A THREE LEVEL ABSTRACTION HIERARCHY

TO REPRESENT PRODUCT STRUCTURAL INFORMATION

Marcela Vegetti, Horacio Leone

Instituto de Desarrollo y Diseño(INGAR), Avellaneda 3657, Santa Fe, Argentina

Gabriela P. Henning

INTEC (Universidad Nacional del Litoral, CONICET), Güemes 3450, Santa Fe, Argentina

Keywords: Product Model, Ontology, BOM.

Abstract: Product models should integrate and efficiently manage all the information associated with products in the

context of industrial enterprises or supply chains (SCs). Nowadays, it is quite common for an organization

and even, each area within a company, to have its own product model. This situation leads to information

duplication and its associated problems. In addition, traditional product models do not properly handle the

high number of variants managed in today competitive markets. Therefore, there is a need for an integrated

product model to be shared by the organizations participating in global SCs or all areas within a company.

One way to reach an intelligent integration among product models is by means of an ontology. PRONTO

(PRoduct ONTOlogy) is an ontology for the Product Modelling domain, able to efficiently handle product

variants. This contribution presents a ConceptBase formalization of PRONTO, as well as an extension of it

that allows the inference of product structural knowledge and the specification of valid products.

1 INTRODUCTION

Within an organization, many management and

production functions make use of product structural

data in different manners depending on their

requirements. Thus, such information is represented

in formats that best meet the needs and business

processes of the various organizational areas. In

addition, traditional product models do not properly

handle the high number of variants that characterize

today competitive markets. These situations lead to

the presence of redundant and possibly inconsistent

product information. Moreover, all the planning,

coordination and support functions, required for

carrying out manufacturing and logistic activities,

demand accurate and reliable product information of

different granularities in order to be efficient.

Circumstances get worse when organizational

units not only use product data for their own needs

but also exchange it with other partners, e.g. during

cooperative product development, when outsourcing

manufacturing activities, interacting with logistics

providers, etc. In all these cases the use of different

product models can lead to semantic problems.

In the last decade ontologies have been

recognized as key elements to reach semantic

integration, since they provide formal models that

establish a consensual and precise meaning to the

information communicated among different sources.

In previous works (Giménez et al., 2008; Giménez et

al. 2009), an ontology named PRONTO (PRoduct

ONTOlogy) was presented. This ontology integrates

two hierarchies to represent product information: the

Abstraction Hierarchy (AH) and the Structural one

(SH). However, these contributions were limited to

the representation of explicit data at each level of the

AH.

This paper presents a ConceptBase (Jarke et al.,

2004) formal specification of PRONTO that focuses

on the structural hierarchy of the ontology and in the

way structural information can be inferred from

explicit knowledge at each AH level. This proposal

efficiently handles a great number of variants and

allows representing product information with

distinct granularity degrees, useful for planning

activities taking place at different time horizons.

Additionally, constraints associated with the

specification of valid products are introduced in the

299

Vegetti M., Leone H. and P. Henning G. (2010).

A THREE LEVEL ABSTRACTION HIERARCHY TO REPRESENT PRODUCT STRUCTURAL INFORMATION.

In Proceedings of the 12th International Conference on Enterprise Information Systems - Artificial Intelligence and Decision Support Systems, pages

299-308

DOI: 10.5220/0002907102990308

Copyright

c

SciTePress

ontology. Section 2 briefly introduces PRONTO

concepts, describes its formalization, presents how

implicit knowledge can be inferred from the explicit

one. Section 3 illustrates the use of the implemented

ontology by means of a case study. Finally,

conclusions are drawn.

2 PRONTO SPECIFICATION

Within the scope of this contribution, a product is a

complex concept (indeed much more complex than a

mere thing or substance produced by a natural or

industrial process) that will be defined at different

levels of abstraction. The term ProductAbstraction is

used to represent such complex thing.

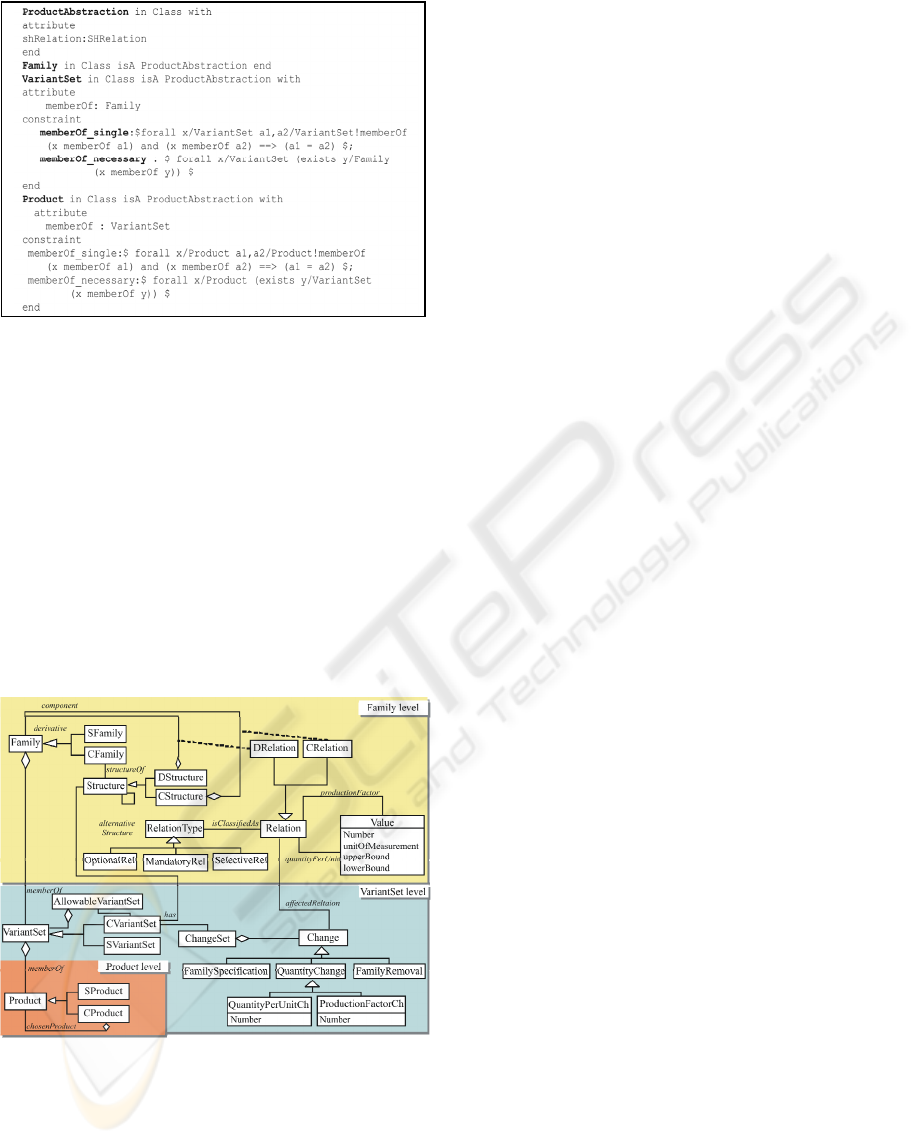

In order to manage the complexities of product

information, two model hierarchies are included in

PRONTO: the Abstraction Hierarchy (AH) and the

Structural Hierarchy (SH) (see Fig. 1). The first one

represents the product concept at three abstraction

levels: Family, VariantSet and Product. The

Structural Hierarchy organizes the knowledge

related to product structural information. The SH is a

mechanism to manage the information associated

with the multiple recipes and/or processes available

to manufacture a given product or a group of similar

products. Within this hierarchy, a piece of

information that is typically handled is the Bill of

Materials (BOM) representation.

PRONTO allows representing BOMs of products

that are obtained by assembling component parts, as

well as others that are obtained by the

decomposition of non-atomic raw materials. Hence,

the SH considers two types of hierarchies, one which

relates a product with its component parts and

another one which associates a product with its

derivative parts. The relationships that are used to

represent each of these types are named component

Of and derivativeOf, respectively. As shown in Fig.

1, both relations are a specialization of the

SHRelation class, which links a ProductAbstraction

instance (whole) with zero or more

ProductAbstraction instances (part), which are

defined at the same abstraction level.

The Abstraction Hierarchy (AH) shown in Fig. 1,

is oriented towards managing the complexity that

results from the huge number of products that are

manufactured by current industrial facilities. It

includes the following abstraction levels:

Figure 1: Abstraction and Structural hierarchies.

Family: It is the highest level of abstraction and

represents a set of similar products. They can

share one or more common structures. Such

structures can be specialized in the following

abstraction level of the hierarchy.

VariantSet: It is the second level and models a

subset of Family members that share the same

structure and/or similar characteristics; i.e. a

subfamily. The structure of a VariantSet can

include modifications in the structure of the

family of which it is associated.

Product: It corresponds to the lowest level in the

AH. It represents individual items (real products)

that are members of a particular VariantSet.

Therefore, each product has the structure that is

associated with the VariantSet of which it is a

member.

The proposed ontology has been formally

specified in the O-Telos language, which combines

object-oriented principles with first order logic

properties. It has been implemented in ConceptBase

(Jarke et al., 2004), a deductive object-oriented data

base manager. ConceptBase integrates techniques

from deductive and object oriented databases in the

logical framework of the O-Telos data model, a

dialect of Telos.

Fig. 2 shows how the ProductAbstraction class

and its subclasses are expressed in ConceptBase.

The specification also presents the constraints that

the memberOf relationship (attribute memberOf, in

Fig. 2) has to satisfy. This constraint establishes that

entities belonging to the two lower levels of the AH

are related to just one entity defined at their

immediate upper level through the memberOf

relationship (memberOf_necessary constraint) and

such relation is unique for each instance of the lower

level (memberOf_single constraint).

ICEIS 2010 - 12th International Conference on Enterprise Information Systems

300

Figure 2: ProductAbstraction class and its subclasses.

Fig. 3 presents the complete conceptual model of

the ontology with the main concepts of each

abstraction level.

The Abstraction Hierarchy is related to the

Structural one by means of the SHRelation. As it

was previously mentioned, the componentOf and

derivativeOf relations define the two possible

structural associations among entities belonging to

the same abstraction level (Fig. 2). Both relations,

which define the SH, are not explicitly represented

in the conceptual model of Fig. 3, but they can be

inferred from the explicit information that is

recorded at each level of the AH.

Figure 3: PRONTO concepts.

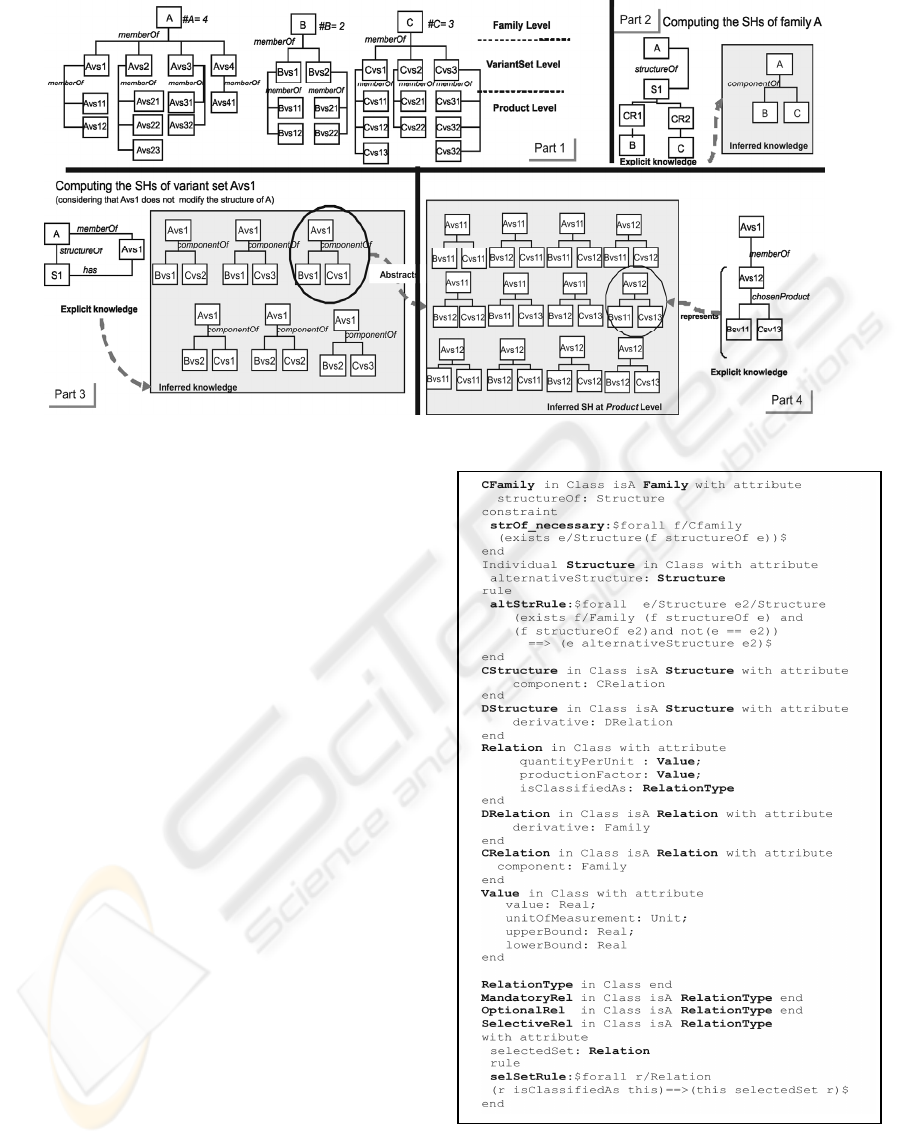

Fig. 4 illustrates, by means of an example, the

SH that can be computed at each abstraction

hierarchy level. The first part of this figure shows

the abstraction hierarchies of three product families:

A (having 4 members: Avs1, Avs2, Avs3 and Avs4),

B (having 2 members) and C (having 3 members).

Fig. 4 also shows that the variant set Avs1 has

products Avs11 and Avs12 as members. Part 2 of this

figure presents the structural hierarchy of family A,

which has families B and C as its components.

Finally, parts 3 and 4 of Fig. 4 show a partial view

of the structural hierarchies that can be inferred at

the variant set and product levels, respectively.

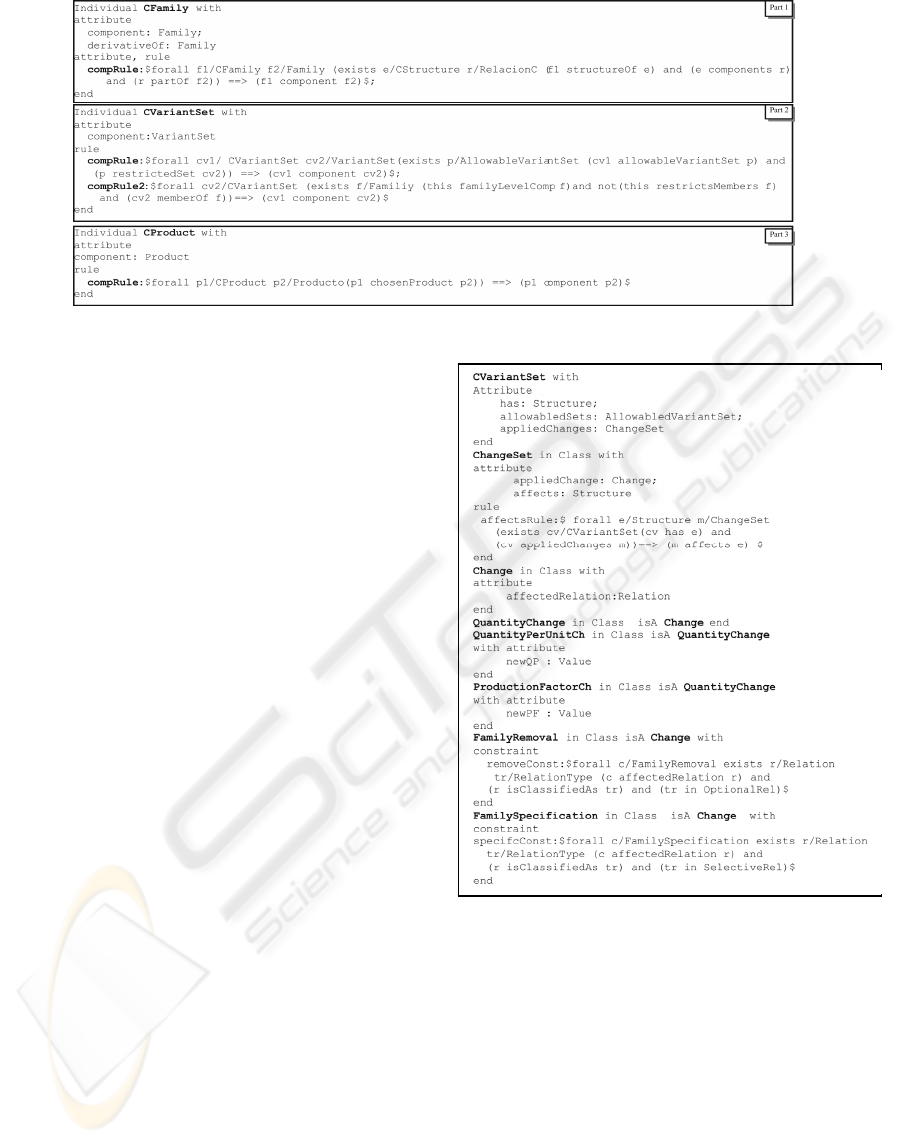

2.1 Family Level Concepts

PRONTO prescribes that a family (Family) may be

composite (CFamily) or simple (SFamily),

depending on whether it represents a product having

or not a structure. A product has a structure when it

is made out of other products or other products can

be derived from it. In order to be a CFamily, it is

necessary to define a structureOf relation between

such family and at least one structure (this constraint

is specified at the beginning of Fig. 5). If more than

one structure is defined for a given CFamily, the

alternative structures of such family are linked by

the alternativeStructure relationship. As Fig. 5

shows, the values of the alternativeStructure

attributes are computed by the AltStrRule deductive

rule of the Structure class.

A CFamily represents a set of similar products

and, as already mentioned, such products could be

obtained by the assembly of others or by the

disaggregation or decomposition of non-atomic raw

materials. Therefore, the Structure class has been

specialized to represent these different types of

structures by means of the CStructure and

DStructure subclasses which, in turn are related to

the components or the derivatives of a family by

means of the CRelation and DRelation classes,

respectively. Both classes are specializations of the

Relation one. Each of them contains, at least,

information about: (i) the quantity/number of a

given component needed to manufacture a unit of

product (CRelation) or the quantity/number of

intermediate units obtained from the decomposition

of a unit of non-atomic raw material (DRelation);

and (ii) the proportion that a given component

represents in one unit of the product in whose

structure such component participates (CRelation) or

the yield that a given intermediate product renders

from the decomposition of a unit of a non-atomic

raw material (DRelation); (iii) minimum and

maximum allowed quantities and the quantities’ unit

of measure; as well as (iv) the relation type.

Besides, different kinds of relations are specified

to capture the rules needed to incorporate a certain

component (derivative) in a particular product

structure: (i) Mandatory: the component

(derivative) MUST be present in the structure of all

A THREE LEVEL ABSTRACTION HIERARCHY TO REPRESENT PRODUCT STRUCTURAL INFORMATION

301

Figure 4: Inferred structural hierarchies at each level of the AH.

the family members; (ii) Optional: the component

(derivative) CAN PARTICIPATE OR NOT in a

particular product structure; and (iii) Selective: the

component (derivative) should be selected from a set

of components, but ONLY ONE member of such set

(see selectedSet attribute and selSetRule rule of the

SelectiveRel class in Fig. 5) must be part of the

structure. Fig. 3 shows that such classification is

represented in the model with the isClassifiedAs

relation, the RelationType class and its subclasses

(OptionalRel, MandaroryRel and SelectiveRel). The

formal specification of these concepts is shown in

Fig. 5.

Due to the fact that the structure is explicitly

defined at the Family level, it is straightforward to

infer the SHRelations among the entities belonging

to this level. The composition relations (CRelation)

identify the components of a composite structure

CStructure, while the decomposition relations

(DRelation) do the same with the derivatives of a

DStructure. The definition of the deductive rule

(compRule) that infers the values of the component

attribute of a CFamily is specified in Part 1 of Fig.6.

In turn, the specifications of compRule

corresponding to the other two levels, CVariantSet

and CProduct, are shown in Parts 2 and 3 of Fig. 6.

Figure 5: Formalization of Family level concepts.

ICEIS 2010 - 12th International Conference on Enterprise Information Systems

302

Figure 6: Examples of deductive rules that compute the components of the structural hierarchies at different AH levels.

2.2 Variant Set Level Concepts

At the Variant Set level, the structural hierarchy of

an entity depends on the structure of the family from

which such entity is a memberof. A VariantSet may

have the same structure of its family or may

introduce some modifications on it. CFamily

members having a similar structure are clustered

within the composite variant set concept

(CVariantSet in Fig.3). In the ontology model, a

CVariantSet instance is linked with one and only

one of the structures of its family by means of the

“has” relation. Fig. 7 presents a partial view of the

specification of the variant set level concepts.

The ChangeSet class groups all the changes that

are applied to the family structure in order to obtain

the particular structure of a composite variant set.

Each specified change (Change class) affects only

one relation of such structure, which is pointed out

by the affectedRelation association of the Change

class, presented in Fig. 7. The Change class is

specialized into the QuantityChange, Family

Removal and FamilySpecification subclasses to

represent the different types of modifications

considered in the model. They represent (i) a value

change of the quantity per unit (quantity PerUnitCh)

or production factor (productionFactorCh)

attributes; (ii) the elimination of a component; or

(iii) the choice of one association that belongs to the

set of the SelectiveRelations of the modified

structure.

Applying the different types of modifications to

a structure depends on the type of the affected

relation. The first type of change is acceptable for all

relation types. However, removing a relation from a

structure requires such relation to be an optional one,

while the last type of change is only valid for

relations being of selective type.

Figure 7: Formalization of some Variant Set level

concepts.

As it was previously mentioned, Fig. 3, Part 3,

presents all the structural hierarchies that can be

computed for Avs1, which is one of the variant set

members of A. The total number of SHs of Avs1 is

obtained by multiplying the number of B members

(#B) by the number of C members (#C). Sometimes,

not all the SHs of a variant set are valid. Let us

assume, for example, that for commercial reasons

the products that are members of Avs1 must be

manufactured by using only products that are

members of the Bvs1 variant set. In such a case, only

three of the SHs that are shown in Fig. 3 Part 3 are

A THREE LEVEL ABSTRACTION HIERARCHY TO REPRESENT PRODUCT STRUCTURAL INFORMATION

303

valid (those that have Bvs1 as a component). In

order to represent this restriction, the model resorts

to the AllowableVariantSet class, which links a

variant set with the variant sets that are compulsory

to be used in its associated structural hierarchies. In

the case of the aforementioned example, an instance

of AllowableVariantSet has to be defined indicating

that Bvs1 is the allowable variant set of Avs1.

Part 2 of Fig 6 shows the deductive rule that was

defined to infer the components of a variant set. A

variant set vs2 is a component of another variant set

vs1 if:

There exists an instance of the Allowable

VariantSet a1 in vs1 that has vs2 as a restricted

Set (compRule); or

vs2 is a memberOf a family f2, which is

component of a family f1 from which vs1 is a

member of. Besides, no restriction applies to the

members of f2 defined in vs1 (restrictsMember

property) and the relation that specifies f2 as a

component is not eliminated from the structure

of vs1 (compRrule2).

2.3 Product Level Concepts

The most concrete level of the proposed Abstraction

Hierarchy represents real products that are members

of a VariantSet. Such membership relation is

represented by the memberOf link between the

VariantSet and the Product classes (specified in Fig.

2). A Product can be simple (SProduct) or

composite (CProduct) depending on whether it is a

member of SVariantSet or CVariantSet, respectively.

The instances of the CProduct subclass are members

of the corresponding CVariantSet instances and

represent non-atomic products; that is, products

having a structure. The variant set to which a

product belongs determines and restricts its SH. In

order to identify which product member is the one

that participates in the structural hierarchy of a

specific product, the chosenProduct relation is

employed (Fig. 3).

At the variant set level, all the components

(derivatives) included in the structural hierarchies

are instances of the VariantSet class. At the product

level, the entities included in a SH must be products

that are memberOf components (derivatives)

participating in the corresponding SH defined at the

variant set level. The deductive rule (compRule) that

is shown in Part 3 of Fig. 6 establishes that a product

p2 is a component of a product p1 if it is member of

a variant set cv2 that, in turn, is a component of the

variant set from which p1 is a member of.

Structural hierarchies at the product level can be

computed for each SH defined at the variant set

level. It should be noted that the model does not

explicitly represent all the potential SHs at the

product level. It is possible to calculate the explicit

product structural hierarchies that are required at a

given time; e.g., when receiving a production order

from a customer.

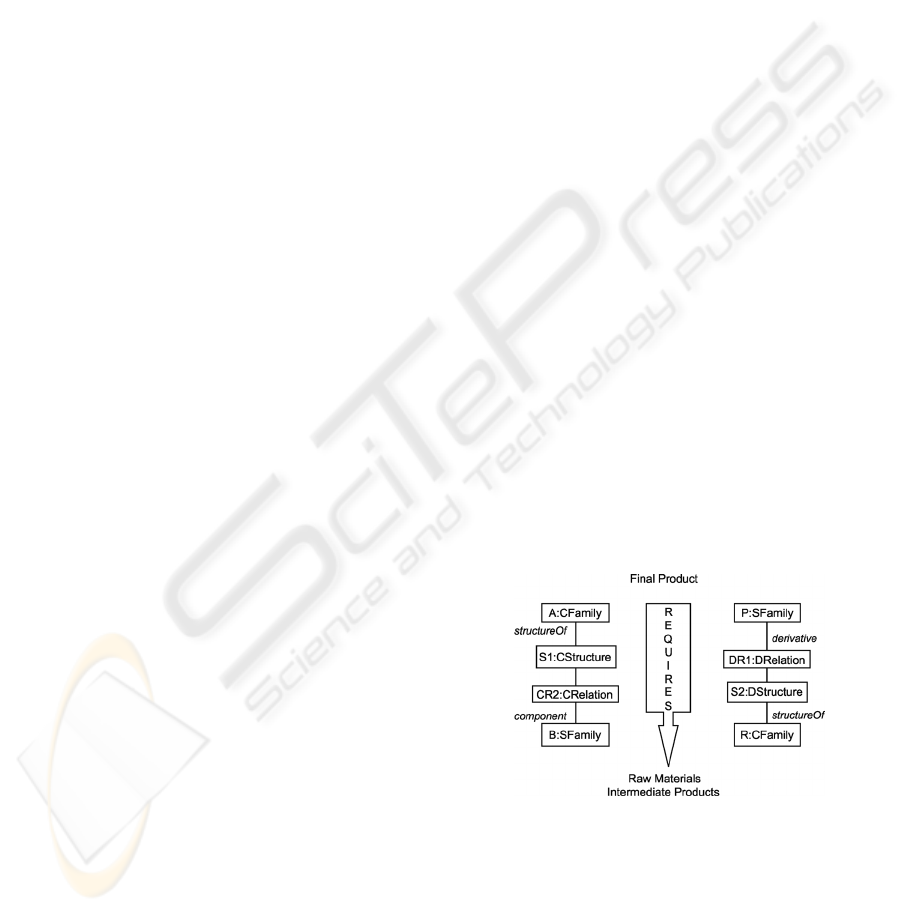

2.4 Material Requirements Inference

Product structural information is necessary to build

the Production Master Plan, which determines the

amounts of raw materials and intermediate products

that need to be purchased or manufactured in order

to fulfill a given final product demand. Therefore, as

important as the inferred information about

components and derivatives of a final product are

the quantities of materials that are required to

manufacture a certain amount of it.

One of the main contributions of the product

model is its ability to capture the manufacturing

composition and decomposition structures of

products. As shown, the ontology employs two

different types of structures (CStructure and

DStructure) with two types of relations (CRelation

and DRelation) to represent this information. Also,

each type of structure computes in a different way

data needed about manufacturing requirements of

raw materials and/or intermediate products. Fig. 8

shows two families, representing final products A

and P. The former is obtained by assembling a set of

raw materials and intermediate products. The latter

is a derivative of a non-atomic raw material R.

Figure 8: Conceptual representation of the computation

of manufacturing product requirements.

For composition structures, the families that are

required to manufacture the composite family A (by

means of the S1 CStructure) match with the values

of the component attribute of the CRelation

associated with such structure (CR2).

ICEIS 2010 - 12th International Conference on Enterprise Information Systems

304

For decomposition structures, the required

families have to be inferred in the inverse direction;

that is, starting from family P, it is necessary to

obtain the decomposition relation for which P is the

value of the derivative attribute (DR1), then, find the

decomposition structure in which this relation is part

of (S2) and, finally, from such structure the required

family R can be found. In order to implement these

mechanisms, the capabilities of Concept Base views

have been chosen. A ConceptBase view allows

presenting information of instances of a specific

class in a particular manner and defining attributes

whose values can be computed by means of

deductive rules. Such values can also be generic

views which can be particularized by assigning

values to parameters defined in the generic view. In

this PRONTO implementation, specific views were

defined in order to calculate the material

requirements of the different types of Product

Abstractions. In particular, the FamilyReq view

computes requirements at the family level and the

results of its execution are presented in Section 3.

2.5 Product Constraints Concepts

In this proposal, as in other approaches that are

based on the generic structure concept of a product

family, rules are used to properly specialize

structures into particular ones. In general, a great

number of possible component (derivative)

combinations are allowed (e.g. see the partial view

shown at the bottom of Fig. 4). However, some of

these combinations can be invalid due to technical or

commercial reasons. Generic product structures

defined at the Family and VariantSet levels include

an implicit product structure model, which provides

additional conditions that must be satisfied by a

valid product instance (Mänisto et al, 1998). In order

to obtain valid particular structures from generic

ones, it is necessary to have a methodology to: (i)

specify constraints among components (families,

variant sets or products) and, (ii) test the satisfaction

of such rules when generating more specific

(particular) structures. Based on these requirements,

the proposed model includes mechanisms to express

constraints which have to be fulfilled when creating

new particular or generic structures.

The proposal includes three types of restrictions,

according to the three abstraction hierarchy levels. It

is possible to define constraints among: (i) families

(FRestriction); (ii) variant sets (VSRestriction); and

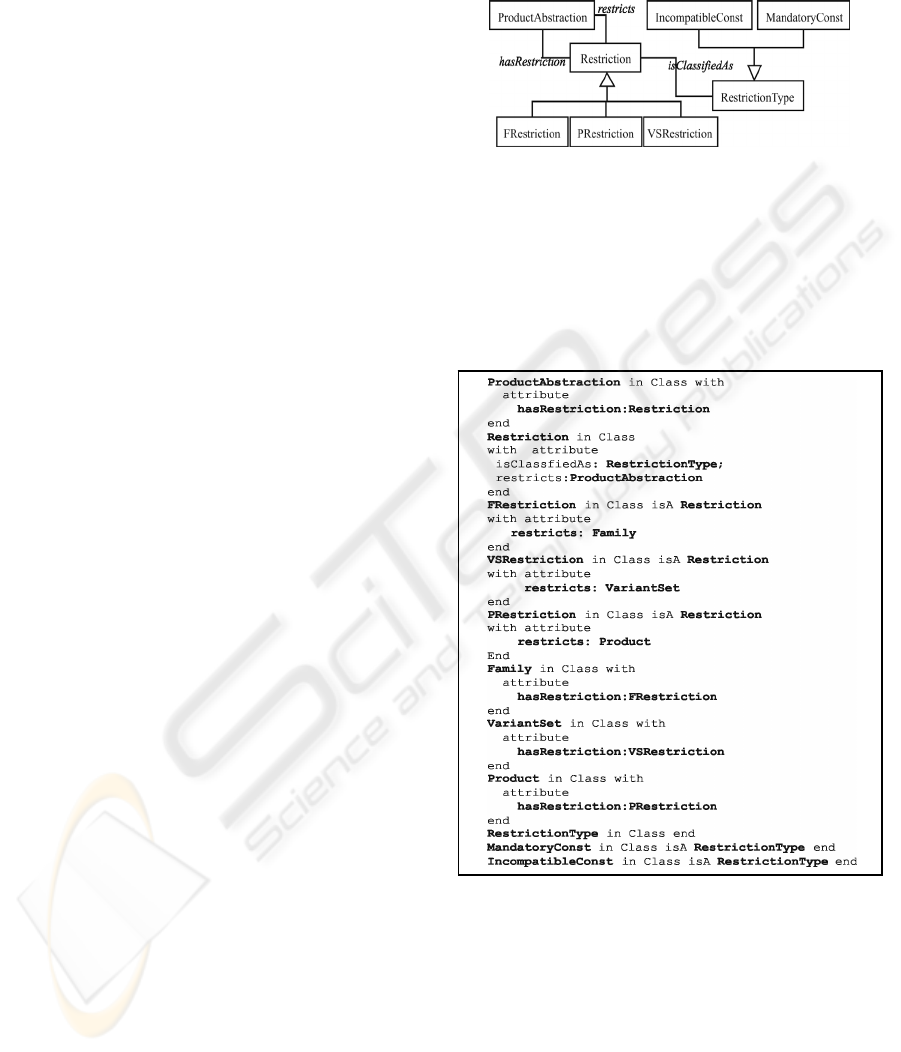

(iii) products (PRestriction). Fig. 9 shows the classes

that represent such concepts, which are formalized

in Fig. 10. The specialization in FRestriction,

VSRestriction and PRestriction subclasses limits the

definition of constraints among entities of the same

AH level.

Figure 9: Product constraints concepts.

Fig. 10 shows that the restricts attribute has

different values in each Restriction subclass of the

AH. Similarly, the type of the hasRestriction

attribute is limited to have the FRestricion,

VSRestriction and PRestriction values in the Family,

VariantSet and Product classes, respectively

Figure 10: ConceptBase implementation of product

constraints concepts.

At any AH level it is possible to identify two

main types of restrictions among components: (i)

Obligatory and (ii) Incompatible; both must be

satisfied to obtain valid structures. Fig. 9 and 10

show that a Restriction is linked with its type by the

isClassifiedAs association and that the Mandatory

Const and IncompatibleConst classes represent the

constraint types defined in the model. The first type

forces a given component (family, variant set or

A THREE LEVEL ABSTRACTION HIERARCHY TO REPRESENT PRODUCT STRUCTURAL INFORMATION

305

product) to participate at any level of the SH of the

ProductAbstraction instance that specifies the

mandatory constraint. In contrast, incompatible

restrictions require a given component (family,

variant set or product) to be not present at any level

of the SH of the ProductAbstraction instance that

specifies such constraint. Both types of constraints

must be fulfilled in order to obtain valid structures.

Constraints defined in the previous paragraph are

to be tested for any pair of components (derivatives)

located at any SH level. Since the componentOf

(derivativeOf) relations are just defined for adjacent

levels, they need to be extended to consider multiple

levels of the SH. So, the mlComponentOf and

mlDerivativeOf attributes, and their corresponding

deductive rules, are defined for the Family, Variant

Set and Product classes. Such attributes allow

identifying whether a given product abstraction

participates at any level of the SH of another product

abstraction. Fig. 11 shows an example of ml

ComponentOf and its corresponding deductive rule

for the Family class. Thus, a family f2 is a multi

level component of f1 if f2 is direct component of f1

or there exists another family f3,

which is component

of f1, and f2 family is mlComponentOf f3.

Figure 11: Attributes and constraints added to test

restriction compliance.

Additionally, some integrity constraints have to be

defined in the Restriction class in order to ensure

restriction compliance. Two of such constraints are

presented in Fig. 11 as attributes of the Restriction

class. The first one, named MandConst, specifies

that the existence of a mandatory type of restriction

between two product abstractions (pa1 and pa2)

requires pa2 to be a multilevel component of pa1.

The other one, named IncompConst, which

prescribes an incompatibility restriction between pa1

and pa2, implies pa2 not to be a multilevel

component of pa1.

3 CASE STUDY

The meat industry was chosen to test the PRONTO

implementation presented in this paper. This

industry produces large quantities of a wide range of

products. Each product is sold in different packages,

depending on the market. Besides, a given cut is

considered a distinct product depending on the

quality of the steer from which it was obtained.

Therefore, the number of products variants handled

by this industry is very high. In addition, meat

products have complex hybrid composition/

decomposition structures. Raw materials are non

atomic, i.e., a sequence of decomposition operations

is needed to obtain intermediate products which are

later transformed into finals ones by manufacturing

processes. In addition, decomposition operations can

be made in different ways, so distinct products may

be obtained from a unique intermediate product.

The example presented in this section (due to

lack of space, just a test case partial view) focuses

on the representation of intermediate products,

which, together with packaging materials, participate

in the production of frozen cooked beef final

products. The AH that was defined for the products

considered in the example is shown in Table 1.

Table 1: Abstraction Hierarchy of an example product.

Family Variant Set Product

Frozen

Cooked

Beef

CookedBeefforDicing (CBD)

CBD1

CBD2

CBD4

SeasonedCookedBeef (SCB)

SCB3

SCB5

GroundCookedBeef (GCB)

GCB6

GCB7

GCB2

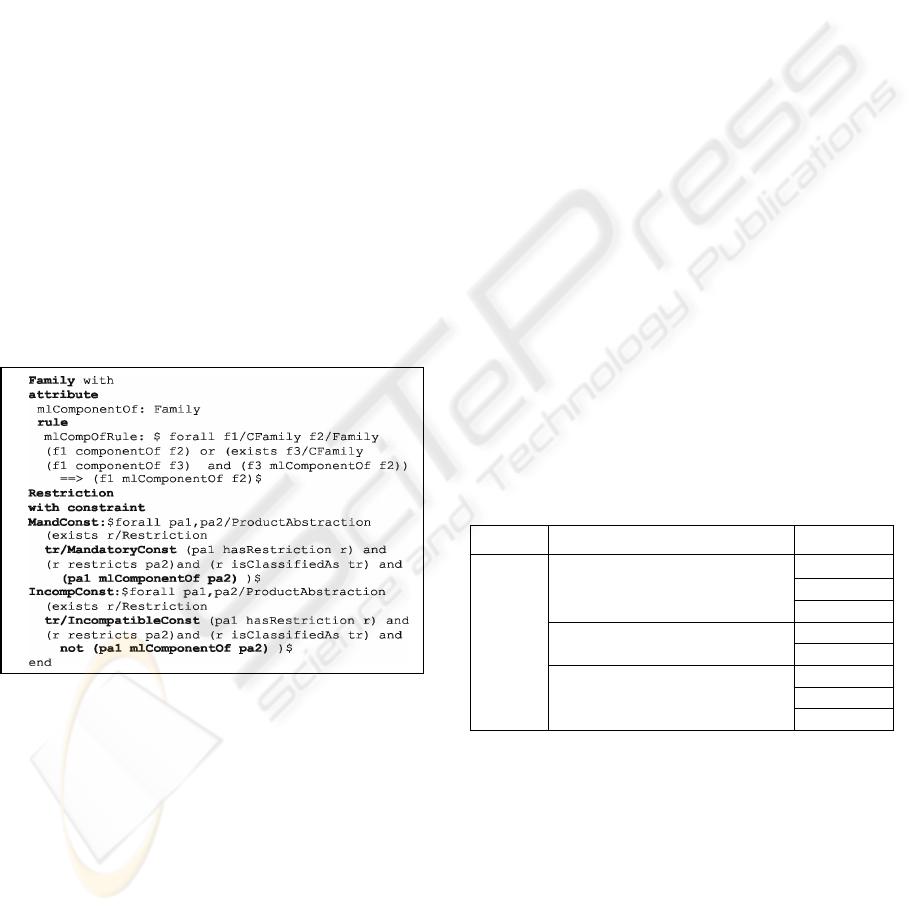

Fig. 11 presents the FrozenCookedBeef family,

its structures and the relationships of one of them.

FrozenCookedBeefSTR is a composition structure

(CStructure) that is defined by four composition

relations: R12, R13, R14a and R14b. Fig. 12 also

shows that Salt, Gelatin, CookedBeefRM3 and

CookedBeefRM2 correspond to the values of the part

attribute of the above relations. In the same way,

1754KG, 15KG and 12KG are the values of the

quantityPerUnit attribute corresponding to each

component.

ICEIS 2010 - 12th International Conference on Enterprise Information Systems

306

Fig. 12 also shows that R12 is a mandatory

relation, while R13 is an optional one. R14a and

R14b are selective relations, which imply that only

one of them has to be present in the structure of a

particular product. Thus, two structural hierarchies

are implicit in the definition of the Frozen

CookedBeefSTR: (i) one that comprises 12KG of

Gelatin (R12), 15KG of Salt (R13) and 1754 KG of

CookedBeefRM3 (R14a); (ii) and another one

composed of 12KG of Gelatin (R12), 15KG of Salt

(R13) and 1754KG of CookedBeefRM2 (R14b).

Figure 12: FrozeenCookedBeef family.

It is also possible to see in Fig. 13 that the

CookedBeefRM2 family participates in two different

structures: as a derivative in the decomposition

structure of the CapOfRump family and also as a

component of the FrozenCookedBeef one.

Figure 13: CookedBeefRM2 participating in composition

and decomposition structures.

To exemplify the definition of a variant set, Fig.

14 illustrates the representation of CookedBeefFor

Dicing, which is member of FrozenCookedBeef

family and has FrozenCookedBeefSTR as its

structure. Also, Fig. 14 shows that the CookedBeef

ForDicing variant set introduces three changes into

the family structure. The figure also depicts

elements of the variant set and product levels. The

middle part of it illustrates how an instance of

AllowableVariant Set relates to CookedBeefFor

Dicing. Such instance specifies the CookedBeef

RM2.1 variant set as one of the components of the

possible SHs of the variant set being defined. The

bottom part of Fig. 14 presents two members of the

CookedBeefForDicing variant set, the CBD1 and

CBD2 products, which by means of the

chosenProduct relations specify the components of

their respective structural hierarchies.

To illustrate the use of views for inferring

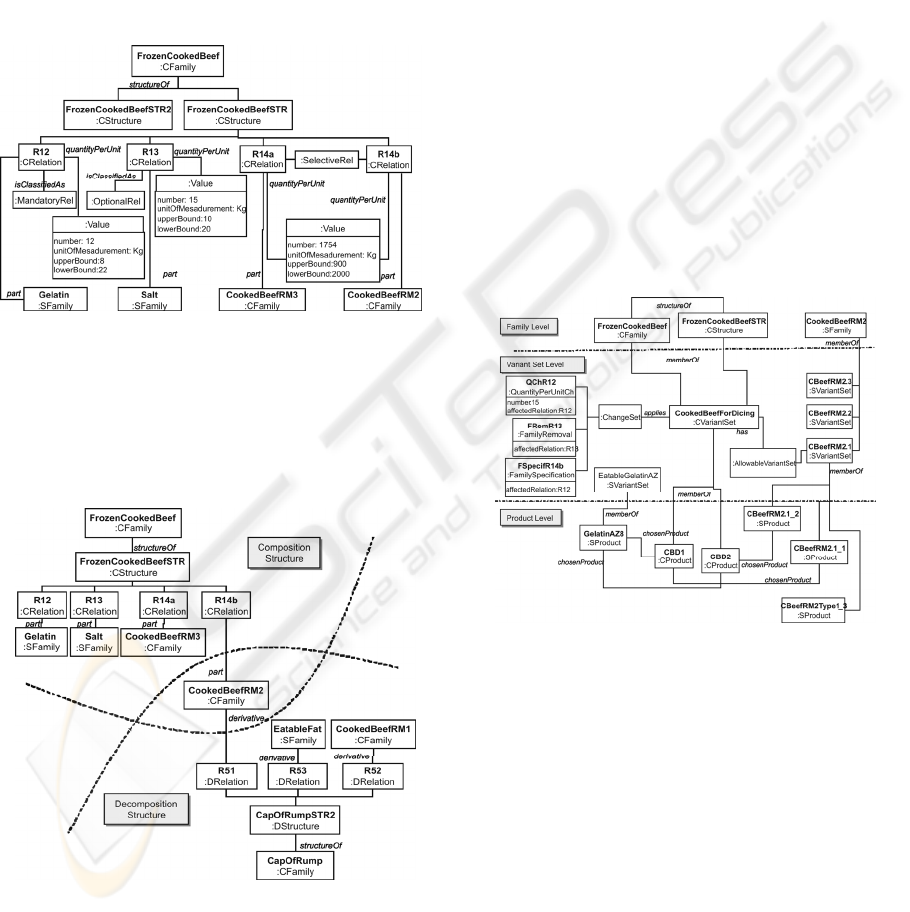

implicit knowledge from the defined concepts, Fig.

15 presents some of the results of executing the

FamilyReq view. In particular, this picture shows the

material requirements of the CookedBeefRM2

family.

Figure 14: CookedBeefForDicing definition.

In Fig. 15, the [CookedBeedRM2/this_par] label

corresponds to the parameter value adopted in this

execution of the view. Two values of the STRreq

attribute are computed, corresponding to an

execution of a generic view that has the family

already mentioned as a parameter. These two values

represent alternative material requirements

corresponding to different structures. In particular,

CookedBeedRM2 either requires 1 unit of CapOf

Rump (by the CapOfRumpSTR2 structure) or 1 unit

of RumpWC (by the RumpWCSTR3 structure).

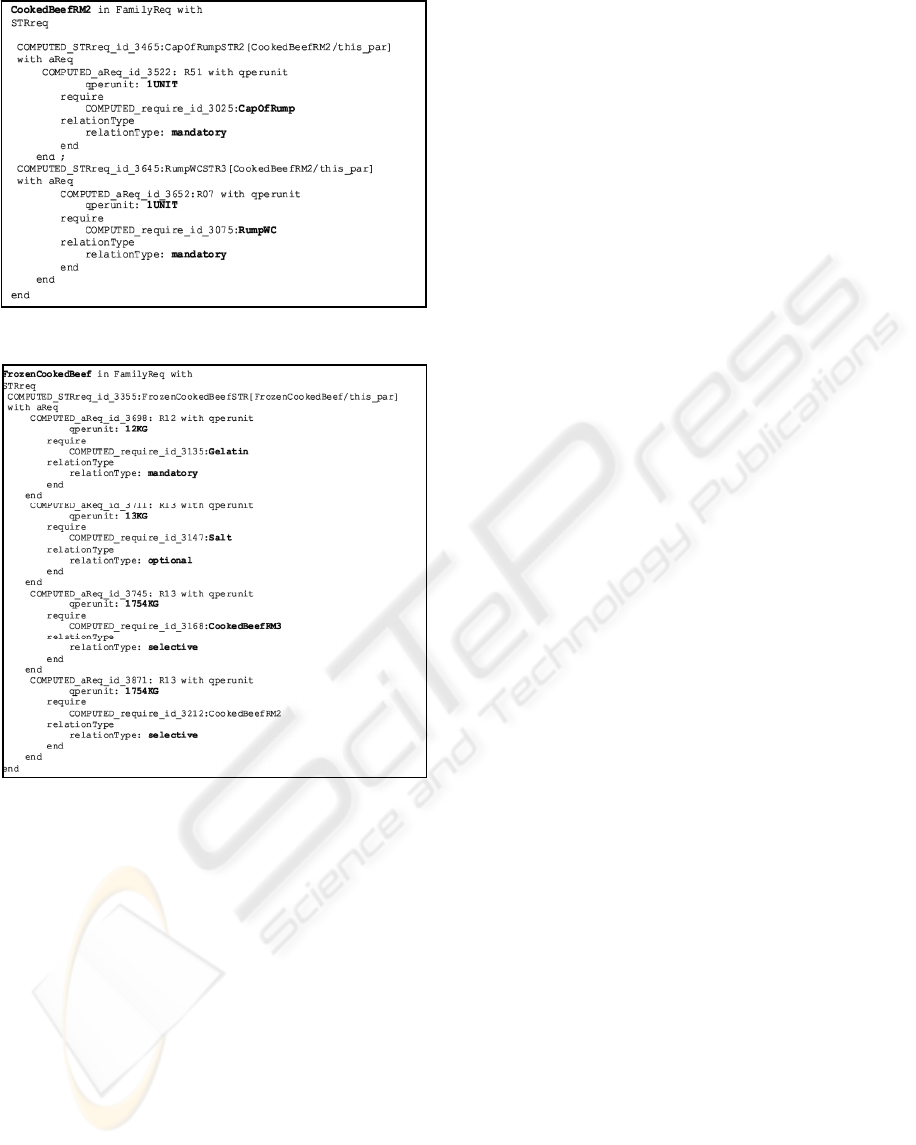

Similarly, Fig. 16 shows the results of executing the

FamilyReq view for the FrozenCookedBeef family.

A THREE LEVEL ABSTRACTION HIERARCHY TO REPRESENT PRODUCT STRUCTURAL INFORMATION

307

Figure 15: CookedBeefRM2 family requirements.

Figure 16: FrozenCookedBeef family requirements.

4 CONCLUSIONS

The main contribution of this paper is the formal

specification of PRONTO, a product information

ontology, which integrates two hierarchies: the

abstraction hierarchy (AH) and the structural one

(SH), which contains BOM related information.

The AH establishes three different abstraction

levels for the definition of products: Family,

VariantSet and Product. Such hierarchy allows

representing different granularity product data and

efficiently dealing with a high number of variants. It

uses mechanisms to maintain consistent structural

information between the different aggregation

levels. The SH organizes knowledge related to the

structural information of products. This hierarchy is

a mechanism to properly manage product

information associated with the multiple available

recipes or processes to manufacture a particular

product or a set of similar products. At each one of

the levels of the AH, the SH defines the relations

that exist between raw materials, intermediate and

final products participating in a product structure.

Another contribution of PRONTO, that is not

included in other proposals, is its intrinsic capability

of representing both, the structure of products that

are obtained by the assembly of parts (typical of

discrete manufacturing environments), as well as the

structure of those that are decomposed to obtain

intermediate products (characteristic of dairy, meat

or petrochemical industries), that can participate as

components of other products.

The proposal also manages constraints which

prevent the derivation of invalid product structures.

This feature is very important in production

environments where client specifications have a

strong influence on the definition products to be

manufactured/assembled. Thus, it avoids a client

from requiring an incorrect product configuration.

The integrated model was formalized using the

O-Telos language and implemented in ConceptBase.

This implementation provides a common vocabulary

for the definition of product structures and specifies

the semantics of each term in a non-ambiguous way

by means of first order logics. It also allowed

verifying the consistency of the proposed model,

which can be easily extended by adding new

concepts, deductive rules, queries and views.

ACKNOWLEDGEMENTS

This work has been supported by ANPCYT (PAE-

PICT2007 00051 and 02315), CONICET (PIP 2754),

UTN (PID), and UNL (CAI+D 2009).

REFERENCES

Giménez, D. M., Vegetti, M., Leone, H. P. and Henning,

G.P. 2008. PRoduct ONTOlogy: Defining product-

related Concepts for logistics planning activities.

Computers in Industry, 59, 231–241.

Giménez, D. M., Leone, H. P. and Henning, G. P. 2009. A

Hierarchical Product-Property Model to Support

Product Classification and Manage Structural and

Planning Data. LNBI, 24, 639-650.

Jarke, M., Jeusfeld, M., and Quix, C., Editors. 2004.

ConceptBase V6.2 User manual.

Mänisto, T. Peltonen, A. and Sulomen, R. (1998).

Modeling generic product structure in STEP.

Computer Aided Design, 30, 1111-1118.

ICEIS 2010 - 12th International Conference on Enterprise Information Systems

308