MODELLING AND TRIALS OF PYROELECTRIC SENSORS FOR

IMPROVING ITS APPLICATION FOR BIODEVICES

Andrés Díaz Lantada, Pilar Lafont Morgado, Héctor Hugo del Olmo, Héctor Lorenzo-Yustos

Javier Echavarri Otero, Juan Manuel Munoz-Guijosa, Julio Muñoz-García and José Luis Muñoz Sanz

Grupo de Investigación en Ingeniería de Máquinas – E.T.S.I. Industriales – Universidad Politécnica de Madrid

C/ José Gutiérrez Abascal, nº 2. 28006 – Madrid, Spain

Keywords: Pyroelectricity, Ferroelectric Polymers, Sensors Behaviour, Medical Devices.

Abstract: Active or “Intelligent” Materials are capable of responding in a controlled way to different external physical

or chemical stimuli by changing some of their properties. These materials can be used to design and develop

sensors, actuators and multifunctional systems with a large number of applications for developing medical

devices.

Pyroelectric materials, with thermoelectrical properties coupling, can be used as temperature sensors with

applications in the development of several biodevices, including the combination with other thermally

active materials, whose actuation can be improved by means of precise temperature registration.

This paper makes an introduction to pyroelectricity and its main applications in the development of

biodevices, focusing also in the pyroelectric properties of polyvinylidene fluoride or PVDF and presenting

some results related with sensors’ behaviour modelling and characterization.

1 INTRODUCTION TO

PYROELECTRICITY

Pyroelectricity is the ability of certain materials to

generate an electrical potential when they are heated

or cooled. As a result of this change in temperature,

positive and negative charges move to opposite ends

through migration (the material becomes polarized)

and, therefore, an electrical potential is established.

This kind of phenomenon appears in dielectric

materials with spontaneous polarizations due to

dipole orientation within their structure. These

effects have been known to mankind even since

Antiquity, especially regarding ceramic materials

and metallic oxides.

The name of pyroelectricity was given by

Brewster in 1824. But investigations on polymer

pyroelectricity are more recent, starting around 1955

with some initial results, which were not

commercially promising.

New attention was given to this property with

the discovery of pyroelectric effects in

polyvinylidene fluorides (PVDF and copolymers) by

Bergman in 1971, after the discovery of

piezoelectricity in these materials by Kawai in 1969.

During the last decades important progress has

been made in creating artificial pyroelectric

materials, usually in the form of a thin film, out of

gallium nitride (GaN), caesium nitrate (CsNO

3

),

polyvinylidene fluorides (PVDF and copolymers),

derivatives of phenylpyrazine cobalt phthalocyanine

and other materials.

The main applications developed so far of these

materials in biomedical devices are explained below,

before paying attention to pyroelectricity in

polymers, modelling, signal conditioning and trials.

2 PYROELECTRIC MATERIALS

AND POTENTIAL BIODEVICES

The main industrial applications are related with the

development of temperature sensors, presence

sensors, humidity and leakage sensors and for

measuring other processes which mean a

temperature change. It can also be applied in

biological or medical context as explained in the

following examples.

453

Díaz Lantada A., Lafont Morgado P., del Olmo H., Lorenzo-Yustos H., Echavarri Otero J., Munoz-Guijosa J., Muñoz-García J. and Muñoz Sanz J. (2009).

MODELLING AND TRIALS OF PYROELECTRIC SENSORS FOR IMPROVING ITS APPLICATION FOR BIODEVICES.

In Proceedings of the International Conference on Biomedical Electronics and Devices, pages 453-457

DOI: 10.5220/0001828304530457

Copyright

c

SciTePress

Infrared Thermography Cameras. Infrared

Thermography is a technique for carrying out

inspections and non-destructive tests which has

multiple applications in the development of

machines and products, equipment and facilities

maintenance, and troubleshooting.

Since all bodies emit (according to their

temperature) infrared radiation, which increases in

intensity as the temperature rises, variations in this

intensity can be detected by using infrared sensors.

Thermal cameras can detect radiation in the

infrared range of the electromagnetic spectrum

(usually between a 900 and 14000 nm wavelength,

instead of operating in the visible range of 450 to

750 nm) and can produce images of this radiation.

These cameras are fitted with a sensor matrix

(called microbolometer) that can be developed using

pyroelectric materials. Depending on the intensity of

the radiation more or less current is sent to the

camera’s control electronics, which with the aid of

specific software enables temperature maps to be

obtained.

Some of the fundamental advantages of the

technique are its speed and ease of use, easy to

interpret temperature map-based results and the fact

that it is a non-destructive technique that does not

damage the systems under study (Schindel, 2007,

Maldague, 2001).

Apart from these applications, its use as a

support tool for developing medical devices,

especially those based on the use of thermal

materials has also been proposed (Paumier, 2007).

Biometric Systems. Pyroelectric materials can also

be used as part of complex biometric systems for

real-time recognition of people inside a building or

room with security purposes, or in the medical field

for evaluating the progress of injuries that limit the

mobility of patients (Fang, 2007).

Aided Surgery. These materials have also been

proposed and tested for measuring blood

temperature during surgeries, such as coronary stent

placements, with the purpose of relating temperature

profile with the blood velocity field and using this

comparison as a method of controlling the surgical

procedure (Mochi, 2004).

Flow Sensors. Dymedix Co. has developed nasal

flow sensors using PVDF, that besides being

piezoelectric has also pyroelectric properties and can

be used as temperature sensor. This products allow

an active management of pathologies such as sleep

apnea or sudden death in children. Such devices are

placed adjacent to the nostrils and patient breath

induces charges to the sensor, with a typical and

recognisable pattern. When breathing ceases, the

pattern changes and the microcontroller detects such

problem and activates an alarm to alert both the

patient and his or her relatives.

X-Ray Intensity Sensors. Based on corporal

heating due to absorption of X-Ray (during

radiological explorations) pyroelectric sensors can

be used, so as to make an estimation of the dosage

received and in order to avoid risk situations. The

phenomenon has been proved “in vivo” during

mammography scans with positive results according

to precision and sensitivity (De Paula, 2005).

3 PVDF PYROELECTRIC

POLYMER SENSORS

Polyvinylidene fluoride or PVDF -(CH

2

-CF

2

)-

n

and

its co-polymers such as poly(vinilydenefluoride-

trifluoroethylene) or P(VDF-TrFE), are the polymers

of this kind with the largest number of industrial

applications. They posses partial crystalinity with an

inactive amorphous phase and an elastic modulus

close to between 1 and 10 GPa.

The ferroelectric structure makes this polymer both

piezoelectric and pyroelectric, which increases its

applications, not only as temperature and pressure

sensor, but also as actuator. Its use as actuators is

limited by the need to apply high electric fields

(around 20 V/μm for a 3% deformation), but their

use as pressure sensors is taking the place of

traditionally used piezoelectric ceramic materials.

Regarding pyroelectricity its important value of

pyroelectric coefficient, together with its greater

resistance and sensitivity is displacing the use of

pyroelectric ceramics.

Figure 1: Metallized PVDF sheets. Piezotech S.A..

To make the sensors, we took PVDF 40 μm

thick sheets from Piezotech S.A. with Au-Pt coated

electrodes. These sheets were cut, joined to the

connecting wires and suitably encapsulated into

flexible polyurethane layers to protect them.

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

454

The sensors obtained and the main properties of

the PVDF used, along with some alternatives of the

same materials’ family, are shown below.

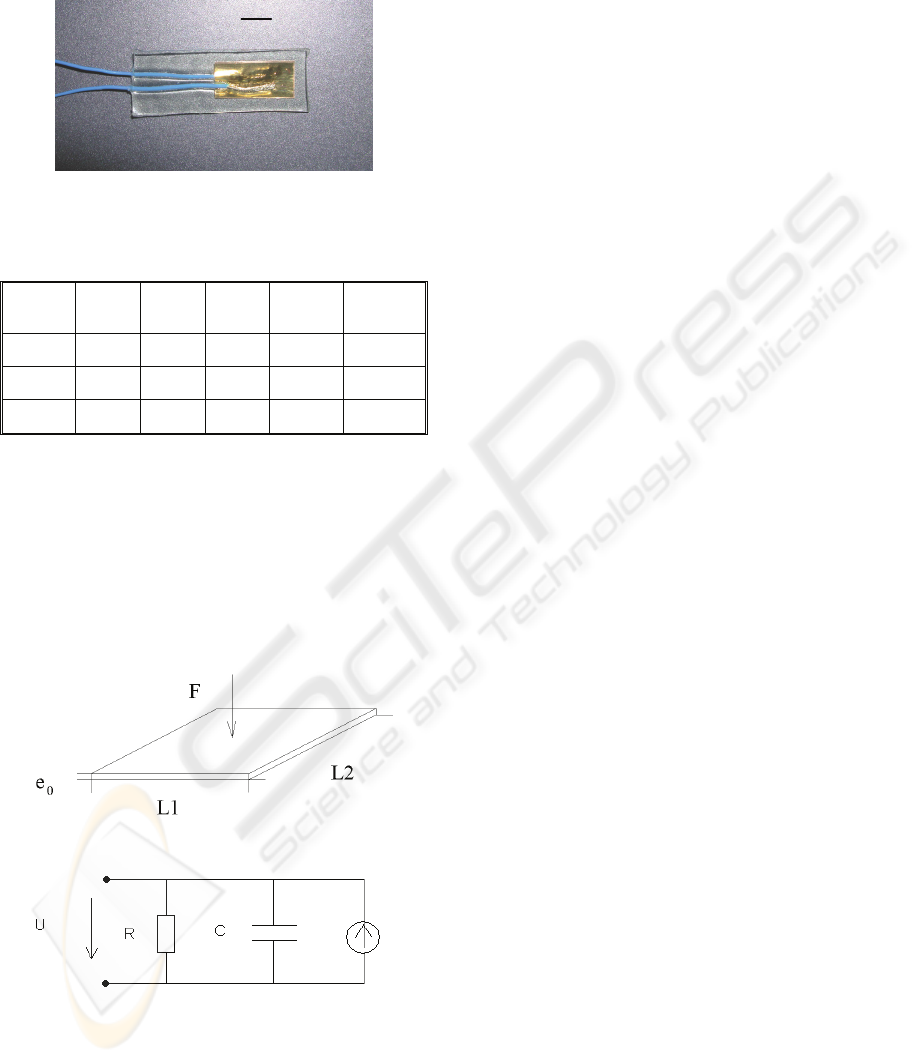

Figure 2: PVDF pyroelectric polymer sensor for fluidic

applications with polyurethane protecting layer.

Table 1: Pyroelectric polymers’ main properties.

d

33

pC/N

d

31

pC/N

d

32

pC/N

ε

F/m

p3

μC/m

2

·º

C

Uni-ax.

PVDF

-20 18 3 1,1·1

-10

25

Bi-ax.

PVDF

-24 7 7 1,1·1

-10

25

P(VDF

-TrFE)

-24 7 7 0,9·1

-10

25

The sensors’ behaviour due to combined

piezoelectric and pyroelectric properties can be

studied in first approximation using the following

equations.

Figure 3 a) shows the sensor layout. The charge

displacement (produced when a force of temperature

change is applied to the piezoelectric sensor) can be

represented using the equivalent electric circuit

depicted in Figure 3 b).

a)

b)

Figure 3: a) Piezoelectric Sensor. b) Electrical behaviour

circuit diagram of the piezoelectric sensor.

Force F on the sensor acts as a generator of

intensity powering a C capacity condenser. Ec (1).

C = C(F) = ε · (L

1

·L

2

) / e (1)

Where:

ε.- The dielectric constant of the sensor.

L

1

·L

2

.- The effective area of the sensor.

e.- The thickness of the sensor.

The thickness of the sensor, e, depends on the

initial thickness, e

0

, on the pressure applied, σ = F /

(L

1

·L

2

), and the Young modulus of the material, E,

using the following expression Eq. (2):

e = e

0

· (1 – σ / E) (2)

Current intensity, I, generated by applying force,

F, depends on the transversal piezoelectric

coefficient of sensor d33 according to Eq. (3).

Q = d33 · F Æ I = dQ / dt = d33 · dF / dt (3)

Current intensity, I, generated by applying

temperature chages, ΔT, depends on the pyroelectric

coefficient p

3

and can be expressed as:

Q = p

3

· (L

1

·L

2

) · ΔT Æ

I = dQ / dt = p

3

· (L

1

·L

2

) · dT / dt (4)

The total amount of current intensity can be

obtained as addition of Eq. (3) and (4).

When the sensor is connected to an external

circuit, as is shown in Figure 3 b), it discharges in

accordance with the equivalent R resistance of this

external circuit (i.e. oscilloscope, charge amplifier).

The intensity is given by Eq. (5).

I = d33 · dF / dt = U / R + C · dU / dt (5)

The effect of thermal expansion has to be taken

also into account when the deformations produced

due to important temperature changes become

relevant, as consequence of the thermo-electro-

mechanical coupling in these materials.

Similar equations have been used to model and

simulate the behaviour of this kind of materials as

part of more complex devices. They can be used not

only for design purposes, but also as a way of

estimating adverse effects due to piezo and pyro

effects coupling, in applications that are intended to

use these materials only as pressure sensors or only

as temperature sensors.

In case of willing to obtain positive voltages

when using this sensors for measuring compressive

stresses a polarity change in the connections is

enough, but then temperature increases lead to

decreasing voltages (as happens in our PVDF trials

explained below).

Following chapter shows some characterization

trials of the pyroelectric behaviour of PVDF sensors

and the influence of parameter changes for its

applicability.

5 mm

MODELLING AND TRIALS OF PYROELECTRIC SENSORS FOR IMPROVING ITS APPLICATION FOR

BIODEVICES

455

4 TRIALS WITH PVDF

PYROELECTRIC SENSORS

For proving the pyroelectric response of PVDF

sensors a charge amplifier for signal conditioning

was designed. It has typical impedance for such

conditioning circuits of 10 TΩ and includes a

voltage supply of 3.7 V.

The trial bench includes an additional

Measurement Computing LS1208 data acquisition

card, connected via USB to a personal computer.

The trials were carried out by introducing the

sensor from room temperature (26 ºC) into a water

vase with temperature control.

Several trials were made, changing water

temperature, before introducing the sensor into it, so

as to study the influence of ΔT on the speed

response of the sensor, which can be measured as a

function of the origin slope of the function V(t).

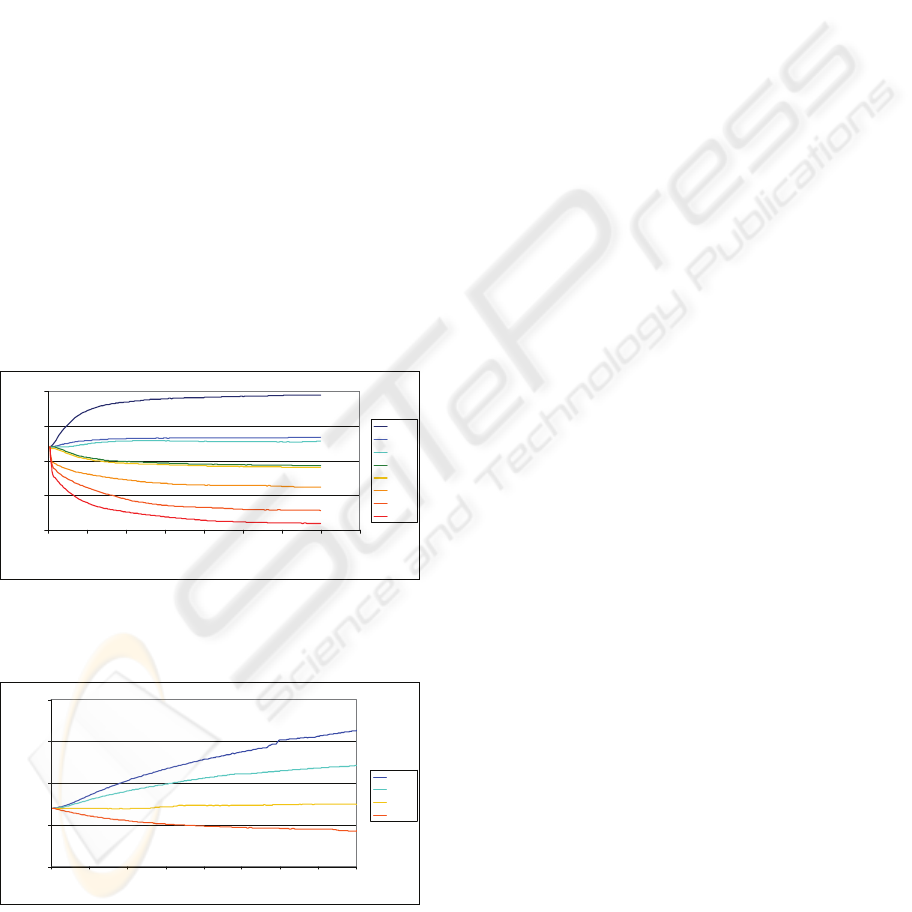

The main results are shown below. Figure 4

represents the trials made using a sensor with just

one polyurethane protecting layer. Figure 5 was

obtained by using a sensor with three protecting

layers and shows a slower response, due to the effect

of thermal isolation produced by the polyurethane.

0,0

0,5

1,0

1,5

2,0

0 5 10 15 20 25 30 35 40

Time (s)

Voltage (V)

25ºC

26ºC

26,5ºC

27,5ºC

29ºC

32,5ºC

34ºC

36ºC

Figure 4: Voltage changes due to introduction of the

PVDF sensors in water at different temperatures. (One

protecting layer).

0,500

1,000

1,500

2,000

2,500

0 5 10 15 20 25 30 35 40

Time (s)

Voltage (V)

23ºC

25ºC

26,3ºC

27,3ºC

Figure 5: Voltage changes due to introduction of the

PVDF sensors in water at different temperatures. (Three

protecting layers).

These trials help to show the sensitivity of PVDF

as temperature measuring material, due to its

pyroelectric properties. The fact that temperature

changes can be detected, even using a 4.5 mm thick

polyurethane protecting layer, is important for

increasing the number of applications of such

materials, which can be used not only as surface

sensors, but also for measuring surface temperature

changes from the inside of a biodevice.

5 CONCLUSIONS

The work presented shows an introduction to

pyroelectricity and its main applications in the

development of biodevices, focusing also in the

pyroelectric properties of polyvinylidene fluoride or

PVDF.

Additionally, some results related with sensors’

behaviour modelling, signal conditioning and

characterization trials are presented.

This type of materials can also be applied to

medical devices in combination with other active

materials, especially those based on thermal

activation.

Thus pyroelectric sensors could be used as a way

of monitoring temperature and optimising activation

of the active part of the device.

REFERENCES

S. Ashley, Artificial Muscles. Scientific American 2003.

Y. Bar-Cohen, Electroactive Polymer (EAP) Actuators as

Artificial Muscles. SPIE Press, Second Edition.

Washington 2004.

Y. Bar-Cohen, et al. Characterization of the

Electromechanical Properties of EAP Materials. Jet

Propulsion Laboratory (JPL)/Caltech. SPIE. Newport,

CA, 2001.

B. Schindel, Thermographie in der Theorie und Praxis.

www.irPOD.net. 2007.

Maldague, X., 2001. Nondestructive evaluation of

materials by infrared thermography. John Wiley &

Sons Publishers.

G. Paumier, et al., Thermoresponsive Polymer-Based

Microdevice for Nano-Liquid Chromatography.

Biodevices 2008 – International Conference on

Biomedical Electronics and Devices. IEEE

Engineering in Medicine and Biology Society.

INSTICC Press.

J.S. Fang, A Pyroelectric Infrared Biometric System for

Real-time Walker Recognition by use of a Maximum

Likelihood Principal Components Estimation

(MLPCE) method. Optics Express. 2007.

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

456

M. Mochi, et al., A Study for a Portable IR Sensor to

detect the Blood Temperature during Coronary

Bypass Implantation. CNR – University Pisa. 2004.

M. De Paula, et al., Microcontrolled pyro-electric

instrument for measuring X-ray intensity in

mammography. Medical and biological engineering

and computing. 2005.

M. Hafez, Course on Polymer Based Actuators as

Artificial Muscles. FSRM (Swiss Foundation for

Research in Microtechnology). Zurich 2006.

Measurement Specialties, Inc., Piezo Film Sensors

Technical Manual. Sensor Products Division 1999.

MODELLING AND TRIALS OF PYROELECTRIC SENSORS FOR IMPROVING ITS APPLICATION FOR

BIODEVICES

457