A RECEDING HORIZON GENETIC ALGORITHM FOR DYNAMIC

MULTI-TARGET ASSIGNMENT AND TRACKING

A Case Study on the Optimal Positioning of Tug Vessels along the Northern

Norwegian Coast

Robin T. Bye, Siebe B. van Albada and Harald Yndestad

Department of Technology and Nautical Sciences, Ålesund University College, Postboks 1517, N-6025 Ålesund, Norway

Keywords:

Genetic algorithm, Receding horizon predictive control, Resource allocation, Multi-target tracking, Dynamic

environments.

Abstract:

Combining methodologies from cybernetics and artificial intelligence (AI), we present a receding horizon

genetic algorithm (RHGA) for solving the task of dynamic assignment and tracking of multiple targets. We

demonstrate the capabilities of the algorithm by means of a case study on optimal positioning of tugs to reduce

the risk of oil tanker drifting accidents along the northern Norwegian coast. Through simulations we show that

the RHGA performs intelligent target assignment and close target tracking while constantly reevaluating its

suggested solutions based on current and predicted information. We see great potential for further development

and consider our RHGA and problem description a platform for further research.

1 INTRODUCTION

The task of assigning agents to the tracking of multi-

ple targets in a dynamic environment constitutes sev-

eral overlapping challenges. First, there is the prob-

lem of resource allocation: Which agents shall track

which targets? If there is redundancy, that is, there

are more agents than targets, each target can have at

least one agent assigned to it. However, as is com-

monly the case, the number of targets exceeds the

number of agents, meaning that agents are assigned

more than one target. In addition, some targets may

be more important to track than others. This poses a

second problem of tracking, or dynamic positioning,

of agents relative to the targets: How can the agents

collectively move so that net tracking performance is

maximised? Third, tracking performance can be de-

fined as the ability to reduce a cost measure, or func-

tion. How is this cost measure defined? Finally, being

in a dynamic environment, agents need to constantly

reevaluate these problems: How can the agents in-

corporate future changes in the state space, such as

motion of targets and changing dynamics of the sur-

roundings?

In this paper we present a receding horizon ge-

netic algorithm (RHGA) for solving the abovemen-

tioned challenges. To aid the reader and to emphasise

the usefulness of such a method, we undertake a case

study of a real-world example regarding the position-

ing of tug vessels along the coast of northern Norway.

The Norwegian Coastal Administration (NCA) is in

charge of a vessel traffic services (VTS) centre in the

town of Vardø, which in turn administers a number

of tugs. The main task of these tugs is to patrol the

coastline in a manner that reduces the overall risk of

oil spill resulting from drift grounding accidents in-

volving oil tankers.

Oil tankers are required by law to sail along prede-

fined corridors distant to the coastline, meaning that it

is possible to predict a ship’s future position, for ex-

ample by linearly extrapolating its speed along its cor-

ridor. Furthermore, both static (identity, destination,

cargo, etc.) and dynamic (speed, position, heading,

etc.) ship information are constantly being transmit-

ted through the automatic identification system (AIS)

and made available to VTS centres. Together with

weather forecasts and models of factors such as wind

and ocean currents, this information can be used to

predict potential drift trajectories and grounding posi-

tions, for example in the case of a ship losing manoeu-

vrability through steering or propulsion failure (Eide

et al., 2007b). If a tug is close enough, it can inter-

cept the ship’s drift trajectory and tow the ship away

before it runs ashore. Thus, in keeping with the termi-

114

T. Bye R., B. van Albada S. and Yndestad H..

A RECEDING HORIZON GENETIC ALGORITHM FOR DYNAMIC MULTI-TARGET ASSIGNMENT AND TRACKING - A Case Study on the Optimal

Positioning of Tug Vessels along the Northern Norwegian Coast.

DOI: 10.5220/0003087101140125

In Proceedings of the International Conference on Evolutionary Computation (ICEC-2010), pages 114-125

ISBN: 978-989-8425-31-7

Copyright

c

2010 SCITEPRESS (Science and Technology Publications, Lda.)

nology in the introductory paragraph, the patrol tugs

correspond to agents and the oil tankers’ drift trajec-

tories correspond to target trajectories.

The NCA has developed risk-based decision sup-

port tools based on dynamical risk models that draws

on a vast pool of information (Eide et al., 2007a; Eide

et al., 2007b). Some of this information is static and

certain, such as a ship’s type, its crew, and amount and

type of oil it is carrying. Information about other fac-

tors is uncertain and based on models of wind, ocean

currents, accident frequency and consequences, spill

size and impact, and so on. The decision support tools

are able to aid a human operator at a VTS centre in

commanding tugs by pointing out high-risk positions

that tugs should approach. However, as the number of

tugs and oil tankers grows, the problem of allocating

tugs to several positions quickly becomes non-trivial.

Thus there seems to be a need of a computer program,

or algorithm, that can take the existing models and

decision support tools one step further by calculating

where each tug should move. The calculation may be

based on a number of input variables set by the oper-

ator. For example, particular oil tankers or areas may

be given special priority.

The program should run in real-time, however,

given that it usually takes many hours from the mo-

ment that a ship loses manoeuvrability until it runs

ashore and the relatively slow dynamics of ocean cur-

rents, a moderate update rate suffices.

In the following sections, we will present a sim-

plified version of the tug positioning problem and an

algorithm that solves it by combining receding hori-

zon control (RHC) with a genetic algorithm (GA). We

will show how the RHGA performs in some simulated

scenarios and finally we will discuss our results, lim-

itations to our approach, and future potential.

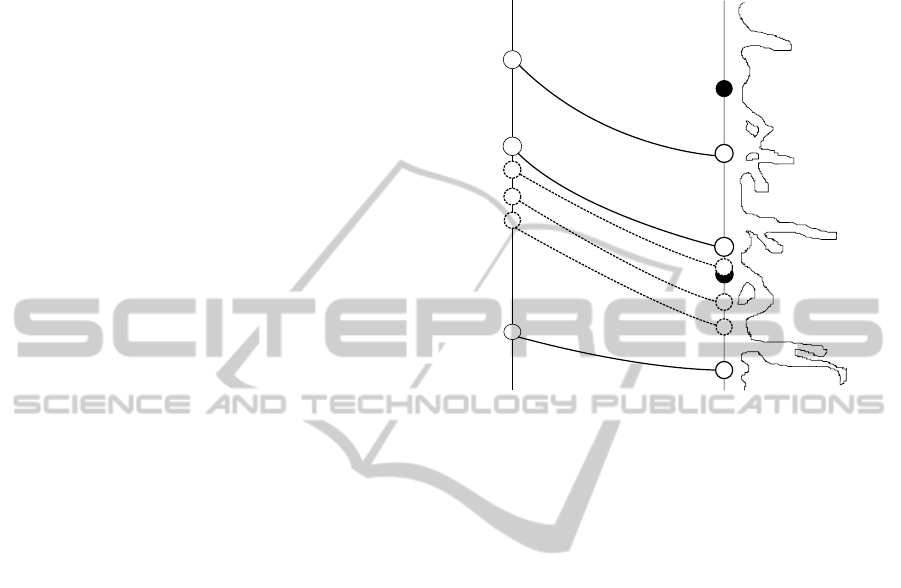

1.1 Problem Description

To simplify the problem, we will assume that N

o

oil

tankers move in one dimension only up and down

(north and south, say) an oil tanker line of motion y

o

.

This seems reasonable considering that oil tankers are

required to follow predefined straight-line-segmented

corridors. Closer to shore, we assume that N

p

tugs

are moving, or patrolling, up and down a patrol line of

motion y

p

parallel to that of the oil tankers. We ignore

collisions between oil tankers and patrol tugs on their

respective lines of motion. Naturally, we acknowl-

edge that the coastline with its fjords, peninsulas, and

islands does not constitute a straight line, however,

given that tugs should stop drifting ships before they

reach land or danger zones, it seems reasonable to

simplify the problem as described. Figure 1 shows

a graphical representation of the problem description.

Next, we assume the availability of an accurate

Oil tanker line

yo

Patrol tugs line

yp

Coast line

Oil tanker

Oil tanker

Oil tanker

Patrol tug

Patrol tug

D

r

i

f

t

t

r

a

j

e

c

t

o

r

y

D

r

i

f

t

t

r

a

j

e

c

t

o

r

y

D

r

i

f

t

t

r

a

j

e

c

t

o

r

y

Cross

point

Cross

point

Cross

point

t = td

t = td

t = td + 1

t = td + 2

t = td + 3

t = td

t = td

t = td + drift time

t = td

t = td + 2 + drift time

t = td+3 + drift time

t = td + 1 + drift time

t = td + drift time

t = td + drift time

Figure 1: Problem description. Oil tankers (white circles)

and patrol tugs (black circles) move in one dimension up

and down (north and south, say) lines y

o

and y

p

, respec-

tively. Predicted drift trajectories starting at some time

t = t

d

with corresponding cross points on the patrol line are

shown as indicated. In addition, dashed circles and lines in-

dicate another three predicted cross points from future drift

trajectories starting at t = t

d

+1, . .. ,t

d

+3 for the oil tanker

in the middle. How should the tugs move in order to best

prevent drift grounding accidents?

model, or set of models, such as those developed by

the NCA and described in Section 1. These mod-

els are able to predict future positions of oil tankers

along y

o

and their corresponding potential drift trajec-

tories given current and predicted information about

ships (e.g., speed and direction) and the environ-

ment (e.g., wind and ocean currents). Specifically,

for an oil tanker positioned at y

o

(t) at time t = t

d

,

the model can predict its future position ˆy

o

(t) for

t = t

d

+ 1, . . . , t

d

+ T

h

, where T

h

is the prediction hori-

zon and we use a discrete-time formulation with a

sampling time of 1 hour. For each position ˆy

o

(t) there

is a corresponding predicted drift trajectory that may

or may not reach the patrol line y

p

at some time in the

future depending on ocean currents, wind conditions,

and other factors. Collecting all predicted drift trajec-

tories for all oil tankers, the model can thus provide

a distribution of cross points where potential drift tra-

jectories cross the patrol line predicted a time T

h

into

the future.

Figure 2 shows an example scenario. Based on

such a distribution, the problem is to calculate trajec-

tories (sequences of patrol points) along y

p

for each

A RECEDING HORIZON GENETIC ALGORITHM FOR DYNAMIC MULTI-TARGET ASSIGNMENT AND

TRACKING - A Case Study on the Optimal Positioning of Tug Vessels along the Northern Norwegian Coast

115

of the patrolling tugs in such a manner as to minimise

the risk that an oil tanker in drift cannot be reached

and saved before grounding. This is a difficult prob-

lem dealing both with resource allocation (which tugs

shall cover which areas) and tracking (how the cover-

age, or tracking of cross points shall be accomplished)

in a dynamic environment.

0 5 10 15 20 25

−100

−80

−60

−40

−20

0

20

40

60

80

100

Time (hours)

Patrol line y

p

or oil tanker line y

o

Figure 2: Example scenario. White squares indicate the

positions of six oil tankers on the oil tanker line y

o

at

t = 0. White circles indicate where predicted drift trajec-

tories cross the patrol line y

p

as a function of time. Black

circles indicate three random patrol trajectories on y

p

for

t = 0, . . . , T

h

, where the prediction horizon is set to T

h

= 24

hours. The regions reachable by the three tugs at full speed

from y

p

(0) are depicted by the dotted lines. All positions

are in arbitrary units.

2 METHOD

2.1 Genetic Algorithm

For the simplest case of a single oil tanker and a sin-

gle tug, classical control theory and mathematics can

provide an analytical solution to solve the problem de-

scribed in Section 1.1, however, this case is mostly

of academic interest. Just by slightly increasing the

number of oil tankers and tugs the problem becomes

exceedingly difficult, cf. Figure 2, which shows three

tugs and three randomly generated patrol trajectories

they may follow in order to track the drift trajecto-

ries of six oil tankers. One possible approach is to

examine a finite number of sets of potential patrol tra-

jectories for the tugs and for each set evaluate some

kind of cost function in order to measure the perfor-

mance of the tugs. There are several methods that

likely can find near-optimal solutions in reasonable

time for this approach, for example variants of Monte

Carlo methods, simulated annealing, ant colony opti-

misation,genetic algorithms (GAs), or other artificial

intelligence (AI) methods. Here, we use a continuous

GA based on a version as described in (Haupt and

Haupt, 2004).

2.1.1 Characteristics of the GA

The GA used in this paper follows the general scheme

used in most GAs (Haupt and Haupt, 2004):

1. Define a cost function and a chromosome encod-

ing and set some GA parameters (mutation, selec-

tion).

2. Generate an initial population of chromosomes.

3. Evaluate a cost for each chromosome.

4. Select mates based on a selection parameter.

5. Perform mating.

6. Perform mutation based on a mutation parameter.

7. If the desired number of iterations or cost level is

reached, stop algorithm and return solution, oth-

erwise, repeat from Step 3.

The selection parameter is in the range 0–1 and

determines how many chromosomes in a population

survives from one iteration to the next. The cost as-

sociated with each chromosome is evaluated and the

chromosomes are given a weighted selection proba-

bility according to their cost, where a smaller cost

results in a greater probability. For a selection pa-

rameter of 0.5, half the population is then randomly

picked, with low cost chromosomes having a greater

chance of being picked, and kept for survival and re-

production. The other chromosomes are discarded to

make room for new offspring.

For mating, the GA uses a combination of an ex-

trapolation method and a crossover method. Informa-

tion from two parent chromosomesare combined with

an extrapolating method to obtain new offspring vari-

able values bracketed by the parents’ variable values.

A single crossover point is used to determine which

parts of the parent chromosomes are used for creating

offspring.

After mating, a fraction of the genes are mu-

tated, which means that the values of these genes

are changed to random numbers within an allowable

range. A mutation rate determines how many genes

are mutated at every iteration. The interested reader

may refer to (Haupt and Haupt, 2004) for further de-

tails on this mating process.

Specific to the problem described in this paper is

the choice of cost function and chromosome encod-

ing. These are described in detail in respective Sec-

tions 2.1.2 and 2.1.3 below.

ICEC 2010 - International Conference on Evolutionary Computation

116

2.1.2 Cost Function

For the results presented in this paper, we define the

cost function as the sum of the distances between all

cross points and the nearest patrol points. The rea-

soning behind this is that if an oil tanker in drift can

be saved by a tug a certain distance away, it is ir-

relevant that other tugs further away can save it at a

later time. Note that "later time" assumes that all tugs

have the same maximum speed.

1

Moreover, as will be

demonstrated in Section 3, choosing this cost function

also yields proper task allocation, as patrol tugs will

tend to spread out and track different groups of cross

points, thus reducing the overall risk of grounding.

We may drop the subscript p for the patrol line y

p

and define y

p

t

as a patrol point on the pth tug’s patrol

trajectory at time t. Similarly, we may define y

c

t

as

a cross point on the cth oil tanker’s drift trajectory at

time t. For N

o

oil tankers and N

p

patrol tugs we can

then define the cost f(t, C

i

) as a function of time t = t

d

and the ith chromosome C

i

:

f(t, C

i

) =

t

d

+T

h

∑

t=t

d

N

o

∑

c=1

min

p∈P

|y

c

t

− y

p

t

| (1)

for P = {1, . . . , N

p

}. C

i

and y

p

t

are defined in the fol-

lowing in Equations 2 and 3, respectively.

2.1.3 Chromosome Encoding

A patrol trajectory for tug p can be obtained from a se-

quence of piecewise constant control inputs (speeds)

u

p

t

in the interval [−1, 1] for points in time t = t

d

+

1, . . . , t

d

+ T

h

. The maximum values at −1 and 1 are

equivalent to tugs going with maximum speed in the

negative or positive y

p

-direction, respectively. This

encoding is generic as it is independent of each tug’s

maximum speed.

To encode N

p

control trajectories as sequences u

p

t

of length T

h

(the prediction horizon) for each patrol

tug p ∈ {1, . . . , N

p

} we use chromosomes C

i

of length

N

p

× T

h

:

C

i

=

h

u

1

1

, . . . , u

1

T

h

, u

2

1

, . . . , u

2

T

h

, . . . , u

N

p

1

, . . . , u

N

p

T

h

i

(2)

That is, each chromosome is a concatenation of N

p

control trajectories, each consisting of T

h

future con-

trol inputs.

The predicted patrol points for tug p are then ob-

tained through linear extrapolation using the differ-

ence equation

y

p

t

= y

p

t−1

+ u

p

t

v

p

m

t

s

, (3)

1

For cases where tugs have different maximum speeds,

one could define arrival time as distance divided by maxi-

mum tug speed and sum the minimum arrival times for each

cross point.

where t

s

= 1 hour is the sampling time, v

p

m

is the max-

imum speed for the pth tug, and t = t

d

+1, . . . , t

d

+T

h

.

2.2 Receding Horizon Control

Given a GA that performs satisfactorily by obtain-

ing patrol trajectories that minimise our desired cost

function, the human operator at a VTS centre could

instruct the tugs to follow the chosen patrol trajecto-

ries in an open-loop manner and perhaps run the al-

gorithm again after some time has passed. A better

choice, however, would be to have the GA run at reg-

ular intervals, constantly incorporating new informa-

tion about oil tanker positions and direction, ocean

currents, weather conditions, and so forth. When

new patrol trajectories have been calculated, the tugs

could replace their respective patrol trajectories with

the new ones. This strategy is equivalent to a receding

horizon control (RHC) scheme, which is interchange-

ably termed model predictive control (MPC) in the

literature.

In RHC, a control strategy, or optimal trajectory,

that minimises some cost function is calculated a pre-

specified duration, or prediction horizon, into the fu-

ture. However only the first portion of the strategy

is implemented before another optimal trajectory is

calculated based on new and predicted information

available. This new trajectory replaces the old one

but again only the first portion is implemented and

the process then repeats.

RHC is currently one of the most popular control

algorithms employed in computer-controlledsystems,

predominantly in the petrochemical industry, but also

increasingly so in electromechanicalcontrol problems

(Goodwin et al., 2001). It can be shown that RHC can

be designed with guaranteed asymptotic closed-loop

stability (Goodwin et al., 2001) and this remarkable

property is perhaps the most important reason for its

popularity.

2.2.1 Constraints

An advantage of using RHC is that constraints can be

handled in the design phase of a control system and

not in some post hoc fashion after the design (Good-

win et al., 2001; Maciejowski, 2002). For the tugs,

an inherent limitation is the maximum speed at which

they can operate. This speed limits the size of the

envelopes in Figure 2 and thus the number of reach-

able cross points. Using RHC combined with the GA

ensures that this limitation is incorporated in the plan-

ning of tug trajectories.

A RECEDING HORIZON GENETIC ALGORITHM FOR DYNAMIC MULTI-TARGET ASSIGNMENT AND

TRACKING - A Case Study on the Optimal Positioning of Tug Vessels along the Northern Norwegian Coast

117

2.2.2 Optimisation

A good choice of initial population for a GA allows

it to quickly (with fewer iterations) find a good solu-

tion. Given that the dynamics of the simulated sce-

nario has not changed "too much," a solution found at

one RHC step should also be a viable solution at the

next RHC step. This is achieved by keeping the best

chromosome at one RHC step, modifying it slightly,

and inserting it into the GA’s initial population at the

next RHC step.

The kept chromosome has to be slightly modified

to accommodate planned trajectories now starting at

the next time instance of the simulation. This involves

a time-shift by discarding the first sample of the tra-

jectories in the best chromosome and adding a new

sample at the end, either with a random value, or, as

we choose to do here, with the same value as the next-

to-last sample.

2.3 Simulation Study

To implement and simulate the scenario presented

above we used the technical computing software

package MATLAB.

2

A number of choices had to be

made about positions, speeds, and directions of ships,

drift rates and directions, the GA and RHC, and gen-

eral settings. After performing some preliminary test-

ing we decided to use the settings described below.

2.3.1 Number of Ships

Based on information provided by NCA staff or af-

filiates and a recent report (Havforskningsinstituttet,

2010), we chose to use N

p

= 3 tugs and N

o

= 6 oil

tankers for our simulations. Whereas these figures are

realistic as of 2009, this situation will change dras-

tically in the near future due to the development of

nearby oil and gas fields (see Section 4.5).

2.3.2 Position of Ships

The initial position of ships at time t = 0 was varied

for each simulation. Specifically, we placed the oil

tankers on the oil tanker line y

o

at positions drawn

randomly from a uniform distribution in the range

[−50, 50] (arbitrary units). Likewise, we placed the

patrol tugs randomly in the same range on the patrol

line y

p

. The reason for doing so was to compare the

performance of the trajectories found by the RHGA

with just keeping the patrol tugs stationary at their ini-

tial positions.

2

MATLAB R2010a, available at http://www.mathworks.

com/.

2.3.3 Velocities of Ships

Each oil tanker was initialised with a random speed

in either the negative (southbound) or positive (north-

bound) y

o

-direction and drawn from a uniform distri-

bution in the range [−1, 1] (arbitrary units). The oil

tankers kept their respective speeds throughout each

simulation.

The patrol tugs were assigned a maximum speed

of 3 (arbitrary units) corresponding to the envelopes

presented previously in Figure 2. This choice was

made to ensure that tugs are much faster than oil

tankers and hence allow for more dynamic task al-

location (change of targets to track) and better track-

ing in our simulations. However, it should be kept in

mind that in the real world, oil tankers have a typical

operating speed of 14–15 knots (Det Norske Veritas,

2009) whereas tugs have a global average maximum

speed of about 12 knots, spanning from 5–26 knots

(Eide et al., 2007b).

3

2.3.4 Drift Trajectories

While we acknowledge that ocean currents and other

factors likely lead to curved drift trajectories perhaps

resembling those in Figure 1, we chose to assume that

any oil tanker in drift will move in a straight line per-

pendicular (directly east) to the patrol line and cross

it after some drift time. That is, if an oil tanker loses

manoeuvrability at y

o

(t

d

) = x, it will cross the patrol

line at y

p

(t

d

+ ∆t) = x after some drift time ∆t.

For each oil tanker we chose a random integer

drawn from a uniform distribution [8, . . . , 12] to be its

drift time and kept it constant throughout each simu-

lation. According to (Eide et al., 2007b), this choice

corresponds to a situation of "fast drift," whereas

"slow drift" means that most tankers will not run

aground within the first 30 hours. Thus, keeping our

drift times in the interval 8–12 hours is a conservative

estimate and in most cases, tugs will have more time

to come to the rescue of a drifting ship.

2.3.5 GA Settings

At every RHC step, we set the GA to perform N

iter

=

100 iterations searching for a solution set of opti-

mal trajectories minimising the cost function given by

Equation 1. A larger number improves the solutions

but it should be kept in mind that each solution set

is replaced at the next RHC step. This next step also

3

A close affiliate to the NCA recently informed us that

typically, in the geographical area of this case study, the

maximum speed of tugs is 15 knots and operating speed of

oil tankers is 10–14 knots.

ICEC 2010 - International Conference on Evolutionary Computation

118

takes advantage of the predictability of the drift tra-

jectories (straight lines) and uses a modified version

of the best chromosome found in the previous RHC

step (see Section 2.2.2).

The population size was set to 10 chromosomes

while the mutation rate was set to 0.1. The selection

parameter was set to 0.5, which implies that the best

half of each population was kept for mating at each

GA interation. These choices gave a good tradeoff

between exploration and exploitation given the other

simulation parameters described previously.

2.3.6 RHC Settings

The GA were used to find optimal trajectories with a

prediction horizonof T

h

= 24 hours for the patrol tugs.

At every RHC step, only the first sample (1 hour)

of these trajectories was executed by the tugs, before

another solution set of trajectories was found by the

GA. This process was repeated for N

RHC

= 26 RHC

steps (that is, each scenario was simulated for t

d

= 0

to t

d

= 25 hours).

2.3.7 General Settings

A total of N

sim

= 20 scenarios (random initial posi-

tions, velocities, and drift times) were simulated. For

each scenario, the optimal costs at each RHC step

were calculated and averaged and stored in vector

f

RHGA

of length N

sim

. Similarly, the costs that would

occur if the patrol tugs would not move from their

initial random positions (static trajectories) were cal-

culated and averaged and stored in a vector f

static

of

length N

sim

.

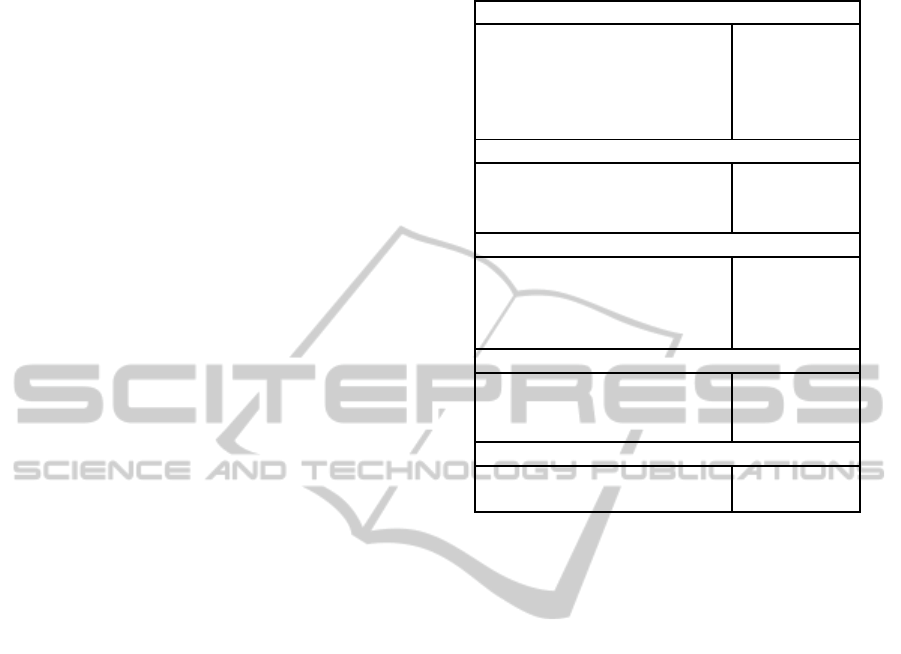

2.3.8 Settings Summary

The simulation settings for patrol tugs and oil tankers

as well as algorithm settings for the GA, the RHC

scheme, and some general settings are summarised in

Table 1.

3 RESULTS

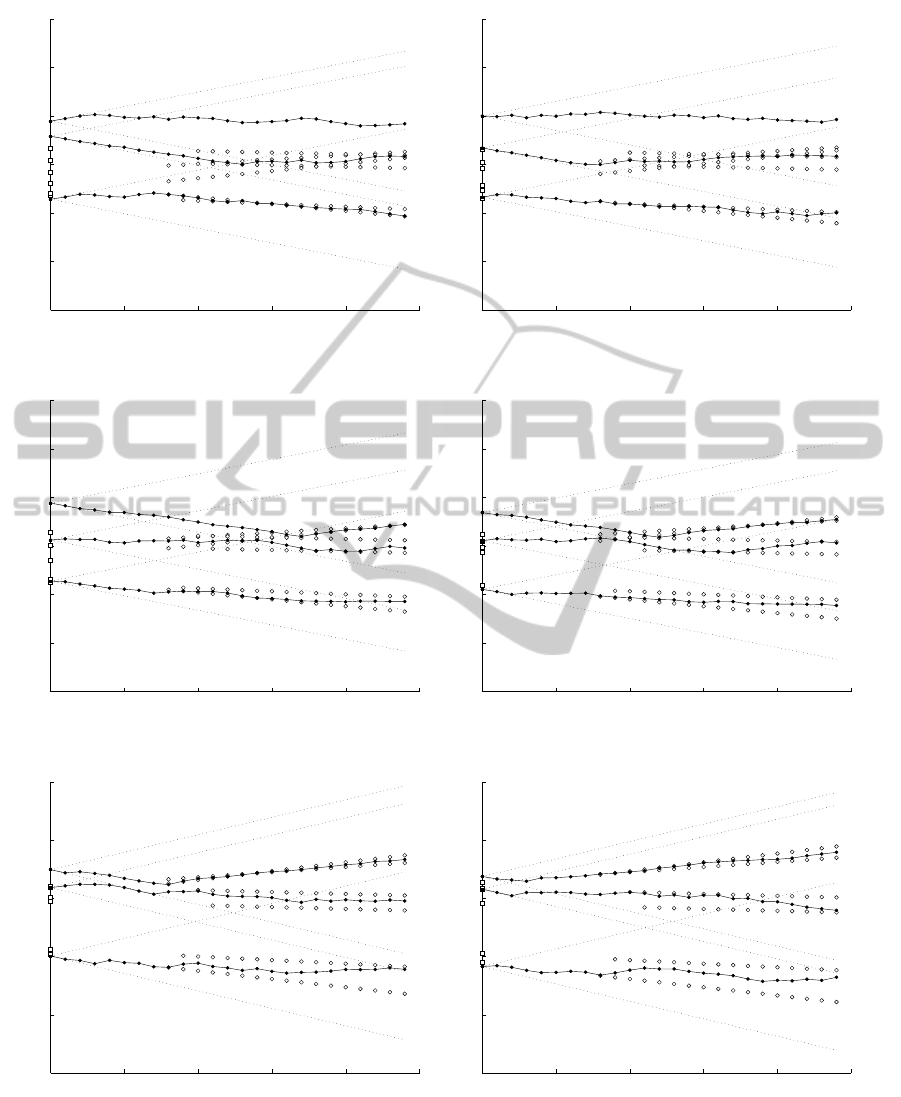

3.1 Simulation example

Figure 3 shows a simulation example using the set-

tings given in Table 1. Initially at drift time t

d

= 0

(Figure 3(a)), three patrol trajectories, each of dura-

tion T

h

= 24 hours into the future, are planned for

the tugs based on the predicted distributions of cross

points, that is, the positions and times where drift tra-

jectories cross the patrol line. The bottom two drift

Table 1: Simulation settings.

Oil tankers

Number of tankers N

o

6

Random initial position [−50, 50]

Random velocity [−1, 1]

Drift direction East

Random drift time ∆t (hours) [8, 9, . . . , 12]

Patrol tugs

Number of tugs N

p

3

Random initial position [−50, 50]

Max velocity ±3

GA settings

Iterations N

iter

100

Population size 10

Mutation rate 0.1

Selection 0.5

RHC settings

Prediction horizon T

h

(hours) 24

Simulation step (hours) 1

Number of steps N

RHC

26

General settings

Number of scenarios N

sim

20

Cost comparison f

RHGA

, f

static

trajectories are close together at around y

p

≈ −40,

thus the RHGA allocates the first and closest tug po-

sitioned at y

1

p

≈ −38 to these two oil tankers by plan-

ning a patrol trajectory that minimises the sum of dis-

tances from these drift trajectories’ cross points to

the nearest patrol points (see Section 2.1.2). Simi-

larly, the remaining four drift trajectories are clustered

around y

p

= 0, and the RHGA allocates the second

and closest tug at y

2

p

≈ 35 to these four oil tankers. Fi-

nally, the third and northmost tug at y

3

p

≈ 48 is not as-

signed any oil tanker and a roughly stationary "don’t

care" trajectory is planned for this tug.

At the next RHC step at t

d

= 1, each tug executes

the first sample (1 hour) of their planned trajectory be-

fore a new set of patrol trajectories, again of duration

T

h

= 24 hours, is planned based on updated informa-

tion about tug and oil tanker positions and predicted

drift trajectories and cross points. This process re-

peats for t

d

= 2, 3, . . . , 25, with the prediction horizon

constantly being shifted one sample, hence the con-

cept of RHC.

Figure 3(b) shows the current positions of oil

tankers and patrol tugs at t

d

= 5. The tugs are allo-

cated the same oil tankers as at t

d

= 0, however, be-

cause some oil tankers are moving north, their pre-

dicted drift trajectories are getting closer to the third

tug at y

3

p

≈ 50. As a result, a change in target alloca-

tion occurs in Figure 3(c), which shows a snapshot of

the situation at t

d

= 10.

A RECEDING HORIZON GENETIC ALGORITHM FOR DYNAMIC MULTI-TARGET ASSIGNMENT AND

TRACKING - A Case Study on the Optimal Positioning of Tug Vessels along the Northern Norwegian Coast

119

0 5 10 15 20 25

−150

−100

−50

0

50

100

150

Time since start: 0 hour(s)

Time (hours)

Patrol line y

p

or oil tanker line y

o

(a) t

d

= 0.

5 10 15 20 25 30

−150

−100

−50

0

50

100

150

Time since start: 5 hour(s)

Time (hours)

Patrol line y

p

or oil tanker line y

o

(b) t

d

= 5.

10 15 20 25 30 35

−150

−100

−50

0

50

100

150

Time since start: 10 hour(s)

Time (hours)

Patrol line y

p

or oil tanker line y

o

(c) t

d

= 10.

15 20 25 30 35 40

−150

−100

−50

0

50

100

150

Time since start: 15 hour(s)

Time (hours)

Patrol line y

p

or oil tanker line y

o

(d) t

d

= 15.

20 25 30 35 40 45

−150

−100

−50

0

50

100

Time since start: 20 hour(s)

Time (hours)

Patrol line y

p

or oil tanker line y

o

(e) t

d

= 20.

25 30 35 40 45 50

−150

−100

−50

0

50

100

Time since start: 25 hour(s)

Time (hours)

Patrol line y

p

or oil tanker line y

o

(f) t

d

= 25.

Figure 3: Example simulation. White squares indicate the positions of six oil tankers on the oil tanker line y

o

at time of drift

t

d

= 0, 5, . . . , 25. White circles indicates where predicted drift trajectories cross the patrol line y

p

as a function of time. Black

circles indicate the current positions and patrol trajectories suggested by the RHGA for three tugs on y

p

for t = t

d

, . . . , t

d

+T

h

,

where T

h

= 24 hours is the prediction horizon. The regions reachable by tugs going at maximum speed from their current

positions y

p

(t

d

) are depicted by the dotted lines. All positions are in arbitrary units.

ICEC 2010 - International Conference on Evolutionary Computation

120

Here, the RHGA plans a trajectory for the third and

northmost tug to begin tracking of the two northmost

drift trajectories (which are so closely positioned that

they are difficult to distinguish), another trajectory is

planned for the second tug to track the two middle

drift trajectories, and the first and southmost tug is

still assigned the two southmost drift trajectories.

Figures 3(d)–3(f) show that this allocation scheme

is maintained for the rest of the simulation: The first

(southmost) tug moves south while tracking the two

southmost drift trajectories, the second (middle) tug is

slowly moving north in order to track the two middle

drift trajectories, and the third (northmost) tug moves

south to track the two northmost drift trajectories.

Notice that in the latter case for the third tug,

the planned trajectories involves moving south at first

to "meet" the northbound drift trajectories and then

move north again while performing close tracking. If

the simulations had been run for t

d

> 25, this would

have become evident in the actually executed position

of the third tug (given that the oil tankers continue

their predicted movements). Similarly, the trajectory

for the second tug begins to tend southward at t

d

= 25

due to the predicted drift trajectories also going south.

Quantitatively, one possible performance measure

is obtained by comparing the cost of applying the

RHGA-generated trajectories to that of static trajec-

tories, that is, keeping each patrol tug p stationary

at its initial position, or y

p

t=0

= y

p

t=1

= . . . = y

p

t=T

h

.

For this simulation example, the overall RHGA cost

was found by summing the costs at t

d

= 0, . . . , 25 and

finding the average cost for each RHC step, which

equalled 463.7 (arbitrary distance units). The static

cost was 1837.4, thus the RHGA improved the static

cost by 74.8 %.

3.2 Main Study

Table 2 summarises the results from the simulation

example above (simulation run 1) and 19 other simu-

lated scenarios based on the settings presented in Ta-

ble 1. For every run, the average cost at each RHC

step t

d

= 0, . . . , 25 is calculated for the static case

(f

static

) and the RHGA case (f

RHGA

). Performance is

measured as the reduction in cost (in percent) from

applying the RHGA instead of the static strategy.

The best performance of the RHGA compared to

static trajectories was obtained in simulation run 12

and showed a cost reduction of 79.0%. The worst per-

formance happened in simulation run 2 and showed a

cost reduction of 26.2%. The mean performance was

a cost reduction of 65.8%.

Comparing the standard deviation of the costs for

static and RHGA trajectories, RHGA showed a reduc-

tion of 70.4%. This is not surprising, considering that

the static strategy can result in low cost trajectories by

chance simply because the drift trajectories roughly

coincide with the initial positions of tugs. Likewise,

the static strategy can lead to some very costly tra-

jectories, because the cross points are far away from

the static tug positions. As a result, the cost for each

simulation scenario will vary greatly depending on

each scenario. The RGHA trajectories, on the other

hand, are constantly being reevaluated at each sample

interval, accommodating both current and predicted

changes to the overall situation. This results in the

RHGA trajectories very effectively tracking the drift

trajectories and reducing the overall cost, which tend

to vary much less than in the static case.

Table 2: Simulation results.

Simulation f

static

f

RHGA

Performance

run (%)

1 1837.4 463.7 74.8

2 1552.2 1145.9 26.2

3 2278.0 675.1 70.4

4 3097.3 1314.0 57.6

5 2822.3 855.8 69.7

6 3929.4 1526.9 61.1

7 2431.7 633.5 73.9

8 2877.1 880.2 69.4

9 3174.7 794.0 75.0

10 1221.5 665.2 45.5

11 3839.0 1113.4 71.0

12 4356.1 914.3 79.0

13 1921.9 818.8 57.4

14 1536.1 583.4 62.0

15 1489.2 869.5 41.6

16 1546.6 575.5 62.8

17 1456.7 457.1 68.6

18 1836.8 445.8 75.7

19 950.8 559.9 41.1

20 3068.0 874.4 71.5

Mean 2361.2 808.3 65.8

Standard dev. 984.7 291.6 70.4

Best run: 12 79.0

Worst run: 2 26.2

3.3 Conclusions

The simulation results show that the RHGA is able

to simultaneously perform multi-target allocation and

tracking in a dynamic environment. The GA calcu-

lates patrol trajectories for allocation and tracking at

regular intervals in time. However, as the environ-

ment changes, an RHC process is employed, where

the GA is constantly used to replan new trajectories

based on current and predicted information.

A RECEDING HORIZON GENETIC ALGORITHM FOR DYNAMIC MULTI-TARGET ASSIGNMENT AND

TRACKING - A Case Study on the Optimal Positioning of Tug Vessels along the Northern Norwegian Coast

121

Employing a cost function related to the distance

from each cross point (where the predicted drift tra-

jectories crosses the patrol line y

p

) to the nearest pre-

dicted patrol trajectory gives good tracking but also

provides task allocation "for free." In short, the patrol

trajectories suggested by the RHGA yield good pre-

vention against possible drift accidents due to taking

the predicted future environment into account.

Nevertheless, this study should be considered a

preliminary study only that perhaps raises more ques-

tions than it answers. These questions will be dis-

cussed in Section 4.

4 DISCUSSION

4.1 Optimisation

Whereas this paper is not concerned with algorithmic

speed optimisation per se, an obvious point of opti-

misation is the choice of initial population in the GA

that must be set at every step of the receding horizon

planning process. Because the dynamics of the prob-

lem scenario is relatively slow-changing (e.g., ocean

currents, wind, or oil tanker speeds and directions),

the initial population should include good individ-

uals, and/or their offspring, from the previous time

step. This will ensure that the GA quickly can tune

in on good solutions, given that the scenario has not

changed too much from the previous time step. For

the simulations presented here, we chose to keep a

modified version of the best chromosome found in

one RHC planning step and put it in the initial pop-

ulation of the next one as described in more detail in

Section 2.2.2.

Moreover, this strategy can be further modified

to reduce the overall number of GA iterations: Af-

ter running a number of iterations at the first RHC

step until a good solution is obtained, only a fraction

of this number of iterations is needed for subsequent

RHC steps. This is because the dynamics are slow-

varying and the GA has "tuned in" to a good solution

space where the previously found solution greatly as-

sists the GA in finding the new, best solution.

Another modification that may speed up algorith-

mic conversion is to include boundary solutions cor-

responding to the trajectory envelope of each tug, that

is, to include solutions in the population correspond-

ing to tugs moving with maximum speed either north

or south. This ensures that "hard-to-find" cross points

far away from the tugs are detected and taken into

considerations.

Finally, it should be kept in mind that only the

best chromosome is transferred at every RHC step.

The other chromosomes are still initialised randomly

(or with some set to boundary solutions as suggested

above). Hence, if novelties have been introduced at

some RHC step, the RHGA will still be able to find

good solutions (albeit requiring more iterations than

for a more static scenario).

4.2 Evaluating Performance

There are several ways to evaluate the performance of

an algorithm. If one is concerned with algorithm con-

vergence speed, one may compare the time or number

of iterations it takes an algorithm to find a solution

with that of other algorithms. We are not particularly

concerned with the rate of convergence of the RHGA

for the case study investigated here. The reason for

this is that the dynamic scenario is relatively slow-

changing and even for a much larger number of sim-

ulated oil tankers and tugs, our algorithm will still be

able to plan trajectories and update them faster than

the real-world time.

To simulate one RHC step with three tugs and six

oil tankers for a particular scenario took about 30 sec-

onds on a MacBook Pro Core 2 Duo 2.53 GHz com-

puter. Increasing the number of oil tankers tenfold to

60 (which might be realistic in the not too distant fu-

ture, see Section 4.5), one RHC step took slightly less

than five minutes. This shows that the RHGA can ac-

commodate much greater complexity than simulated

in this study while staying within the real-time re-

quirement of finishing each RHC step within an hour

of real-time. It also implies that more accurate so-

lutions can be obtained by increasing GA parameters

such as population size and number of iterations at

each RHC step.

Conversely, the small execution time for a RHC

step means that the simulated duration of an RHC

step (1 hour) can be greatly reduced if desired. This

may not be relevant for the study presented here but

implies that systems with much faster dynamics may

take advantage of the RHGA. An example where each

RHC step must be in the range of tenths of seconds or

smaller is real-time control of football-playing robots,

where algorithm speed will most definitely be an is-

sue. For such applications, it is possible to adjust the

GA and RHC settings to obtain small RHC step du-

rations as required. Specifically, one may reduce the

prediction horizon, number of iterations, and popula-

tion size. This may not necessarily degrade perfor-

mance. For example, employing a large prediction

horizon in a football game where it is only possible to

predict actions a short period ahead will not increase

performance, it may even degrade it if it causes each

RHC step to take too long.

ICEC 2010 - International Conference on Evolutionary Computation

122

Another method for measuring performance of an

algorithm is to investigate its ability to reduce a cost

function (or conversely, increase some fitness func-

tion). Using the cost function defined by Equation 1

in Section 2.1.2, we compared the cost of applying

an RHGA strategy with a static strategy where tugs

are kept stationary at their initial random positions.

We found that the RHGA greatly reduces the cost

compared with the static strategy, however, it still re-

mains to compare the RHGA with other intelligent

algorithms for the same problem defined in this pa-

per. Nevertheless, we believe that the results from this

study are very promising and that the RHGA provides

a viable method for solving problems of the kind pre-

sented here.

4.3 Cost Functions

Choosing a suitable cost function is essential for a GA

to be able to solve the problem at hand. While we

believe our choice of cost function in Section 2.1.2 is

a very reasonable one, there are likely other choices

that may be equally, or better, suited to our problem.

One possible cost measure is to count the num-

ber of nonreachable cross points from tug positions

at time t = t

d

to t = t

d

+ T

h

ahead. Nonreachable

points are easily identified as the points that lie out-

side the dotted lines, or envelopes, that depict pa-

trol trajectories of tugs at maximum speed in Fig-

ure 2. Here, one of the southernmost drift trajectory’s

cross points is nonreachable by the southernmost tug

at y

p

(0) ≈ −20. Similarly, seven of the northmost

drift trajectory’s cross points are nonreachable by the

northmost tug at y

p

(0) ≈ 10. This count may then be

repeated for envelopes starting at t = 1, 2, . . . , T

h

− 1

and ending at t = T

h

and finally integrated for all t.

The goal of the GA would then be to select patrol tra-

jectories that minimise the total number of nonreach-

able points, integrated over time.

Preliminary results (not presented in this paper)

using a cost function involving nonreachable cross

points are promising but needs to be investigated fur-

ther. One major drawback is that this method is com-

putationally much more expensive compared to using

the cost function in Section 2.1.2. Another possible

drawback is that the RHGA will not lead to the same

close tracking of predicted drift trajectories as seen in

Figure 3. The reason for this is that the algorithm will

not punish patrol trajectories further away from cross

points than close ones as long as the number of non-

reachable crosspoints does not increase. On the other

hand, this may not be a problem for the case study

presented here. After all, the main goal of the tugs is

to be able to stop a drifting oil tanker from running

aground. Whether this is achieved by close tracking

of predicted drift trajectories or by some other intelli-

gent positioning is not as relevant, although secondary

goals such as minimisation of fuel consumption could

mean that close tracking be given importance.

A potential modification to the cost function in

Section 2.1.2 is to include a term for the control input

in order to punish excessive fuel consumption. For

example, consider Figure 3(a), where the third and

nortmost tug is not assigned any drift trajectory and

as a consequence is given a somewhat "random" os-

cillatory trajectory. Instead of planning such a fuel-

consuming trajectory, including a small input term in

the cost function would ensure that this patrol tug was

simply assigned a stationary trajectory, thus avoiding

unnecessary fuel consumption.

4.4 Other Heuristics

While we have compared the performance of our al-

gorithm with that of a static solution, it could have

been informativeto compareits performancewith that

of an algorithm using some simple heuristic method.

One such method is to let each patrol tug be allocated

the nearest oil tanker not already allocated to another

tug and then let it track that tanker’s drift trajectory.

We have not included any simulations using such a

heuristic in this paper. Nevertheless, we have found

that this method performs well when the numbers of

tugs and tankers are approximately equal but as the

number of tankers increases its performance drops

significantly compared to that of the RHGA. The rea-

son, of course, is that when all tugs have been allo-

cated an oil tanker, they "do not care" about the drift

trajectories of the remaining oil tankers, which in turn

causes evaluations of the cost function to increase.

Another simple heuristic is to spread out the tugs

evenly along the patrol line. Although not simu-

lated, we assume that this method could work rea-

sonably well for very large numbers of tankers since

the tankers’ cross points would then likely be roughly

uniformly distributed along the patrol line (assuming

the tankers not clustering). For a small number of

tankers, on the other hand, this heuristic would not be

able to perform well as cross points would not very

often occur close to the positions of the tugs.

4.5 Simulation Scenarios

There are numerous alternative scenarios that we

could have investigated in this paper. For exam-

ple, we could have lifted some of our restrictions

and incorporated changing drift dynamics (e.g., use

a dynamically-changing vector map for ocean curren-

A RECEDING HORIZON GENETIC ALGORITHM FOR DYNAMIC MULTI-TARGET ASSIGNMENT AND

TRACKING - A Case Study on the Optimal Positioning of Tug Vessels along the Northern Norwegian Coast

123

ts), let patrol tugs have different maximum speeds,

let oil tankers be weighted (e.g., based on their age,

cargo, crew, etc.), and so on. However, most of these

changes will be handled with ease by the RHGA as

they only amount to scaling of variables.

More relevant is the choice of number of ships.

Based on recent information in a governmental re-

port made by the Norwegian Institute of Maritime Re-

search (Havforskningsinstituttet, 2010), our choice of

three tugs and six oil tankers represents a realistic and

typical scenario as of today. Nevertheless, since these

figures are calculated based on measures of yearly

traffic, there will inevitably be days when the num-

ber of oil tankers is greater than six. Moreover, due

the development of large oil and gas fields in the Bar-

ents Sea such as Goliat, Snøhvit, and Shtokman, oil

(and gas) tanker traffic will greatly increase over the

next 10–15 years. As mentioned in Section 4.2, the

RHGA can easily handle the tenfold number of oil

tankers while maintaining real-time requirements and

thus appear well suited for much heavier traffic than

that of today.

We have not simulated cases where drifting actu-

ally occurs nor the situation where a tug becomes un-

available due to refuelling at land or being busy res-

cuing a drifting tanker. Nor have we tried to estimate

how many tugs are necessary to maintain a sufficient

degree of safety for a given number of tankers, which

is highly relevant considering the foreseen increase in

tanker activity. We intend to investigate this further,

in particular in light of other applications where re-

source allocation and deallocation happens even more

frequently.

Finally, it would be of interest to include more re-

alistic two-dimensional (2D) planning for ships and

three-dimensional (3D) planning for aeroplanes or

submersible vehicles. As discussed below, we intend

to continue development of our RHGA to accommo-

date such scenarios.

4.6 Other Applications

In addition to the one-dimensional (1D) problem de-

scribed in this paper, we believe that the RHGA is

suitable for performing multi-target allocation and

tracking in dynamic environments also in 2D and 3D.

This will require modifications to the algorithm and

we have already started this work. A 2D version in

environments with slow dynamics will required lit-

tle modifications, however, for fast dynamics and/or

3D environments, it is likely that the algorithm must

be improved, for example through distributed, paral-

lel control.

Moreover, it could be interesting to combine the

RHGA with so-called boid, or flocking, rules involv-

ing cohesion, separation, and alignment (Reynolds,

1987). In a promising effort, (Luo et al., 2010)

presents a flocking algorithm that modifies the flock-

ing rules by (Reynolds, 1987) and succeeds in multi-

target tracking performed by multiple agents. We

envision that through further development a modi-

fied version of the RHGA could perform equally well

as the algorithm used for the scenarios described by

(Luo et al., 2010).

Furthermore, we note that the problem defini-

tion used in this paper somewhat resembles that of

the RoboFlag Drill described by (Earl and D’andrea,

2007). They describe a scenario where a set of de-

fenders are guarding a circular defence zone against a

set of attackers. The attackers are randomly placed in

an outer circle circumscribing the inner defence zone

and move with constant velocity towards the zone.

The goal of the defenders is to intercept as many of

the incoming attacking trajectories before they reach

the defence zone. It would be of great interest to test

our RHGA for this scenario and compare our results

with those of (Earl and D’andrea, 2007).

4.7 Concluding Remarks

This paper shows that a GA combined with RHC is

able to perform multi-target assignment and track-

ing in dynamically changing environments. Whilst

our results are promising, we consider our study a

preliminary one that needs to be extended for more

scenarios and compared with other intelligent algo-

rithms. Nevertheless, we believe that our problem

description is an interesting and non-trivial challenge

for researchers in the field and welcome alternative

attempts at solving it. Building on the work presented

here, we will continue to refine and extend our RHGA

to other problem scenarios.

Whereas classical control theory and mathemat-

ics can aid in solving assignment and tracking prob-

lems, we see tremendous potential for artificial intel-

ligence (AI) methods in problems where analytical

solutions become non-existent or at least very hard

to find. Such problems may involve nonlinearities

and constraints that AI methods solve with ease. We

firmly believe that the fusion between control systems

theory and AI is the way forward for solving difficult

multi-agent, multi-target problems.

ACKNOWLEDGEMENTS

We wish to thank Jon Leon Ervik at the Norwegian

Coastal Administration and Kjell Røang at Christian

ICEC 2010 - International Conference on Evolutionary Computation

124

Michelsen Research for providing useful information

about oil tanker traffic and positioning of tugs along

the northern Norwegian coast.

REFERENCES

Det Norske Veritas (2009). Rapport Nr. 2009-1016. Re-

visjon Nr. 01. Tiltaksanalyse — Fartsgrenser for skip

som opererer i norske farvann. Technical report, Sjø-

fartsdirektoratet.

Earl, M. G. and D’andrea, R. (2007). A decomposition ap-

proach to multi-vehicle cooperative control. Robotics

and Autonomous Systems, 55:276–291.

Eide, M. S., Øvyind Endresen, Brett, P. O., Ervik, J. L.,

and Kjell Røang (2007a). Intelligent ship traffic mon-

itoring for oil spill prevention: Risk based decision

support building on AIS. Marine Pollution Bulletin,

54:145–148.

Eide, M. S., Øyvind Endresen, Øyvind Breivik, Brude,

O. W., Ellingsen, I. H., Kjell Røang, Hauge, J., and

Brett, P. O. (2007b). Prevention of oil spill from ship-

ping by modelling of dynamic risk. Marine Pollution

Bulletin, 54:1619–1633.

Goodwin, G. C., Graebe, S. F., and Salgado, M. E. (2001).

Control System Design. Prentice Hall, New Jersey.

Haupt, R. L. and Haupt, S. E. (2004). Practical Genetic

Algorithms. Wiley, second edition.

Havforskningsinstituttet (2010). Fisken og havet, særnum-

mer 1a-2010: Det faglige grunnlaget for oppdaterin-

gen av forvaltningsplanen for barentshavet og havom-

rådene utenfor lofoten. Technical report, Institute of

Marine Research (Havforskningsinstituttet).

Luo, X., Li, S., and Guan, X. (2010). Flocking algo-

rithm with multi-target tracking for multi-agent sys-

tems. Pattern Recognition Letters, 31:800–805.

Maciejowski, J. M. (2002). Predictive Control with Con-

straints. Prentice Hall, first edition.

Reynolds, C. W. (1987). Flocks, herds and schools: A

distributed behavioral model. In Computer Graphics

(ACM SIGGRAPH), volume 21, pages 25–34.

A RECEDING HORIZON GENETIC ALGORITHM FOR DYNAMIC MULTI-TARGET ASSIGNMENT AND

TRACKING - A Case Study on the Optimal Positioning of Tug Vessels along the Northern Norwegian Coast

125