MOTION GENERATION FOR A HUMANOID ROBOT WITH

INLINE-SKATE

Nir Ziv*, Yong Kwun Lee* and Gaetano Ciaravella**

*Center for Cogntive Robotics, University of Science and Technology (UST) & Korea Institute of Science and Technology

(KIST), 39-1 Hawolgol-Dong, Wolsong-Gil 5, Seongbuk-gu, Seoul, South Korea

**Cognative Center for Robotic Research, Korea Institute of Science and Technology (KIST), Seoul, South Korea

Keywords: Humanoid, Inline-Skate, Skating Motion, Wheeled Locomotion.

Abstract: A lot of research has been done for bipedal walking and many positive results have been produced, such as

the ASIMO robot from Honda. However, although bipedal walking is a good solution for moving over

uneven surfaces; bipedal walking is inefficient over an even surface because the robot’s walking speed and

stability are limited. Consequently, employing a wheeled locomotion on even surfaces can be advantageous.

This paper presents a mathematical model and simulation of wheeled biped robot with two passive wheels

on each foot. This enables the robot to move more efficiently over even surfaces. Also, this paper attempts

to produce a more human-like inline-skating motion than previously created inline-skating simulations.

1 INTRODUCTION

Over the last few years, research on bipedal walking

has progressed and has lead to major successes

within the robotics field. One good example of this

success is the ASIMO robot, a Honda creation. At

the time of writing this paper, ASIMO can run with

a speed of 6 km/h and is able to walk at a speed of

2.7 km/h (Honda). When considering the strongest

achievements which leg locomotion has achieved

until now, one major progressive accomplishment

has been the ability for robots to move across

uneven surfaces.

However, when considering robotic leg

locomotion across only even tarains, the advantages

of wheeled locomotion are greater than bipedal (or

leg) locomotion. The reason for this is because the

wheeled robot’s moving speed and efficiancy are

stronger and more stable. This is because leg

locomotion algorithms are more complex than

wheeled motion, making it more difficult for bipedal

robots to walk or run quickly. (Jo et al 2008).

Therefore, to combine the advantages of both leg

and wheeled locomotion, hybrid robot systems were

developed. For example, WorkPartner is a

quadruped system that can detect the type of surface

it is on, even or uneven, and can then choose

accordingly the type of locomotion to use, wheeled

or bipedal (Ylonen et al 2002). Another example of

hybrid locomotion is WS-2/ WL-16 (Waseda Shoes

– Number 2 / Waseda Leg – Number 16)

(Hashimoto et al 2005) which also combines bipedal

walking with wheeled locomotion. Both

WorkPartner and WS-2/WL-16 use DC motorized

wheels.

However, because both WorkPartner and WS-

2/WL-16 utilize motor wheels, this means that the

brake and steering are also motorized. As a result, a

robot with motorized wheels has larger wheels and

its robotic system becomes heavier and, therefore,

less agile.

To solve this issue, passive wheel locomotion

has been suggested. One example of a hybrid,

passive wheeled robot is the Roller-walker,

developed by Hirose and Takeuchi (Hirose et al

1996, 1999, 2000.) In this system, the wheel motion

is not generated by a DC motor, instead the robot

moves by making a roller skating-like motion.

Another example of passive wheel locomotion is the

Rollerblader (Chitta et al 2003), which has two

passive wheels that move in symmetric and anti-

symmetric motions to propel the Rollerblader

forward and in a rotary motion respectively.

Similarly, in this paper we present a simulation

of a passive wheeled robot to generate a forward

motion; our robot consists of two legs with two

passive wheels attached along the middle of each

354

Ziv N., Lee Y. and Ciaravella G. (2010).

MOTION GENERATION FOR A HUMANOID ROBOT WITH INLINE-SKATE.

In Proceedings of the 7th International Conference on Informatics in Control, Automation and Robotics, pages 354-359

Copyright

c

SciTePress

foot. However, unlike the Rollerblader, our

simulation and model will attempt to create a more

human-like motion using ‘D’ shape movement for

the pushing leg where near the end of the movement

the pushing leg will be raised in the air.

This paper is organized as follows. The

following section will describe the modelling and

the equations of the robot’s motion. In section 3, we

will show the simulation, motion steps and results.

We will conclude with a brief discussion about the

simulation’s results, as well as problems that need to

be solved within further research in the future.

2 MODELLING

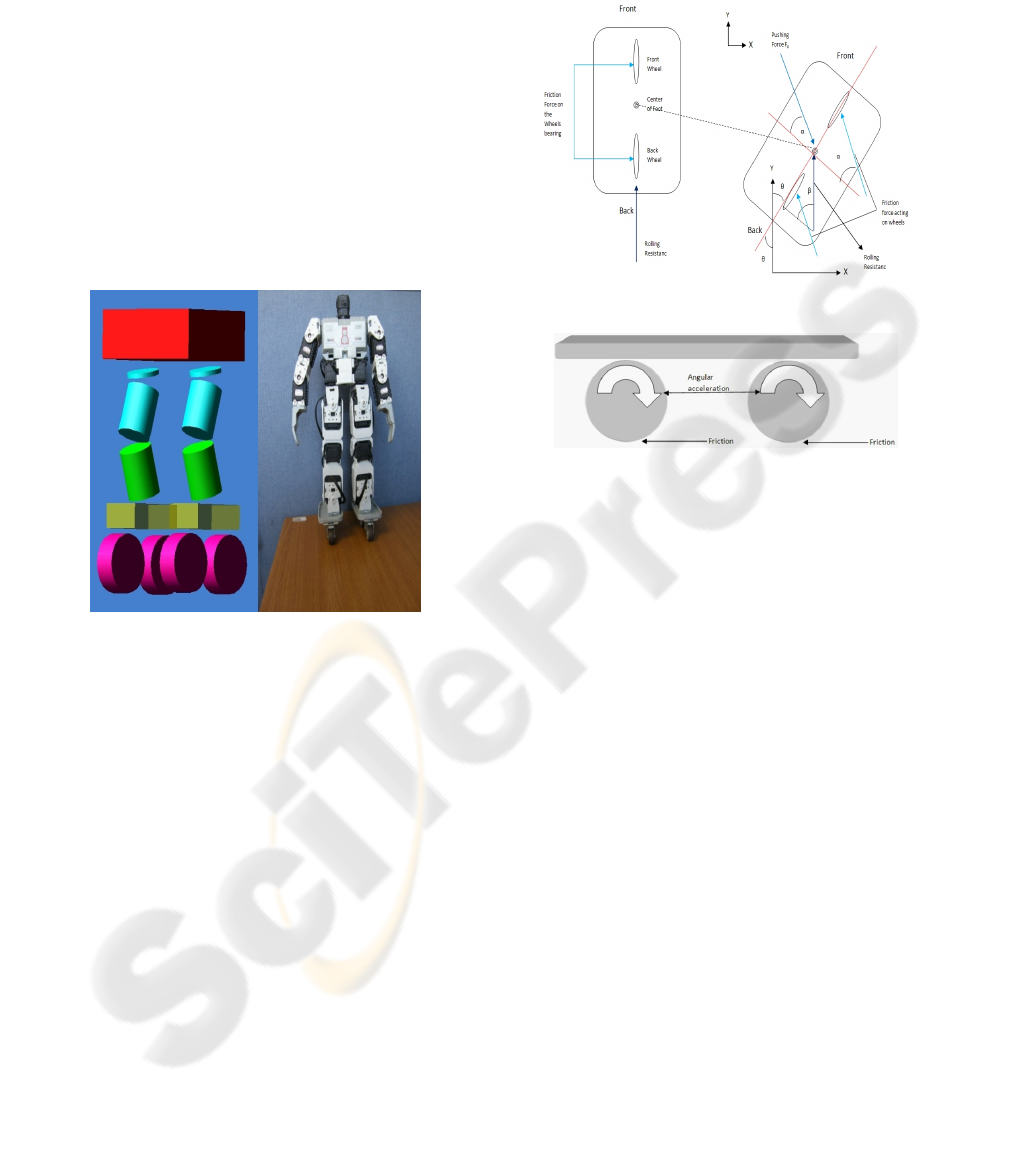

Figure 1: MSC.ADAMS Model and Read Small Size

Humanoid.

The modelling of the robot (figure 1) was done by

using MSC.ADAMS software. The robot has a total

of 12 Degrees Of Freedom (DOF), where each leg

contains 6 DOF. Two passive wheels were added to

each foot along the middle of the foot.

The forces acting on the robot configuration

(figure 2) and a derivation of the equations of

motion are shown and explained in more detail in

the next section.

2.1 Parametric Modelling

Solving the equations of motion for this system is a

very complex process; therefore, the following few

assumptions were made:

Even though the motion is continuous, we will

solve it for a time equal to t (where t is a segment of

the whole motion.)

External force, such as air resistance, external

push and wind are negligible.

The simulation motion is a forward motion.

This will reduce the amount of forces acting on the

model for rotational motion.

Figure 2: Forces Acting on the Robot.

Figure 3: Side View of the Forces Acting on the Robot.

Because we are trying to simulate a forward

motion, the forces acting on the model should satisfy

the following equations:

0

(1)

F

M

y

(2)

Where F

x

and F

y

are the forces acting on the X

axis and Y axis respectively. M

t

is the total mass and

y is acceleration. As figure 2 shows, we will

calculate the forces that act on the model.

First, we will analyze the stationary foot. Figure

2 shows the robot’s stationary foot as the left foot.

(3)

NM

g

Where F

r

, C

rr

and N are the rolling resistance

force, the rolling resistance coefficient and the

normal force respectively (Peck et al 1859,National

Research council 2006) and, in this instance, the

normal force is total mass (M

t

) times gravity (g).

(4)

Where F

fs

is the frictional force on the stationary

MOTION GENERATION FOR A HUMANOID ROBOT WITH INLINE-SKATE

355

foot, µ

f

is the friction coefficient, N is the normal

force, M

t

is the total mass and g is the gravitational

force.

Because the stationary foot will always point

forward (there is no Z axis rotation) and the foot will

be perpendicular to the ground, the rolling resistance

force will always act on the Y axis. The frictional

force from equation (4) will be used for the wheels’

momentum as described next.

The last force acting on the stationary foot is the

wheels momentum force. This can be seen in figure

3. The force acting on the wheels can be expressed

as follows:

(5)

MO

w

is single wheel momentum, I is the inertial

mass,

is angular acceleration F

fs

is frictional force

on the stationary foot and r is the wheel radius.

Because we have two wheels on each foot, we can

express equation (5) as follows:

(6)

MO

t

is the total momentum force acting on the

stationary foot’s wheels.

Until now we have described the forces which

are acting on the stationary foot (or the left foot from

figure 2). Now we will describe in the same manner

the forces acting on the pushing foot (or the right

foot from figure 2).

First, we will look at the pushing force. The

pushing force will act on the pushing leg with an

angle of α. This angle will vary with time. However,

as stated earlier to simplify the equations, we assume

that we are looking at a given time t and therefore

remove the dependency of time.

Because the pushing force is acting with an

angle, we will need to derive the X and Y

component of this force. These components are as

follows:

(7)

F

px

and F

py

are the pushing forces on the X axis

and the Y axis respectively. F

p

is the pushing force

and α is the angle between the pushing force and the

pushing foot.

As a reaction force to the pushing force, the

pushing foot will experience a frictional force as

well. This force can be written as:

(8)

As with the pushing force, we will need to work

on the X axis and Y axis components of the friction

force. Using equation 8 with angle α produces the

following equations:

(9)

Where F

fpx

is the frictional force on the pushing

foot on the X axis and F

fpy

is on the Y axis.

Using equations (1) and (2) and summing all the

forces that act on the X axis and Y axis, we can

rewrite equations (1) and (2) as follows:

(10)

(11)

Using equations (3) – (9) and solving equation

(11) for , we can rewrite equation (11) as follows:

(12)

(13)

(14)

(15)

(16)

Where

,

and

.

For a full derivation of how we developed equation

(12), please refer to the appendix.

2.2 Model Analysis

From equation (16) above, we notice that in order to

make the acceleration higher, and therefore make the

robot move forward faster, we needed to identify a

few components of the equation and check the

values that qualify our needs.

Equation (16) can be written in simple form as

follows:

(17)

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

356

Where:

(18)

(19)

2

sinC

cos sin

(20)

In order to make ÿ bigger, we must make A and

B bigger and make C as small as possible. To make

equation (18) bigger, we identified α as the variable

since F

p,

M

t

and µ are constants. Using this notion,

we plotted equation (18) into Matlab. The results are

shown in figure 4.

As can be seen in figure 4, which shows when α

is static and not dynamically changed by time, the

value of α that will be the best in order to make the

pushing force greatest ( i.e. part A) is α =

or ,in

other words, when α = 90

o

. At the same time, the

best value for µ is 0.2. When looking in detail at

equation (20), we identified α and β as the variables

because the rest of equation (20) is constant.

Because we already determined the value of α from

equation (18), we will need to find the best value of

β. Using the same value of α with β, we will succeed

to minimize equation (20) since cos (90

o

) will make

the last part of C equal to zero.

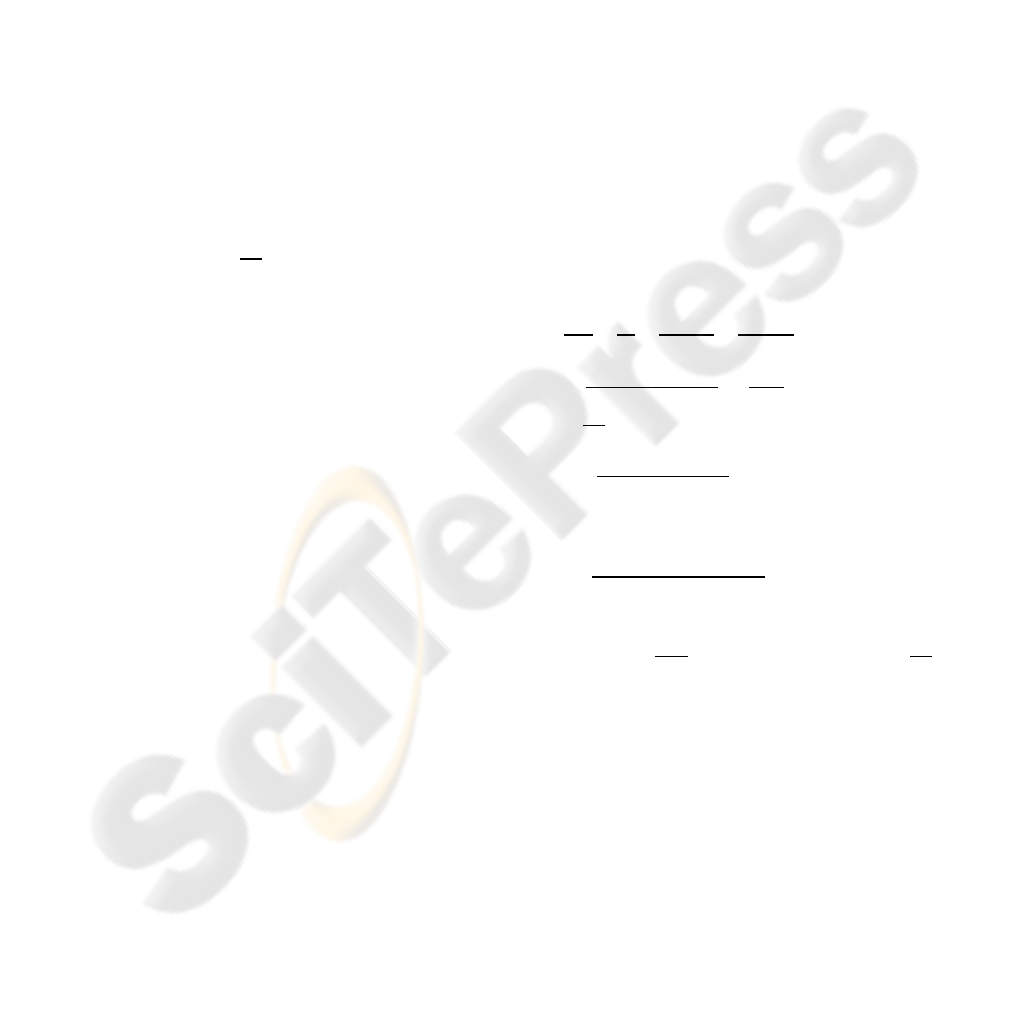

Figure 4: Matlab Plotting the relationship between values

of µ and α to maximize pushing force.

The middle part of equation (18) is shown in

equation (19) and has been plotted in Matlab; it can

be seen in figure 5. In figure 5, we showed the

relationship between the angular acceleration,

, and

the robot acceleration, ÿ. As expected, the

relationship between the two accelerations is linear,

which means that the faster the angular acceleration

on the wheels will be, the faster the robot

acceleration will be. Also, we verified the equations

with different values of the pushing force.

Figure 5: Matlab plotting the relationship between

acceleration and angular acceleration.

3 SIMULATION

We used MSC.ADAMS to simulate the skating

motion. The model is a simple model of the real

humanoid (see figure 1) and the motions were

generated by using three general motions that act on

the model (one general motion on the hip with

relation to the ground, one general motion on the left

leg with relation to the hip and the last general

motion on the right leg with relation to the hip as

well). With these three general motions we

controlled the angles or the joint and displacements

of the rigid bodies. The skating motion is combined

of six steps, three for the right foot, and three for the

left foot to produce a full cycle of motion.

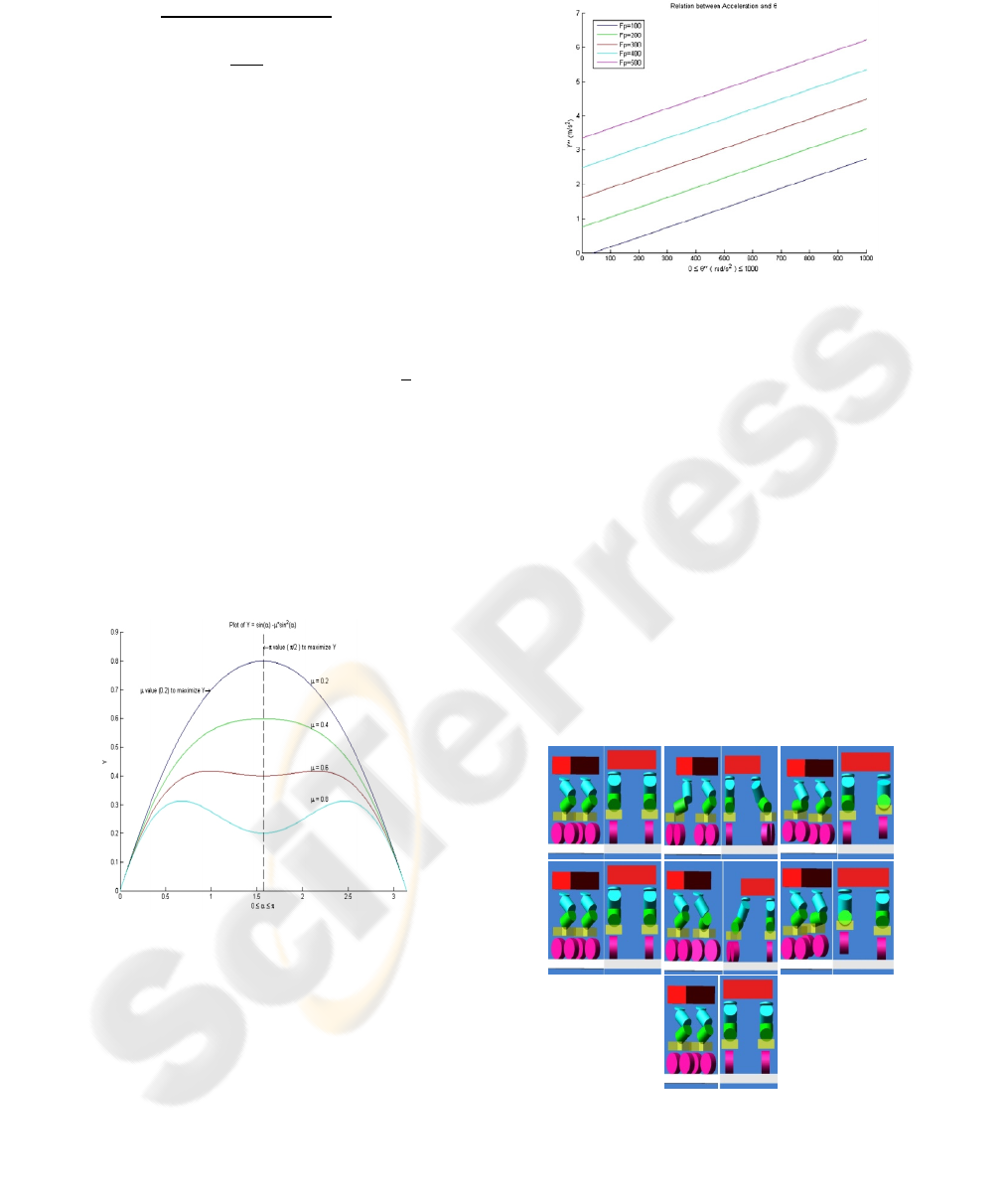

Figure 6: The Simulation Algorithm Sequence. The left

image in each square shows the view from the side and the

image on the right shows the view from the back.

The shape of the pushing leg motion is like a ‘D’

MOTION GENERATION FOR A HUMANOID ROBOT WITH INLINE-SKATE

357

shape, starting from the top left corner and can be

viewed in two parts. In the first part, the pushing leg

is on the ground and is moving in slow motion. In

the second part, the pushing leg is in the air and to

maintain balance this step part is faster than the first

part of the cycle.

The following are the motion steps (assuming

that we begin with the right foot):

1. To start, the right foot is pushed away from

the body, creating a ‘D’ shape

2. Before the ‘D’ is completed, the right foot is

returned to the ground and a triangle shape between

the pushing leg, body and stationary leg is formed.

3. Then the pushing leg is lifted and returned to

its starting position, parallel to the stationary leg.

4. Step 1 is repeated, except that the left foot

replaces the right foot.

5. Before the ‘D’ is completed, the left foot is

returned to the ground and a triangle shape between

the pushing leg (this time it is the left leg), body and

stationary leg (this time it is the right leg) is formed.

6. Then the pushing leg is lifted and returned to

its starting position, parallel to the stationary leg.

One can note that steps 4-6 are a mirror of steps

1-3. Figure 6 shows the images of these 6 steps.

Notice the top right image from figure 6 where the

triangle between the pushing leg, body and

stationary foot is formed.

The time interval for the simulation is 5 seconds

with 100 frames. During that simulation the skating

motion (steps 1-6) ran twice, this means that each

leg creates the pushing force twice. The result of this

run was that the robot created enough pushing force

to overcome the friction and succeeded to create a

forward motion.

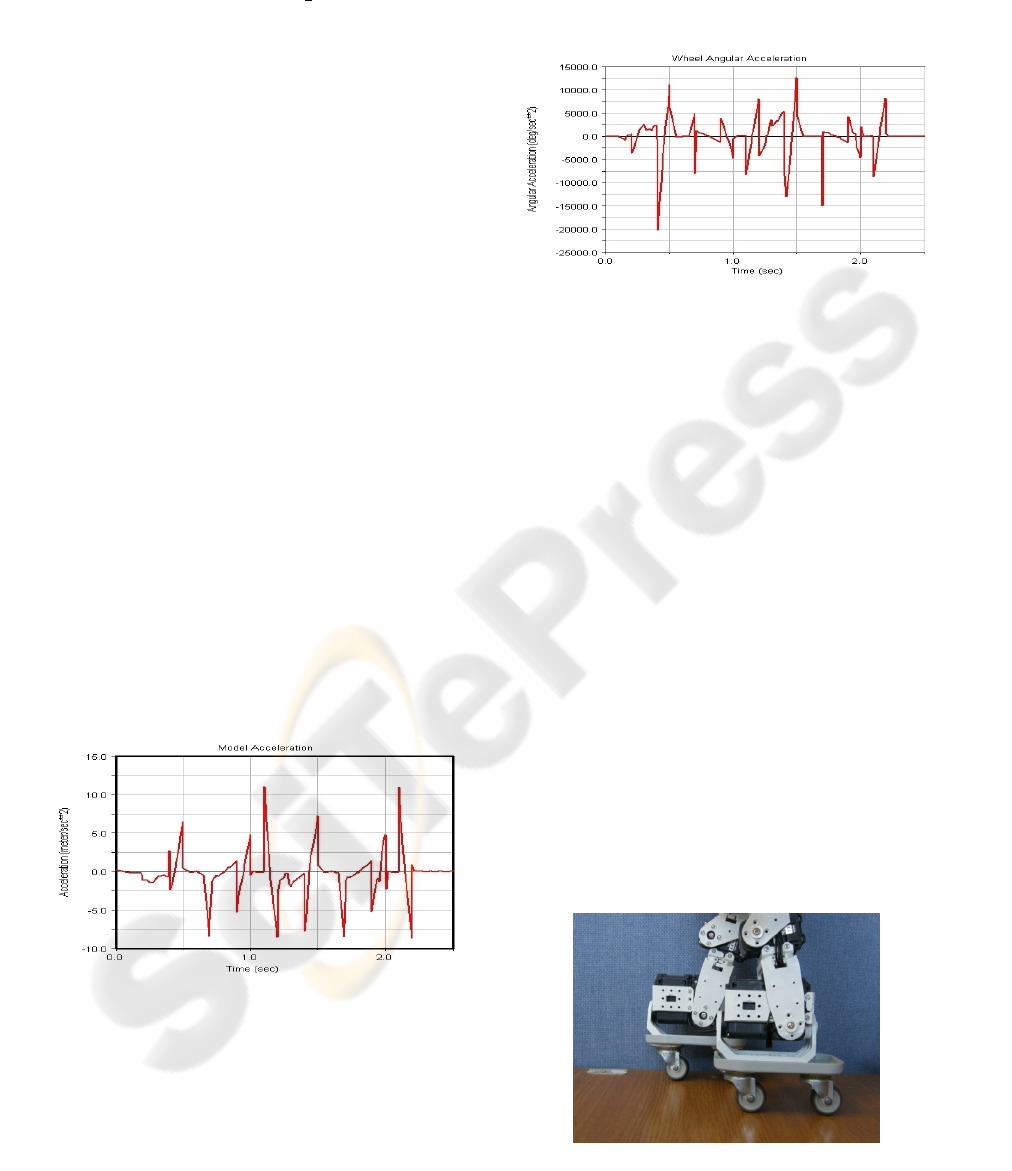

Figure 7: ADAMS Model Acceleration.

Figure 7 and figure 8 are showing the

acceleration and angular acceleration of the model

and a single wheel of the model respectively. These

plots were taken from MSC.ADAMS software.

Comparing these values to our Matlab plotting in

figure 4 and figure 5 we can see that the results in

both MSC.ADAMS simulation and our derivation of

the equations of motion agree with one another.

Both results show that as the acceleration increases

the angular acceleration on the wheels will increase

as well.

Figure 8: ADAMS Wheel Angular Acceleration.

4 CONCLUSIONS

This paper presents a simulation model with defined

motion steps to generate a human-like skating

motion. The simulation uses a robot which has two

passive wheels on each foot along the middle of the

foot. We successfully simulated the skating motion

and generated a forward motion.

We also calculated the equations of motions for

this model, and used Matlab to find a feasible value

for dependent variables. The results were compared

between the simulation and the mathematical model

successfully. Even though this was a successful

simulation, our next step will be to generate this

motion in a real humanoid that follows the model, as

can be seen in figure 9, figure 10 and figure 11.

Additionally, researching a sounder algorithm to

produce a more smooth ‘D’ shape would be

valuable. Finally, further research would be to

create a humanoid based on our model which would

have the ability to transform itself between wheeled

locomotion and leg locomotion depending on the

surface it is crossing (even or uneven).

Figure 9: Small Size Humanoid Wheels.

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

358

Figure 10: Small Size Humanoid Front View.

Figure 11: Small Size Humanoid Side View.

REFERENCES

Chitta S., Kumar V., 2003. Dynamics and Generation of

Gaits for a Planar Rollerblader. International

Conference of Intelligent Robots and Systems.

Endo G., Hirose S., 1999. Study on Roller-Walker

(System Integration and Basic Experiments.)

International Conference on Robotics and

Automation.

Endo G., Hirose S., 2000. Study on Roller-Walker (Multi-

mode Steering control and Self-contained

Locomotion.) International Conference on Robotics

and Automation.

Hashimoto K., Hosobata K, Sugahara Y., Mikuriya Y,

Lim H., Takanishi A., 2005. Realization by Biped

Leg-wheeled Robot of Biped Walking and Wheel-

driven Locomotion. International Conference on

Robotics and Automation.

Hirose S., Takeuchi H., 1996. Study on roller-walker

(Basic Characteristics and its Control.) International

conference on Robotics and Automotion.

Honda, ASIMO, January, 13

th

2010. The New ASIMO –

Major Features Summary. http://www.hondauk-

media.co.uk/uploads/presspacks/bf27134f6692b1c050

d8ae9c29bc21840af2a723/Major_Features_Summary.

pdf

Jo S., Chu J., Lee Y., 2008. Motion Planning for Biped

Robot with Quad Roller Skates. International

conference on Control, Automation and System.

National Research Council Special Report 286, 2006.

Tires and Passengers Vehicle Fuel Economy.

Washington D.C.

Peck William Guy , 1859. Element of Mechanics: For the

Use of Colleges, Academics and High Schools. A.S.

Barnes & Burr. New York

Ylonen S. J., Halme A. J., 2002. WorkPartner – Centaur

like Service Robot. Intl. Conference on Intelligent

Robots and Systems.

MOTION GENERATION FOR A HUMANOID ROBOT WITH INLINE-SKATE

359