NON UNIFORM GEOMETRY BEND SENSORS EXPLOITED

FOR BIOMEDICAL SYSTEMS

Giovanni Saggio, Stefano Bocchetti, Carlo Alberto Pinto, Giuseppe Latessa and Giancarlo Orengo

Dept. of Electronic Engineering, University of Rome “Tor Vergata”, Rome, Italy

Keywords: Bend sensors, Human postures, Data glove, Linearization.

Abstract: In biomedical systems the bend sensors have been increasingly used stands their interesting properties

useful to measure human joint static and dynamic postures. These commercially available sensors are

usually made of a polyester film printed on with a special carbon ink. The film acts as a support while the

ink’s resistance value changes with bending dues to an applied external force. The substrate film material is

usually made by Kapton and/or Mylar for their properties, stands the fact that substrate must be able to bend

repeatedly without failure for the sensor to work. In spite of their interesting properties the commercial bend

sensors have a resistance vs. bent angle characteristic which is not actually ideal as a linear function, to

measure human postures, would be. So we introduce here a novel solution useful to linearize the sensor

response.

1 INTRODUCTION

Commercial bend sensors are usually made of a few

micrometer tick resistive material deposited onto a

thicker plastic insulating substrate. The overall

thickness is anyway negligible compared to the total

largeness and lengthiness, giving to the sensor a

rectangular geometry, with one side somewhat larger

than the other.

Figure 1: Unbent sensor (a) top (b) lateral view and bent

sensor (c) with the sensible part elongated.

These devices can be adopted as sensors when

placed on human joints with the larger side bent

according to the joints.

From a characterization point of view, the model

which takes into account the mechanical aspect of

the sensor predicts a linear behavior of the electric

resistive variation with the bending angle (Saggio et

al., 2009). Even the Ohm’s law,

⁄

, with

resistivity, l length and S section, suggests that

when the lengthiness l of the resistive sensor

material increases due to bending (see Fig. 1),

supposing a constant value of , it must correspond

a linear increase of the value R.

Nevertheless an electrical characterization of the

sensors furnishes non linear characteristics.

2 SENSOR

CHARACTERIZATION

We measured the characteristic of several

commercial bend sensors thanks to an home made

set-up previously described (Saggio et al., 2009;

Orengo et al., 2009) and as a result we selected

sensors provided by Flexpoint Inc. In particular, we

investigated the 2 inches long Flexpoint non

encapsulated sensors, polyester encapsulated sensors

and polyimide encapsulated sensors.

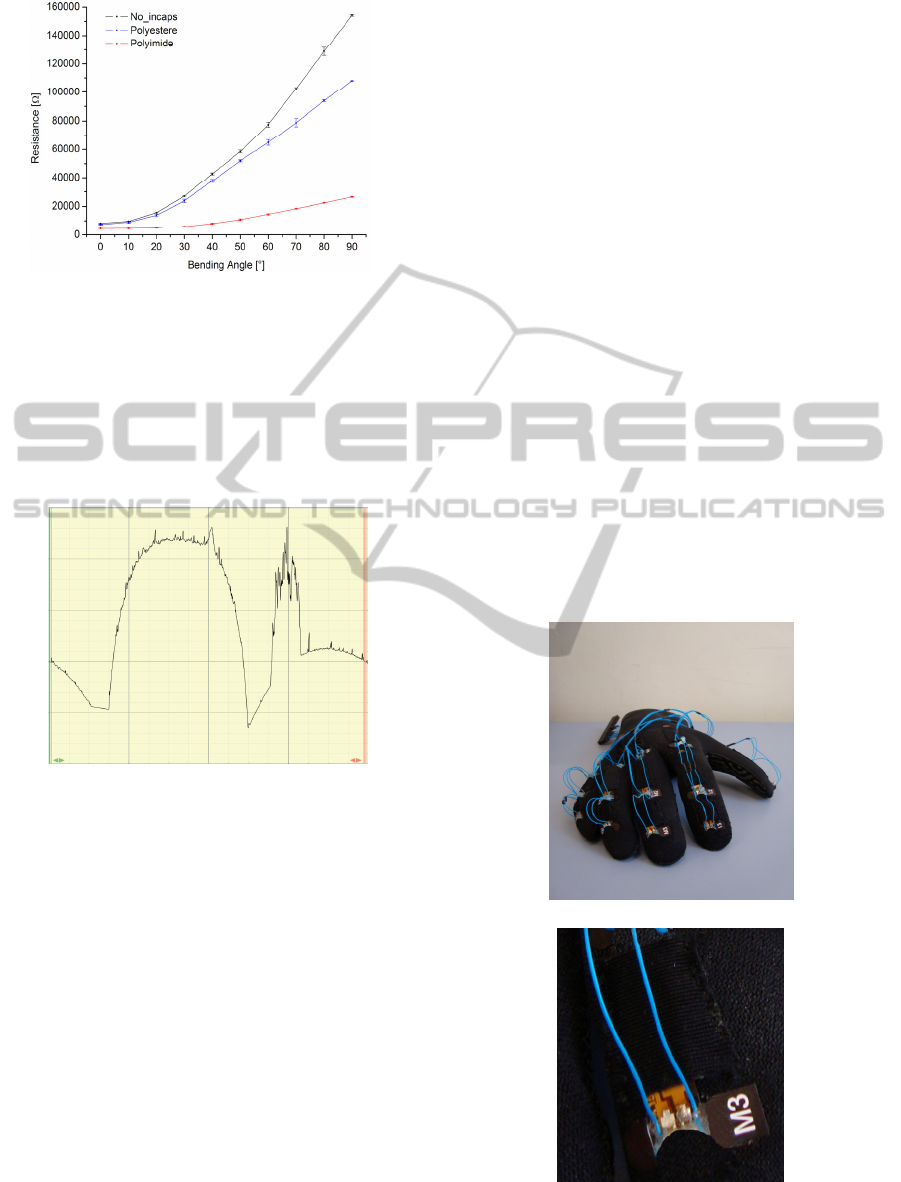

The results of our measurements, reported in Fig.

2, demonstrated the non linear mentioned

characteristic. In particular the resistance variation is

greater for non encapsulated sensors stands their

higher flexibility.

389

Saggio G., Bocchetti S., Pinto C., Latessa G. and Orengo G..

NON UNIFORM GEOMETRY BEND SENSORS EXPLOITED FOR BIOMEDICAL SYSTEMS .

DOI: 10.5220/0003121203890392

In Proceedings of the International Conference on Bio-inspired Systems and Signal Processing (BIOSIGNALS-2011), pages 389-392

ISBN: 978-989-8425-35-5

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

Figure 2: Resistance variation vs bending angle for three

different Flexpoint sensors.

These imply that the resistive material must be non

isotropic and must present non uniformity variation

when bent. This hypothesis can be demonstrated by

the profilometer measure we performed on the

shorter side of a Flexpoint bend sensor and reported

in Fig. 3.

Figure 3: Profilometer characteristic of the sensor by

Flexpoint. The two profiles are of the sensible film and the

contact film respectively.

3 LINEARITY VS NON

LINEARITY

The non linearity in the sensor’s characteristic is the

cause of some important drawbacks such as the time

consuming calibration and the more complexity in

designing both the conditioning electronics and the

algorithms to analyze the recorded data.

So to reduce these drawbacks an interesting

method to increase sensor linearity has been

previously proposed (Gentner & Classen, 2009).

Differing from that, here we propose a novel

approach to solve the same problem in a simpler

way.

4 SENSOR EXPLOITATION

These kind of sensors are usually (but not solely)

adopted for realizing the so called data glove, i.e. a

wearable system which is capable to measure all the

static and dynamic postures of the human hand (Di

Pietro et al., 2008). So, in order to measure finger

joint positions and movements, as a usual way of

proceeding, the sensors are commonly inserted in a

closed sleeve on top of a Lycra glove in

correspondence of each finger joints (Simone et al.,

2007). Differing from that, we adopted each sensor

in a open pocket a bit wider but a bit shorter than the

sensor itself (see Fig. 4). The pocket’s open end

allows free sliding movements for the sensor. Only

the sensor tip having the two electric terminals

lodged is stitched with the pocket. All the system is

then housed sewn on the Lycra glove in

correspondence to a finger joint. Let’s indicate this

as the 1F (1 end Fixed) configuration. With joint

bending, this configuration does not bent always the

same part of the sensor, because of a translation of

the sensor itself (due also to skin and glove

elongation), as depicted in Fig. 5 where is

represented our measurement bench with a hinge

applied to simulate the human finger joint.

(a)

(b)

Figure 4: (a) Data glove, 1F configuration (b)

magnification of a detail.

0 3000 6000

2

5

20

15

10

5

μ

m

μ

m

BIOSIGNALS 2011 - International Conference on Bio-inspired Systems and Signal Processing

390

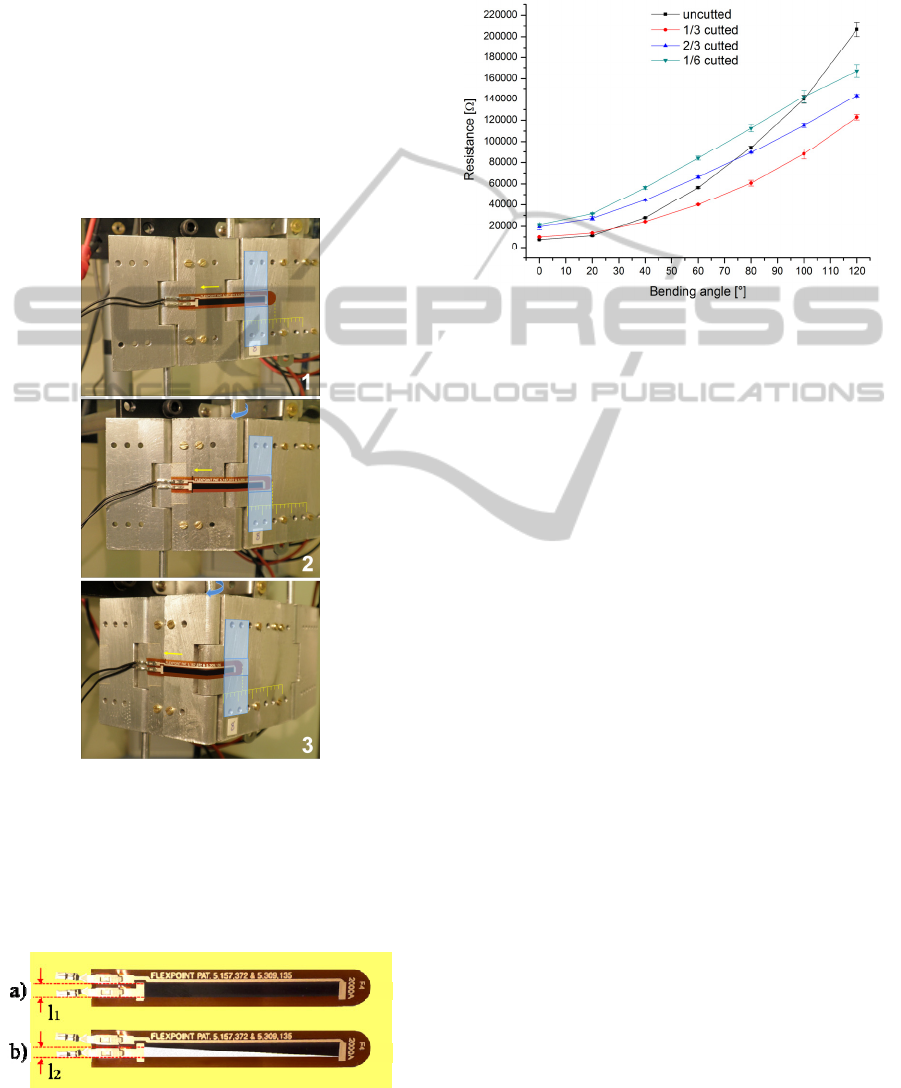

So, since the section of the sensor bent depends

on the bending angle, we can calculate exactly

which section is concerned every time.

Stand these points our idea was to change the

regular (rectangular) geometry of the sensor cutting

some part of it, so to increase or decrease its

resistance value, obtaining a linearization of the

previously reported non linear behavior (Fig. 2). In

particular our necessity was to increase the sensor

resistance value especially near the stitched sensor

tip, so the cut was done in a triangular shape with a

greater amount near the contacts (in correspondence

of the electrical terminals), matching the low

bending angle values (as represented in Fig. 6).

Figure 5: The sensor section which is bent changes @

every bending angle.

The validity of the idea was proved with ad hoc

measures. Several sensors, differing from their

triangular cut part in the shorter cathetus b) with

respect to a) in Fig. 6, were characterized.

Figure 6: (a) Regular (uncut) geometry sensor, (b)

changed (cut) geometry sensor.

Different amount of cuts were tried, and the results

for some of them, in particular for the non

encapsulated ones (which present greater non

linearity), are reported in Fig. 7.

Figure 7: Resistance variation vs. bending angle measured

for 3 different amount of cut.

As it can be noticed the linearization was increased

with the amount of cut, leading to a very good

behavior for a b) cathetus value of 1/6 with respect

to the uncut sensor. Indeed our measurements

demonstrated how a really interesting linearization

of the sensor resistance variation vs. bending angle

can be obtained with a sensor not rectangular shape

differing with respect to the common commercial

sensors.

5 CONCLUSIONS

The linearization of the bend sensor’s characteristic

leads to undeniable advantages. So here we

demonstrated how a linearization can be obtained for

such sensors especially when they are exploited for

measure human joint static and dynamic postures.

The linear characteristic was obtained with a

novel method operating few changes on the sensors

geometry and the measures demonstrated really

interesting results.

REFERENCES

Saggio G., Bisegna P., Latessa G., Bocchetti S.,

“Mechanical modeling of bend sensors exploited to

measure human joint movements” 1th IEEE

International WoWMoM Workshop on

Interdisciplinary Research on E-Health Services and

Systems, IREHSS 2009, Kos (Greece) June 2009, 978-

1-4244-4439-7/09/$25.00 ©2009 IEEE.

NON UNIFORM GEOMETRY BEND SENSORS EXPLOITED FOR BIOMEDICAL SYSTEMS

391

Orengo G., Giovannini L., Latessa G., Saggio G., Giannini

F. “Characterization of piezoresistive sensors for

goniometric glove in hand prostheses” Wireless

Vitae09 - Wireless Communications, Vehicular

Technology, Information Theory and Aerospace &

Electronic Systems Technology, Aalborg (Denmark),

17-20 May, 2009 – pp. 684-687

Gentner R., Classen J., “Development and evaluation of a

low-cost sensor glove for assessment of human finger

movements in neurophysiological settings” Journal of

Neuroscience Methods 178 (2009) 138–147

Dipietro L., Sabatini A. M., Dario P., “A Survey of Glove-

Based Systems and Their Applications” IEEE

Transactions on Systems, Man, And Cybernetics—Part

C: Applications and Reviews, Vol. 38, No. 4, July

2008

Simone L. K., Sundarrajan N., Luo X., Jia Y., Kamper D.

G., “A low cost instrumented glove for extended

monitoring and functional hand assessment” J

Neurosci Methods 2007;160:335–348

BIOSIGNALS 2011 - International Conference on Bio-inspired Systems and Signal Processing

392