OPTIMUM TRAJECTORY PLANNING FOR INDUSTRIAL

ROBOTS THROUGH INVERSE DYNAMICS

K. Koray Ayten, P. Iravani and M. Necip Sahinkaya

Department of Mechanical Engineering, University of Bath, BA2 7AY, Bath, U.K.

Keywords: Optimum control, Inverse dynamics, Torque minimization, Trajectory planning.

Abstract: This paper presents a method for developing robot trajectories that achieve minimum energy consumption

for a point-to-point motion under kinematic and dynamic constraints. The method represents trajectories as

a fourth degree B-spline function. The parameters of the function are optimised using a multi-parametric

optimization algorithm. Actuator torques have been considered for the formulation of the cost function,

which utilizes an inverse dynamics analysis. Compared to other trajectory optimization techniques, the

proposed method allows kinematic and dynamic constraints to be included in the cost function. Thus, the

complexity and computational effort of the optimization algorithm is reduced. A two-link simulated robot

manipulator is used to demonstrate the effectiveness of the method.

1 INTRODUCTION

Most of industrial robotic applications are based on

repetitive processes, where minimum cycle time is

an important factor to reduce the production time

and to increase the profit of the production (Zoller

and Zentan, 1999). However, the minimum time

criterion is not suitable if a smooth path for the

motion is required. When the actuators run at high-

speeds, they can cause physical vibrations and

undesirable shocks to the system. These unwanted

vibrations can result in a wide range of problems

including loss of accuracy, increased energy

consumption and a decrease in actuator life.

Energy requirement has been a significant

feature in robotic systems, e.g. robots for space or

submarine exploration, or unmanned reconnaissance

vehicles (Saravanan and Ramabalan, 2008). This

paper focuses on energy minimization in the context

of trajectory planning. The cost function in

(Gasparetto and Zanotto, 2007) and (Zanotto and

Gasparetto, 2007) consists of two terms. The first

term is the total execution time and the second is the

jerk. Some of the approaches include the travel time

in the cost function (LoBianco and Piazzi, 2002).

Also the mechanical power of the actuators and

energy for gripper action are considered for the

formulation of cost function in (Saramago and

Ceccarelli, 2004) and just the mechanical power in

(Garg and Kumar, 2002).

This paper proposes a path planning trajectory

method to generate an optimum path based on

minimum torque and/or energy consumption. The

proposed method considers an inverse dynamic

model of the robot manipulator. The resulting

optimization algorithm can be applied to various

robots, such as redundant or parallel robots in order

to optimize the desired trajectory. The method has

the advantage that kinematic and dynamic

constraints are included in a sequential manner in

the cost function and solving the inverse dynamics is

avoided when the constraints are not satisfied.

In this study, the dynamic modelling of the robot

is based on Lagrangian dynamics (Wells, 1967),

which describes the system in terms of its energy.

The DYSIM software (Sahinkaya, 2004) is used to

construct the equations of motion automatically for

both forwards and inverse dynamic analysis of the

system. In this study, DYSIM was operated in the

MatLab/Simulink.

2 OPTIMIZATION

Path planning techniques are associated with the

way in which a robot manipulator moves from one

point to another in a controlled manner (Niku,

2001). One of the important stages of path planning

is that of trajectory optimization. Trajectory

optimization problems can be divided into the

105

Ayten K., Iravani P. and Sahinkaya M..

OPTIMUM TRAJECTORY PLANNING FOR INDUSTRIAL ROBOTS THROUGH INVERSE DYNAMICS.

DOI: 10.5220/0003536301050110

In Proceedings of the 8th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2011), pages 105-110

ISBN: 978-989-8425-74-4

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

following components:

• Parametric path function

• Path coordinates

• Optimization technique

• Cost function

• Constraints

2.1 Parametric Path Function

Selection of the parametric path function is the first

step of the trajectory optimization technique.

Generally in optimization, a small number of

parameters is preferred without restricting the

motion space. Also, for manipulator motions, the

trajectory function has to be at least twice

differentiable in order to provide smooth and

continuous accelerations.

In this study, a fourth order B-spline function is

used to define joint motions because of its simplicity

and computational efficiency (De Boor, 1978), see

(Qin, 2000) for details. A fourth order B-spline

function consists of nine parameters. Three of them

are used for the start condition (position, and its first

and second derivatives). Three parameters are used

for the end condition (position, and its first and

second derivatives). The remaining three free

parameters are calculated by the optimization

algorithm.

2.2 Path Coordinates

Trajectory planning can be done either in the joint-

space or Cartesian-space. Planning a trajectory in the

joint-space has a significant advantage that the

control system will be acting on the robot joints

rather than on the end effector. In this case, it is

easier to set the necessary trajectory in terms of the

design requirements. However, the trajectory of the

end effectors will not be easily predictable (Niku,

2001). On the other hand, Cartesian-space

trajectories are more realistic and very simple to

visualize, but these have to be converted to joint

space for control purposes. In this paper, joint space

trajectories are used. However, the method can

handle Cartesian-space trajectories if required.

2.3 Optimization Technique

The selection of the optimization technique is

important as a large number of parameters and

coefficients may adversely affect the results of

optimization, and computational efficiency (Garg

and Kumar, 2002). In the proposed method, there is

no need to use computationally intensive

optimization techniques such as genetic algorithms.

Therefore, a sequential quadratic programming

technique (the default method in""

function in MatLab (The Mathworks, 2007) is used.

2.4 Cost Function

In the literature, the most common objectives to be

optimized are minimum travelling time, minimum

energy (or actuator effort, e.g. torque), and minimum

jerk (Gasparetto and Zanotto, 2007).

Minimum energy consumption was taken into

account here, but other quantitative indicators could

be considered according to design objectives. The

cost function of actuator effort (or torque)

minimization is described by:

=

()

(1)

where is the actuator cost function,

the actuator

torques/forces applied at joint along the trajectory,

K the number of actuators, and the total travelling

time between initial and final positions. Calculation

of the cost function in Eq. (1) requires the solving of

the inverse dynamic model for T seconds. Three free

parameters of the B-spline function are used to

optimize each joint trajectory.

2.5 System Constraints

Robot manipulators will have some physical

constraints such as the limits of the position,

velocity, acceleration and torque. Using these

constraints, unrealistic or unreachable motions of the

manipulator are automatically avoided in the

optimization procedure. Other constraints can also

be added (such as obstacle avoidance, singularity

avoidance) to the optimization algorithm for

trajectory planning.

The cost function calculations involve running

the inverse dynamic model, which is time

consuming. In conventional methods the constraint

equations are handled separately, and the cost

function is called regardless of whether the

constraints are satisfied or not. In order to improve

computational efficiency in the proposed method,

constraints are handled within the cost function

calculations and the inverse dynamic analysis is only

evaluated when these constraints are satisfied. In

order to achieve this, an alternative cost function is

formulated to handle constraints as follow:

1. A variable, c, is created to count the number of

cost function calls where the parameters do

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

106

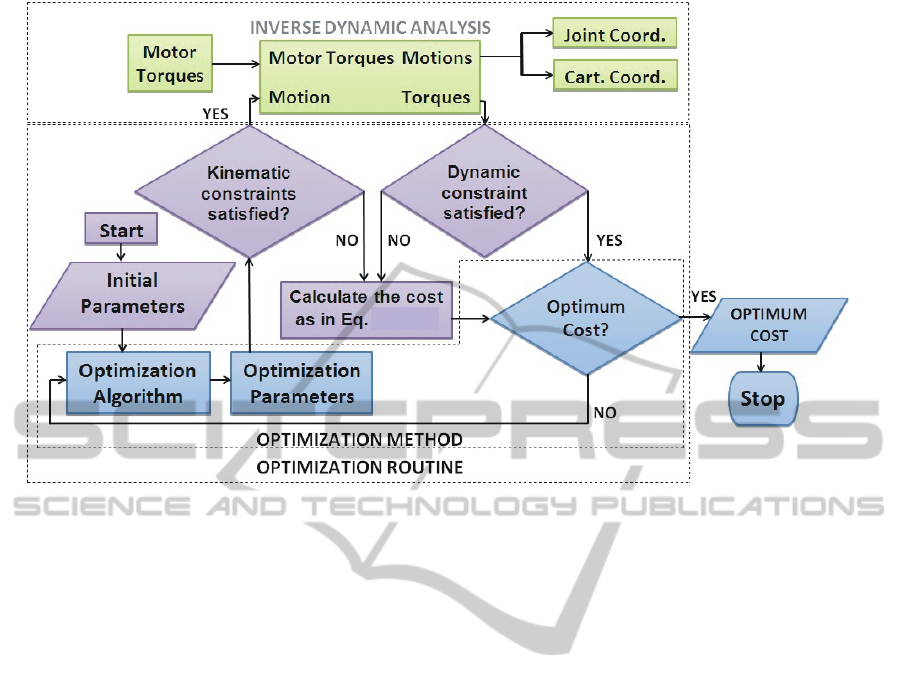

Figure 1: Optimization routine with inverse dynamic programming.

not satisfy the constraint equations.

2. During the cost function call, if any of the

constraints are not satisfied, the following

alternative cost function is used:

=+1 (2)

=∗(1+/10) (3)

where b is a large base value. This formulation

ensures that the cost function will result in a higher

value than previous violation of constraints to avoid

a local minimum to be found outside the constraints.

The value b=10

5

is used here.

3 PROPOSED ALGORITHM

The steps of the proposed energy minimization

algorithm based on inverse dynamics analysis can be

summarized as follow:

1. Before executing the optimization algorithm, all

kinematic and dynamic constraints of the

mechanism have to be identified. In this

example, constraints are based on maximum and

minimum values of position, velocity,

acceleration and torque.

2. Thereafter, the optimization algorithm will start

with suitable initial conditions in joint

coordinates.

3. When calculating the cost function, the

optimization algorithm will check the kinematic

constraints.

a) If the kinematic constraints are not satisfied,

the inverse dynamic analysis will not be carried

out. The alternative calculation of the cost

function will be carried out in accordance with

Eqs. (2) and (3).

b) If the kinematic constraints are satisfied,

inverse dynamic simulation will be run in order

to calculate the dynamic cost function as in Eq.

(1). If the torque limitations or other dynamic

constraints are violated, the simulation will be

terminated and the alternative cost function in

3 (a) above will be used.

4. This procedure will continue until the

optimization algorithm finds the lowest cost

value. The procedure of the optimization

algorithm is shown in Fig 1.

4 SYSTEM DESCRIPTION AND

SIMULATION

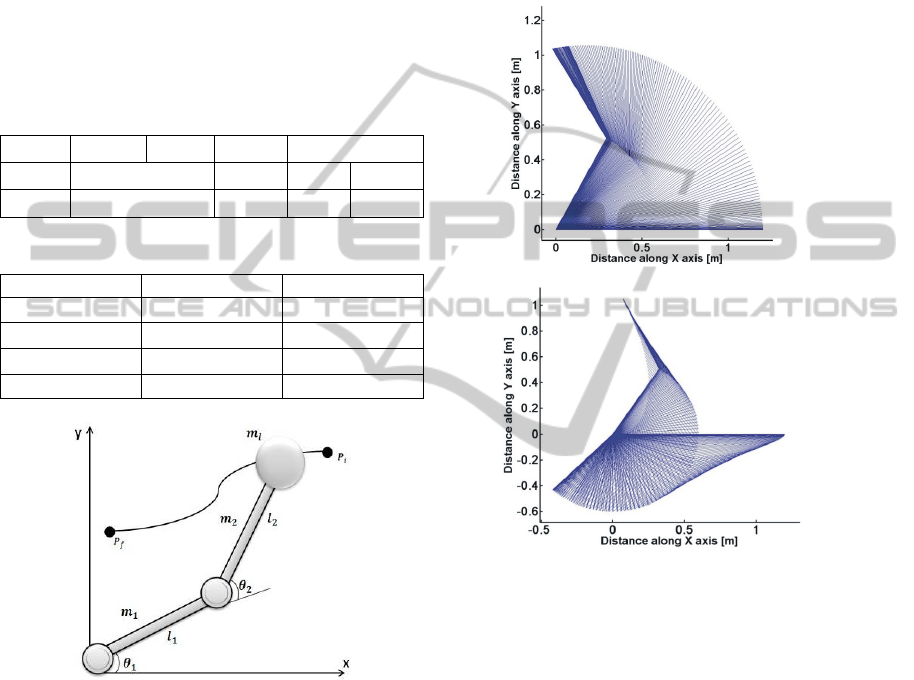

This section introduces numerical simulations using

a simple 2-DOF planar manipulator with revolute

joints as shown in Fig. 2. The simulation is carried

out by the program DYSIM. Two motors control the

motion. The centre of gravity of the links is in the

middle of the each link. A load mass of

= 1 kg is

(2,3)

OPTIMUM TRAJECTORY PLANNING FOR INDUSTRIAL ROBOTS THROUGH INVERSE DYNAMICS

107

attached at the end of the second link. The

manipulator has two identical links detailed in Table

1. Gears ratios are

=100,

=80. The viscous

friction effects of the joints are also included in the

simulation.

The manipulator task consists of transporting the

load mass from an initial point

(

=

=0)

to a final one

(

=

=1) in joint space

coordinates. The motion duration is specified as

T=2s. The initial and final velocities and

accelerations are zero for all joints. The limits for

each actuator are given in Table 2.

Table 1: 2-DOF robot manipulator data.

Joints Length Mass Inertia Friction

Joint 1

0.6

1

0.01 0.4

Joint 2

0.6

1

0.01 0.4

Table 2: Limit performances of the 2-DOF manipulator.

Conditions Joint 1 Joint 2

()() -/+3/2 -/+3/2

()(/)

-/+6 -/+6

()(/

)

-/+25 -/+25

()()

-15/+25 -15/+25

Figure 2: Schematic diagram of the robot and a prescribed

trajectory given by initial and final points.

5 RESULTS AND DISCUSSION

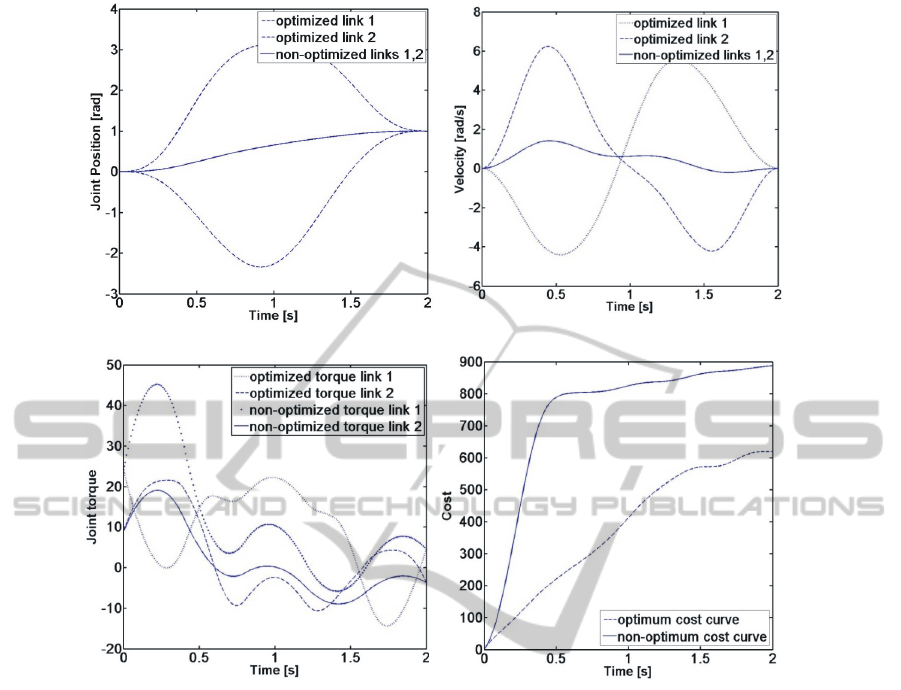

The proposed method was implemented in Simulink.

The prescribed non-optimized (initial) manipulative

task is shown in temporal trajectory position in Fig.

3(a), and the optimum trajectory is traced in Fig.

3(b). The labels ‘−’ and

‘’ in the figures denote the result for the

case with initial parameter values corresponding to a

linear motion in joint space and the case with

optimization, respectively.

Figure 4 shows profiles of joint position (),

velocity (/), torque () and cost function

results. The initial path was a straight line in the

joint space between

and

and cost value for the

non-optimized trajectory was 897.683. After

optimization, the cost function is reduced to

620.129, which corresponds to 31% energy

consumption reduction.

Figure 3: Temporal positions of (a) non-optimized and (b)

optimized trajectories.

Figure 4(b) shows that optimized velocity is

faster than the non-optimized one. As it can be seen

from the Fig. 4(c), non-optimized link-1 has a large

peak torque magnitude. Figure 4(d) shows the

evolution of the cost functions. There is a sudden

ascension on the non-optimized cost curve.

Excessive growth of the cost value can be shown to

be due to lifting of the first and second arm with

minimum joint movements between 0 and 0.5

seconds. On the other hand, optimized cost curve is

increasing smoothly by utilising the potential energy

of the system.

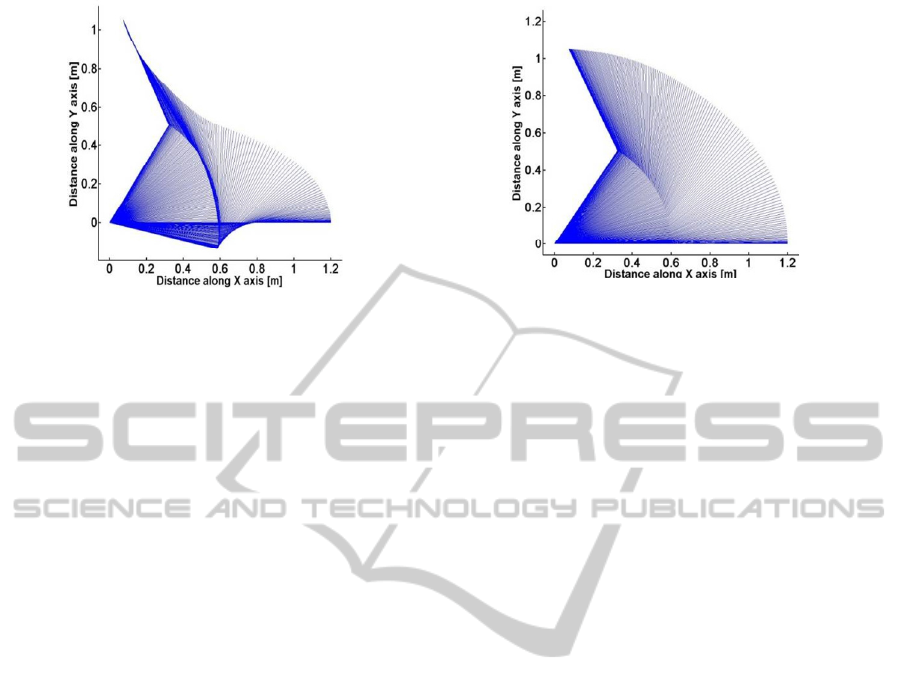

The optimization was also run by using different

friction coefficient values. Temporal position results

are shown in Fig. 5. With increasing coefficient of

viscous friction in the system, the trajectory of the

end effectors has noticeable changed. The trajectory

(a)(a)

(b)

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

108

Figure 4: Results for the designed non-optimal and optimal path in terms of time history of (a) joint positions, (b) joint

velocities, (c) joint torques, and (d) cost value of the system.

of the end effector moves towards minimum joint

displacements in order to minimize energy

consumption in the system.

Each cost function call (whether within the

workspace or not) requires the inverse dynamic

simulations, which has significant effect on the

computational efficiency of the optimization. The

computational cost in the proposed algorithm is

reduced due to not running the inverse model in the

alternative cost function calculations when the

constraints are not satisfied. To further demonstrate

the advantages of the proposed algorithm over the

conventional method of handling the constraints, the

same optimization was run with Mathlab “fmincon”

function with the cost function as in Eq. (1), and the

constraints specified separately as nonlinear

inequality constraints. It was observed that the

optimization algorithm called the cost function even

when the parameters did not satisfy the constraints.

The number of cost function calls with parameters

values outside the permissible workspace was

significant (82 out of 243 iterations), resulting

unnecessary solving of the inverse dynamics.

In addition to computational efficiency, in cases

where the B-splines are used to describe the

trajectory in Cartesian coordinates, an additional

nonlinear constraint has to be added to make sure

that the end point does not fall outside the circle of

radius

21

ll +

during the motion. The conventional

constraint handling would still call the inverse

dynamics model when this constraints was not

satisfied. This would cause the inverse dynamics

simulation to crash or terminate prematurely as the

required motion cannot be physically achieved. The

proposed algorithm avoids this problem.

6 CONCLUSIONS

A methodology for optimal trajectory planning of

robotic manipulators has been described in this

(b)

(a)

(d)

(c)

OPTIMUM TRAJECTORY PLANNING FOR INDUSTRIAL ROBOTS THROUGH INVERSE DYNAMICS

109

(a) friction coefficient of 1.5 (b) friction coefficient of 5

Figure 5: Results for the designed optimal path in terms of temporal positions for increasing friction values.

paper. A fourth degree B-spline function was used to

define the trajectory and hence the continuity of

velocity and accelerations were guaranteed for the

desired trajectory. An inverse dynamic analysis of a

two degree of freedom manipulator is performed by

using Lagrangian dynamics and an in-house

software package Dysim. In the proposed

optimization method, all the constraints are built in

the cost function. Therefore, computational

complexity is reduced by avoiding inverse dynamic

analysis when the parameters produce a motion that

does not satisfy the constraints. The proposed

algorithm also avoids the problems with cases where

the inverse dynamics model cannot be run when

some specific constraints are not satisfied.

REFERENCES

De Boor, C., 1978. A Practical Guide to Spline, Springer.

New York.

Garg, D, P., Kumar, M., 2002. Optimisation techniques

applied to multiple manipulators for path planning and

torque minimisation. Engng Appl Artif Intell 15, pp.

241–252.

Gasparetto, A., Zanotto, V., 2007. A technique for time-

jerk optimal planning of robot trajectories. Robotics

and Computer-Integrated Manufacturing. In:

press:doi:10.1016/j.rcim.

LoBianco, C, G., Piazzi, A., 2002. Minimum-time

trajectory planning of mechanical manipulators under

dynamic constraints. Int J Contr 75 (13), pp. 967–980.

Niku, S, B., 2001. Introduction to Robotics: Analysis,

Systems, Applications, Prentice Hall.

Qin, K., 2000. General Matrix Representations for B-

Splines. Visual Computer, vol. 16, no. 3/4, pp. 177-

186.

Sahinkaya, M, N., 2004. Inverse dynamic analysis of

multiphysics systems. Proceedings of the Institution of

Mechanical Engineers Part 1-Journal of System and

Control Engineering. 218(T1): 13-26.

Saramago, S., Ceccarelli, M., 2004. Effect of basic

numerical parameters on a path planning of robots

taking into account actuating energy. Mechanical and

Machine Theory 39, pp. 247–260.

Saravanan, R., Ramabalan, S., 2008. Evolutionary

minimum cost trajectory planning for industrial robots.

Journal of Intelligent and Robotic Systems 52:1, pp.

45-77.

The Mathworks Inc. Matlab R2007a. Computer Program.

Wells, Dare, A., 1967. Schaum's Outline of Theory and

Problems of Lagrangian Dynamics with a treatment of

Euler's Equations of Motion, Hamilton's Equations,

and Hamilton's Principle. New York: McGraw Hill

Book Company.

Zanotto, V., Gasparetto, A., 2007. A new method for

smooth trajectory planning of robot manipulators.

Mech Machine Theory, 42, pp. 455–471.

Zoller, Z., Zentan, P., 1999. Constant Kinetic Energy

Robot Trajectory Planning. Peridica Polytechnicaser.

Mech. Eng. Vol. 43, No.2, 213 – 228.

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

110