RAPID PROTOTYPING OF 3D ANATOMICAL MODELS TO

HEMODYNAMIC STUDIES

Vania Freitas

Engenharia Biomédica, Instituto Politécnico de Bragança

Campus Stª Apolónia, Apartado 134, 5301-857 Bragança, Portugal

Luís Queijo

1, 2

and Rui Lima

1,3

1

Departamento de Tecnologia Mecânica, Instituto Politécnico de Bragança

Campus Stª Apolónia, Apartado 134, 5301-857 Bragança, Portugal

2

CIBER - Centro de Investigación Biomecánica y Ergonomía

Parque Científico - Universidad de Valladolid, Campus Miguel Delibes – Valladolid, Espanha

3

CEFT - Centro de Estudos de Fenómenos de Transporte

Faculdade de Engenharia da Universidade do Porto, 4200-465 Porto, Portugal

Keywords: Carotid, Rapid prototyping, FDM, TDP, PDMS, Hemodynamics.

Abstract: The purpose of this work is mainly to manufacture several anatomical models in a polymeric material –

polydimensiloxane (PDMS) to study the blood flow through a carotid artery bifurcation. Over the last few

decades, research has been shown that the geometry of the carotid artery is closely related to the

development of serious cardiovascular diseases. Hence, there is a considerable interest in the development

of in vitro experimental techniques able to obtain accurate measurements of the blood flow behavior

through a realistic carotid artery. In this study we decide to apply rapid prototyping (RP) technologies

combined with a PDMS casting technique in order to fabricate an anatomically realistic model of a human

carotid to investigate, in a near future, the effect of the geometry on the local hemodynamics and

consequently improve the understanding of the origin and development of these pathologies. Based on a

human carotid computerized tomography (TC) it has been developed a 3D model through the application of

two rapid prototyping techniques – Fused Deposition Modeling (FDM) and Tridimensional Printing (TDP).

By combining the rapid prototyping techniques with a PDMS casting technique it was possible at the end to

obtain an anatomically transparent model of a human carotid artery made by an elastomeric material, i.e.

PDMS. Hence, we believe that this combination is a promising technique to perform in vitro blood studies

through anatomically realistic models, such as a carotid artery.

1 INTRODUCTION

Large arteries that carry blood out from the heart and

their branches are the most important blood vessels

from human body. These arteries can be classified as

elastic due to their big diameter and predominance

of elastic fibers in their walls. Aortic and carotid

arteries are included in this classification (Williams

and Warwick, 1995).

Cardiovascular diseases are responsible for more

morbidity and mortality than any other disease,

being atherosclerosis, the most common and

significant in a clinic perspective (Collins et al.,

2001). Hemodynamic studies have been shown that

the geometry of the carotid artery produces

favorable conditions for the development of

cardiovascular diseases such as, atherosclerosis and

thrombosis. Hence, it is important to investigate new

in vitro experimental techniques able to obtain

accurate measurements of the blood flow behavior

through anatomically realistic artery models.

In the conversion process of a computerized

tomography in to a 3D model, it is needed a

sequence of cross sections from the studied object.

Using a 3D reconstruction software it is possible to

transform these bi-dimensional images in a three-

dimensional model that can be used to produce a

246

Freitas V., Queijo L. and Lima R. (2010).

RAPID PROTOTYPING OF 3D ANATOMICAL MODELS TO HEMODYNAMIC STUDIES.

In Proceedings of the Third International Conference on Biomedical Electronics and Devices, pages 246-251

DOI: 10.5220/0002787702460251

Copyright

c

SciTePress

solid model in rapid prototyping equipment

(Foggiatto, 2006).

With the objective of obtain a real model from

the anatomical structure a TC image set was used

once this technology was able to provide us the

definition wanted and allowed us to identify the

arteries in the main anatomical area.

After the identification is done, the image

processing starts with the goal to do the artery

segmentation, which means, to isolate the arteries

from the other existent anatomical structures, visible

in the images.

Rapid prototyping technology has been applied

to the previously rendered images in order to obtain

a good quality, low cost and fast manufacture 3D

anatomical model.

After converted into a STL (stereolitography)

file, the 3D digital model is sliced and processed by

the RP equipment that builds the model, layer, by

layer, where each layer is added to the previous one.

In this process we choose two different techniques –

Fused Deposition Modeling (FDM) and

Tridimensional Printing (TDP or 3DP).

Once obtained the wanted tridimensional

structures, these are placed in a molding box to

manufacture the PDMS transparent anatomical

model. This polymer belongs to a group of

organometalic polymers usually known by silicon

and is a biocompatible, transparent, inert, non-toxic

and non-flammable material with a great elastic

effect and, therefore, is used to simulate blood

vessels and other soft tissues.

This structure will allow, in the future,

hemodynamic studies and simulations.

2 EXPERIMENTAL PROCEDURE

2.1 Image Processing

With the objective of obtain a real model from the

anatomical structure a TC image set was used once

this technology was able to provide us the definition

wanted and allowed us to identify the arteries in the

main anatomical area.

After the identification, the image processing

starts with the goal to do the artery segmentation,

which means, to isolate the arteries from the other

existent anatomical structures, visible in the images.

Segmentation process has been performed in the

software ScanIP

®

to where TC images can be

transferred in DICOM format. To do this step,

binarization and thresholding techniques have been

applied to the images in order to obtain a mask in a

range of grey values that includes, in each image, the

tissues from the study object – carotid artery.

By evaluating the type of anatomical structure in

question, the chosen range has been from 204 to

255:

where g(x,y) is the resultant in the image after the

application of binarization technique and f (x,y) is

the image obtained from TC (Alves et al., 2001).

The result after the first iteration has not been

satisfactory due to the existence the other areas in

the same grey range so, in a complementary phase, it

was needed to process each image, pixel by pixel by

removing the structures that were not needed. It was

created a mask to each one of the arteries (right and

left) to allow us to have available, if needed, both of

them.

Once concluded artery model finishing by

smoothing all the surfaces, it was kept the main

structure with the bifurcation where most of the

pathologies are developed and erased all the

ramifications that will not make part of this study.

The result can be seen in figure 1 where transversal,

coronal and sagittal plans are illustrated as well as

the 3D rendered model.

Figure 1: Different working plans in ScanIP® software.

When all the image processing phases are

concluded, the file is converted in a STL format file

through internal software translator models and then

processed in printing management software that will

slice the model and allow choosing the printing

parameters to each of the used equipments.

⎩

⎨

⎧

≥

<

=

204),(,255

204),(,0

),(

yxf

yxf

yxg

RAPID PROTOTYPING OF 3D ANATOMICAL MODELS TO HEMODYNAMIC STUDIES

247

Figure 2: Carotid arteries 3D rendered models.

2.2 Rapid Prototyping

By the STL file conversion into a SLI (slice) format

file we are able to print the model, whatever is the

RP method choosen. This type of file contains the

information to each one of the layers to be printed,

as well to the orientation in which the model should

be printed.

This situation is due to the additive-constructive

characteristic in which the RP processes are based

(Rocha and Alves, 2000).

2.2.1 Fused Deposition Modeling

Fused Deposition Modeling – FDM, builds the

model by extruding ABS polymer filaments through

a printing head. This polymer is heated and melted

when going through the printing head and each layer

is deposited over the previous one melting it,

partially, and becoming a continuous structure.

During work, printing head moves along the

coordinates (x,y) and the depth (z) is obtained by the

platform movement where the model is being

printed.

This process has as particularity the need of use

of a second material as supportive layer where the

main structure doesn’t have any contact with the

previous material layer. The printing head has two

extrusion nozzles to feed, when needed, both

materials in the same layer. At the end of each layer

printing, the working platform is descended in a

distance equal to the deposited layer depth. This

process is made until the entire model is printed.

The model obtained by this process has a good

surface quality and is ready to use after the

supportive material is removed, which is easily

done.

Figure 3: Carotid artery model manufactured by FDM

process.

2.2.2 Tridimensional Printing

In this RP process, the model is built from a

composite dust material (a specific combination of

materials). In printing process, the composite

material is prepared by a cylinder action that flattens

the surface each time a layer is printed. In each layer

the printing head draws the correspondent section in

the material surface in glue aqueous liquid. When

the new material is deposited to the new layer, it is

glued to the previous one by the cylinder action.

Also, in this case, the printing head covers the

coordinates (x,y), being the depth fulfilled by the

movement of the working surface. Each time a layer

is printed the working surface descends and the new

material is deposited maintaining the distance to the

printing head.

All process is repeated until the model is

completely built.

After the model manufacture it is needed to

remove the model from the non-glued material that

can be recycled.

In TDP process, however, some additional tasks

must be performed, once the model surface is dusty

and non-stable. To remove the excess of material not

glued, it is needed to perform a surface cleaning

through the application of a compressed air flow.

Most of cases, to stabilize the surface, it is applied a

layer of cyanoacrylate or epoxy resin (Queijo et al.,

2009).

In this work, two models were printed with

different finished surfaces. To one of them it was

applied one cyanoacrylate layer while the other was

left with unstabilized surface.

BIODEVICES 2010 - International Conference on Biomedical Electronics and Devices

248

Figure 4: Carotid artery model manufactured by TDP

process.

2.3 Fabrication of PDMS Anatomical

Channels

In vivo animal research is an excellent way of

performing experiments with in environments that

closely mimics the human body. However, in vivo

experiments are laborious, expensive and difficult to

control several parameters and consequently it is

extremely complex to obtain accurate

measurements. On the other hand, by using in vitro

models, besides reducing the number of sacrificed

animals, this kind of models have many other

advantages over in vivo models, such as the ability

to control important parameters, obtain accurate

measurements and reproducible experiments. For

hemodynamic researchers in vitro models have been

extremely attractive as this kind of models allows

systematic flow studies. Hence, many studies on the

blood flow behavior in vitro models have been

performed over the past years. However, most

studies have been done in rigid or simplified models

(Goldsmith et al., 1996)(Lima, 2007). As a result,

there is a need to develop more realistic in vitro

models with geometries and environments that

closely mimics the human body. In this study we

applied two rapid prototyping techniques – Fused

Deposition Modeling (FDM) and Tridimensional

Printing (TDP) combined with a PDMS casting

technique to obtain anatomically realistic models of

a carotid artery.

The PDMS carotid artery was fabricated by

using two kinds of rapid prototyping techniques, i.e.,

Fused Deposition Modeling (FDM) and

Tridimensional Printing (TDP). The main steps for

fabricating the PDMS carotid channel (Figure 5)

were as follows. First, the human carotid geometry

was obtain by computerized tomography (TC) and

then printed by means of FDM and TDP. By

applying the FDM we were able to obtain the carotid

model in a copolymer of acrylonitrile, butadiene,

and styrene (ABS), whereas by using a TDP we

have obtained another kind model in a composite

powder. Next, carotid models with clay supports

where positioned in the bottom of a molding box in

order to pour an elastomeric material into the mould.

Note that, the model obtained by FDM technique

needed to be cut around the branch in order to pull

the model from the casting material without

breaking it. The elastomeric material selected was

the polydimensiloxane (PDMS) due to its

outstanding properties, including good optical

transparency and biocompatibility, easily reversible

sealing to glass, elasticity, replication of fine and

complex geometries, permeable to gases, thermally

stable, and low cost (Lima, 2008). The PDMS

prepolymer was prepared by mixing a commercial

prepolymer and catalyzer (Silpot 184; Dow Corning,

USA) at a weight ratio of 10:1. After removing the

bubbles, created during mixing, by a vacuum pump

the PDMS mixture was poured into the mould

containing the carotid model and then baked into a

oven for about 2 hours at a temperature of about

60°C. Both model and mould with PDMS were then

cooled to room temperature.

Figure 5: Main steps to fabricate PDMS carotid channels.

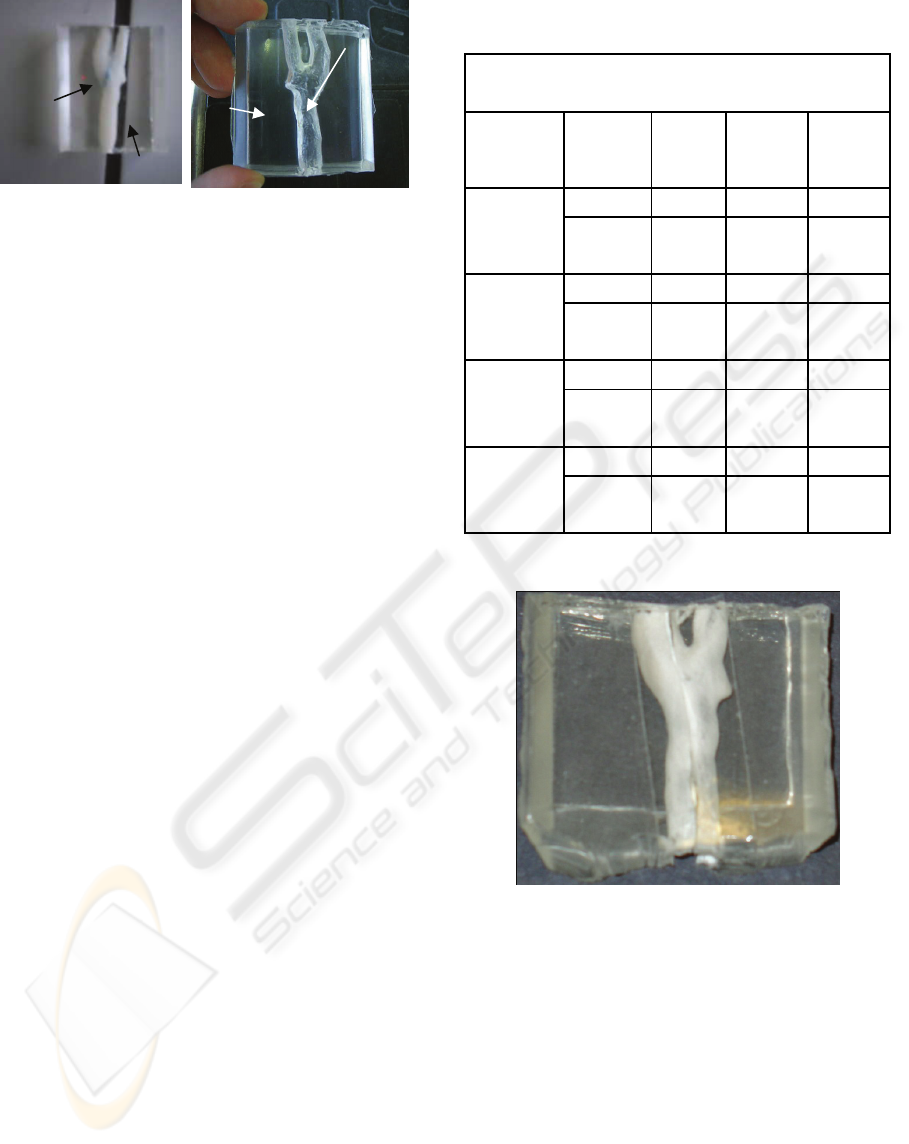

The embedded carotid model manufactured by

the FDM technique was pulled out of the PDMS and

as result it was possible to obtain an anatomically

transparent model of a human carotid artery (see

Figure 6). From Figure 6 it is possible to observe

that the PDMS carotid model seems to have enough

good transparency able to perform blood flow

visualization studies. However, should be pointed

out that walls of this PDMS carotid model have high

levels of roughness due to the rapid prototyping

technique (FDM) used to manufacture the ABS

carotid model. In a near future, we are planning to

polish the surface of the ABS carotid model to

decrease roughness of the model.

RAPID PROTOTYPING OF 3D ANATOMICAL MODELS TO HEMODYNAMIC STUDIES

249

Figure 6: a) ABS carotid model manufactured by the FDM

technique embedded in PDMS; b) PDMS carotid channel

by means of a FDM technique.

For the case of the carotid model manufactured

by the TDP technique it was not possible to pull out

from the PDMS due to the extremely fragile

characteristics of the composite powder. Hence, we

decided to examine the solubility of several solvents

in both PDMS and TDP carotid model in order to

determine the most suitable solvent able to dissolve

the embedded carotid model without significantly

modifying the physical properties of the PDMS. In

this study we used four kinds of solvents, i.e.,

acetone, hydrochloric acid (HCl), sodium hydroxide

(NaOH), petroleum ether (PET). Table 1

summarizes the most relevant results obtained by

using the selected solvents. Generally, we used 8 test

tubes : 2 with acetone, 2 with HCl, 2 with NaOH and

2 with PET. For each solvent we have immersed a

small piece of PDMS and the composite powder

used to fabricate the carotid model by means of the

TDP. First, both solutes were weighted before the

immersion into the solvent. After 24 hours, the

samples were first inserted into an ultrasound

machine for 15 minutes and then into an oven for 4

hours at a temperature of 60ºC. Finally, by means of

a vacuum pump the remaining water was completely

removed from the samples and ready to be weighted

once again. After 48 hours, this process was

repeated once again and as a result we could obtain

the data presented in Table 1.

The results from Table 1 show that the

hydrochloric acid (HCl) has the highest solubility

followed by the sodium hydroxide and the petroleum

ether. Hence, we decided to immerse the PDMS

containing the carotid model into hydrochloric acid

(HCl). Although most of the solute was dissolved we

have also observed that small amount of the

composite power was still attached on the wall of the

carotid channel and it was extremely difficult

remove them from the walls (Figure 7). These

preliminary observations show that this technique

still needs to be improved in a near future.

Table 1: Experimental results obtained for four different

kinds of solvents.

Experimental results

Solvent Solute

Initial

weight

(g)

Weight

after

24 hours

(g)

Weight

after

24 hours

(g)

Acetone

PDMS 0.2578 0.2488 0.2488

TDP

carotid

model

0.3361 0.3195 0.3128

Hydrochloric

acid (HCl)

PDMS 0.3476 0.3449 0.3448

TDP

carotid

model

0.2214 * *

Sodium

hydroxide

(NaOH)

PDMS 0.3643 0.3642 0.3640

TDP

carotid

model

0.2022 0.1274 0.1110

Petroleum

ether (PET)

PDMS 0.2155 0.2040 0.2430

TDP

carotid

model

0.2620 0.2043 0.2025

* All the solute was completely dissolved in the

given solvent.

Figure: 7: PDMS carotid channel by means of a TDP

technique.

3 CONCLUSIONS

The main objective consisted in applying two kinds

of rapid prototyping technologies to manufacture

several in vitro carotidal anatomical models in

PDMS polymer for posterior hemodynamic studies.

The conclusions drawn from this work can be

resumed as follows:

It was possible to conciliate several rapid

prototyping techniques to obtain PDMS

anatomical models;

PDMS

Blue

clay

PDMS

Carotid

channel

BIODEVICES 2010 - International Conference on Biomedical Electronics and Devices

250

Rapid prototyping technology has proven that is

a useful technology in the fast manufacture of

good quality anatomical models from medical

images, providing the ability of obtaining

complex human structures that would very

difficult to obtain by other means;

The model obtained by using a FDM technique

has shown the best surface transparency to

perform in vitro blood flow visualization

studies.

4 FUTURE DIRECTIONS

The PDMS transparent models obtained by the FDM

technique seems to be promising way to perform in

vitro blood flow studies through anatomically

realistic replica of a human carotid artery bifurcation

made by PDMS. Currently, an ongoing study to

perform flow measurements trough the PDMS

carotid models is currently under way. Figure 8

shows the experimental set-up that we planning to

use to perform those studies.

Figure 8: Experimental set-up to perform in vitro flow

visualizations through the fabricated PDMS carotid

channels.

ACKNOWLEDGEMENTS

The authors would like to thank Mr. Bruno

Magalhães and Dr. João Carlos Noronha, from the

Krug Noronha Clinic, for providing TC images and

also Dr. António Pontes and Mr. Miguel Queirós,

from Minho University, for supplying some ABS

carotid models tested in this work.

REFERENCES

Alves, Fernando; et al., 2001. Prototipagem Rápida.

Protoclick, Porto.

Collins, Tucker, Robbins, Stanley L., Cotran, Ramzi S.,

Kumar, Vinay, 2001. Fundamentos de Robbins -

Patologia Estrutural e Funcional, Guanabara Koogan.

Brasil, Sexta edição.

Foggiatto, J. A., 2006. O Uso da Prototipagem Rápida na

Área Médico-Odontológica. Tecnologia &

Humanismo, 60-68.

Goldsmith, H., Turitto, V., 1986. Rheological aspects of

thrombosis and haemostasis: basic principles and

applications. ICTH-Report-Subcommittee on Rheology

of the International Committee on Thrombosis and

Haemostasis. Thromb Haemost. 55(3), 415–435

Lima, R.. et al., 2007. In vitro confocal micro-PIV

measurements of blood flow in a square microchannel:

the effect of the haematocrit on instantaneous velocity

profiles. Journal of Biomechanics, 40, 2752-2757

Lima, R., et al., 2008. In vitro blood flow in a rectangular

PDMS microchannel: experimental observations using

a confocal micro-PIV system. Biomedical

Microdevices, 10(2),153-67

Queijo, Luís, Rocha, João, Barreira, Luísa, Pereira, Paulo

Miguel, Barbosa, Tiago, San Juan, Manuel, 2009. A

surgical training model manufacture using rapid

prototyping technology. Innovative developments in

design and manufacturing – Advanced Research in

Virtual and Rapid Prototyping, Taylor & Francis.

Rocha, J. & Alves, L., 2000. Utilização de moldações

cerâmicas compósitas no fabrico de ferramentas

metálicas. 2º Encontro nacional do colégio de

engenharia mecânica da ordem dos engenheiros.

Coimbra. Portugal.

Williams, P.L, Warwick, R., 1995. Gray’s Anatomy,

Churchill Livingstone. Edinburgh, 38

th

Edition.

RAPID PROTOTYPING OF 3D ANATOMICAL MODELS TO HEMODYNAMIC STUDIES

251