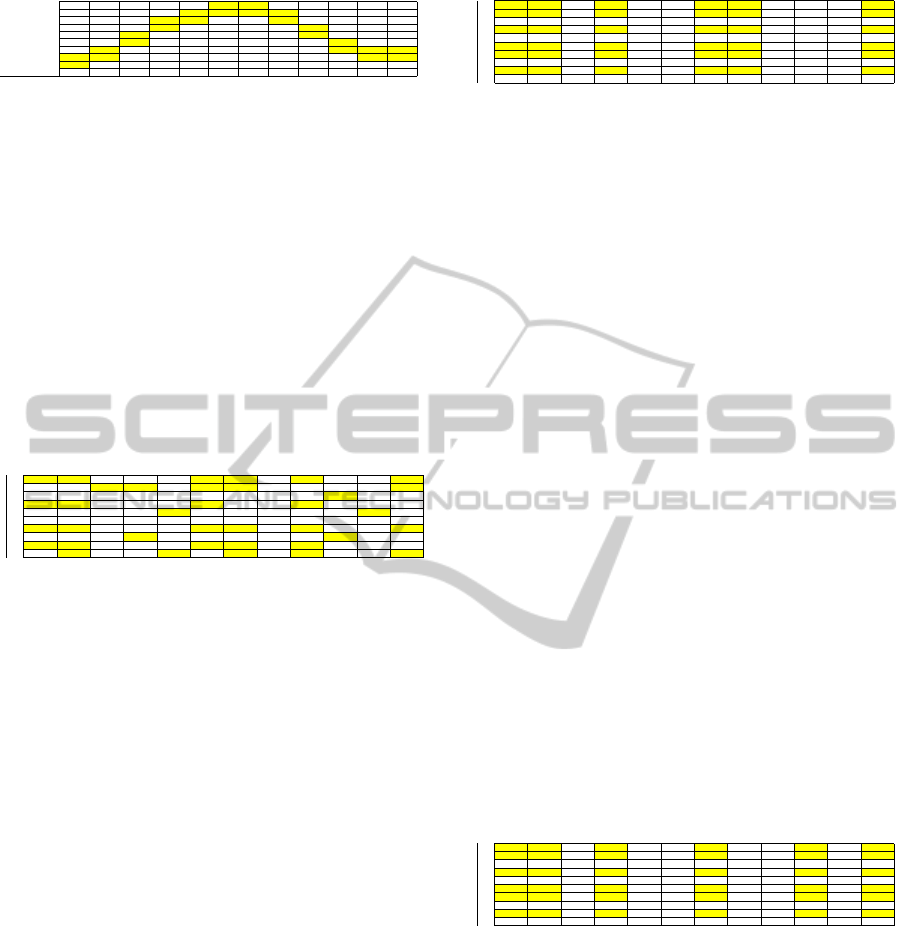

Figure 2 is illustrative of many of the input pa-

rameters. It shows the FLC on the grid of all pos-

sible SS points, which are denoted by circles. The

transient points are superimposed on this figure and

are denoted by stars. The torque value, T

e

= 1300

TRQ, corresponds to the SS point that is directly

above the highest point on the FLC. In this figure,

FT

max

= 1255 TRQ is just slightly above the pos-

sible SS point, x

1897

, which has a torque value of

1250; hence, T

e

is giventhe next highest torque value,

1300 TRQ. There are a total of n = 1755 possible SS

points. In our implementation, the indexing scheme

for each possible SS point starts from the bottom left

corner of the grid and continues up from left to right

(see Figure 3). Each possible SS point has an asso-

ciated engine speed and torque, but is not indexed

over engine speed and torque. For example, in Fig-

ure 2 x

161

is a SS point with an engine speed, E

161

,

and a torque, T

161

, where (E

161

,T

161

) = (2100,100).

Also shown in the Figure are FE

max

= 3800 RPM,

E

e

= 3800 RPM, (FLE

10

,FLT

10

) = (1050,818.25),

FLTD

10

= 800 TRQ, and FLTU

10

= 850 TRQ.

Engine Speed (RPM)

Torque (TRQ)

T

e

FLTU

10

(FLE

10

,FLT

10

)

FLTU

10

(E

161

, T

161

)

(E

161

, T

161

)

x

1897

FT

max

FE

max

E

e

Figure 2: This figure shows all possible grid points in the

engine speed and torque space labeled with example input

parameters.

2.2 Variables

In this section, we introduce the decision variables for

the model. The first binary variable will determine if a

possible SS point will be included in the 16× 16 grid.

x

j

=

1 if j ∈ S is selected to be a SS

point in the 16× 16 grid

0 otherwise

The second binary variable will determine which

of the SS points that are selected to be included in the

16× 16 grid will have a DoE run at that point. These

selected points will have to cover the other grid points

for which a DoE will not be run and cover all transient

points:

y

j

=

1 if j ∈ S is a SS point selected for

testing

0 otherwise

2.3 Objective Function

Our objective function is currently to minimize the

size of the cover. Since we consider all points in the

cover of equal value, we are just minimizing the num-

ber of SS points needed to cover the transient points

and all other possible SS points. Our current objective

is to minimize the cover points, which is reflected in

min

∑

j∈S

y

j

. (1)

The objective function could easily account for

different costs associated with each selected point to

include things such as the actual distance between the

cover of SS points and the points it is covering. This

would capture the case where the greater the distance

between the point in the cover and the points it is cov-

ering, the worse the cover. For example, this could

accommodate if the error rate for interpolating a SS

value was worse for a greater distance between the

interpolated point and its cover point. However, this

could increase the number of tested points.

2.4 Constraints

This section describes the cover constraints, as well as

additional constraints that capture certain points that

must be included in the cover, grid spacing require-

ments, and constraints to ensure the resulting grid is

16 × 16. To illustrate these constraints, we introduce

a small example, where p = 6, E

s

= 500, E

e

= 1200,

T

s

= 0, T

e

= 450, GX

min

= 50, GY

min

= 50, DX

max

=

150, and DY

max

= 150. There are q = 12 possible

engine speeds from which to choose for the grid in

the x-direction and r = 10 possible torque values from

which to choose for the grid in the y direction. Note

that in this example we need to choose a 6 × 6 grid

(i.e. 36 points) from a total of 120 points, whereas in

the typical problem we need to choose 256 points to

form the grid from a total of 1755 points. Figure 3

shows the indexing scheme for this size problem: the

highlighted indices are the grid points directly above

and below the FLC (i.e. FLTU

k

and FLTD

k

∀ k ∈ K).

ENGINE CALIBRATION PROCESS OPTIMIZATION

337

R Torque

10 450 109 110 111 112 113 114 115 116 117 118 119 120

9 400 97 98 99 100 101 102 103 104 105 106 107 108

8 350 85 86 87 88 89 90 91 92 93 94 95 96

7 300 73 74 75 76 77 78 79 80 81 82 83 84

6 250 61 62 63 64 65 66 67 68 69 70 71 72

5 200 49 50 51 52 53 54 55 56 57 58 59 60

4 150 37 38 39 40 41 42 43 44 45 46 47 48

3 100 25 26 27 28 29 30 31 32 33 34 35 36

2 50 13 14 15 16 17 18 19 20 21 22 23 24

1 0 1 2 3 4 5 6 7 8 9 10 11 12

500 650 700 800 850 900 950 1000 1050 1100 1150 1200

1 2 3 4 5 6 7 8 9 10 11 12

Eng ine Sp eed

K

Figure 3: This figure shows all possible grid points and cor-

responding index from which a 6× 6 grid must be chosen.

2.4.1 Choosing a Grid

The first constraint guarantees that we have exactly

p× p SS points in the grid:

∑

j∈S

x

j

= p× p (2)

Note that this constraint does not guarantee that all

of the points are chosen to be in the same rows and

columns. Figure 4 shows an example selection of 6×

6 = 36 highlighted points that were chosen based on

this constraint, but they do not form a 6× 6 grid.

10 450 109 110 111 112 113 114 115 116 117 118 119 120

9 400 97 98 99 100 101 102 103 104 105 106 107 108

8 350 85 86 87 88 89 90 91 92 93 94 95 96

7 300 73 74 75 76 77 78 79 80 81 82 83 84

6 250 61 62 63 64 65 66 67 68 69 70 71 72

5 200 49 50 51 52 53 54 55 56 57 58 59 60

4 150 37 38 39 40 41 42 43 44 45 46 47 48

3 100 25 26 27 28 29 30 31 32 33 34 35 36

2 50 13 14 15 16 17 18 19 20 21 22 23 24

1 0 1 2 3 4 5 6 7 8 9 10 11 12

0 500 650 700 800 850 900 950 1000 1050 1100 1150 1200

Figure 4: This figure shows highlighted in blue the 6× 6 =

36 points that were chosen to satisfy constraint (2).

The next two constraints address this problem and

guarantee that we have exactly p columns and p rows

chosen to compose the grid. Note that the two con-

straints (3) and (4) make constraint (2) redundant, but

having it improvesthe solve time by around 5% based

on our testing, as it gives a better representation of the

convex hull (typically, additional constraints in BIPs

help improve solve time (Geoffrion, 1976)). The con-

straint to ensure we choose exactly p columns is

∑

j

2

∈S:E

j

1

=E

j

2

x

j

2

= px

j

1

∀ j

1

∈ K. (3)

The following guarantees we choose exactly p rows:

∑

j

2

∈S:T

j

1

=T

j

2

x

j

2

= px

j

1

∀ k ∈ {0,. .. ,r − 1} (4)

∀ j

1

∈ S : j

1

= qk+ 1.

Figure 5 shows an example grid selection, choosing

columns 1, 2, 4, 7, 8, and 12 and rows 2, 4, 5, 7, 9, and

10. The next few constraints enforce maximum spac-

ing between the grid points in both the engine speed

and torque directions. We ensure that the first (i.e.,

left-most) column in the grid must be at most DX

max

away from the starting value of E

s

:

∑

j∈S:E

j

≤E

1

+DX

max

x

j

≥ p. (5)

10 450 109 110 111 112 113 114 115 116 117 118 119 120

9 400 97 98 99 100 101 102 103 104 105 106 107 108

8 350 85 86 87 88 89 90 91 92 93 94 95 96

7 300 73 74 75 76 77 78 79 80 81 82 83 84

6 250 61 62 63 64 65 66 67 68 69 70 71 72

5 200 49 50 51 52 53 54 55 56 57 58 59 60

4 150 37 38 39 40 41 42 43 44 45 46 47 48

3 100 25 26 27 28 29 30 31 32 33 34 35 36

2 50 13 14 15 16 17 18 19 20 21 22 23 24

1 0 1 2 3 4 5 6 7 8 9 10 11 12

0 500 650 700 800 850 900 950 1000 1050 1100 1150 1200

Figure 5: This figure an example grid with exactly 6 rows

and 6 columns.

Note that in Figure 5, column 1 is selected, and since

E

s

= 500, this constraint holds.

Next, we require the grid to be spaced at most

DY

max

in the torque direction:

x

j

1

+

∑

j

2

∈S:j

2

> j

1

∧|T

j

1

−T

j

2

|≤DY

max

x

j

2

≥ p+

∑

c∈S:T

c

=T

j

1

x

c

(6)

∀ k ∈ {0,. ..,((T

end

− DY

max

)/GY

min

)}

∀ j

1

∈ S : j

1

= qk+ 1.

Following Figure 5, we can see that the maxi-

mum space between any two rows is 100, and since

DY

max

= 100, this constraint holds.

Finally, we guarantee that the grid can be spaced

at most DX

max

in the engine speed direction:

x

j

1

+

∑

j

2

∈S:j

2

> j

1

∧|E

j

1

−E

j

2

|≤DX

max

x

j

2

≥ p+

∑

c∈S:E

c

=E

j

1

x

c

(7)

∀ j

1

∈ {1,.. .,((E

end

− DX

max

− E

s

)/GX

min

+ 1)}.

Following Figure 5, we can see that the maximum

space between any two columns is 200 (e.g. columns

8 and 12), and since DX

max

= 150, this constraint is

violated. Figure 6 shows a grid selection that satisfies

all constraints up to this point, with a maximum space

between any two columns equal to 150.

10 450 109 110 111 112 113 114 115 116 117 118 119 120

9 400 97 98 99 100 101 102 103 104 105 106 107 108

8 350 85 86 87 88 89 90 91 92 93 94 95 96

7 300 73 74 75 76 77 78 79 80 81 82 83 84

6 250 61 62 63 64 65 66 67 68 69 70 71 72

5 200 49 50 51 52 53 54 55 56 57 58 59 60

4 150 37 38 39 40 41 42 43 44 45 46 47 48

3 100 25 26 27 28 29 30 31 32 33 34 35 36

2 50 13 14 15 16 17 18 19 20 21 22 23 24

1 0 1 2 3 4 5 6 7 8 9 10 11 12

0 500 650 700 800 850 900 950 1000 1050 1100 1150 1200

Figure 6: This figure is an example grid selection that satis-

fies all constraints in Section 2.4.1.

2.4.2 Required Grid Points

There are a couple of types of SS points that are re-

quired to be a part of the grid. The first require-

ment forces the grid to contain points that have values

greater than or equal to the max torque on the FLC.

This is equivalent to forcing the maximum value in

the grid to be selected.

∑

j∈S:T

j

=T

e

x

j

= p. (8)

ICORES 2012 - 1st International Conference on Operations Research and Enterprise Systems

338

Similarly, the grid has to contain points that have val-

ues greater than or equal to the max engine speed on

the FLC.

∑

j∈S:E

j

=E

e

x

j

= p. (9)

We can see that the grid of chosen SS points in Figure

6 satisfies these two constraints because row 10 and

column 12 are selected.

The next requirement is that points on the zero

axis must be selected:

∑

j∈K

x

j

= p. (10)

Note that the grid of chosen SS points in Figure 6

does not satisfy this constraint because row 1 is not

selected. Figure 7 shows a grid selection that satis-

fies this constraint, as well as all of the constraints

in Section 2.4.1. Note that selected rows have been

changed: row 1 instead of row 2 and row 3 instead of

row 4 to maintain DY

max

= 100.

10 450 109 110 111 112 113 114

115

116 117 118 119 120

9 400 97 98 99

100

101 102

103

104 105 106 107 108

8 350 85 86 87 88 89 90 91 92 93 94 95 96

7 300 73 74 75

76

77 78 79 80 81 82 83 84

6 250 61 62 63 64 65 66 67 68 69 70 71 72

5 200 49

50

51 52 53 54 55 56 57

58

59 60

4 150 37 38 39 40 41 42 43

44 45 46 47 48

3 100

25 26

27

28

29 30

31

32 33

34

35

36

2 50 13 14 15 16 17 18 19 20 21 22 23 24

1 0

1

2 3 4 5 6 7 8 9 10 11

12

0 500 650 700 800 850 900 950 1000 1050 1100 1150 1200

Figure 7: This figure is an example grid selection that sat-

isfies constraints (2) - (15) with the cells containing the

indices above and below the FLC outlined and the cover

points in large, bold text.

2.4.3 Cover Constraints

This section describes the standard cover constraints

and also additional constraints needed to require cer-

tain selected grid points to be in the cover. The first

standard type of cover constraints guarantee that all

transient points are covered:

∑

j∈S

a

ij

y

j

≥ 1 ∀ i ∈ I. (11)

Next, we ensure that all SS points that are not in the

cover are covered:

∑

j

2

∈S

b

j

1

j

2

y

j

2

≥ 1 ∀ k ∈ K : E

k

≤ E

end

∀ j

1

∈ S : (12)

T

j

1

≤ FLTU

k

∧ E

j

1

= FLE

k

.

The following constraints are not standard cover-

ing constraints: they guarantee that the points directly

above and below the FLC are not only included in the

selected grid but are also selected as part of the cover.

First, though, we must ensure that if a point is chosen

to be part of the cover, then it must have been selected

to be a part of the grid:

y

j

≤ x

j

∀ j ∈ S. (13)

Next, we guarantee that p SS points directly above the

FLC are selected to test:

∑

k∈K:E

k

≤E

end

∑

j∈S:T

j

=FLTU

k

∧E

j

=FLE

k

y

j

= p. (14)

Additionally, we guarantee that p SS points directly

below the FLC are selected to be in the cover:

∑

k∈K:E

k

≤E

end

∑

j∈S:T

j

=FLTD

k

∧E

j

=FLE

k

y

j

= p. (15)

Finally, we must ensure that all the SS points in the

selected grid that are above the point directly chosen

above the FLC are not selected as a part of the cover:

∑

k∈K

∑

j∈S:T

j

>FLTU

k

∧E

j

=FLE

k

y

j

= 0. (16)

Figure 7 shows an example selected grid that sat-

isfies all of the constraints: the indices in the high-

lighted cells represent the selected grid, the indices di-

rectly above and below the FLC are outlined in black,

and the cover points are denoted by large, bold text.

We used IBM ILOG CPLEX Optimization Studio

12.2 (IBM, 2010) to solve the BIP. CPLEX takes on

average 90 minutes to obtain an optimal solution.

3 EXAMPLE

The following example is of the grid and SS test point

selection for a typical internal combustion engine.

The target of this model application is to reduce the

number of speed/load point combinations necessary

to develop an engine calibration that delivers equiva-

lent performance in terms of NO

X

, particulate, noise,

and fuel consumption.

3.1 Inputs

We provide the values for the inputs introduced in

Section 2.1. Refer to Figure 2 for a pictorial of the

entire grid space, the FLC, and the transient points

for the internal combustion engine in this example.

In Table 1, we provide the values for the engine

start and end speed, the torque start and end speed,

the grid dimensions, minimum grid spacing in the

engine and torque grid directions, maximum engine

speed and torque for the FLC, and cover require-

ments. Other parameters that are calculated from

these values are the number of possible grid points

ENGINE CALIBRATION PROCESS OPTIMIZATION

339

along the x-axis, the y-axis, and the number of possi-

ble SS points: q =

E

e

−E

s

+GX

min

GX

min

=

3800−600+50

50

= 65,

r =

T

e

−T

s

+GY

min

GY

min

=

1300−0+50

50

= 27, and n = q × r =

65× 27 = 1755.

Table 1: Input Parameters: scalar numbers.

Param. Value Unit Param. Value Unit

E

s

600 RPM n 1755

E

e

3800 RPM m 2618

T

s

0 TRQ DT

max

300

T

e

1300 TRQ DS

max

300

p 16 DX

max

550 RPM

GX

min

50 RPM DY

max

150 TRQ

GY

min

50 TRQ FE

max

3800 RPM

q 65 FT

max

1255 TRQ

r 27

We define the sets for the engine speed and torque

grid point indices, the possible SS points, and the

transient points as follows: K = {1,. .. ,65}, R =

{1,...,27}, S = {1, .. ., 1755}, and I = {1,...,2618}.

The engine speed, E

j

, starts with 600 RPM and ends

at 3800 RPM with an increment of 50 RPM. Torque,

T

j

, has a starting point of 0 TRQ and increments by

50 TRQ with a maximum of 1300 TRQ. The dis-

tance between possible SS point j

1

and j

2

for ev-

ery j

1

, j

2

∈ S is calculated using the Euclidean For-

mula d =

p

(x

2

− x

1

)

2

+ (y

2

− y

1

)

2

, where x

1

and x

2

are the engine speed of j

1

and j

2

, and y

1

and y

2

are

the corresponding torque values. Similarly, we use

the Euclidean distance formula to calculate the dis-

tance between all transient points i ∈ I and SS points

j ∈ S. As there are 2,619 transient points, we do

not include them in this paper. The following points

on the FLC are in terms of engine speed (RPM) and

torque (TRQ): (0,373), (650, 445), (800, 623), (1000,

778), (1200, 939), (1400, 1061), (1600, 1147), (1800,

1140), (2000, 1152), (2200, 1185), (2400, 1205),

(2600, 1234), (2900, 1255), (3000, 1209), (3200,

1117), (3400, 979), and (3800, 325).

3.2 Results

In this section, we present the optimization grid spac-

ing and test point results for the internal combustion

engine used in our study. We will also demonstrate

how the selected grid and test points satisfy all con-

straints.

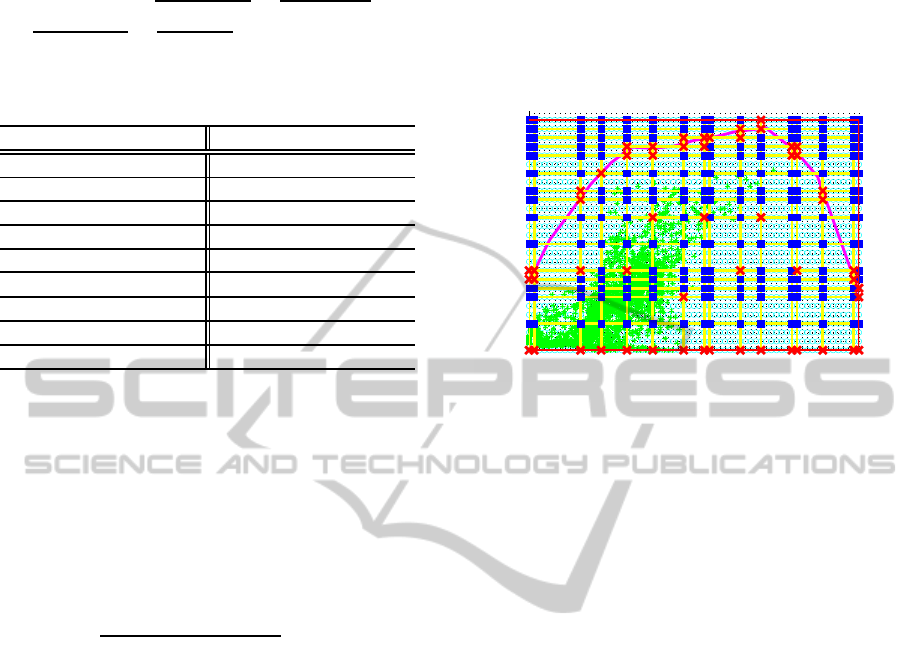

First, we can see in Figure 8, the selected grid

points (defined by the 256 selected SS points) for

the 16 × 16 grid. This grid selection satisfies the

constraints specified in (2), (3), and (4) to have ex-

actly 256 points chosen, with exactly 16 rows and 16

columns. In addition, the maximum spacing between

the grid points in this example in the engine speed

direction is 550 RPM and 150 TRQ in the torque di-

rection, which satisfies constraints (5), (6), and (7).

600 1000 1400 1800 2200 2600 3000 3400 3800

0

50

100

150

200

250

300

350

400

450

500

550

600

650

700

750

800

850

900

950

1000

1050

1100

1150

1200

1250

1300

Egine Speed (RPM)

Torque (TRQ)

Figure 8: 54 Selected SS Points.

Furthermore, we confirm that the selected grid

points satisfy i) constraints (8) and (9) that require the

grid to contain points that have values greater than or

equal to the max engine speed and max torque on the

FLC; and ii) constraint (10) that forces the points on

the zero axis to be selected. Figure 8 shows three lines

that represent these grid constraints and demonstrate

that our solution satisfies them.

The second part of our solution identifies which

of the grid points are selected as SS points to test.

Our solution yields a minimum number of 54 out of

256 SS points to test, which are identified by an X

in Figure 8. We can see that test points are selected

only from points that have been chosen to be in the

grid: this satisfies constraint (13). Also note that all

16 SS points directly above and below the FLC are

selected to be tested, and none of the points beyond

the 16 points above the SS points are chosen to be

tested: this satisfies constraints (14), (15), and (16).

Finally, we demonstrate how all of the transient

points and SS points that were not selected for testing

are covered by the SS points selected for testing (con-

straints (11) and (12)). Figure 9 shows which points

are covered by the selected test points. Each selected

test point, denoted by an X, has a radius of 300 that

is marked by a circle. Any transient point or SS point

that is in the circle is covered by that SS point at the

center of the circle: note that due to different scaling

in the torque and engine axes, the circles appear as

ellipses. We can see that all of the transient and SS

points that were not selected for testing are covered

by at least one of the 54 SS points selected for testing.

For this example, the current testing process for

the internal combustion engine would have required

ICORES 2012 - 1st International Conference on Operations Research and Enterprise Systems

340

600 1000 1400 1800 2200 2600 3000 3400 3800

0

50

100

150

200

250

300

350

400

450

500

550

600

650

700

750

800

850

900

950

1000

1050

1100

1150

1200

1250

1300

Engine Speed (RPM)

Torque (TRQ)

Figure 9: This figure shows the coverage of non-selected

transient and SS points.

testing 122 points with the standard grid spacing. Our

method selects a different grid spacing and chooses

only 54 points to test, giving us around a 56% reduc-

tion in the number of points needed for testing.

4 SUMMARY

Completing a DoE at all possible steady-state engine

operating points is a time consuming process. This

project focused not on reducing the time to complete

the DoE, but on reducing the number of experiments

that needed to be performed. We captured the con-

straints to ensure that by minimizing the number of

tests to perform, we could still satisfy regulatory re-

quirements and internal testing constraints.

We introduced a BIP formulation that is based on

a set-covering approach to select the best grid dimen-

sions and to minimize the number of SS points. This

formulation yields an optimal solution to simultane-

ously solving the grid selection and covering prob-

lem. We demonstrated the optimization methodology

for a typical internal combustion engine and provided

an optimal grid selection that resulted in an approxi-

mately 56% reduction in the points for which to per-

form a DoE.

While we applied this approach to the area of en-

gine calibration, this method could also be applied to

other automotive related areas. One example would

be to select the minimum number of points on a sur-

face on which to weld in order to satisfy certain ma-

terial properties. Another example would be to min-

imize the number of stamping facilities and to deter-

mine the best locations to add stamping facilities in

order to guarantee that every assembly plant would

have at least one stamping facility within a certain

distance. These are just a couple of examples that

illustrate the diverse types of problems for which this

approach can be applied.

REFERENCES

Balas, E. and Padberg, M. (1972). On the set coverying

problem. Operations Research, 20:1152–1161.

Castagn´e, M., Bentolila, Y., Chaudoye, F., Hall´e, A., Nico-

las, F., and Sinoquet, D. (2008). Comparison of engine

calibration methods based on design of experiments

(DoE). Oil & Gas Science and Technology, 63:563–

582.

EPA (1977). Title 40 - protection of environment, CFR § 86

subpart B.

Geoffrion, A. (1976). A guided tour of recent practical

advances in integer linear programming. OMEGA,

The international Journal of Management Science,

4(1):49–57.

IBM (2010). IBM ILOG CPLEX opti-

mization studio (OPL). http://www-

01.ibm.com/software/integration/optimization/cplex-

optimization-studio/.

Langou¨et, H., M´etivier, L., Sinoquet, D., and Tran, Q.

(2008). Optimization for engine calibration. In En-

gOpt 2008 - International Conference on Engineering

Optimization. Rio de Janeiro, Brazil.

Maloney, P. (2009). Objective determination of minimum

engine mapping requirements for optimal SI DIVCP

engine calibration. Warrendale: SAE International.

Wolsey, L. (1998). Integer Programming. John Wiley &

Sons, Inc.

Yoshida, S., Ehara, M., and Koroda, Y. (2011). Rapid

boundary detection for model-based diesel engine cal-

ibration. Warrendale: SAE International.

ENGINE CALIBRATION PROCESS OPTIMIZATION

341