BUILDING A BUSINESS PROCESS MAP USING BPM TOOLS

AND BPMN NOTATION

Francesc Xavier Berjano Tresserras

Mediterranean Consulting,Marinel.lo bosch 115-B, 08222 Terrassa, Barcelona, Spain

francesc@mediterranean-consulting.com

Keywords: BPMN notation, BPM, BPM open source tools, BPMI.

Abstract: This paper aims at discussing business process management tools and the BPMN notation, identifying

particular strengths of these tools and notation, supported by a case example, namely a project case on

business process re-engineering. We will explicitly consider the phases that we normally follow in realizing

such a project (project organization, key people, tasks, resources, deliverables and a project management

method). This will support our concluding about strengths of the above-mentioned tools and notation.

1 INTRODUCTION

This paper aims at discussing business process

management tools and the BPMN notation,

identifying particular strengths of these tools and

notation, supported by a case example, namely a

project case on business process re-engineering. We

will explicitly consider the phases that we normally

follow in realizing such a project (project

organization, key people, tasks, resources,

deliverables and a project management method).

This will support our concluding about strengths of

the above-mentioned tools and notation.

In general, companies need Business Process

Management (BPM) model(s), as a way of assuring

good organization. The process mapping related to

this is therefore essentially important. It appears like

a key activity in managing and organizing all

(business goal –driven) activities within a company.

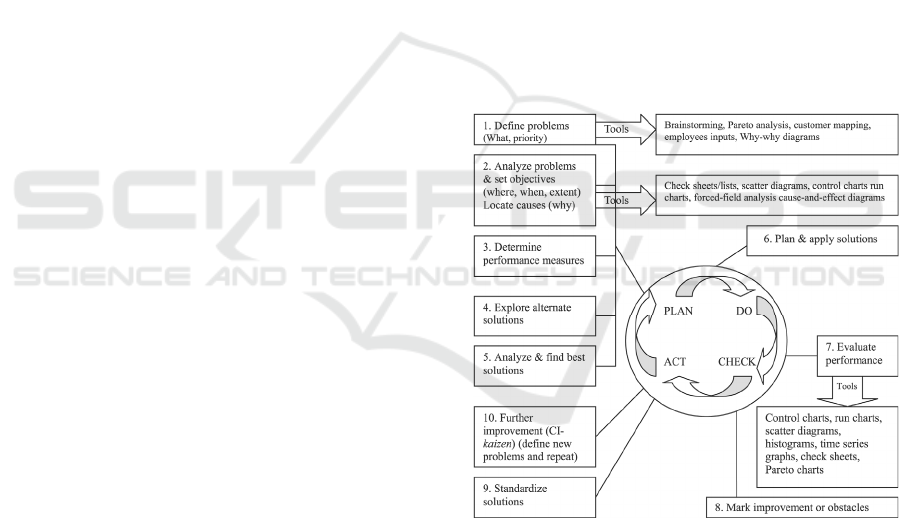

In considering BPM strategies in our work, we

are based on the PDCA interactive four-step

management process (PDCA stands for ‘plan–do–

check–act’); the PDCA process is typically used in

considering quality issues. It is also known as the

Deming circle (Walton & Edwards, 1988).

As suggested by Fig. 1, a problem definition

should come first, followed by analysis & objective

setting, measures determination, consideration of

alternative solutions, and identification of the best

solution. All this concerns the planning. Then

solutions need to be applied and evaluated, and

finally improvement actions and/or standardization

would need to be applied.

Figure 1: A typical PDCA model.

This is known in theory but applying adequate

management and establishing appropriate control in

practice remains a challenge.

As already mentioned, we aim in the current

paper at considering BPM tools + BPMN notation,

and identifying particular strengths of theirs with

regard to the above challenge.

The remaining of this paper is organizaed as

follows: Section 2 will briefly introduce and discuss

the BPMN notation; further on, Section 3 will

consider a business process re-engineering process;

185

Tresserras F.

BUILDING A BUSINESS PROCESS MAP USING BPM TOOLS AND BPMN NOTATION.

DOI: 10.5220/0004460101850188

In Proceedings of the First International Symposium on Business Modeling and Software Design (BMSD 2011), pages 185-188

ISBN: 978-989-8425-68-3

Copyright

c

2011 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Section 4 and Section 5 then discuss these in the

light of a case study – introducing the case is done in

Section 4 and tool consideration is done in Section

5; Section 6 contains the conclusions.

2 MODELING STRATEGY USING

BPMN NOTATION

Being a business process modeling standard, BPMN

was developed by Business Process Management

Initiative (BPMI), and is currently maintained by the

Object Management Group (BPMN Home, 2011).

With respect to this, it is interesting to consider

BPMN from a methodological perspective - origin

and which are the key elements, which it possesses.

It is interesting not only discussing this but also

establishing where to obtain more information and

which are the principal institutions linked with

BPMN.

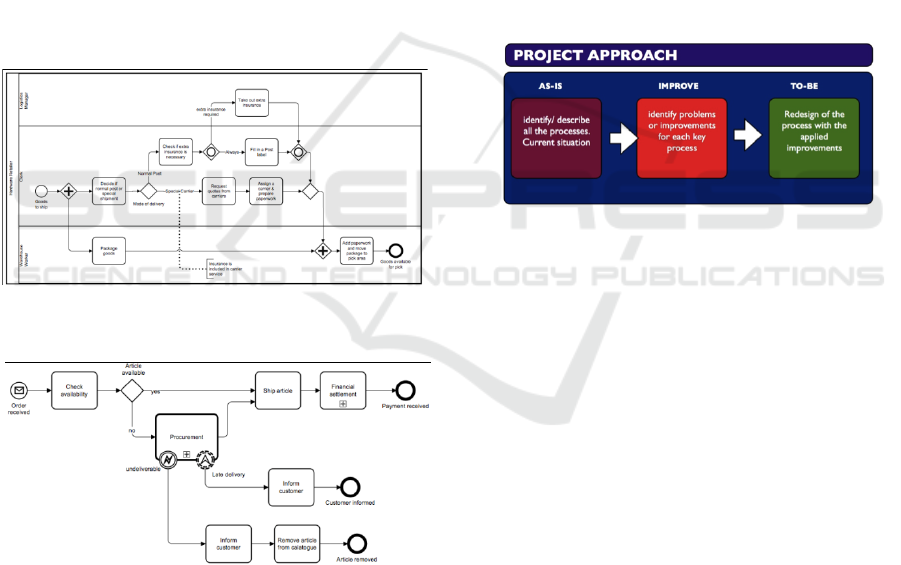

Figure 2: A shipment process of a hardware retailer (a

sample).

Figure 3: Order fulfilment and procurement (a sample).

Figure 2 and Figure 3 illustrate some important

features of BPMN and for more information

interested readers are referred to (BPMN Home,

2011).

For the sake of brevity, we will not discuss

BPMN in more detail in the current section.

3 PROCESS RE-ENGINEERING

PHASES

As according to Dietz (1994), the re-engineering of

business processes needs sound modeling and proper

notations, such that the re-designed (part of the)

business processes are guaranteed to fit in the

broader context.

As process improvement is concerned, the

typical process re-engineering phases are to be taken

in consideration, being reflected in addressing the

following points: project organization, key people,

tasks, resources, deliverables and project

management method.

For the sake of brevity, we will not go into

further detail here, presenting only (for partial

exemplification) the "Buldeza´s Project" that has

been realized in the northern Bulgarian city of

Pleven.

Figure 4: The approach followed in the “Buldeza’s

Project.

As seen from Fig. 4, the ‘to be’ situation is

reached by properly projecting improvements,

having an ‘as is’ situation as starting point.

The way we are modeling and the notations we

are using are thus of great importance for

appropriately introducing our intention in a real-

world business system.

4 DESCRIPTION OF THE

“BULDEZA’S” PROJECT

As already mentioned in the current paper, we will

discuss a case study – the “Buldeza’s” project.

4.1 Why a BPR Project

The company under consideration is undergoing

reorganization in its plant in Bulgaria (Pleven),

focused on the improvement of management

processes efficiency. The need for reorganization

has been motivated not only by the company’s

BMSD 2011 - First International Symposium on Business Modeling and Software Design

186

growth but also by a forecast concerning the support

of this increase in next years.

4.2 The Project

The project has been structured in the improvement

of three principal areas: production, confection and

store of raw material. Also initially, has been setup

the control of presence of the people, using an

integrated system with the headquarters in Spain.

In production area has been proceeded the

improvement of the manufacturing processes, as

well as a reorganization of the human resources.

There was established a performance control system

in plant. After realizing this step, one proceeded to

analyze the flow of confection and to establish

mechanisms to increase the performance as well as

the traceability of the garment inside the area. Later

been setup the logistic control integrated to

BULDEZA's central warehouse.

The system is based on a method of locations

and areas management, , where, since the receipt of

the raw material, a total traceability exists: the

spinning is identified in the warehouse and is

located in a specific position of the store sorted by:

qualilty of the spinning, color, and dyed.

4.3 Results

After finishing this project, the company has in

production area one performance control system in

plant diary, in different perspectives: machines,

articles, people or section.

The Warehouse of raw materialis integrated

with the production process, then when an order of

manufacture is emitted, the spinning is visualized

and the system tell us the number of kilos availabe

in the Warehouse and his exact position (X,Y).

For this reason, the time of search of the spinning

has diminished because now this information is

obtained automatically.

Definitively, nowadays the set of processes of

manufacture – confection are more efficient and

have allowed to optimize the resources and at the

same time to increase the productivity.

5 TOOLS USED

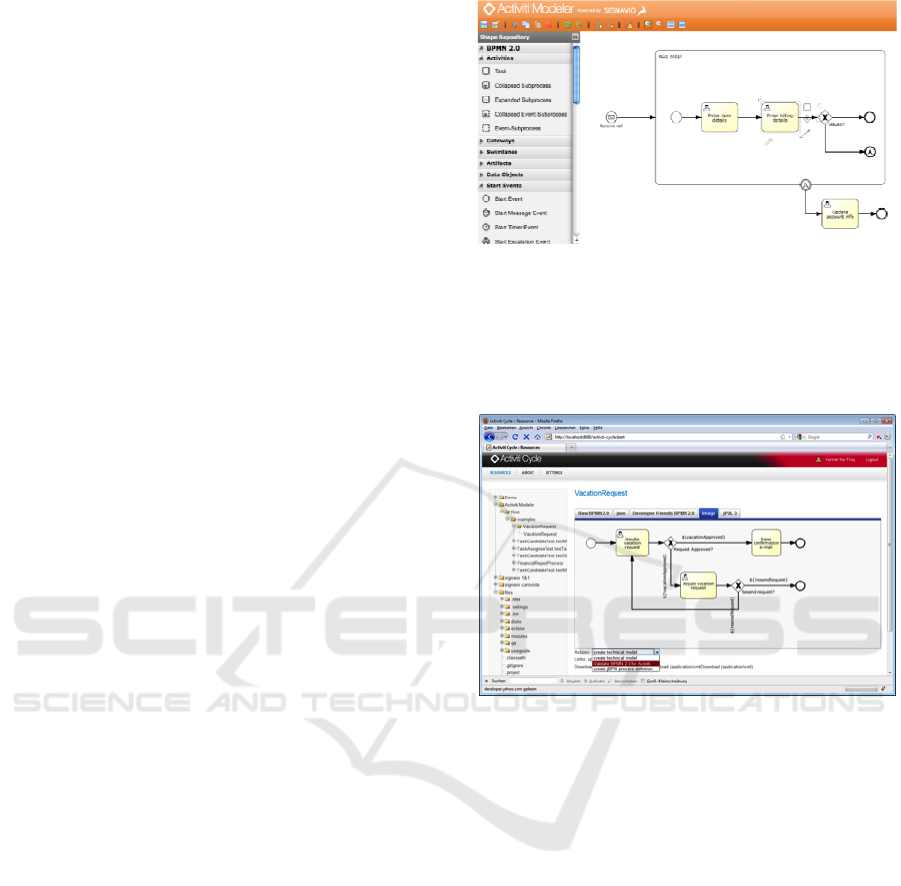

Both for the sake of managing the project and

introducing improvements, it is necessary to apply

modeling tools and graphical notations in directions

discussed already in the paper; Fig. 5 and Fig. 6 are

just illustrating this.

Figure 5: Tools used (Take Order).

As it is seen from these figures, the tools have

potential for supporting the management with regard

to possible (re-)design of business processes,

simulating them, and visualizing their execution.

Figure 6: Tools used (Vacation Request).

This potential has been demonstrated in the case

study considered.

6 CONCLUSIONS

Business Process Modeling Notation (BPMN) is a

graphical representation for specifying business

processes in a business process model. BPMN was

developed by Business Process Management

Initiative (BPMI), and is currently maintained by the

Object Management Group since the two

organizations merged in 2005. On the other hand,

there are business process modeling tools available

on the market, based on BPMN, that could be

helpful in realizing process generation using an easy

and understandable process map. These tools can be

grouped by functions such as: modeling,

documentation, simulation and execution (in

essence, BPM tools take graphical process

descriptions as input). A process is composed of

BUILDING A BUSINESS PROCESS MAP USING BPM TOOLS AND BPMN NOTATION

187

activities that are connected with transitions.

Processes represent an execution flow. The graphical

diagram of a process is used as the basis for the

communication between non-technical users and

developers. This all makes BPM tools and the

BPMN notation useful at the management level of

companies, as a way for mastering complexity and

leading businesses properly.

REFERENCES

BPMN Home (2011), http://www.bpmn.org.

Dietz, J. L. G. (1994): Modelling Business Processes for

the Purpose of Redesign. In: Business Process Re-

Engineering.

Walton, M., Edwards, W. (1988). The Deming

Management Method. Berkley Publishing Group, New

York (USA).

BMSD 2011 - First International Symposium on Business Modeling and Software Design

188