Prospects of “One-level” Architecture of Control Systems

on the basis of Ethernet Network - DCS "Tornado-N"

with “One-level” Architecture on the basis of Ethernet

Oleg V. Serdyukov

Institute of Automation and Electrometry

Siberian Brunch Russian Academy of Science

Akademika Koptiuga ave, 1a, Novosibirsk, Russia

Abstract. Modern DCS of technological processes have “multi-level”

architecture. The “low” level of DCS is represented by controllers. They

provide three main functions: data acquisition, processing and control of object.

Input-output devices are connected directly to controller for information

interchange with object and processing unit (CPU). The upper level connects

controllers together and provides their interaction with "the top" level of a

system. In systems with such architecture, controller which needs to obtain

variables connected to an other controller, it requires to have a special complex

service for interconnection with the other controller: for performance of base

“low” level function of input-output, upper level is involved. Many suppliers of

control systems do not have a solution for it, i.e. the data exchange function of

controller in vast majority of systems is absent. Level of today's network

technologies allows to construct homogeneous “one-level” control system on

the basis of a high-efficiency local network, for example Fast Ethernet. In such

systems network is used not only for interaction of workstations, servers, but

for direct interaction with input-output devices, connected directly to Fast

Ethernet network. Thus the concept of classical controllers disappears and

control algorithms may be carried out in any point of the system.

1 Introduction

The idea of common bus interface now exists for more than 30 years. This principle is

being used to construct separate subsystems (e.g. computers, controllers) and

integration of such subsystems. There exists a majority of bus interfaces for these

purposes.

Bus (e.g. PCI) merges all the primary devices in computers and servers, bus

interface in controllers merges all processor and I/O modules. Thus, different

subsystems use different inner bus interfaces. Modern distributed control systems

(DCS) of technological processes have “multi-level” architecture. The “low” level of

controllers providing information interchange and commands with object through the

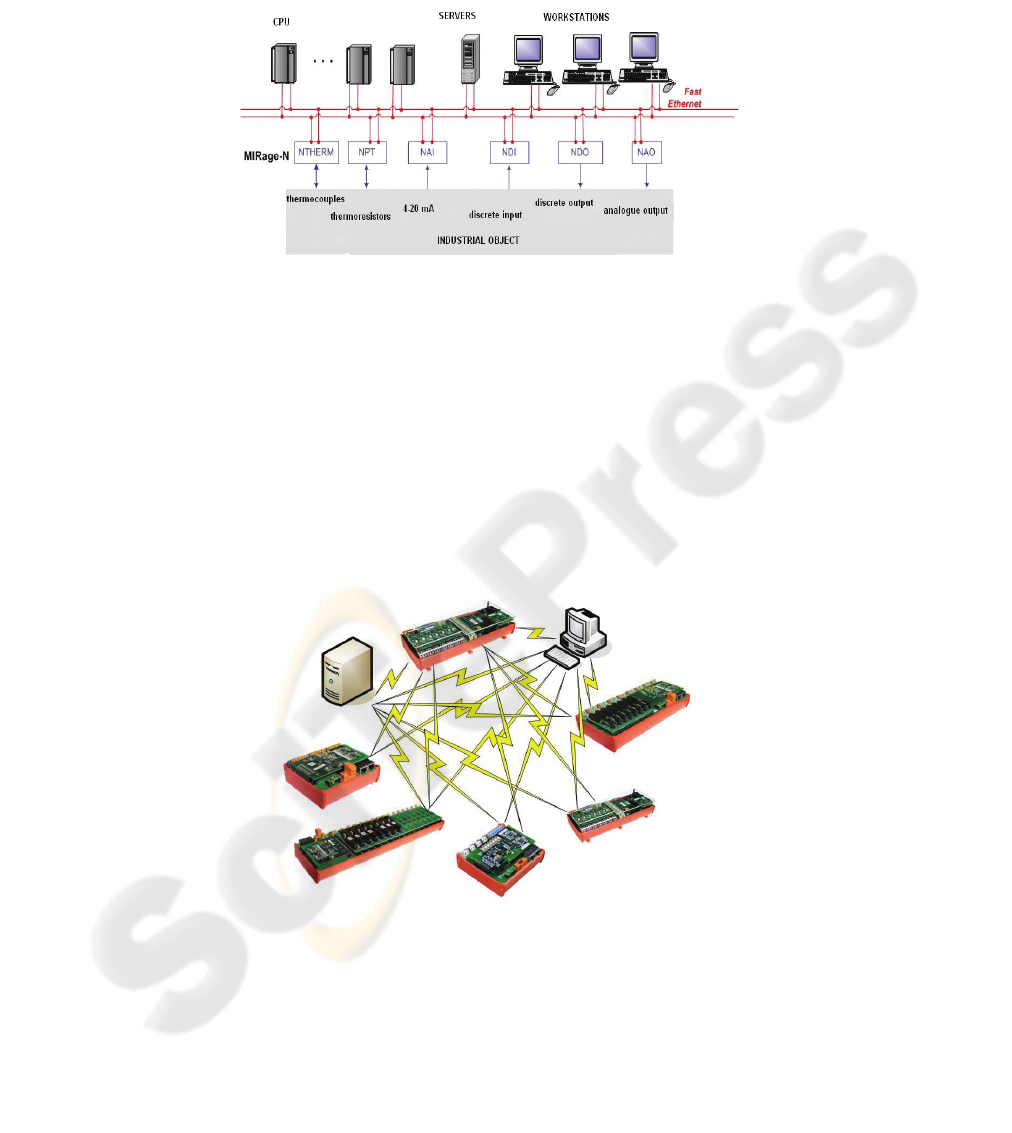

devices of input-output, connected directly to the controller (Figure 1).

The next upper level connects controllers together and provides their interaction

with "the top" level of a control system. In systems with such architecture, controller

Serdyukov O. (2009).

Prospects of “One-level” Architecture of Control Systems on the basis of Ethernet Network - DCS ”Tornado-N” with “One-level” Architecture on the basis

of Ethernet.

In Proceedings of the International Workshop on Networked embedded and control system technologies: European and Russian R&D cooperation,

pages 75-80

Copyright

c

SciTePress

which needs to obtain variables connected to an other controller requires to have the

special complex service for interconnection with the other controller, i.e. for

performance of base “low” level function of input-output, upper level will be

involved.

Fig. 1. Traditional heterogeneous architecture.

This problem not so is simple, as may seem and many suppliers of control systems

do not have a solution for it, i.e. the data exchange function of the controller’s in vast

majority of systems is absent. The level of today's network technologies allows to

construct homogeneous “one-level” control system on the basis of a high-efficiency

local bus interface (Fig. 2). In such systems the network is used not only for

interaction of workstations, servers, but for direct interaction with input-output

devices, connected directly to network. It is quite possible to suggest the possibility of

building the whole system based on one common bus interface (a homogeneous

system). Nowadays Ethernet technology gives the developers of Industrial Control

Systems all the sufficient facilities.

2 Fast Ethernet Bus

Analyzing the history of computer systems progress one can note such tendency that

with development of new technologies the system constructor gets an opportunity to

deal with more and more higher-level interfaces of informational exchange.

Nowadays Ethernet is a Bus Interface of high-level for building DCS. If I/O modules

are connected directly to the common-system bus interface, we have different

architecture of DCS with a list of new advantages; controllers are assumed as

something different from familiar sight.

Thus the concept of classical controllers disappears. Control algorithms can be

carried out in any point of the system, but for reasons of reliability it is more

preferable and better to allocate special computing devices of "an automation server".

76

It is possible to consider such architecture almost "ideal", possessing nearby

considerable advantages. It is possible to expect that the future development of

control systems will go this way.

Fig. 2. Homogeneous architecture.

The main goal of “Modular Systems Tornado” company’s (www.tornado.nsk.ru,

Nosovibirsk, Russia) developers was to create the automation facilities for maximum

broad spectrum of process tasking, to have an opportunity to use these facilities on

really large major industrial objects. MIRage-N I/O modules with duplex Ethernet bus

may be successfully implemented not only in systems of general-automation use but

the module line is sufficient for objects with enhanced reliability, fail-safety and high-

availability requirements. Distributed I/O modules of this product line can be

implemented both as parts of DCS and for local means of visualization and

maintenance.

Unlike the other products of distributed I/O, MIRage-N line provides the data of

industrial workflow directly to the common Fast Ethernet industrial bus aggregating

all elements of the automation system: CPU modules, servers and workstations.

Fig. 3. MIRage-N: equal right DCS member.

Architecture with absence of controllers (in usual assumption) gives a new degree

of freedom to developer. There is no need in affixment of I/O modules to the

77

specified definite CPU (like in all common systems). This factor substantially

simplifies the process of DCS cabinet’s construction: MIRage-N modules transfer

data to any active CPU of the system attaining the state of distribution of data

collecting and data processing.

2.1 MIRage-N Advantages

Thereby systems with distributed I/O based on MIRage-N modules have such

advantages:

It’s standard and innovative, specified by use of progressive Ethernet

technologies and organization of data transfer services by copper cables, optical

cables and radio communication;

Fail-safety provided by duplex Ethernet bus. Communication channel

restoration is an expensive long-run and complicated procedure. Duplication of

the industrial bus gives an opportunity to detect and restore the failure troubles.

Such system is operable and runs even with failure of one communication

subsystem. Also according to requirements it is possible to duplicate the

functional parts and assemblies of the system;

Reduction of charges: as an industrial bus interface, Fast Ethernet (10/100

Mbit/sec) gives a wide variety of computing sources from industrial CPU to

PC-compatible devices that dramatically reduces the upper-level cost of

industrial control system. Distributed structure of the system allows to make

changes “on-site” enhancing operational and metrological characteristics of the

system and substantially reducing expenditures for cable materials;

High Availability: the system architecture allows to make hot-swap of any

system element, replacement of defective modules without an impact on the

rest of the system with minimum time;

hot-swap of any system element, replacement of defective modules without an

impact on the rest of the system with minimum time;

Convenience in exploitation. The module construction allows the mounter to

make the replacement of defective elements without demounting of field cables.

Signals from sensors are plugged directly in MIRage-N modules in WAGO

spring clips that do not require periodic maintenance;

Scalability, extensibility. The functioning system may be populated with

additional modules. The scaling procedure does not require any modification of

functioning part of the system. Industrial interface bus of large and major

industrial objects may contain several segments that use different

communication mediums, e.g. copper wire, optical cable and radio connection;

Developed software for integration of MIRage-N modules with ISaGRAF

programming environment. Developed applications include .dll libraries

implementing Modbus interfaces; OPC DA server supplying compatibility with

SCADA systems for Windows OS supplying duplex Ethernet bus interface;

components for usage of modules in LabView environment;

Fixed time cycle of data acquisition for all devices equal to time of answering

interval for one device (1 msec). The possibility of same time device scan rids

from necessity of passive reply wait.

78

Open standards and technologies used in bus interface modules MIRage-N give

the possibility to develop and maintain any systems of automation with different

configuration of Ethernet, any processing devices, any programming environments

and SCADA-systems, servers, e.t.c. The configuring of MIRage-N modules and

visualization of data is maintained with “Configurator” software.

Unified module body of MIRage-N allows the installation of the module on DIN-

rail (35 mm), it provides electrical insulation, galvanic isolation, fail-safe connection

of the sensor cables. Field cable cross section square is 0,08 to 2,5 mm2.

2.2 Module Construction

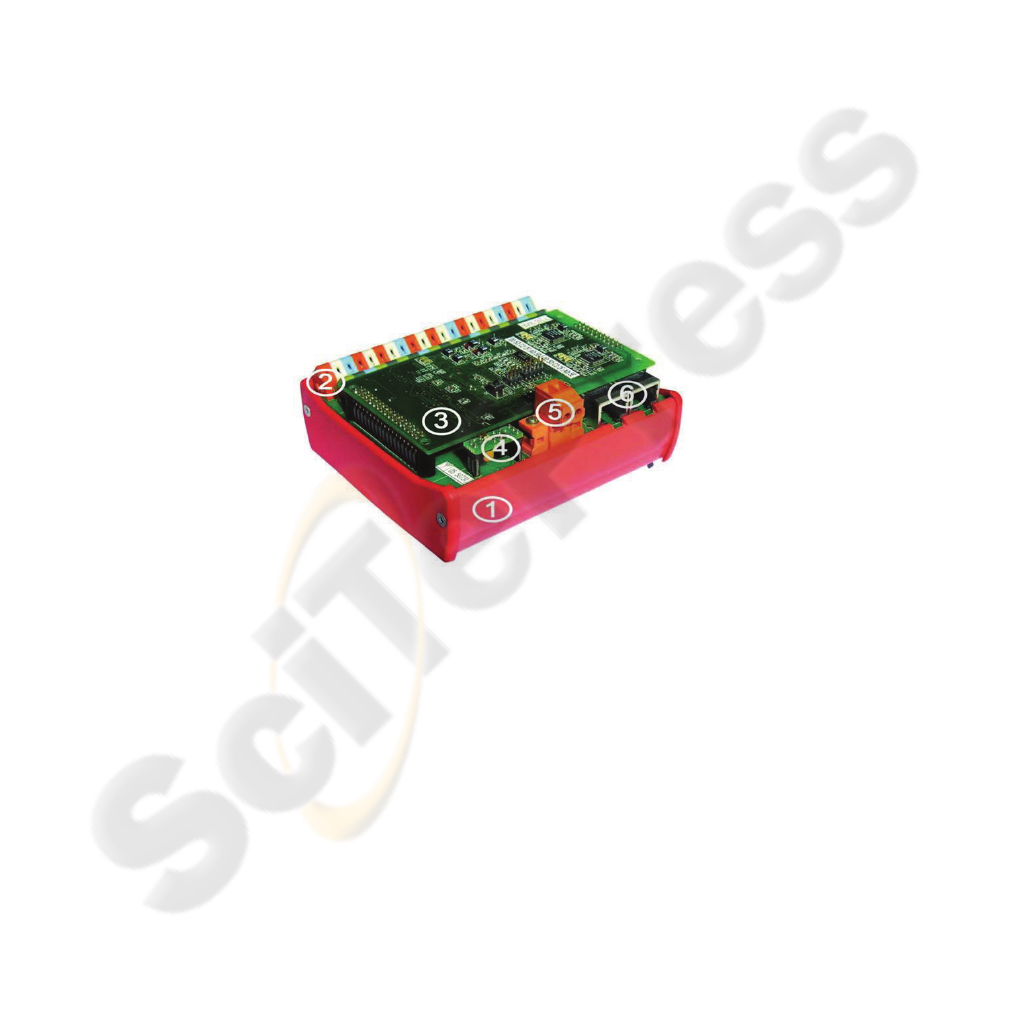

Every MIRage-N module is a two-part construction – motherboard and plug-in boards

- mezzanines. Mezzanines contain all the active elements. Figure 4 features MIRage-

N parts:

1. Motherboard with no active elements;

2. Field Terminal blocks;

3. Mezzanine connectors;

4. Protective device;

5. Power supply connection;

6. Fast Ethernet connection inputs.

Fig. 4. MIRage-N module construction (with cover removed).

2.3 MIRage-N Line

The MIRage-N line includes all types I/O modules to fulfil the requirements of

Industrial Control Systems:

MIRage-NAI – 16 differential channels or 32 single channels, analogue signal

input -20 + 20- mA, -10 +10 V, 16-bit delta-sigma ADC, 3-pole digital filter,

individual DC-DC converter to power supply of sensor.

MIRage-NDIO – 24 discrete channels. 12 input channels, 12 output channels.

24 V, 220 V.

MIRage-NDI – 24 input channels. 24 V or 220 V, 4mA input current.

79

MIRage-NDO – 24 output channels. 24 V or 220 V AC/DC: 3 A – AC, 0,5 A –

DC.

MIRage-NAO – 4 analogue output channels, 8 programmable discrete

channels.

NIRage-NTHERM – 8 analogue channels, thermocouples.

MIRage-NPT – 8 analogue channels, thermoresistors.

The company "Modular Systems Tornado" has finished system engineering of

DCS "Tornado-N" with “one-level” architecture on the basis of Ethernet. Today DCS

“Tornado-N” is used to build industrial control systems of large power units for

power stations.

3 Conclusions

In architecture where all system elements are connected directly to integrated Ethernet

bus interface the developer gets one of the most promising solutions applicable in

DCS development. DCS “Tornado-N” architecture with common Ethernet bus based

on MIRage-N distributed I/O line gives substantial economic benefits; in comparison

with other world well-known industrial automation companies DCS “Tornado-N”

decreases expenses up to 30 % in major automation systems of heat and power

engineering plants with hundreds and thousands of signals and furthermore gives

developer new levels of freedom in system construction allowing to use different

connection schemes and benefit from open standards and technologies underlying in

described approach philosophy.

Described above architecture approach is currently being implemented in

automation systems of power stations, thermal power plants and other major

industrial objects in Russia and CIS and demonstrated it’s positive qualities.

It is very likely that soon this approach will become the most widespread architecture

in modern DCS.

References

1. Serdyukov, O.V., Timoshin A.I., 2005. Paper templates. In Bus interface of industrial

controllers development. IAE, Novosibirsk.

2. Serdyukov, O.V., 2006. Tornado-TM complex, ISUP, 1(9). Moscow.

3. Serdyukov, O.V., 2008. DCS “Tornado”: life in major power engineering, REM magazine.

Moscow.

4. Lubashin, A.N., 2007. Industrial Ethernet: form office to industrial plant, The Industrial

Ethernet Book. Moscow.

5. Kolesnikov, S., 2005. Technologies and protocols of data transfer in industry: Fast

Ethernet . IT in industry.

6. Krugliak, K.V., 2003. Ethernet networks in industrial automation: faster, longer, reliable.

STA, 1/2003.

80