EVALUATION SYSTEM FOR MONITORING OF VITAL

PARAMETERS AND ACTIVE BODY CLIMATE CONTROL

A. Gharbi, C. Krähling, W. Stork and K. D. Mueller-Glaser

Karlsruhe Institute of technology (KIT), Institute for Information Processing Technology, Karlsruhe, Germany

Keywords: Vital parameters monitoring, Correlation and regression analysis, Energy expenditure, Regulation

algorithm, Active body climate control.

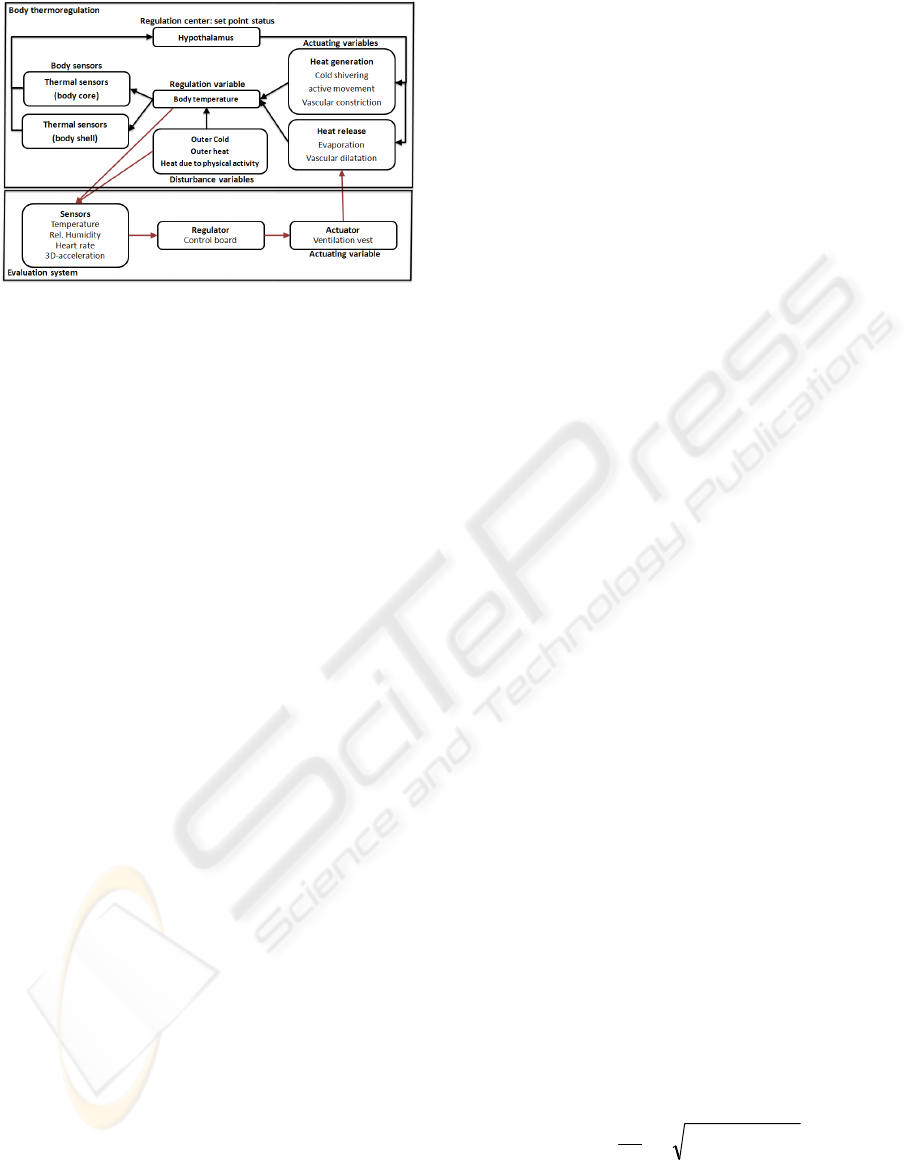

Abstract: This work presents a textile integrated evaluation system for active body climate control. The evaluation

system registers several vital parameters of the user (skin temperature, skin relative humidity, heart rate,

breathing rate and 3D acceleration data), its current subjective feedback and some surrounding parameters

(temperature and relative humidity) and thus automatically controls the air ventilation level inside a cooling

vest. For the climate control, a regulation algorithm influencing the body heat exchange processes and

leading to thermal comfort at different workloads and different surrounding conditions is heuristically

designed. In addition, a field study is conducted. This study involves 11 test persons and aims at validating

the sensor data of the evaluation system and determining the energy expenditure of the body from the sensor

data by analyzing the correlation between these data and the reference data of a spirometer. Besides, a

verification of the suitability of the evaluation system for daily use and a validation of the

implemented regulation algorithm is conducted.

1 INTRODUCTION

The active body climate control has several

interesting aspects and its benefits can be shown in

different use case scenarios. In fact, it can be

integrated into the protective clothing of rescue and

relief personnel (fire fighters and special police

units) who work under extreme thermal conditions

due to the thermal isolation of their clothing, which

is caused by its protective functionality (e.g. ballistic

protection). In this case, the active body climate

control system is primarily a cooling system that

prevents overheating of the body and protects the

wearing subject thereby increasing his physical

performance. Another very interesting application

field for such a technology is the medical field,

where it can actively support the physiological

thermoregulation mechanisms of elderly and weak-

hearted patients and thus avoid a collapse of their

cardiovascular system due to excessive heat of the

surroundings.

Besides, the active body climate control offers a

big potential for energy saving. In fact, a portable

cooling system would need an electrical power of

about 3 to 4 watts (primarily for the integrated

ventilator), which corresponds to about 1/1000 of

the energy consumed by a commercial room air

conditioner.

Apart from compensating high surrounding

temperatures, the active body climate control helps

the wearing subject to transport away the generated

body heat due to metabolic activity (especially

through evaporation and convection). This leads to

an increase of the performance even during high

physical activity and contributes to a better thermal

comfort.

2 METHODS

2.1 Evaluation System

In this section, the implemented evaluation System,

which is used in the field study conducted to validate

the reliability of the sensor data and the conceived

body climate regulation algorithm, is described.

The evaluation system comprises a modular

hardware set-up, which has a variety of sensors

integrated into a sensor shirt, a cooling vest for the

air ventilation, a control board for data processing

(sensor data as well as user feedback data),

regulation algorithm and wireless communication

94

Krähling C., D. Mueller-Glaser K., Stork W. and Gharbi A. (2010).

EVALUATION SYSTEM FOR MONITORING OF VITAL PARAMETERS AND ACTIVE BODY CLIMATE CONTROL.

In Proceedings of the Third International Conference on Bio-inspired Systems and Signal Processing, pages 94-102

DOI: 10.5220/0002748300940102

Copyright

c

SciTePress

a) b)

Figure 1: Evaluation system: a) Sensor shirt, b) Whole

system.

and a feedback interface including a scroll wheel

and a PDA.

2.1.1 Sensor Shirt

In order to get an idea about the actual body climate

and its energy expenditure due to physical activity,

several sensors for the measurement of the vital

parameters need to be used. Due to comfort and

reliability issues, the sensors have been integrated

into a shirt having elastic material permeable to the

moisture, which better fits the body form and lets the

generated evaporation heat of the body diffuse into

the ventilation air. In this way the sensors do not

need to be attached to the body surface and thus

makes the use of the system in the field study very

practical. The sensors integrated in the shirt are in

addition connected to the control board by means of

a detachable connector interface.

The sensor shirt includes the following vital

parameter sensors:

Temperature and Moisture Sensors:

The skin temperature at the thermal balance of the

body is influenced by many factors like the clothing

and the metabolism or activity level of the body.

Thus, its deviation from a set point temperature

Tsk

m0

can be used to recognize a ventilation need.

Due to the non uniform distribution of the skin

temperature (Olesen, 1973) (Crawshaw, 1975)

(Fiala, 1999), this latter is measured at four positions

on the body skin surface. Two digital temperature

sensors are integrated in the textile area at the

abdomen and the upper back. Additional two

combined sensors for measuring temperature and

relative humidity (temperature compensated) are

used in the area of the chest and the lower back. The

four temperature values are then weighted with the

corresponding skin area and thus the mean skin

temperature can be determined. The relative

humidity at the skin surface is in addition a good

index for determining the amount of energy losses in

form of evaporation. This represents the biggest part

of the whole energy given up to the surroundings

and especially at high surrounding temperature

and/or metabolic activity.

Heart Rate Sensor:

It comprises two textile electrodes integrated into the

shirt and connected to an analog frontend module,

which detects the QRS complexes out of the ECG

signal and generates digital square pulses at each

QRS event. This digital signal is connected to an

input capture module of the microcontroller on the

control board, where the heart rate can be calculated.

In order to improve the quality of the detected

ECG signal, the cross over resistance between the

skin surface and the electrodes has to be very low. In

the case of sport activity the fast formation of a

sweat film under the electrodes decreases the

crossover resistance. In the conducted measurements

a cream for ECG electrodes is applied in order to get

the best signal quality.

Respiration Sensor:

It comprises a piezoelectric crystal, which is

stretched by means of a band attached to the shirt at

the chest level. The output signal of the sensor is

proportional to tensile stress and therefore shows a

good correlation with the chest movements due to

the respiration.

Acceleration Sensor:

A 3D acceleration sensor is attached to the shirt in

the left shoulder. Out of the three acceleration values

in the three axes, the activity level can be

determined (Jatobá, 2007).

2.1.2 Cooling Vest

The cooling vest is worn over the sensor shirt and

integrates a space holder material, through which

fresh air can circulate. The inner textile separation

layer is, unlike the outer one, permeable to the

moisture. The cooling vest has an air inlet at the

most lower part on the back and an air outlet in the

front at the most lower part of the vest. A ventilator

is placed at the outlet and is responsible for the

ventilation of the body by aspiring the air, which

circulates from the inlet over the back, the shoulders,

the chest and the abdomen towards the outlet. At the

outlet the air blown out gets warmer and more

EVALUATION SYSTEM FOR MONITORING OF VITAL PARAMETERS AND ACTIVE BODY CLIMATE

CONTROL

95

humid due to the body heat, which is released

especially by evaporation and convection. In

addition the cooling vest integrates two combined

sensors for measuring temperature and relative

humidity at both the inlet and the outlet, which can

be used to monitor the surrounding conditions (from

the sensor at the inlet) and the thermal exchange

between the body surface under the vest and the

circulating air in the vest (from the sensor at the

outlet). It also has a rechargeable battery, which

allows up to more than 10 hours operating time of

the ventilator at full performance. The applied

voltage to the ventilator is controlled by a PWM

modulator on the control board and thus the

ventilation level in the vest can be changed

according to the current level of the regulation

algorithm.

2.1.3 Control Board

It is the main part of the system, where the signal

processing, the climate regulation algorithm and the

control of the ventilation take place. The main

microcontroller of the control board PIC24FJ256GB

also uses an integrated SDHC memory card in order

to save all sensor and regulation algorithm data,

which can be offline analyzed on a PC.

2.1.4 Feedback Interface

On the one hand, the user has the possibility to

change the ventilation level according to his

individual preferences through manipulating a scroll

wheel, which is integrated in a wrist-band. This

latter also integrates an RGB led, which is used to

show the status of the system. On the other hand, the

evaluation system has another interface channel

namely a PDA, which communicates with the

control board via Bluetooth and online visualizes all

vital and system parameters.

Figure 2: Evaluation system: sensor nodes and control

board (in the middle).

2.2 Climate Regulation Algorithm

In order to maximize the climate comfort for the

wearing subject of the evaluation system, a

regulation algorithm for active body climate control

needs to be designed. Outgoing from the measured

and surrounding parameters, the regulation

algorithm should control an appropriate actuating

variable responsible of the climate control. In the

designed system only the active cooling is

integrated. Nevertheless, an active heating

component is planned to be integrated in the next

generation of the system.

2.2.1 Actuating Variable

The actuating variable for the active climate control

is the ventilation level. This latter corresponds to the

rotation speed of the ventilator at the outlet. This

speed is controlled by the control board that varies

the operating voltage of the ventilator through a

PWM modulator. The voltage interval, in which the

ventilator is active, is linearly split in 10 discrete

levels. Since the ventilator needs a minimum voltage

in order to overcome its inertia, the voltage interval

taken into consideration varies from around 5.8V to

12V. In this way we get the following ventilation

levels:

• Level 0 = ventilator is inactive

• Level 1-9 = ventilator is active

• Level 10 = maximal ventilation

The calculated ventilation level (Vent

Level

) comprises

two components: the ventilation level calculated out

of the measured sensor data (Alg

Level

) and the user

level (User

Level

), which is set up by the user through

manipulating the scroll wheel at the wrist-band and

which gives him the possibility to fine tune the

ventilation level according to its individual comfort

feeling and even switch it off if desired. Thereby the

following formula and constraints are always valid.

Vent

Level

= Alg

Level

+ User

Level

(1)

with 0 ≤ Vent

Level

≤ 10

0 ≤ Alg

Level

≤ 10

− Alg

Level

≤ User

Level

≤ 10

2.2.2 Regulation Algorithm

The aim of the evaluation system is to actively

influence the physiological body thermoregulation

as shown in figure 3.

BIOSIGNALS 2010 - International Conference on Bio-inspired Systems and Signal Processing

96

Figure 3: Active influence of the evaluation system on the

body thermoregulation.

In fact, the actuator component of the implemented

evaluation system supports the heat exchange

mechanisms of the body by improving the

evaporation and the convection. As input for the

regulator, several vital and environmental

parameters are measured and post processed in order

to get information about the cooling needs of the

user.

In a first stage, the regulation algorithm

influencing the body heat exchange processes was

heuristically designed. The reason behind it was that

there have been neither enough sensor data nor

literature sources, which exactly describe the

influence of a similar concept for active climate

control on the thermal processes of the body. In

addition we had no reference sensor data (like

spirometer for detecting energy expenditure

(Hollmann, 2006)) before the field study, which

reflect the quality and reliability of the sensor data

and help to determine an analytical regulation

algorithm. During the design phase, a load test,

similar to the test in the planned field study, was

conducted. In that phase, the wearing subjects had

the possibility to manually set up the ventilation

level by the scroll wheel according to their

individual preferences. In this way, a sensor data set

correlating with subjective optimum could be

registered. Outgoing from the analyzed data of the

temperature, moisture, heart rate and acceleration

sensors the corresponding proportions for the

ventilation level (respectively Tsk

Level

, RH

Level

,

HR

Level

and ACC

Level

) were empirically defined. The

sum of these values builds up the ventilation level

out of the regulation algorithm (Alg

Level

).

Alg

Level

=

Tsk

Level

+ RH

Level

+ HR

Level

+

ACC

Level

(2)

In addition, the determined ventilation level of

each sensor has been limited to a predefined similar

range. This should minimize errors due to

malfunction of the sensors during the load test.

In the following section, the different terms of

formula (2) should be depicted.

The ventilation level outof the measured mean

skin temperature Tsk

m

is determined by formula (3)

and its deviation from the set point temperature

Tsk

m0

is proportional to the thermal heat losses at the

skin and thus the linear correlation with the

ventilation level.

Tsk

Level

= b

T

· (Tsk

m

− Tsk

m0

)

(3)

with − 1 ≤ Tsk

Level

≤ 3, b

T

= 2 and Tsk

m0

= 32 °C

Analog to the mean skin temperature, the mean

skin relative humidity RH

m

is calculated out of the

two moisture sensors and the deviation to the

relative humidity at the inlet of the cooling vest

RH

in

, corresponding to the relative humidity of the

surrounding air, is normalized and the specific

ventilation level can be determined according to the

formula 4.

RH

Level

= b

RH

· (RH

m

− RH

in

) / (100% −

RH

in

)

(4)

with 0 ≤ RH

Level

≤ 3 and b

RH

= 3

The heart rate correlates with the actual psycho

physical load on the body and has a linear

dependency with the workload (Hollmann, 2006).

HR

Level

= b

HR

· (HR

m20

− HR

0

) (5)

with 0 ≤ HR

Level

≤ 4, b

HR

= 1/29 and HR

0

= 75

Thereby HR

0

designates the heart rate at rest and

HR

m20

represents the post processed heart rate signal,

which results from filtering the raw signal by a non

linear median filter having the width of 11, and

averaging over a moving window of 20 values.

The ventilation level ACC

Level

gained out the data

of the acceleration sensor is calculated by the

following formula.

ACC

Level

= b

Eeac

· Max{Var_Eeac

m30

,

Var_Eeac

m150

}

(6)

with 0 ≤ ACC

Level

≤ 3, b

Eeac

= 50

, Var_Eeac = (Eeac − 1)²

&

∑

=

++=

s

f

i

ziyixi

s

aaa

f

1

222

1

Eeac

,

s

f = 20 Hz

EVALUATION SYSTEM FOR MONITORING OF VITAL PARAMETERS AND ACTIVE BODY CLIMATE

CONTROL

97

In this case the variance of the parameter Eeac,

which is an equivalent for the acceleration energy, is

calculated out of the energy of the acceleration

signal in the three axes of the ACC sensor (Jatobá,

2007). Eeac

m30

and Eeac

m150

represent the post

processed Eeac values, which are averaged over a

moving window of respectively the width of 30 and

150 values. The Eeac

m150

enables the integration of a

relaxation phase of 3 to 5 minutes depending on the

activity time and intensity, which precede a rest

phase. In fact after the activity phase, the Eeac

values decrease rapidly to almost 0 but the body still

dissipates a decreasingly important amount of

energy.

2.3 Field Study

The conducted field study aims at collecting detailed

information about the physiological

interdependencies and their correlation with the

workload. Thereby several physiological body

reactions, like the consumption of oxygen, the

breathing rate and the heart rate, etc., are measured

during the load test and saved for offline analysis

with reference to the predefined physical

performance.

2.3.1 Field Study Procedure

Each test person undertakes two load tests on a

treadmill ergometer. The first test is conducted with

only the sensor shirt and a spirometer, which aims at

validating the sensor data of the evaluation system

and determining the energy expenditure of the body

out of the sensor data through analyzing the

correlation between these data and the reference data

of the spirometer. In the second test, each test person

wears the whole evaluation system (including

cooling vest). Through this test, a verification of the

suitability of the evaluation system for daily use and

a validation of the implemented algorithm for active

body climate control can be done.

The test procedure has to be conceived in a way

that it makes it possible to compare the results of the

load tests related to different test persons. Therefore

a low workload level in the beginning of the test and

short workload phases, which not exclude the

reaching of a bio-physiological steady state status,

need to be considered. According to (Wahlund,

1948), an absolute steady state status for light up to

middle workload is reached after 6 minutes.

Investigations of the sports university in Köln /

Germany show that 90 up to 95% of the steady state

status can be registered already after 3 minutes of

the beginning of a constant workload (Knipping,

1953). For the conducted load test, a tradeoff is met

analog to (Hollmann, 1963). After a baseline phase

of 5 minutes, an intensity level of 6 km/h can be set

at the treadmill ergometer for the period of time of 5

minutes followed by an increase of the intensity

level with 1km/h. After the last test phase, which

corresponds to an intensity of 11 km/h, the test

person can rest for 5 minutes.

2.3.2 Test Person Feedback Form

During the study, subjective feedback from the test

persons is collected by means of a test person

feedback form. This latter includes general questions

before the beginning of the load test dealing with the

performance anamnesis (general fitness, physical

and mental state on the day of testing, feeling of the

room climate, etc.) and recording the individual

physiological data of each test person, such as age,

body height, weight, etc. and the climate in the room

of the study (temperature, moisture, etc.).

During the load test with cooling vest, the actual

wearing comfort of the vest and the local thermal

comfort at the chest, the abdomen and the back are

registered at every phase of the test.

After the end of the test, the test persons give

their feedback related to the absolved test and to the

test settings, for instance the evaluation system and

the efficiency of its active climate control.

2.3.3 Test persons

The test persons are 11 high school students (males).

Their age ranges between 21 and 30 years. Two test

persons were not able to run the second test with the

cooling vest. In addition one dataset from the test

with cooling vest was discarded due to the loss of

data after the reset of the control board. In fact a

short circuit at the wrist-band feedback interface

occurred due to an excessive generation of sweat

and a lack of a protective layer.

3 RESULTS

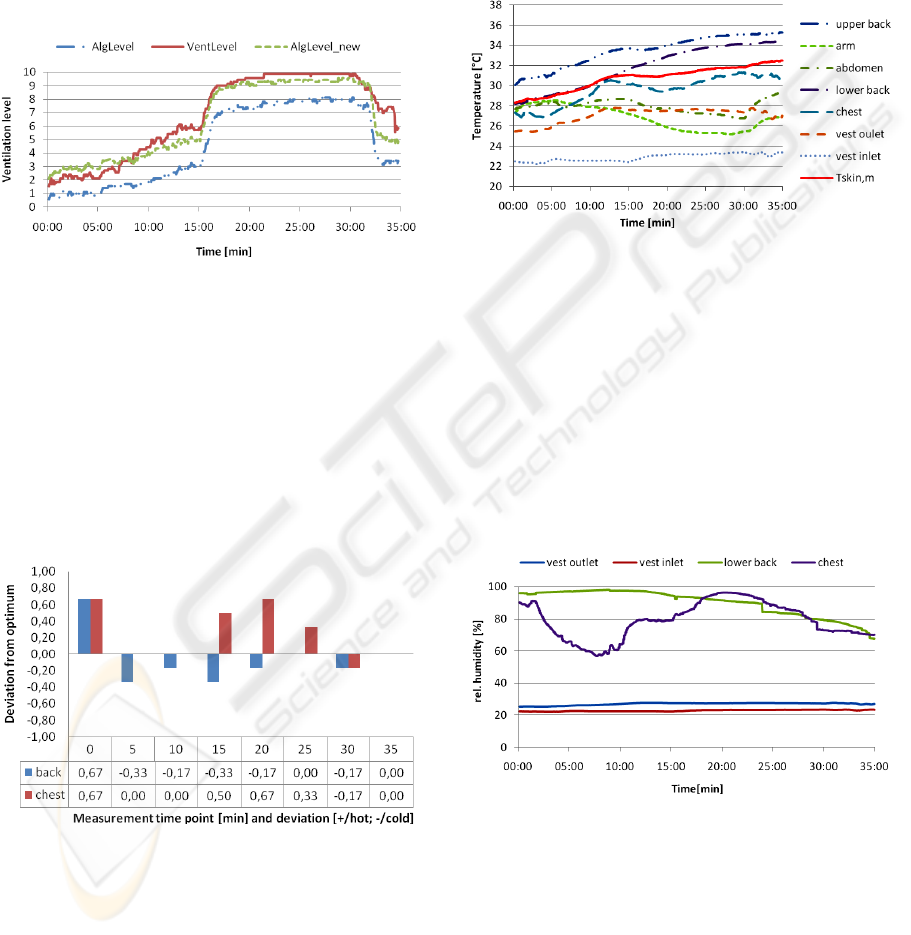

3.1 Cooling Algorithm

To evaluate the quality of the cooling algorithm, the

averaged level of the algorithm (Alg

Level

) over all

datasets is compared to the averaged user adjusted

ventilation level (Vent

Level

). Alg

Level

increases with

the physical load during the exercise and thus the

BIOSIGNALS 2010 - International Conference on Bio-inspired Systems and Signal Processing

98

need for cooling. The deviation between Alg

Level

and

the user adjusted value can in good approximation

be interpreted as an offset failure. Further

investigations show that the expected mean skin set

point-temperature Tsk

m0

varies with different

environmental conditions. To improve the algorithm,

Tsk

m0

is adapted to the mean value (30°C) from the

measurement data from the field study. The resulting

ventilation level Alg

Level_new

shows a good dynamic

and stationary accuracy.

Figure 4: Evaluation of the implemented cooling

algorithm; comparison of the different ventilation levels.

The evaluation of the feedback regarding the

thermal sensation during the load test with active

cooling gives information about the distribution of

the cooling capacity. Since the cold air is aspired at

the lower back of the cooling vest, the thermal

sensation tends to be too cold at that area. With

higher loads, the thermal sensation at the chest is

getting hotter because the air warms up and is almost

saturated and therefore insufficiently cools the chest.

Figure 5: Evaluation of the feedback of the test persons.

3.2 Validation of the Sensor Data

3.2.1 Temperature Sensors

To analyze the temperature sensor data, a dataset is

being examined. In figure 6 one could see that the

temperature sensors can be affected by the dynamic

of the body motion. In particular between 15

minutes, where the test person changes from

walking to running and the end of the exercise at 35

minutes, the measured temperatures at the abdomen

and the chest decrease unlike expected. It seems that

the textile integrated temperature sensors loose

direct contact to the skin, which causes a

temperature drop.

Figure 6: Temperature distribution for a test person.

3.2.2 Relative Humidity Sensors

Since the relative humidity is a function of the local

temperature, the reliability of the temperature

measurement has to be taken into consideration

during the analysis. Therefore the body motion is

also influencing the humidity measurement through

the temperature deviation. At the End of the exercise

the humidity values at the lower back and the chest

are falling. This is caused by an increase in the local

temperature and a high level of the ventilation.

Figure 7: Relative humidity distribution for a test person.

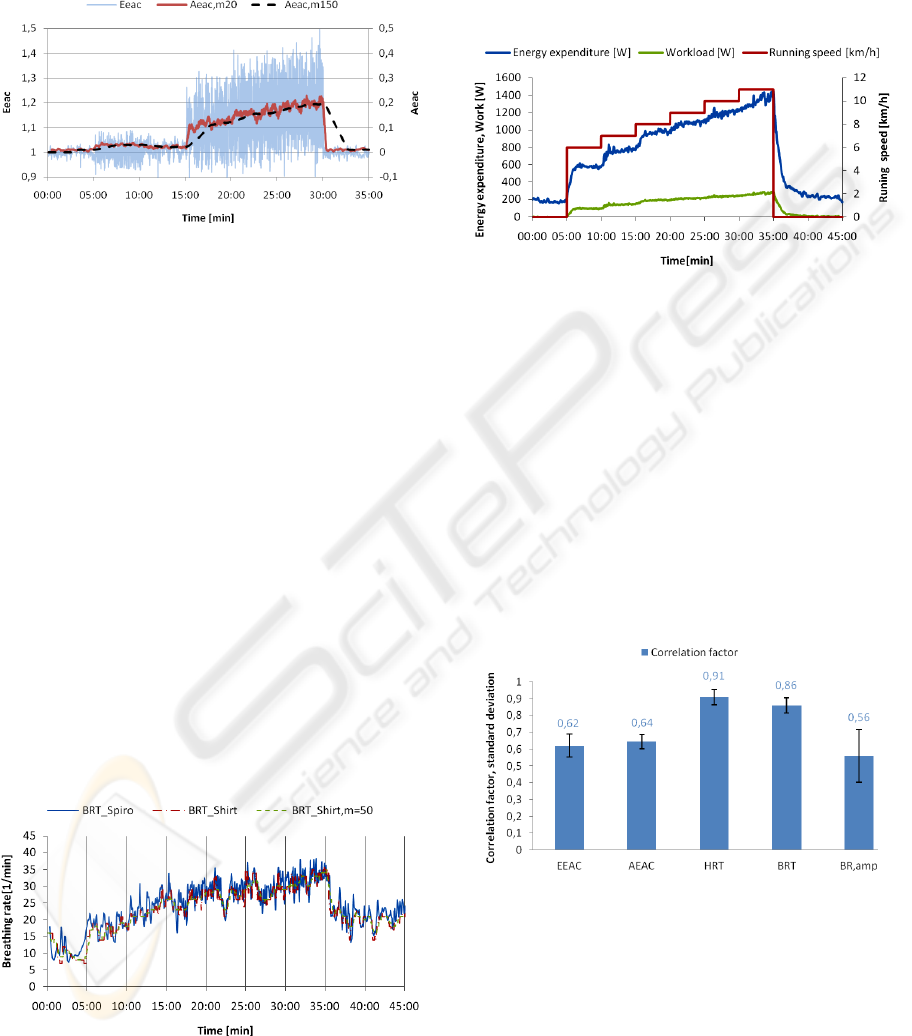

3.2.3 Acceleration Sensor

From the raw data of the acceleration sensor, the

Eeac value is calculated. As can be seen in figure 8,

the signal is not directly used as a control input due

to its strong noise and its offset. To compensate the

offset the corresponding Activity equivalent

acceleration (Aeac) signal is calculated.

EVALUATION SYSTEM FOR MONITORING OF VITAL PARAMETERS AND ACTIVE BODY CLIMATE

CONTROL

99

Aeac

= |Eeac

–

1|

(7)

The resulting Aeac signal is filtered to reduce the

noise.

Figure 8: Raw and post processed acceleration data for a

test person.

3.2.4 Breathing Sensor

To evaluate the results of the breathing sensor

(BRT_Shirt) the measured rate is compared to the

rate measured with the spirometer (BRT_Spiro),

which can be seen as reference value due to its high

accuracy. As figure 9 shows, both measurements

match very well. One also could observe that the

measured breathing rate has a slight latency only at

phases with high dynamic. This latency is caused by

the post processing of the raw signal with a median

filter. In the first design of the regulation algorithm

the breathing rate is not included in obtaining

AlgLevel. In fact the determination of the breathing

time volume, which results out of the product from

th breathing rate and the breathing depth and which

correlates directly with the energy expenditure

(Hollmann, 2006), cannot be determined out of the

measured signal. In addition the breathing sensor is

used only on the chest and therefore may not provide

reliable results in the case of abdominal breathing.

Figure 9: Comparison of the breathing rate data

(BRT_Shirt and BRT_Shirt,m50) with the data from the

spirometer (BRT_Spiro) for a test person.

3.2.5 Energy Expenditure

From the spirometer measurement of the O

2

consumption, an energy equivalent can be

calculated, knowing that the human body needs 1l

O

2

for the conversion of 20.9 kJ (Hollmann, 2006).

Figure 10: Workload and energy expenditure during the

load test of a test person.

3.2.6 Regression Analysis

To determine the relation between the measured

vital parameters and the energy expenditure out of

the spirometer data, a correlation analysis is done.

Out of it, the signals with the highest correlation are

used in a regression analysis in order to approximate

an analytical functional relation. For that purpose,

the linear function coefficients are estimated with

the robust least mean square method and a

confidence interval of 95%. Input data are the

energy expenditure and the corresponding sensor

values for all datasets.

Figure 11: Correlation analysis between the measured vital

parameters and the energy expenditure.

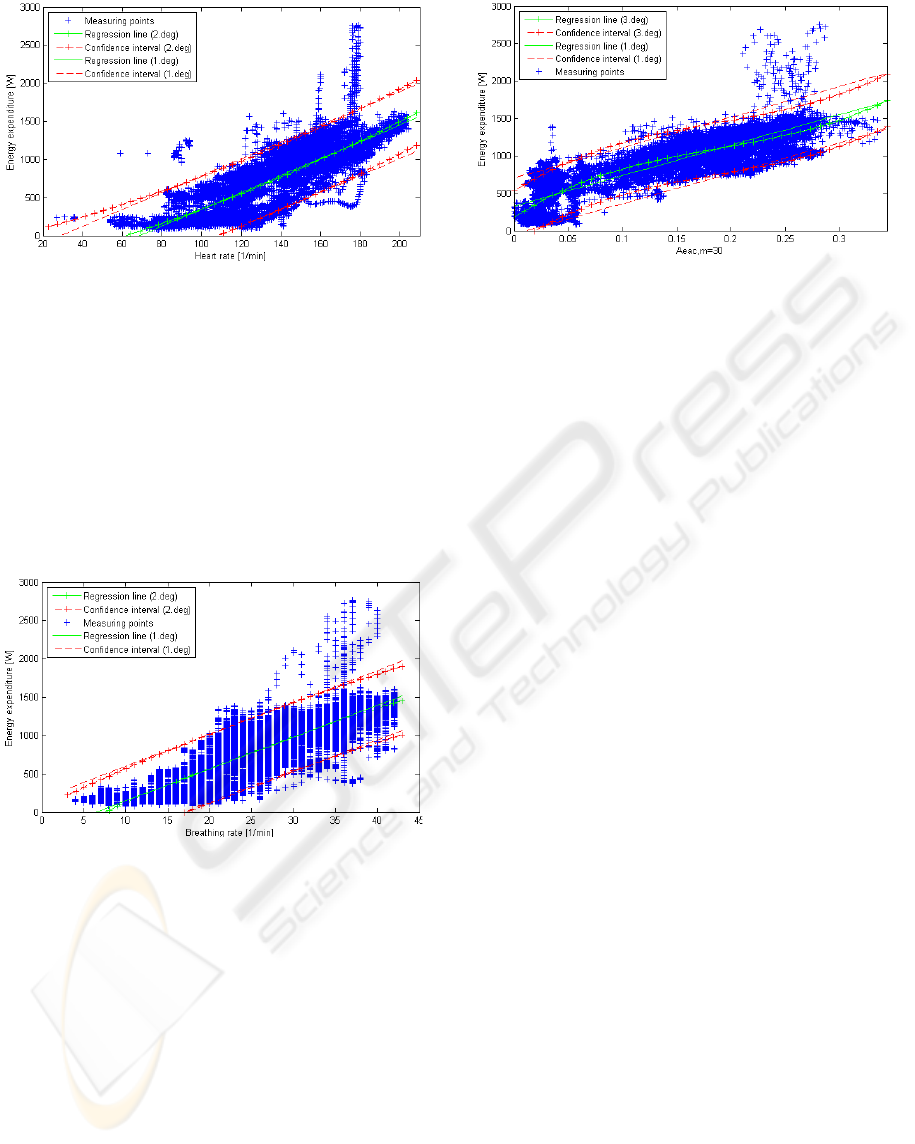

Heart Rate

The heart rate is directly influenced by physical

stress due to the higher blood flow. Therefore the

heart rate and the energy expenditure are strong

correlated. In (Hollmann, 2006), a linear relation of

first degree is postulated, which suits our results.

BIOSIGNALS 2010 - International Conference on Bio-inspired Systems and Signal Processing

100

Figure 12: Regression analysis between the heart rate and

the energy expenditure.

Breathing Rate

The correlation between the breathing rate and the

energy expenditure is accounted by the linear rise in

oxygen demand. To meet the demand, the minute

volume can be raised either through faster or deeper

breathing. Thus a variation of the breathing depth is

intensified used at breathing rates of 15-30 [1/min]

(Hollmann, 2006). There the variation from the

linear approximation is higher.

Figure 13: Regression analysis between the breathing rate

and the energy expenditure.

Acceleration

For the mapping of the acceleration data, a first

degree function is not appropriate. Especially at low

acceleration values, a higher gradient is needed to

meet the constraint that the energy expenditure at

rest (AEAC ~ 0) equals the measured average

measured value (~ 165 W). A function of third

degree is used. Functions of higher degree cannot

significantly improve the results. Unlike the heart

rate and breathing rate, the acceleration is influenced

by the nature of the load. Therefore, it has to be

checked if the estimated relation is valid for other

load patterns.

Figure 14: Regression analysis between the acceleration

data and the energy expenditure.

4 DISCUSSION

In this work a regulation algorithm for active body

climate control is heuristically conceived and tested

with an evaluation system by conducting a field

study. The validation of the current regulation

algorithm shows quite gut results. Nevertheless,

more data are needed in order to take into account

the individual characteristics of different test persons

and different environmental conditions. Out of the

second part of the field study, where a spirometer

has been used as a reference measurement for the

body energy expenditure, a correlation and

regression analysis between the sensor shirt data and

the spirometer data shows a good quality of the post

processed sensor data. In addition, analytical

equations are determined in order to approximate the

actual body energy expenditure out of the sensor

data. This finding can now be used for a more

accurate and systematic regulation algorithm, which

implements a data fusion of the measured vital

parameters and estimates the heat energy that needs

to be transported away from the body surface. In

combination with the estimated heat losses, derived

from temperature, humidity and clothing isolation, it

is possible to equalize the heat balance by

calculating the appropriate ventilation level.

Besides, the design of the evaluation system

needs to be optimized according to the feedback of

the test persons during the field study: better fitting

of the cooling vest, more ventilation resources with a

better distribution, etc. Last but not least, a design of

a wireless body area network (WBAN) with more

sophisticated textile integration techniques could

increase the comfort of the cooling system and its

ease of use.

EVALUATION SYSTEM FOR MONITORING OF VITAL PARAMETERS AND ACTIVE BODY CLIMATE

CONTROL

101

ACKNOWLEDGEMENTS

This work is done in the framework of the joint

research project "KlimaJack", which is financed

from the German ministry for education and

research. Besides the Institute for Information

Processing Technology (KIT), other German

industrial parties (Beurer, IMST, Lodenfrey, MVS

and Ruhlamat) are contributing to the conducted

research work.

The field study described in this work is

accomplished in cooperation with the institute of

sports and sport science of the KIT.

REFERENCES

Crawshaw LI, Nadel ER, Stolwijk JAJ, 1975. Effect of

local cooling on sweating rate and cold sensation,

Pflügers Archiv: European Journal of Physiology

354:19–27.

Fiala D., Lomas K.J., Stohrer M., 1999. A computer model

of human thermoregulation for a wide range of

environmental conditions: The passive system, Journal

of Applied Physiology, 87:1957–1972.

Hollmann W., 1963. Höchst- und Dauerleistungsfähigkeit

des Sportlers, Barth, München.

Hollmann W., Strüder H., Predel H.-G., Tagarakis G.,

2006. Spiroergometrie, Schattauer Verlag: Stuttgart.

Jatobá L., Großmann U., Ottenbacher J., Härtel S., von

Haaren B., Stork W., Müller-Glaser K.D., Bös K.,

2007. Obtaining Energy Expenditure and Physical

Activity from Acceleration Signals for Context-aware

Evaluation of Cardiovascular Parameters, Venezuela:

CLAIB.

Knipping H.W., Albrecht H., Valentin H., Venrath H.,

1953. Über die Atmung und das Herzminutenvolumen

bei Arbeit und Sport, sowie die Herzleistung,

Zeitschrift für die gesamte experimentelle Medizin,

122:356–368.

Olesen, B. W., P. O. Fanger, 1973. The skin distribution

for resting man in comfort, Pflügers Archiv: European

Journal of Physiology 27:A385–A393.

Wahlund H., 1948. Determination of the physical working

capacity, Acta Medica Scandinavica, 132:1–78.

BIOSIGNALS 2010 - International Conference on Bio-inspired Systems and Signal Processing

102