WEARABLE HUMAN BODY JOINT AND POSTURE

MEASURING SYSTEM

P. Dunias

Personal Monitoring Department, TNO Science and Industry, Eindhoven, The Netherlands

R. Gransier

Dept. Orthopaedic Surgery / Dept. Human Movement Sciences, Maastricht University Medical Centre (MUMC+)

Maastricht, The Netherlands

A. Jin, A. Statham

Personal Monitoring Department, TNO Science and Industry, Eindhoven, The Netherlands

P. Willems

Dept. Human Movement Sciences, Maastricht University, Maastricht, The Netherlands

Keywords: Human posture measurement device, Human joint measurement, Knee angle measurement.

Abstract: In many medical applications, especially the orthopaedic setting, ambulatory, monitoring of human joint

angles could be of substantial value to improving rehabilitation strategies and unravelling the

pathomechanics of many degenerative joint diseases (e.g. knee osteoarthritis). With the ageing of the

population and increasing incidence of obesity, the prevalence of degenerative joint diseases is increasing

(e.g. knee osteoarthritis is the single most common cause of pain and disability in middle-aged and older

adults. As an example, In case of osteoarthritis rehabilitation, it is critical to monitor the loading of the

affected joint during activities of daily living (ADL). These measurements allow monitoring of daily

activity patterns, joint angles and walking patterns, which could be of use in adjusting the applied therapy

depending on the results measured.

1 INTRODUCTION

In many medical applications ambulant, continuous

monitoring of human joint angles offers some

appealing added value to existing diagnosis and

rehabilitation means, particularly in areas such as

orthopaedics where monitoring the progress of the

therapy provides more insight regarding therapy

effectiveness. In case of arthritis rehabilitation, for

example, it is desirable to support the recommended

therapy by objectively monitoring the behaviour of

the patient outside the clinic or hospital. Based on

these measurements the specialist may check the

exact exercise of the patient and subsequently adjust

the applied therapy as necessary depending on the

results. In this case the walking pattern of the knee

joint was monitored as the most relevant to

pathologies of this nature.

In more complex situations, for example with

lower back pain prevention and/or rehabilitation, the

level of bending in all directions of the lower back

and the corresponding velocity could also be

monitored preventing situations that should be

avoided occurring by giving direct feedback to the

user.

As a consequence a number of publications have

reported ambulant instrumentation in recent years

(Gransier, 2010), (Riskowski, 2009). However, only

very few wearable systems are accurate enough in a

dynamic situation when, for instance, the user is

walking freely around. On the other hand there are

several systems measuring human joint angles and

268

Dunias P., Gransier R., Jin A., Statham A. and Willems P..

WEARABLE HUMAN BODY JOINT AND POSTURE MEASURING SYSTEM.

DOI: 10.5220/0003195202680272

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2011), pages 268-272

ISBN: 978-989-8425-37-9

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

posture in a laboratory setting which are not of direct

interest in this study.

Comfort, accuracy and a user friendly interface

are key elements for such a device to work

successfully and be accepted in the medical world.

The basic element of the measuring system

introduced here is a very flexible, textile integrated

bending sensor. Several of these basis elements may

be combined in order to measure multi-dimensional

joints or more degrees of freedom of the human

body.

In the next sections the basic element required to

measure bending is described.

2 BENDING SENSOR

2.1 Single Bending Sensor

Measuring bending in our setting is based on the

change of electrical inductance of a very simple coil

(a loop of a conductive wire). It appears that the

inductance of a coil changes as the form of the coil

changes. The mutual inductance by a filamentary

circuit i on a filamentary circuit j is given by the

double integral:

lY

sdds

L

a

CC

i

π

μ

π

μ

44

0

2/][

0

+

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

′

⋅

≈

≥

′

∫∫

R

R

(1)

where

0

μ

denotes the magnetic constant (4πx10

-

7

H/m), C and C

′

are curves along the wires,

R

is

the distance between two points on respectively

C

and

C

′

. The vectors

ds

and

sd

′

represent

vectors along C and C

′

. When

R

becomes zero the

above equation becomes infinitive and therefore

there is an extra condition that

R

has to be larger

than half the thickness of the wire a. In that case the

inductance is only dependant on the radius a and its

length l and some factor Y denoting the current

distribution through the wire (typically Y=1/4).

When the form of the coil changes, the orientation of

ds

and

sd

′

changes and probably the distance

between them too. That results in a change of the

inductance of the coil.

As can be seen in equation (1) the mutual

position and orientation of the wire segments

determine the total inductance of the coil. It is these

elements that vary when the coil bends and thus

consequently changes the inductance

correspondingly. The wire used in this sensor is very

flexible and thin and integrated in a carrier e.g.. knee

brace, t-shirt, strap etc.

In the case that the bend of the coil is directly

connected to a single bending angle of a human joint

(knee, elbow etc.), a simple calibration can be used

to translate the bending inductance readings into an

absolute angle value. Calibration can be done using

a reference measuring system that simultaneously

measures the joint angle.

However in some cases, where the carrier may

be minimally shifted due to movement, the system

can be automatically recalibrated based on extra

information from accelerometers mounted on the

carrier.

2.2 Automatic Recalibration

In many applications where the bending sensors are

firmly attached to a body joint the translation from

inductance reading into joint angles can be done

once based on some discrete calibration

measurements. In particular in the case of a single

joint the calibration can be performed using

mechanical goniometry.

However, wearing a sensory system for a longer

time in a day inherently implies local shifting of the

system on the body, hence a discrepancy of the

calibration of the sensor. In addition, by fitting or

“putting on” the sensory system in a non-

reproducible way, the user introduces an additional

error in the calibration. To account for this an

automatic calibration was introduced based on extra

sensors mounted around the joint. A set of two tri-

axial accelerometers is placed above and below the

joint. When the user is in a steady state (sitting,

standing etc.) the readings of the accelerometers

may be used to calculate the absolute angle of the

joint. In static situations the accelerometers are only

measuring some proportion of the gravitational

force. Based on this, the angle between the

accelerometers is calculated. In dynamic situations

(walking, running etc.), the accelerometers “see”

simultaneously the gravitational force and the

human movement. In this case the calculation of the

joint angle is not possible using the accelerometers.

For this case the inductance measurement is used for

calculating the joint angle. Every static situation

during the day is used to (re)calibrate the bending

sensor compensating for any changes of the bending

sensor attachment on the human joint.

In summary, during static situations the

accelerometers are used to calculate the absolute

joint angle and calibrating the bending sensor, and in

dynamic situations only the calibrated bending

sensor is used.

WEARABLE HUMAN BODY JOINT AND POSTURE MEASURING SYSTEM

269

2.3 Validation of a Single Bending

Sensor

The goal of the validation study was to quantify the

knee angle error during normal activity (i.e.

standing, sitting, and walking). Therefore a single

bending sensor was attached to a knee brace with the

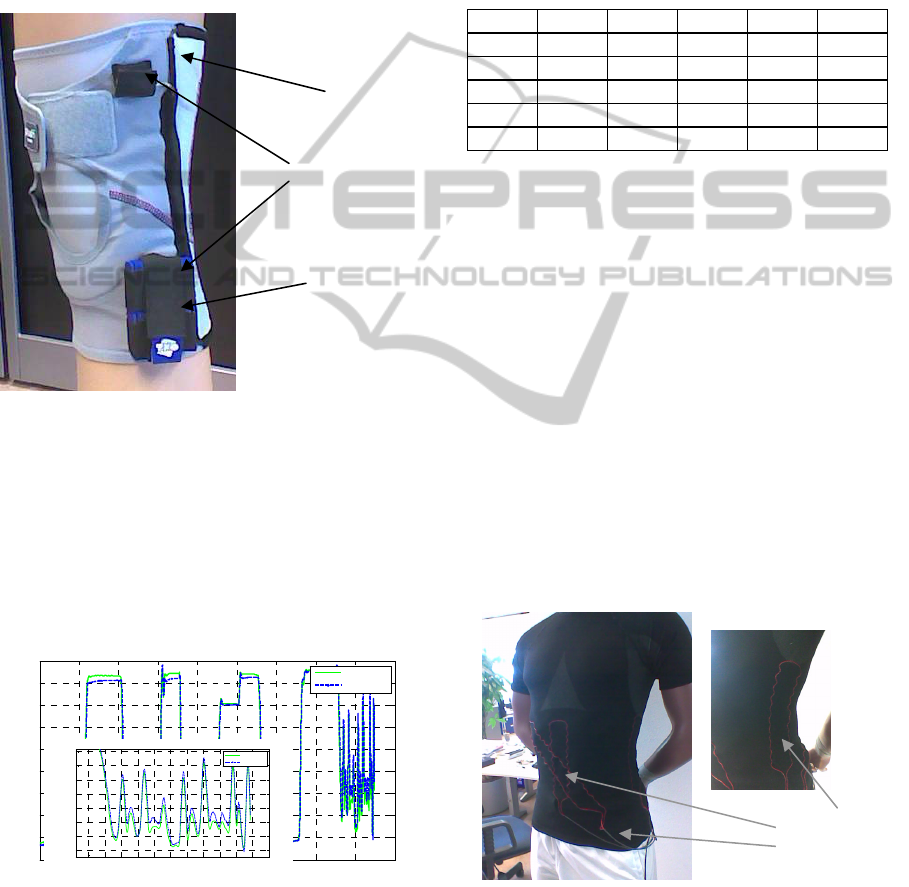

aim to measure the knee joint angle. In Figure 1 a

knee brace is depicted where the inductance loop is

attached.

Figure 1 Knee brace including bending/angle sensor.

Besides this the two accelerometers to be used

for the automatic calibration are attached on the

upper and lower parts of the brace. For validation

purposes, the knee angle was also measured using an

external VICON Camera system

(http://www.vicon.co). Figure 2 depicts a

measurement where the VICON knee angle and the

angle measured can be compared.

0 10 20 30 40 50 60 70 80 90

0

10

20

30

40

50

60

70

80

90

time [s]

angle [deg]

E:\KB\Maastricht06052010\Audrey\Audrey Trial 1.c3d

Vicon angle

KB angle

Figure 2: Measured and reference knee angle (static and

dynamic part).

The protocol followed consisted of a series of

common movements i.e standing, sitting (twice), leg

bending at four positions during sitting, standing,

sitting, standing and walking. A number of users

have been measured (5 reported in this paper), where

mostly five measurements have been performed per

user. A typical sample of the validation results are

shown in Table 1 depicting the maximal absolute

value of the error which is the difference between

the measured angle and the reference angle.

Table 1: Validation Result.

person a b. c d e

Mean 1.851 2.327 2.579 3.085 3.973

Abs. 1.559 2.617 2.093 3.577 3.504

Error 1.804 3.239 1.765 2.970 2.719

[deg] 1.464 2.313 2.446 3.204 2.130

1.421 2.051 2.186 4.246 2.523

An extended description of the validation

procedure and the corresponding validation results

of this specific single bending sensor are reported in

(Gransier et al., 2010) and (Riskowski et al. 2009).

2.4 Multiple Bending Sensor

A combination of the aforementioned single bending

sensor can be used in the case of measuring more

complex human joints, i.e. shoulder, wrist etc. Not

only joints but also body posture i.e. torso, can be

measured using a number of single bending sensors.

Suppose a human body part, the lower back for

example, which should be measured in terms of

three angles (flexion-extension, lateral flexion-

extension and rotation). Using a carrier, in this case

a shirt, it was possible to attach a number of wire-

loops on strategic positions around the body (see

Figure 3).

Figure 3: t-shirt crrier of osture multiple bending senor.

Measuring with a multiple bending sensor

consists of the following steps:

Inductance

bending

Sensors

75 76 77 78 79 80 81 82 83 84 85

10

20

30

40

50

60

70

80

time [s]

angle [ deg]

E:\ KB \M aastric ht 06052010\ Audrey\ Aud rey Trial 1.c 3d

Vic on angl e

KB an gle

Inductance

wire loop

Accelerometerers

Electronics

(acquisition,

storage)

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

270

• Calibration or modeling the single

bending sensors separately

• Calculating the body posture based on

the readings of the single bending

sensors.

2.4.1 Calibration/Modelling

Calibrating a bending sensor really means modeling

the behavior of the inductance loop as function of

the angles or degrees of freedom of the body part

under consideration. Suppose a model of a single

bending sensor:

),( apSL

i

=

(2)

Where

m

R∈p represents the parameter set and

n

R∈a

the angles of the body part under

consideration. Here m number of parameters and n

degrees of freedom is assumed. Commonly there are

three degrees of freedom in the case of most human

joints and body parts.

Based on a number of measured inductances and

the corresponding body posture, the model can be

fitted by tuning the parameters.

2.4.2 Measuring Body Part Posture

Based on the calculated models for a number of

bending sensors it is then possible to calculate the

body part posture. The relationship between bending

sensor readings and body part posture is of a very

complex, non-linear, character. The problem of

calculating the body part posture has bee resolved to

provide an estimation of the real posture

1

.

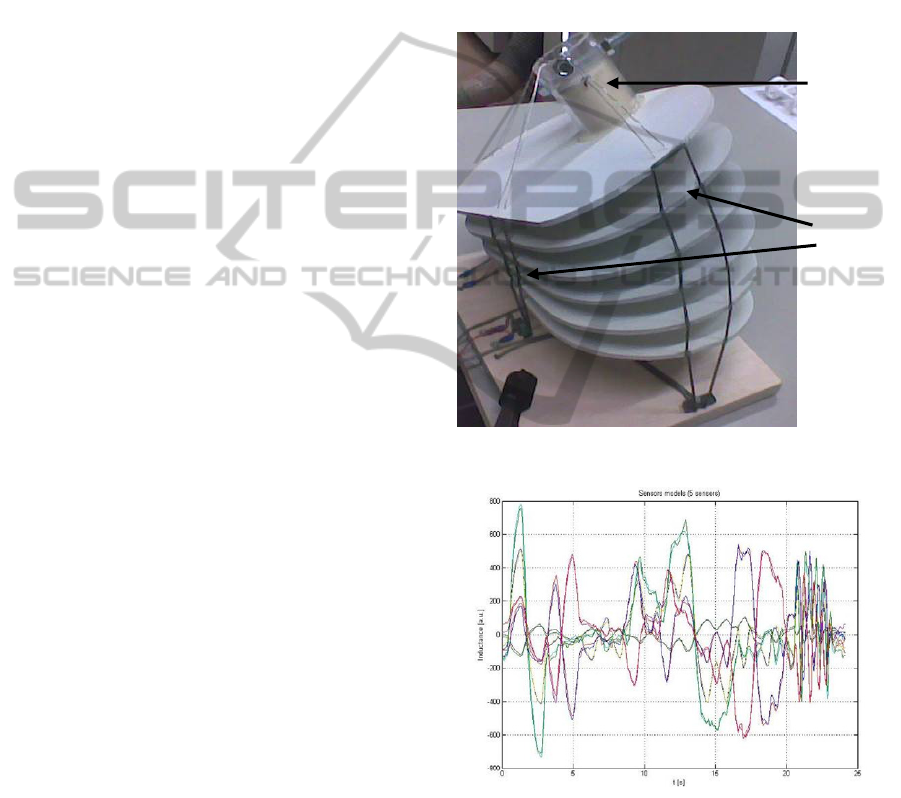

2.5 Validation of a Multiple Bending

Sensor on a Dummy Body

Torso/Spine

Comparable to the single angle bending sensor, for

the multiple bending sensor a carrier was chosen to

attach the inductance wires on the body in the form

of a tightly fitting elastic t-shirt. Before the system

could be implemented on the human body, a dummy

torso model was used to validate the modeling and

measuring method described in the previous

sections. An image of this torso model can be seen

in Figure 4. A flexible column represents the human

spine, with more rigid protruding discs modeling the

skeleton ribs. On this dummy model flexible

conductive wire loops are positioned in such a way

so as to form a multiple bending sensor. By

measuring with a VICON camera system and

simultaneously with the multiple bending sensor the

three degrees of freedom of this model (two bending

directions and one rotation around the spine) we

acquire data for modeling and validation purposes.

In this instance a model has been fitted for every

single bending sensor separately. In Figure 5 the

inductance models of the bending sensors are

depicted as described by equation (2). Based on

these sensor models the validation of the multiple

bending sensor has been investigated. The three

degrees of freedom of posture are then calculated.

Figure 4: Low back model.

Figure 5: Models of bending sensor model.

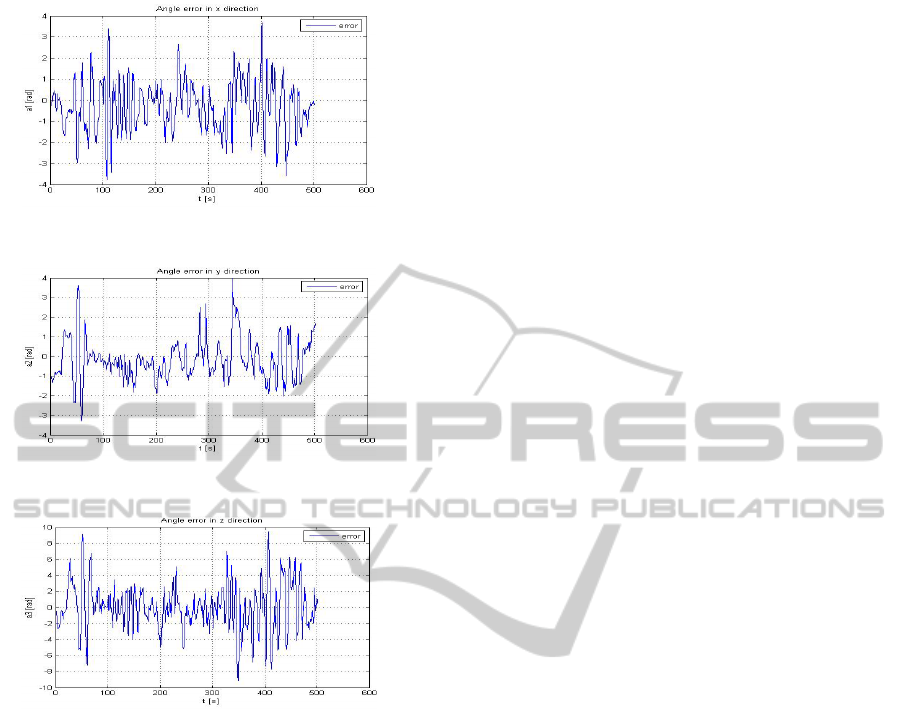

The error between the real angles and the

calculated angle in Figure 6, Figure 7 and Figure 8

for the three separate degrees of freedom in

reference to one sensor.

As appears, in x- and y-direction the angle error

is less than ±2 degrees, and in z-direction less than

±6 degrees.

“Spine”

Sensors

WEARABLE HUMAN BODY JOINT AND POSTURE MEASURING SYSTEM

271

Figure 6: Angle error in x-direction.

Figure 7: Angle error in y-direction.

Figure 8: Angle error in z-direction.

3 CONCLUSIONS

A single bending human joint angle sensor system is

presented. The measuring accuracy of ±2 degrees

gives unique and sufficient basis for clinical

ambulant applications basis for further exploitation

of the technology.

In case of more complicated body moving parts

(shoulder, trunk etc.) a combination of single

bending sensors may be used to measure the relevant

degrees of freedom of the body part under

consideration. The accuracy results for flexion-

extension and lateral flexion-extension are very

promising (<2 degrees). In case of the torso rotation

angle we report higher errors (<6 degrees) and

depending on the application may meet the required

accuracy. Further investigation using realistic sensor

carriers i.e. t-shirt, is on going. Such a system (t-shirt

including sensors, electronics etc) has already been

built and tested.

ACKNOWLEDGMENTS

Special thanks to Merijn Wijnen of TNO Science &

Industry and Paul Willems of Maastricht University

for their support and assistance.

REFERENCES

Gransier, R., Dunias, P., Meijer, K., Deckers, P.,

Guldemond, N., Van Rhijn, L., 2010. Validating an

ambulant clinical monitoring system in Osteoarthritis

of the Knee; “The Knee Coach”. In Abstract

Orthopaedic Research Society.

Riskowski, J., Mikesky, A., Bahamonde, R., Burr, D.,

2009. Design and Validation of a Knee Brace with

Feedback to Reduce the Rate of Loading. In Journal of

Biomechanical Engineering, vol. 131.

Meijer, K., Gransier, R., Dunias, P., Deckers, P.,

Guldemond, N., Willems, P., Van Rhijn, L., 2010.

Determination of Gait Kinematics with a “Smart”

Knee Brace A Validation Study, In 6

th

World

Congress of Biomechanics.

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

272