A FRAMEWORK BASED ON A HIGH CONCEPTION LEVEL TO

GENERATE CONFIGURATIONS IN PRODUCTION SYSTEMS

Marwa Kanso, Pascal Berruet and Jean-Luc Philippe

Lab-STICC, UBS Saint Maude, Lorient, France

Keywords:

Reconfigurable manufacturing systems (RMSs), Model Engineering, Scheduling, Configuration, Recovery &

reconfiguration.

Abstract:

In this paper, a framework is presented to generate configurations in reconfigurable manufacturing systems

(RMS). This framework is based on a high conception level of reconfigurable manufacturing systems, and uses

a multicriteria decision algorithm to select operations to carry out the request. Provisional product scheduling

is then used to define the “simple configuration”. This paper focuses on the generation process of the “near-

most appropriate” configuration to carry out a request. To do so, the same multicriteria decision algorithm

is used to select “reserved operations” to improve the generated configuration.A case of study illustrates our

approach and demonstrates how we can use this framework to generate the “near-optimal” configuration and

improve reconfigurability.

1 INTRODUCTION

Manufacturing flexibility is the key for markets facing

increasing client demands, frequent volume changes

and product requirement. In such a system, choices

at the system organization level can be delayed un-

til exploitation. Indeed, this organization must be

taken into account at the conception level. To help

a designer choose (resources, operations, ...), a set of

analysis and evaluations must be applied to the sys-

tem. The system description must specify all possible

information for this analysis. New scheduling tech-

niques which help to answer more complex demands

are needed. On the other hand, the main goal in to-

day’s markets is the reaction of manufacturing sys-

tems when unexpected events occur. Recently, new

ideas related to design, description, sequencing prod-

ucts, planning, loading and scheduling policies have

been introduced. Architecture design for manufactur-

ing systems, equiped with the correct level of flexi-

bility to face the specific production problem, are in-

troduced in (Nucci and Grieco, 2008) and in (Terkaj

et al., 2009). (Kurnaz et al., 2005) considers that the

order in which products are produced can have a con-

siderable impact on primary performancemetrics. Se-

quencing decisions can impact customer responsive-

ness. In (Dpto et al., 2002), loading and schedul-

ing processes evolves jointly in Felxible Manufactur-

ing Cell (FMC). (Lamotte, 2006) proposes DeSyRe,

a language to describe reconfigurable manufacturing

systems. In this paper, we propose improving the

DeSyRe language to take into account and improve

the reconfiguration concept at the description level.

We also consider how disruptions (machine break-

downs, customer order changes, etc.) impact the gen-

erated configuration in a reconfigurable manufactur-

ing system producing multiple products. The rest of

this paper is organized as follows. Section 2 gives an

extended presentation of the high conception level of

RMS’s. Section 3 presents the configuration gener-

ation process. A use case illustrates the use of our

framework in section 4, before moving on to the con-

clusion in section 5.

2 A HIGH CONCEPTION LEVEL

FOR RMS

Manufacturing systems can generally be described

from multiple levels of granularity. Fractal manufac-

turing systems (Ryu et al., 2003) takes into account

this granularity by using a multi-level representation.

To represent and manipulate reconfigurable manu-

facturing system concepts, we use a description lan-

guage called “DeSyRe” basically developed and in-

troduced by (Lamotte, 2006). Metamodels show re-

lations between different aspects of a RMS. Models

244

Kanso M., Berruet P. and Philippe J. (2010).

A FRAMEWORK BASED ON A HIGH CONCEPTION LEVEL TO GENERATE CONFIGURATIONS IN PRODUCTION SYSTEMS.

In Proceedings of the 7th International Conference on Informatics in Control, Automation and Robotics, pages 244-248

DOI: 10.5220/0002943102440248

Copyright

c

SciTePress

combine a horizontal decomposition between archi-

tecture and configuration and a vertical one between

logical and physical descriptions. We apply this high

level conception to add new dynamic aspects and im-

prove the RMS description. In the next subsections,

we present the extended description language version

“DeSyRe E”.

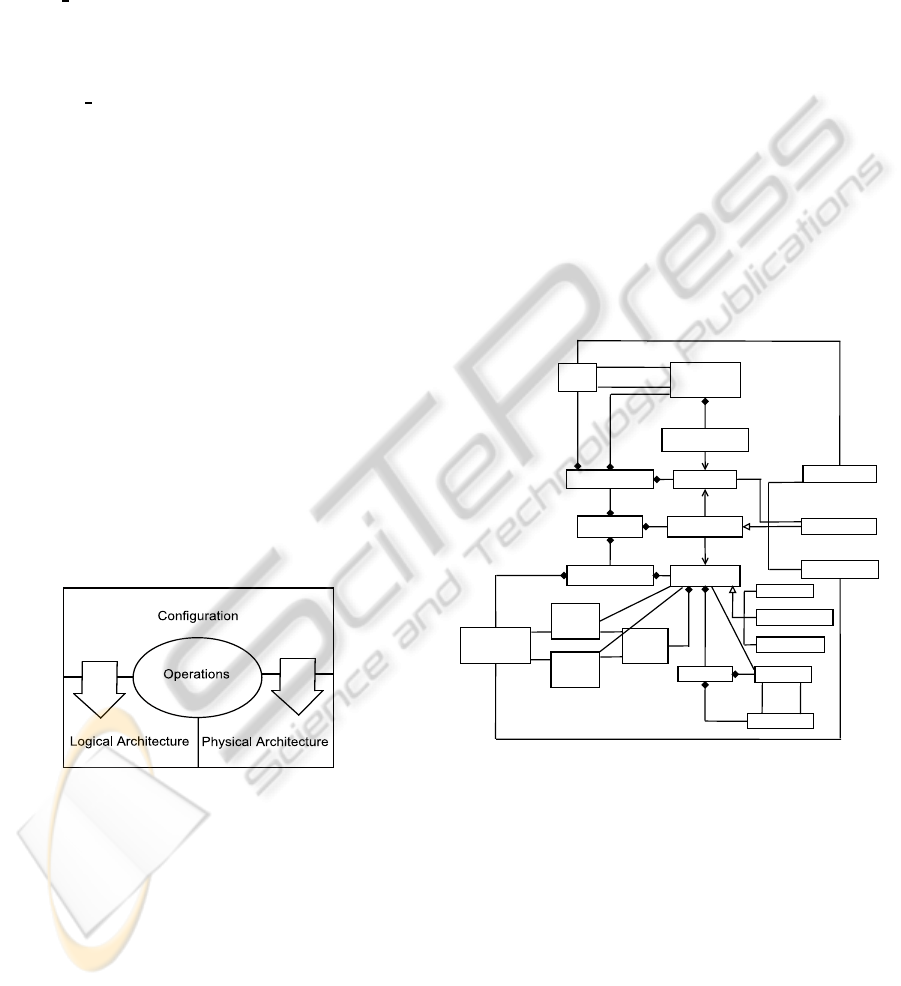

2.1 The represented Aspects

In “DeSyRe E”, the reconfigurable system is broken

down according to the decomposition illustrated in

Figure 1. A horizontal axis separates the architec-

ture of the system from its configuration. The archi-

tecture consists of all system elements (functions, or

resources) and their potential connections. It is pre-

sented in section 2.2. These components are parame-

terized and inter-connected through the configuration

presented in section 2.3. The vertical axis separates

the logical architecture from the physical one. The

logical part consists in the functions and their associ-

ations to form logical operating sequences. The phys-

ical part consists in the resources and the transport be-

tween these resources. The physical part provides the

structure on which the logical part is executed. Oper-

ations are in the center of the model description. Each

operation implements a function on a resource creat-

ing a link between the logical and the physical archi-

tecture. It also links the configuration to the architec-

ture since operations are defined in the architecture

and used in the configuration.

Figure 1: The new decomposition of RMSs.

2.2 A Meta-model to represent

Architectures

The architecture of a reconfigurable manufacturing

system should represent all system potentialities (see

figure 2). It is separated into two parts: the log-

ical architecture, which is constituted by functions

and function sequences applied to products that can

be performed on the system, and the physical archi-

tecture which describes the physical elements of the

system (resources, connections, ports, etc...). To

achieve a complete architecture representation, op-

erating modes of the whole system should be pro-

vided. The role of such representation is to help carry

out decisions about resource modes and configuration

changing. A lot of information is needed to manage

resource modes, see (Hamani et al., 2009), and per-

form performance and cost analysis. This information

is introduced using a simple diagram graph for each

resource to describe their modes and transitions be-

tween these modes. For the sake of simplicity, here,

we propose to take into account the following modes:

the mode “stop” when the power is off, the mode “in

production” when the resource is in use, the mode

“in preparation” when the resource is not in use, nor

ready to execute an operation, the mode “break down”

when a failure occurs on the resource and the mode

“idle” when the power is on and the resource is ready

to use.

Logical architecture is mapped onto physical ar-

chitecture through potential operations, which link a

function with a resource.

Architecture

LogicalArchitecture

PhysicalArchitecture

PotentialOperation

Function

PotentialTransfering

Product

Resource

FunctionSequence

ParamatrizedFunction

MachiningResource

StockResource

Port

Mode

DG

Transition

ToPortRef

FromPortRef

[*]

[*]

[*]

[*]

[*]

[0-1]

[0-1]

[*]

[*]

[*]

[*]

[*]

[*]

[*]

[*]

[*]

[*]

[*]

[*]

[*]

Connection

PotentialMachining

PotentialStocking

[*]

[*]

[*]

[*]

TransportResource

Figure 2: Extended architecture metamodel.

2.3 A Meta-model to represent

Configurations

The concept of configurations lay on the separation of

the componentcontent from its use in the architecture.

A configuration is constituted by function instances to

realize a machining operation, connection instances

to realize a transfer operation, operations which re-

fer to an operation defined in the architecture model

and operation sequences which realize a function se-

quence. The metamodel representing the configura-

tion is given in figure 3.

A FRAMEWORK BASED ON A HIGH CONCEPTION LEVEL TO GENERATE CONFIGURATIONS IN

PRODUCTION SYSTEMS

245

Configuration

OperationSequence

FunctionInstance

Operation

MachiningOPeration

StockingOperation

TransferOperation

ConnectionInstance

[0-1]

[0-1]

OperationInSequence

ProductInState

[*]

[*]

[*]

[*]

[*]

[*]

[*]

[*]

Figure 3: Extended configuration metamodel.

Several types of configurations are defined de-

pending on the use of architecture components. A

minimal configuration contains the needed operations

to carry out a mission. A simple configuration is de-

fined as the set of “used” operations which lead to

the completion of a mission. A flexible configuration

is defined by a set of “used” and “reserved” opera-

tions to simplify the reconfigurability aspect. Finally,

a maximal configuration is defined as the set of poten-

tial operations which lead to carrying out a mission.

In the next section we present the Configuration Gen-

eration module.

3 CONFIGURATION

GENERATION

As can be seen in the figure 4, three technologies

are used: Model driven engineering (MDE), object

oriented programmation and multiCriteria Decision

Making (MCDM). Modeling concepts are introduced

to describe architectures and configurations. The

Model Driven engineering approach (MDE) is then

used, a transformation module is used to generate the

maximal configuration from the architecture descip-

tion model. This transformation is expressed in a

transformation language such as ATL (B´ezivin et al.,

2005).

Extended

Description Model

(Architecture)

Description Model

(maximal Configuration)

Maximal Configuration

Generator

MDE

Object Oriented

MCDM

AHP Algorithm

Step 1

Step 2

Simple Configuration

Generator

+

Products Scheduling

Flexible Configuration

Generator

+

Products Scheduling

"near-optimal"

Configuration

Description Model

("near-optimal"

Configuration)

Figure 4: A framework to generate configurations.

Generated code is based on the architecture and

maximal configuration description models. Object

oriented development (using Java) is then used to

carry out the “near most-appropriate” configuration.

At runtime, both steps (1 and 2) use the MultiCrite-

ria Decision Making approach (MCDM) to solve in-

determinism due to the high flexibility of our system

and to carry out the request in the configuration. For

more details about the MCDM approach see (Kanso

et al., 2009). A simple configuration is generated in

step 1. The obtained configuration contains only the

“used” operations to carry out the mission. It means

that, in case of failure there is no garantee to replace

the failed operation. Our framework tries to avoid the

reconfiguration process as much as possible, by im-

proving the generated configuration with a compati-

ble degree of flexibility. We deal with two kinds of

unexpected events: changes at the request level (case

of customer demand changes) and changes at the sys-

tem level itself (case of failures and system errors).

When unexpectedevents occur, errors, failures or cus-

tomer demand changes provide the need of additional

operations to replace the failed ones. Operations in

need are evidently defined in the architecture. To an-

swer this need, a flexible configuration is generated in

step 2. This last configuration consists of the simple

configuration improved by adding “reserved” opera-

tions using the MCDM approach. The obtained con-

figuration description model is then generated using

MDE.

4 SAMPLE EXPERIMENTATION

We present, in this section, a simple example to

demonstrate how our frameworkcan be used to gener-

ate the “near optimal” configuration. The purpose of

this experimentation is not to generate optimal sug-

gestions, but rather to provide a simple demonstration

to help users taking their decisions during production.

To do so, we consider a simple reconfigurable man-

ufacturing system with two products. The “logical

architecture” contains two functions (F

1

and F

2

) and

three function sequences (S

1

, S

2

and S

3

). S

1

consists

in implementing F

1

. S

2

consists in implementing F

2

.

S

3

consists in implementing F

1

then F

2

.

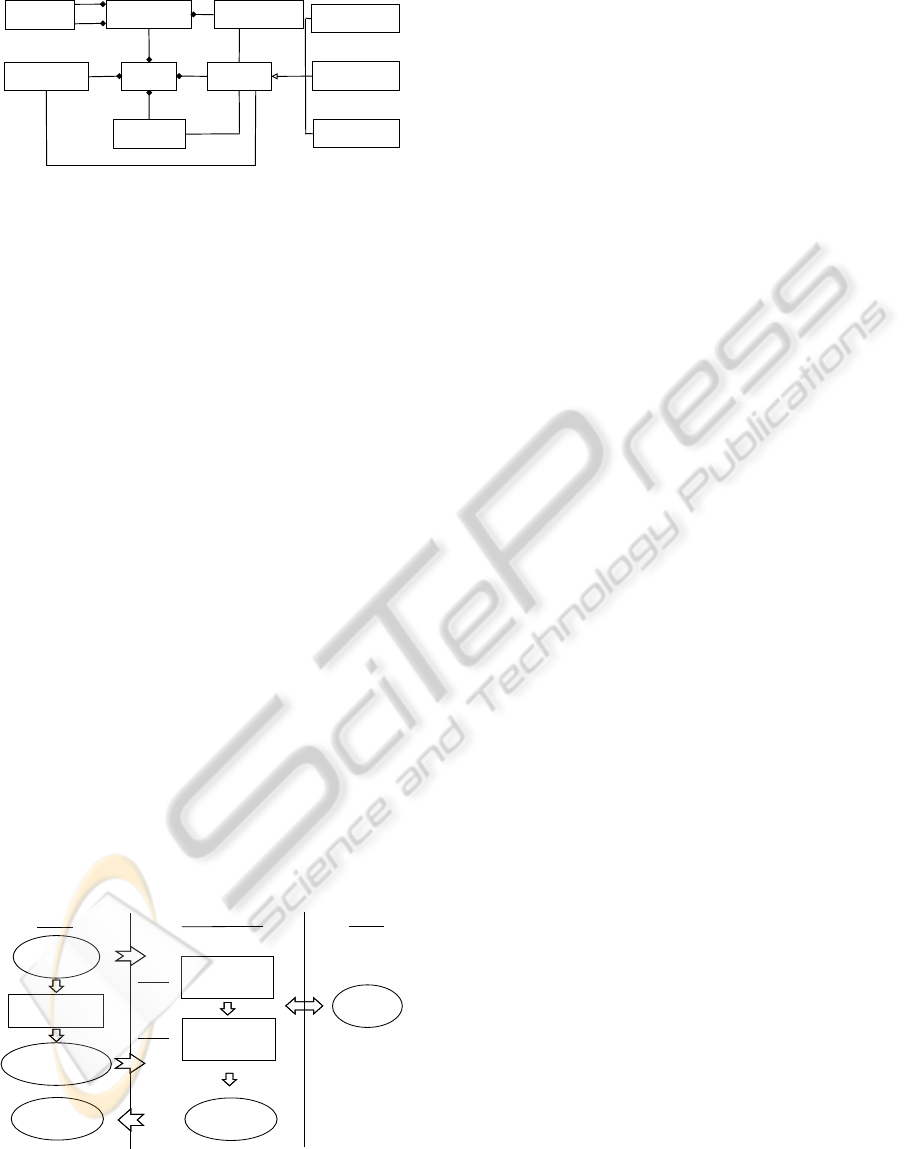

The “Physical Architecture” of the proposed sys-

tem is defined to set up our experiments (see figure 5).

It consists of convoyers (CV

1

- CV

6

), buffers (IN and

OUT), machining areas (M

1

- M

4

) and a robot (Rbt

1

).

To increase the flexibility of the system, this archi-

tecture consists of the two-directional convoyers (CV

2

and CV

5

). In the description model of the architec-

ture, we refine, for each resource, its capacity, its ac-

tive mode, the list of the concerned resource modes

and the transitions between these modes.

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

246

Figure 5: Physical Architecture of the proposed system.

Eight machining operations have been defined to

assign the defined functions to the machining areas:

O

M1,F1

, O

M1,F2

, O

M2,F1

and O

M2,F2

, etc...

Fourteen transfer operations have also been de-

fined to realize a transfer using a transfer ressource:

O

t

Cv1,INM1

, O

t

Rbt,INM1

, O

t

Rbt,INM2

, O

t

Cv2,M1M2

, O

t

Cv2,M2M1

,

etc...

4.1 Maximal Configuration Generation

In this subsection, we present the transformation

module used to generate the “maximal configuration”

using the architecture description model. Based on

the specified mission (product types and quantities),

some operations cannot be used in the system. The

concerned resources are idle during production. To

optimise the configuration cost, we must generate the

“maximal configuration”. At this stage, we take into

consideration the system part which contains the pos-

sible operations to carry out the request. If all po-

tential operations can be used to realize our mission,

the maximal configuration represents the use of the

whole system. For reasons of simplicity, in our ex-

ample, the maximal configuration represents the use

of the whole system to carry out two different prod-

uct types (P

4

and P

5

). Each operation in the architec-

ture model is projected to generate an operation in the

configuration model. The link to a function instance

or a connection instance in the configuration model

is based on the type of the operation in the architec-

ture. A function sequence can be realized by different

operation sequences. For example, S

1

is the function

sequence which consists of applying the function F

1

on a product. It can be realized on the machining re-

source M

1

, M

2

, M

3

or on M

4

. These four solutions

are defined in the configuration model as a set of 88

operation sequences, since transfer may be realized

by different transfer sequences too. Indeed, we gen-

erate 674 possible operation sequences based on the

function sequences defined in the architecture model.

It should be noticed that by using all the opera-

tions and operation sequences of the system in the

configuration at runtime, the reconfiguration time, in

case of failure can be shorten (it depends on calcula-

tion and decision making time), and the cost of the

configuration is surely much higher since a lot of re-

sources are idle. Therefore, we propose to generate

the “near-optimal” configuration which answer a bet-

ter cost-performance trade-off. In the next subsection,

we refine the “Simple Configuration generation” pro-

cess based on the architecture and the maximal con-

figuration description models.

4.2 Simple Configuration Generation

The specified mission consists of producing three lots

of P

4

and two lots of P

5

. Decisions, of which trans-

porter (or machining resource) is used, are taken by

applying the ‘AHP’ algorithm. For more details about

the proposed algorithm please check (Kanso et al.,

2009). The “Simple Configuration Generation” pro-

cess consists of selecting, for each product instance,

an operation sequence taken into account the system

state (resource availability, waiting time, preparation

time, mode changes, transfer between two different

machining resources). We use the necessary informa-

tion in the architecture to decide which is the most

appropriate operation to realize next. This process

has been implemented using Java in eclipse environ-

ment. Once the application is launched, the selection

process starts. The architecture of the proposed sys-

tem is updated depending on each resource capacity

and modes in the system while executing an operation

on a product. The “simple configuration” is obtained

when each product instance specifies its operation se-

quence and its provisional scheduling. We define at

this level the “used operation” as an operation used

by a product to realize a function in a configuration.

For the proposed example we get the configuration

composed of the followed operation sequences:

1. to realize P

4

, S

1

must be applied. Therefore, the

operation sequence chosen is as follows:

• OS

1,S

1

: {O

t

Cv1,INM1

, O

M1,F1

, O

t

Rbt,M1OUT

}

2. to realize P

5

, S

3

must be applied. Therefore, the

operation sequence choosed is as follows:

• OS

12,S

3

: {O

t

Cv1,INM1

, O

M1,F1

, O

M1,F2

,

O

t

Rbt,M1OUT

}

4.3 Flexible Configuration Generation

In case of production problems and more precisely

in case of failure when unexpected events occur

(demand changes, resource breakdowns, unavailable

tools, etc...). Previously generated simple configu-

rations may no longer work. Operations used in the

“simple configuration” may be unique and no another

A FRAMEWORK BASED ON A HIGH CONCEPTION LEVEL TO GENERATE CONFIGURATIONS IN

PRODUCTION SYSTEMS

247

operation, defined at the configuration level, can re-

alize the same function. The obvious solution is to

reconfigure the system. Although, we propose to im-

prove the generated configuration and optimise the re-

quest completion time. Therefore, we need to extend

the “simple configuration” and add “reserved opera-

tions”. At this level, we define a “reserved operation”

as an operation chosen to replace a failed operation

in a configuration. This will help us carrying out

the request in the system without going through the

reconfiguration process. To do so, “reserved opera-

tions” are selected using the ‘AHP’ algorithm. When

the “reserved operations” are specified, we generate

the corresponding operation sequences to fill out the

generated configuration. In other words, we generate

reserved operation sequences to extend the obtained

“simple configuration” and get the “flexible configu-

ration” to improve system responsiveness. Projecting

this extension on our example, we get the “flexible

configuration” by duplicating operations since each

function (or transfer) can be realized using four re-

sources (M

1

- M

4

) for a function, and the robot or

a convoyer for a tranfer). We note that in our case

the obtained “flexible configuration” corresponds to

“162” operation sequence of the “maximal configu-

ration” using two machining resources (M

1

and M

2

)

and “used operations” are realized in priority.

5 CONCLUSIONS

Reconfigurable Manufacturing Systems are faced

with frequent disruptions that impact the production

quality. A low-cost solution is needed to recover

the system. In this paper, the use of a high con-

ception level for reconfigurable manufacturing sys-

tems is presented to include different features and de-

scribe both architecture and configuration. The sug-

gested framework produces “near-optimal ” configu-

ration by generating the corresponding “flexible con-

figuration” based on the generated “simple configu-

ration” and the architecture. A simple example illus-

trating the way we can use the proposed framework

is presented in section 4. First, the production envi-

ronment has been presented. Secondly, the “maximal

configuration” generation is presented by refining the

transformation module. Third, the “simple configura-

tion” generation process is described before moving

on to presenting the “flexible configuration” genera-

tion process. Configuration choices usually depend

on preferences, on choices obtained at the scheduling

level, and on constraintes defined by clients at the re-

quest level. “Minimal” and “Simple” configurations

are not always the best solutions. Configurations with

a higher degree of flexibility may respond to requests

with better measures, and may answer a better cost-

performance trade-off. Although the existing frame-

work provides opportunity for many different types

of analyses, additional extensions will be beneficial

as well. These include inventory management during

production and transfer sequence management; new

configuration extension rules; and more specific crite-

ria to improve operation choice. More generally, we

would like to permit a broader class of configurations,

such as serial parallel lines with crossover, so that the

framework can be applied in an even greater number

of circumstances.

ACKNOWLEDGEMENTS

The authors are pleased to acknowledge the sup-

port by the associate professor at Polytech’Marseille

Fouzia Ounnar.

REFERENCES

B´ezivin, J., Jouault, F., Rosenthal, P., and Valduriez, P.

(2005). The AMMA platform support for modeling

in the large and modeling in the small.

Dpto, A. G., Gmez, A., Fuente, D. D. L., Parreo, J., and

Puente, J. (2002). Scheduling in flexible manufactur-

ing systems. Applied Artificial Intelligence, 15:949–

963.

Hamani, N., Dangoumau, N., and Craye, E. (2009). Re-

active mode handling of flexible manufacturing sys-

tems. Mathematics and Computers in Simulation,

79(5):1421–1439.

Kanso, M., Berruet, P., and Philippe, J. (2009). Multi-

criteria decision making approach for reconfigurable

manufacturing systems. In proceeding ISBN of the

28th EAM Conference on Human Decision-Making

and manual Control, SEPT. 3-4, 2009, pages 37–44.

Kurnaz, S., Cohn, A., and Koren, Y. (2005). A frame-

work for evaluating production policies to improve

customer responsiveness.

Lamotte, F. D. (2006). Proposition d’une approche haut

niveau pour la conception, l’analyse et l’implantation

des systmes reconfigurables 2006. PhD thesis. Uni-

versit de Bretagne Sud, Lorient, France.

Nucci, F. and Grieco, A. (2008). The operational strategies

in focused flexible manufacturing systems. ISC’08

International Supercomputer Conference. Heidelberg,

Germany, June 18 20.

Ryu, K., Son, Y., and Jung, M. (2003). Modeling and spec-

ifications of dynamic agents in fractal manufacturing

systems. Comput. Ind., 52(2):161–182.

Terkaj, W., Tolio, T., and Valente, A. (2009). Designing

manufacturing flexibility in dynamic production con-

texts. In Design of Flexible Production Systems, pages

1–18.

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

248