INTEGRATION OF KNOWLEDGE MANAGEMENT IN

PRODUCT DESIGN PROCESS

Yang Xu and Alain Bernard

IRCCyN, Ecole Centrale de Nantes, 1 Rue de la Noë, 44321 Nantes, France

Keywords: Knowledge management, Product development process, Modelling.

Abstract: In order to keep up with the high adaptability of the product design requirements, it is essential to integrate

knowledge management into product design processes. This paper proposes a model that conjoins the

objects, functions, constraints and knowledge, analyzes the task evolution process by means of state

characterization. By using the schema based on the model, it is practical and efficient to find appropriate

knowledge to a given general object in the context of certain constraints.

1 INTRODUCTION

In this era characterized by worldwide competition,

knowledge management is playing a key role in

every aspect of our lives, especially in enterprise

productions (Bernard and Tichkiewitch, 2008). In

order to improve the possibility of success, a variety

of knowledge management (KM) and computer

integrated manufacturing (CIM) models have

emerged in recent years, such as the FBS-PPRE

model (Labrouse, 2004), advanced technologies

based on CIM (Nagalingam and Lin, 2008), the

GRAI integrated method (GIM) (Doumeingts et al.,

2000), the object-oriented approach based on the

UML (Unified Modelling Language) modelling

(Merlo and Girard, 2004), etc. They all have

particular contributions to the modelling and

analysis of the knowledge management.

Although the notion of knowledge management

has different explanations and its research content is

fairly abundant, the aim of giving appropriate

knowledge to appropriate persons at appropriate

times is widely accepted. Therefore, one of the

challenges for the knowledge management is to

clarify the expectations with constraints in order to

propose the corresponding knowledge to satisfy the

need.

This paper focuses on the architecture and the

process to match the objects, functions, constraints

and knowledge, and proposes an OFCK model

applied to the product design process.

The paper is organized in four parts. Besides the

introduction section, Section 2 proposes a model that

conjoins the objects, functions, constraints and

knowledge, Section 3 analyzes how knowledge is

integrated into the product design process, and

Section 4 concludes the paper with several

perspectives.

2 THE OFCK MODEL

From the experience in product development process,

we know in order to accomplish a complex task, it is

appropriate to divide it into sub-tasks and sub-sub-

tasks until the objects of the indivisible tasks can be

reached easily. The relationship among objects,

constraints and knowledge should be well studied in

order to find appropriate supports effectively.

Consequently, an Object-Function-Constraint-

Knowledge (OFCK) model is proposed to abstract

the relationship among these four aspects in

knowledge management.

2.1 Objects, Functions and Constraints

In practice, any task is consisted of two parts: the

object and constraint, as nothing can be done

without any constraint. Thus, a task is divided into

two sets: the set of objects and the set of constraints,

noted as follow.

• The set of objects

12

{ , ,..., }

op

Sooo= , where

12

, ,...,

p

oo o are called atomic objects. Each

338

Xu Y. and Bernard A..

INTEGRATION OF KNOWLEDGE MANAGEMENT IN PRODUCT DESIGN PROCESS.

DOI: 10.5220/0003093003380341

In Proceedings of the International Conference on Knowledge Management and Information Sharing (KMIS-2010), pages 338-341

ISBN: 978-989-8425-30-0

Copyright

c

2010 SCITEPRESS (Science and Technology Publications, Lda.)

atomic object

i

o corresponds to an atomic

function

i

f , in other words,

i

f can achieve

i

o and they are one-one corresponding:

ii

of⇔ . All these

i

f form the set of

functions

12

{ , ,..., }

f

p

Sfff= .

• The set of constraints

12

{ , ,..., }

cq

Sccc=

,

where

12

, ,...,

q

cc c are called atomic

constraints.

According to the idea of divide-and-conquer that

partitions the problem into fine scale sub-problems

and assembles of the solutions of the partitioned

sub-problems to constitute the overall (Gravemeier

and Wall, 2008), a task

T

can be divided into

several atomic sub-tasks that can be solved simply,

thus, a set of atomic tasks is noted

as

},...,,{

21 pt

tttS = , where

i

t is the atomic sub-

task. Each

i

t is an ordered pair consisted of an

atomic object and a set of constraints, i.e.

}),...,,{,(

21

i

p

ii

ii

cccot =

. Due to

ii

fo ⇔ , we

have:

}),...,,{,(}),...,,{,(

21

*

21

i

p

ii

ii

i

p

ii

ii

cccftcccot =⇔=

As a result, the task

T

is decomposed into a set

of ordered pair

}),...,,{,(

21

i

p

ii

i

cccf

.

2.2 The Knowledge

Knowledge should be organized properly in order to

be useful in practice, so a knowledge base KB is

introduced as the set of the organized knowledge

and it is defined as follows.

Definition 1. The knowledge base KB is a group of

vectors, noted as:

⎪

⎪

⎩

⎪

⎪

⎨

⎧

=

=

=

⎪

⎪

⎭

⎪

⎪

⎬

⎫

⎪

⎪

⎩

⎪

⎪

⎨

⎧

=

},...,,{

...

},...,,{

},...,,{

,

...

,

,

21

22

2

2

12

11

2

1

11

2

1

2

1

n

m

nn

n

m

m

n

n

kkkK

kkkK

kkkK

where

K

K

K

KB

In this definition,

j

K is the knowledge unit,

j

i

k is

the atomic knowledge, and

j

j

i

Kk ∈

.

2.3 The

Function-Constraint-Knowledge

Map

One of the most important targets in knowledge

management is to find required knowledge in the

context of the given objects and constraints, in other

words, to map the objects, constraints and

knowledge in a proper way. As

ii

fo ⇔

, the aim

becomes to build a Function-Constraint-Knowledge

(FCK) map.

Hypothesis 1. An atomic knowledge

j

i

k

possesses

an atomic function

y

f in the context of a certain set

of constraints

},...,,{

21 x

ccc , which is noted as:

{

}

yx

j

i

fccck ⎯→⎯⊗

Δ

,...,,

21

This hypothesis is based on the facts that the

knowledge is regarded as a kind of support in

solving practical problems, so it must have a kind of

function, otherwise, can it be called “knowledge”?

As a result, in the FCK map, there are groups of

“

k

,

f

, },...,,{

21 x

ccc ”.

2.4 Knowledge Seeking

From the previous analysis, once an atomic task

i

t

is given with related constraints, required atomic

knowledge can be found through the FCK map.

Then, an effective method should be referred to in

order to seek the knowledge in the KB that can

provide the atomic knowledge required. One idea is

to apply the inverted list used in the practical

information retrieval systems to support text

searching (Lester et al., 2006), which is an effective

structure that maps from a query term, the atomic

knowledge

1

k , to a posting list that identifies the

knowledge units that contain that term.

3 KNOWLEDGE INTEGRATION

IN PRODUCT DESIGN

PROCESSE

The process of product design is one of the most

complex stages in production which need both

explicit and tacit knowledge. For example, as simple

as a chair, its design process is not as easy as we

thought. Concisely, a designer has to consider about

INTEGRATION OF KNOWLEDGE MANAGEMENT IN PRODUCT DESIGN PROCESS

339

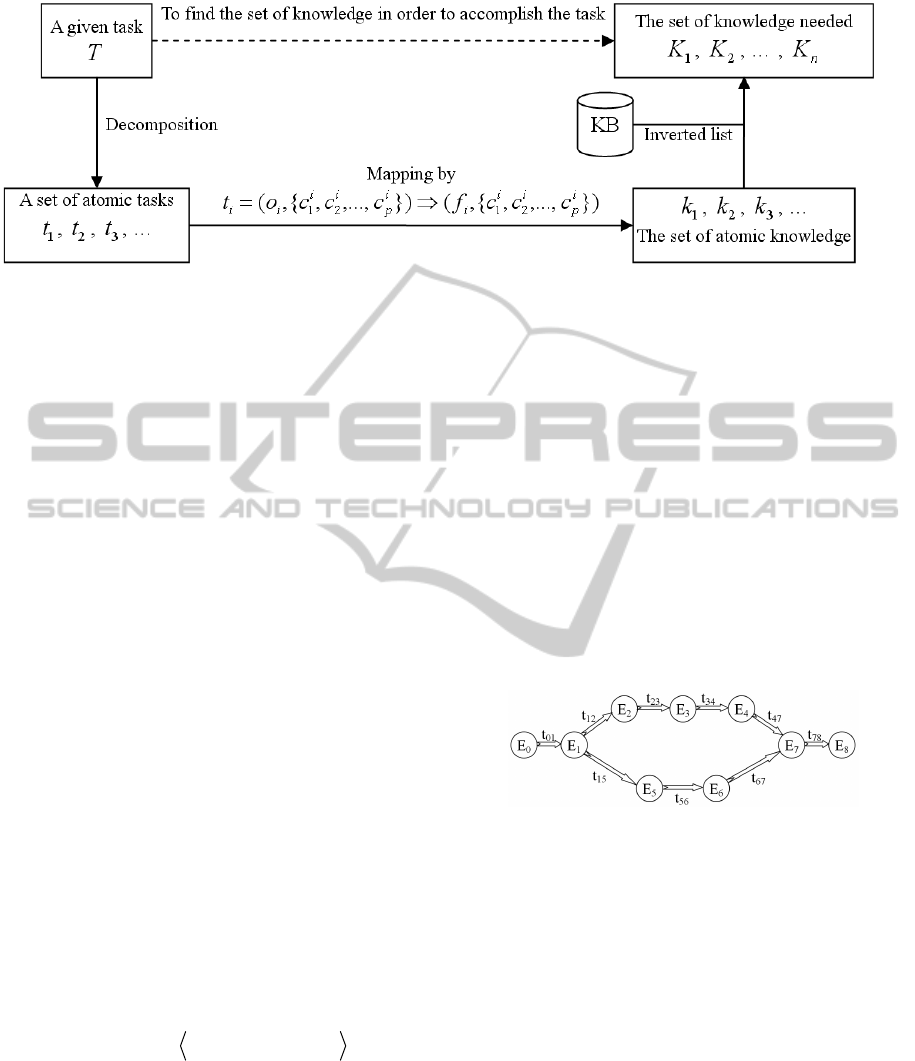

Figure 2: The application process of the OFCK model.

its comfort, mechanical support, recycle possibilities

and manufacturing cost. The complicated

relationships of function, constraints and knowledge

are involved. For example, a designer may use

carton as the main material of the chair to satisfy the

task of “the chair should be recycled”, but can it

meet the requirement of “to support a man of 80kg”?

To achieve this object, different chair architectures

are possible according to different chair materials,

which are related to cost consideration. At the same

time, chair architecture should also take the task of

aesthetic design into account. In a word, design

processes are very complicated, so we need a

knowledge management model to simplify and

realize them.

One basic idea is to decomposed a whole task as

sub-tasks and arrange these sub-tasks. The OFCK

model described in the section previously presented

is atom-unit oriented, so a general task should be

decomposed in order to adapt to the model. To begin

with, the product development process is

characterized as a basis of task decomposition.

3.1 Characterization of the Product

Development Process

In order to characterize the product development

process, a finite state machine of product (FSMP) is

proposed and defined as follows.

Definition 2. A finite state machine of product

(FSMP) is a hextuple

FEQ ,,,,,

0

δ

Π∑

, where:

Q

is a finite and non-empty set of product

states;

∑

is a finite and non-empty set of supports

(knowledge, manipulations, etc.);

Π is a finite and non-empty set of constraints;

δ

is the state transition function:

QQ →Π×∑×:

δ

;

0

E is an initial product state and QE ∈

0

;

F

is the set of final states and

QF ⊂

, and

there is at least a state FE

n

∈

.

In fact, the aim of the OFCK model is to find

appropriate knowledge to realize the supports

according to the given task and constraints.

3.2 Task Decomposition

In order to achieve the main object, the general task

is decomposed by splitting the whole project into

sub-parts, and the process of achieving the general

task is regarded as an evolution process of the

product states, shown in Figure 1.

Figure 1: A product development process described by

FSMP.

In Figure 1,

i

E is the product state and

i

t is the

atomic task to change the related state. Inferred from

the OFCK model, knowledge seeking is processed

as:

i

mapFCKthe

i

p

ii

ii

i

p

ii

ii

k

cccftcccot

⎯

⎯

⎯

⎯

→

⎯

=⇒=

21

*

21

}),...,,{,(}),...,,{,(

Consequently, the formalized definition the

general task

T

is given as follows.

Definition 3. The general task

T

is what to be

accomplished to realize a product development

process, in other words, to evolve the product

P

from

0

E to

n

E . The product

P

is a finite state

KMIS 2010 - International Conference on Knowledge Management and Information Sharing

340

machine defined on the knowledge set

K

and

)(PL

is the language generated by the product, in

other words, a sequence of elements in

K

, noted as:

⎪

⎭

⎪

⎬

⎫

⎪

⎩

⎪

⎨

⎧

==

∈∧∈

=

njni

QEKkkkk

PL

P

j

P

i

P

n

PP

,..,2,1,0;,..,2,1

);()(|...

)(

21

where

T

j

E

is the state in the evolution process of the

product

P .

We have

PT ⇔

, that is to say, each general

task

T

links to a product development process of

product

P

. For example, the task of “design a

chair”, means to realize a product design process,

from the initial state “an idea” to the final state

“details of the chair”.

3.3 The Application Process of the

OFCK Model

Thanks to the OFCK model, some issues in

knowledge management can be simplified to the

problem of seeking solutions from a knowledge base

when the general object and constraints are given

(shown in Figure 2). For example, in a case of

designing a chair, the OFCK model can be applied

to seek the knowledge required.

1. Decomposition. The general task of

“designing a chair” can be decomposed into

sub-tasks such as considering the architecture,

considering the cost, considering the recycle

possibilities, considering aesthetics, etc.

2. Mapping. Once the atomic tasks are clarified

in the design process, the atomic knowledge

can be found by the use of the FCK map.

3. Retrieving. The required knowledge can be

retrieved through the ILK or imported from

the extern.

4 CONCLUSIONS AND

PERSPECTIVES

This paper has proposed the OFCK model to

describe the relationship of objects, constraints and

knowledge, which helps to find the appropriate

knowledge to a given general object in the context of

certain constraints. The main idea of the paper is to

find the appropriate knowledge to a given task.

Further studies may aims at the optimization

procedure of the product design process, in other

words, how to accomplish the tasks in a more

efficient way. Another research opportunity is about

the improvement of the characterization of the

product design process. When some processes have

recursions, the task decomposition process will be

much more complicated and the mapping process

should be reconsidered.

REFERENCES

Bernard, A., Tichkiewitch, S., 2008. Methods and tools for

effective knowledge life-cycle-management. Springer:

Berlin.

Doumeingts, G., Ducq, Y., Vallespir, B., Kleinhans, S.,

2000. Production management and enterprise

modeling. Computers in Industry 42(2-3): 245-263.

Gravemeier, V., Wall, W. A., 2008. A space–time

formulation and improved spatial reconstruction for

the “divide-and-conquer” multiscale method.

Computer Methods in Applied Mechanics and

Engineering 197(6-8): 678-692.

Labrousse, M., 2004. Proposition of a unified conceptual

model for the dunamic enterprise knowledge

management. PhD. thesis, Ecole Centrale de Nantes,

France .

Lester, N., Zobel, J., Williams, H., 2006. Efficient online

index maintenance for contiguous inverted lists.

Information Processing & Management 42(4): 916-

933.

Merlo, C., Girard, P., 2004. Information system modelling

for engineering design co-ordination. Computers in

Industry 55(3): 317-334.

Nagalingam, S. V., Lin, G. C. I., 2008. CIM—still the

solution for manufacturing industry. Robotics and

Computer-Integrated Manufacturing 24(3): 332-344.

INTEGRATION OF KNOWLEDGE MANAGEMENT IN PRODUCT DESIGN PROCESS

341