WELDING INSPECTION USING NOVEL SPECULARITY

FEATURES AND A ONE-CLASS SVM

Fabian Timm, Sascha Klement, Thomas Martinetz and Erhardt Barth

Institute for Neuro- and Bioinformatics, University of Luebeck, Ratzeburger Allee 160, Luebeck, Germany

Keywords:

Feature extraction, One-class classification, Welding seam inspection, Machine vision.

Abstract:

We present a framework for automatic inspection of welding seams based on specular reflections. Therefore,

we introduce a novel feature set – called specularity features (SPECs) – describing statistical properties of

specular reflections. For classification we use a one-class support-vector approach. The SPECs significantly

outperform statistical geometric features and raw pixel intensities, since they capture more complex charac-

teristics and depencies of shape and geometry. We obtain an error rate of 9%, which corresponds to the level

of human performance.

1 INTRODUCTION

In many industrial processes individual parts are

joined by using welding techniques. Soldering and

welding techniques are common in diverse areas such

as printed circuit board assembly or automotive line

spot welding. The quality of a single welding often

defines the grade of the whole product, for example

in critical areas such as automotive or aviation indus-

try, where failures of the welding process can cause

a malfunction of the whole product. Typically, welds

are made by a laser or a soldering iron. During the last

few years lasers and their usage in industrial appli-

cations have become affordable for many companies.

Although the initial cost of a laser-welding system is

still high, their wearout is low and so the service inter-

vals are very long. A laser weld is more precise than

a weld by a soldering iron, but the quality can also

vary due to shifts of the part towards the laser or due

to material impurities. Therefore, an inspection of the

welding is required in order to guarantee an accurate

quality.

There are several machine vision approaches to

automatically classify the quality of solder joints.

These approaches can be divided into two groups.

The first group deals with special camera and lighting

setups to gain the best image representation of the rel-

evant features (Ong et al., 2008; Kim and Cho, 1995;

Chiu and Perng, 2007). In the second group, the cam-

era and lighting setup is often predetermined and the

inspection is done by sophisticated pattern recogni-

tion methods. In the last few years several approaches

for automatic inspection of solder joints concerning

feature extraction, feature selection, and classifica-

tion were proposed (Ko and Cho, 2000; Poechmueller

et al., 1991; Ong et al., 2008; Driels and Lee, 1988;

Kim and Cho, 1995). Like in many other appli-

cations, neural networks and especially the support-

vector-machine have become state-of-the-art (Cortes

and Vapnik, 1995; Boser et al., 1992; Vapnik, 1995).

In this work we focus on the inspection of cath-

odes welded by an Nd:YAG (neodymium-doped yt-

trium aluminium garnet) laser during the production

of lamps. Due to its position in the whole production

process, the camera and lighting setup was fixed and

could not be changed. Since the welded cathode has

specific specular reflections, an appropriate feature

extraction is required in order to achieve an accurate

performance. Therefore, we introduce a novel feature

set called specularity features (SPECs). The SPECs

contain statistics of certain shape characteristics of

single components and can cover a wide range of

complex shape properties and their dependencies. For

the classification we use a one-class support-vector

approach (Sch

¨

olkopf et al., 2001; Tax and Duin, 2004;

Labusch et al., 2008) in order to describe features of

accurate weldings and to separate them from all other

possible inaccurate weldings. We also evaluate those

SPECs that are most relevant for the classification and

compare them to the physical shape of the cathode.

For comparison we use raw pixel intensities and

the statistical geometric feature (SGF) algorithm

which computes simple geometric characteristics of

binary components.

146

Timm F., Klement S., Barth E. and Martinetz T.

WELDING INSPECTION USING NOVEL SPECULARITY FEATURES AND A ONE-CLASS SVM.

DOI: 10.5220/0001776301450152

In Proceedings of the Fourth International Conference on Computer Vision Theory and Applications (VISIGRAPP 2009), page

ISBN: 978-989-8111-69-2

Copyright

c

2009 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

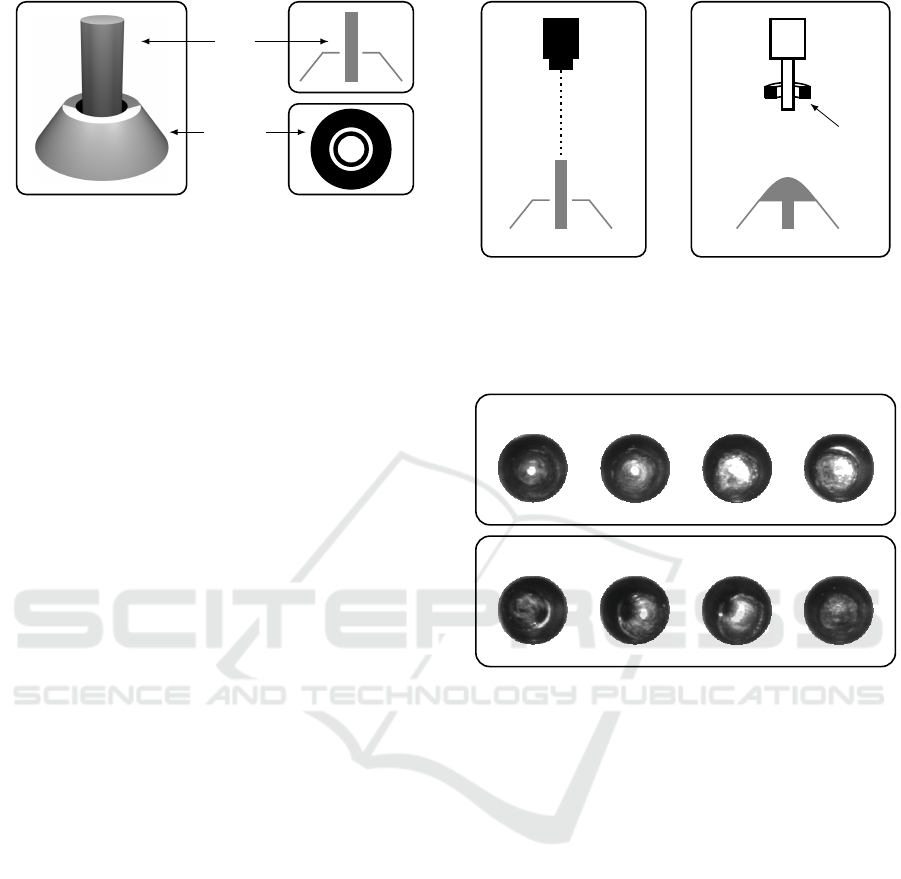

pin

socket

Figure 1: A 3d drawing of the cathode (left), a cross-section

(upper right) and the image of the camera are shown (lower

right).

In section 2 we give a brief overview of the camera

and lighting setting and the image acquisition. The

methods for feature extraction and classification are

described in section 3. Experiments and the results

are shown in section 4. We conclude with a discussion

in section 5.

2 IMAGE ACQUISITION

An unwelded cathode consists of a socket and a pole

that may be composed of different materials (see

Fig. 1). In a top view with directional parallel light

the unwelded cathode simplifies to only four compo-

nents – two black rings (the slant of the neck and the

space between pin and socket), one white ring (neck

of the socket) and one white circle (top of the pin, see

Fig. 1 bottom right). Hence, a component analysis of

the grey value image of the welded cathode can be

used to extract specific features.

A correct combination of camera, lens and illu-

mination is very important to achieve the best perfor-

mance in classification. However, sometimes the best

setup can not be chosen due to limited space or other

requirements. For this work, there was only one cam-

era setup practicable (see Fig. 2). We used a standard

analog monochrome VGA video camera, a single-

sided telecentric lens and a LED ring light with a Fres-

nel lens. We collected 934 images containing 657 im-

ages of non-defective cathodes and 277 images of de-

fective cathodes. All images were labelled by experts,

scaled to unit size (96 × 96 pixel) and smoothed by a

Gaussian filter (5×5, σ = 1). The unwelded cathodes

are first separated by a simple template matching such

that the dataset contains images of welded cathodes.

Moreover, the dataset only consists of images which

are difficult to classify manually.

Since defective cathodes are determined by the

mean time to failure, the true class labels are not

known in general. Therefore, the experts look for

aberrations that were selected by extensive bench-

laser

lens

ring light

camera

Figure 2: Drawing of the setup for laser welding (left) and

image acquisition (right). The laser and the camera are lo-

cated on top of the cathode. The distance between the LED

ring light and the cathode is chosen such that angle of inci-

dence is very small.

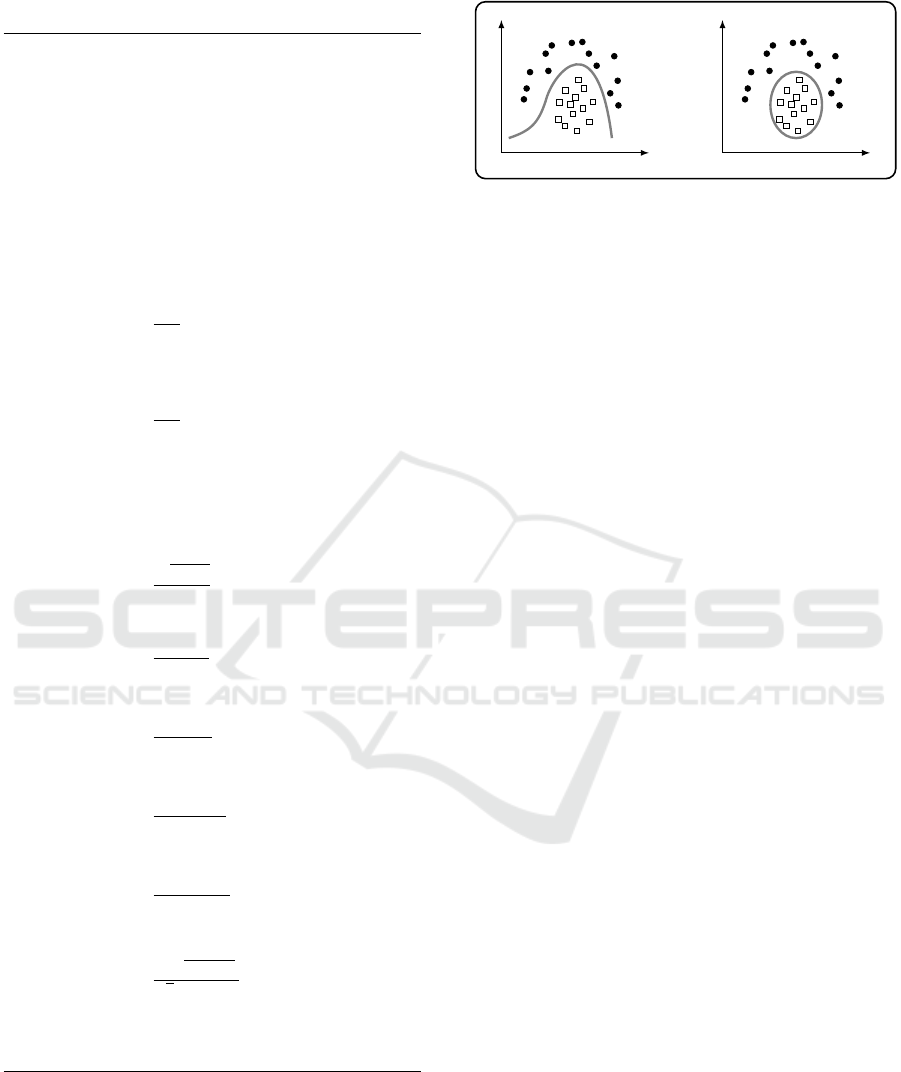

no defects

defects

Figure 3: Example images of cathodes (top row) and defec-

tive cathodes (bottom row).

mark tests. Example images of defective and non-

defective cathodes are shown in Fig. 3. The reflec-

tions of cathodes without a defect vary due to dif-

ferences in material and position of the pin. Also,

a slight deflection of the pin just before the welding

can affect the quality of the welding. Some of the de-

fective cathodes have holes caused by a slanted pin,

others do not have any reflections due to a very rough

surface. Therefore, the variety of defects can not be

described easily, and a feature extraction method that

covers several geometric properties and complex de-

pendencies between components is required.

3 METHODS

Recently, several approaches for the inspection of sol-

der joints were proposed (Ong et al., 2008; Chiu and

Perng, 2007; Ko and Cho, 2000; Kim and Cho, 1995;

Driels and Lee, 1988). Some of these methods com-

pute simple features in a manually tiled binary image,

others use the pixel intensities directly as input fea-

WELDING INSPECTION USING NOVEL SPECULARITY FEATURES AND A ONE-CLASS SVM

147

tures for a neural network or a support vector machine

(Cortes and Vapnik, 1995; Boser et al., 1992; Vap-

nik, 1995). Hence, the preprocessing often involves

a considerable downsampling of the images in order

to reduce the dimensionality. Usually, this downsam-

pling reduces the information of the images and yields

poor error rates. A better performance is achieved by

extracting specific features that describe the relevant

reflections of the weldings.

In this work, we present a novel approach for

the extraction of specularity features called SPECs.

These features describe several complex properties of

specular reflections and their dependencies. For com-

parison we also use the statistical geometric feature

(SGF) approach as well as raw pixel intensities.

In the following, we will describe the extraction of

SGFs and SPECs. Since the images were recorded by

an 8bit monochrome camera, we focus on grey value

images, but the approach can easily be extended to

colour images.

3.1 Statistical Geometric Features

Originally, SGFs were used for texture classifica-

tion with 16 features for each image (Chen et al.,

1995). Further extensions were developed for cell nu-

clei classification and contained 48 features (Walker

and Jackway, 1996). SGFs compute simple shape

properties of local components. Hence, they can be

used to extract specific features of welding images.

Moreover, SGFs are very intuitive and computed effi-

ciently.

For each l-bit grey value image I a stack of binary

images B = {I

τ

} with τ ∈{1, 2, 3,...,2

l

} is generated.

A single binary image I

τ

is computed such that

I

τ

(x,y) =

1 : I(x, y) ≥ τ

0 : I(x, y) < τ

.

(1)

This decomposition is lossless, since the input im-

age can always be recovered by summing up all bi-

nary images. Furthermore, each binary image I

τ

is de-

composed into a set of black and white components,

{C

0

(τ),C

1

(τ)}with C

0

(τ) = {C

(0,τ)

1

,...,C

(0,τ)

m

}, and

C

1

(τ) =

C

(1,τ)

1

,...,C

(1,τ)

n

, respectively (see Fig. 4).

The subscript 0 denotes a black component and the

subscript 1 a white component.

Each component C

( j,τ)

i

= {~x

k

} consists of pixel

positions ~x

k

∈ {1,2, ..., H}×{1, 2,...,W }, where H

and W are the height and the width of the input image.

For convenience we omit the indices of a component

if they are not necessary. We also use C

i

= C

( j,τ)

i

for

abbreviation.

The area of a component equals the number of its

··· ··· ···

I

τ

1

I

τ

k

input image I

C

(1,τ)

1

C

(0,τ)

1

C

(0,τ)

2

Figure 4: Decomposition scheme for a grey value input im-

age. First, the input image (first row) is decomposed into

several binary images I

τ

(second row). Afterwards each

binary image is further separated into its black and white

components (third row). The white component C

(1,τ)

1

is in-

verted, for convenience.

pixels,

AREA (C) = card (C) . (2)

The relative size of a single component C

i

with re-

spect to all components is defined as

PROP (C

i

) =

AREA (C

i

)

∑

k

AREA (C

k

)

. (3)

Based on the stack of binary images, the feature

extraction of the SGF algorithm can be divided into

two stages – a local stage and a global stage. In the lo-

cal stage several features for each component are cal-

culated (see Tab. 1). A single binary image is then de-

scribed by a set of averaged shape and position prop-

erties of all black and white components.

In the second stage the local features are com-

bined to global features using first order statistics (see

Tab. 2). In total, the SGF algorithm determines 48

features for a single input image.

3.2 Specularity Features (SPEC)

Since the statistical geometric features were mainly

developed for classification of textures, i.e. repeti-

tive patterns, they are not suitable for the inspection of

welding seams, which usually do not have a repetitive

structure. Instead, properties that describe the char-

acteristic shapes of specular reflections are required.

For example, some defective cathodes have long nar-

row reflections at the neck of the socket which can

VISAPP 2009 - International Conference on Computer Vision Theory and Applications

148

Table 1: Local features for a single binary image I

τ

of size H ×W (Walker and Jackway, 1996).

description formula

number of black/white components NOC(τ) = |C(τ)|

averaged irregularity IRGL (τ) =

∑

k

IRGL(C

k

) AREA(C

k

)

∑

k

AREA(C

k

)

averaged clump displacement DISP(τ) =

1

NOC(τ)

∑

k

DISP(C

k

)

averaged clump inertia INERTIA(τ) =

1

NOC(τ)

∑

k

DISP(C

k

)AREA(C

k

)

total clump area TAREA(τ) =

1

H W

∑

k

AREA(C

k

)

averaged clump area CAREA

i

(τ) =

1

NOC(τ)

∑

k

AREA(C

k

)

where

IRGL (C) =

1 +

√

π max

~x∈C

k~x −~µ(C)k

p

AREA(C)

−1 is the irregularity of the component C,

DISP(C) =

√

π

k

~µ(C) −~µ

I

k

√

H W

is the relative displacement of the component C,

~µ(C) is the centre of gravity of the component C and~µ

I

is the centre of the image.

be covered by features such as the formfactor and the

extent.

We make use of the general decomposition

scheme of binary images and evaluate appropriate

features covering the properties of specular reflec-

tions. We compute several general properties of each

component (see Tab. 3). Using a 4-neighbourhood

two successive boundary points are denoted by~x

m

and

~x

m+1

, F(α) is the maximum distance between two

boundary points when rotating the coordinate axis by

α ∈ A = {0

◦

,5

◦

,..., 175

◦

}, w

BR

and h

BR

are the width

and height of the bounding rectangle and a, b are the

major and minor axis of the ellipse that has the same

second moments as the region. For a detailed dis-

cussion on geometric shapes see chapter 9 of (Russ,

2007).

Table 2: Global features. f is one of the local features de-

scribed before.

maximum = max

τ

f (τ)

mean =

1

|τ|

∑

τ

f (τ)

sample mean =

1

∑

τ

f (τ)

∑

τ

τ f (τ)

sample std. =

v

u

u

u

u

t

∑

τ

(τ −sample mean)

2

f (τ)

∑

τ

f (τ)

The local features are computed for each compo-

nent and need to be combined to form a single feature.

Hence, we scale each feature in two different ways.

First, we calculate the mean weighted by the relative

size of the components, and second, we scale the sum

by the total number of components. For example, for

the averaged perimeter of the binary image I

τ

these

two scalings are:

PERIM(τ) =

∑

k

PERIM(C

k

) PROP(C

k

) , (4)

PERIM(τ) =

1

NOC(τ)

∑

k

PERIM(C

k

) , (5)

where PROP(C

k

) is defined in Eq. 3. Using these

scalings two aspects can be covered simultaneously.

On the one hand, if small reflections are important,

they are considered by scaling with the number of

components. On the other hand, if large reflections

are relevant, they become important when scaling by

the relative size.

We combine the local features by computing

minimum, variance, median, and entropy besides

the statistics of Tab. 2. Whereas the sample mean and

sample std. range over the threshold τ, the new fea-

tures are statistics over local shape features. Hence,

we can, for example, evaluate the variance of the

number of white components or the entropy of the

formfactor of white components. Moreover, extreme

shape properties of components become less impor-

tant when using the median.

In total, for a single image, we determine 768 fea-

tures consisting of:

WELDING INSPECTION USING NOVEL SPECULARITY FEATURES AND A ONE-CLASS SVM

149

Table 3: Features for a component C.

perimeter:

PERIM(C) =

N−1

∑

m=1

k~x

m

−~x

m+1

k

2

maximum Feret diameter:

MAXFD(C) = max

α∈A

F(α)

minimum Feret diameter:

MINFD(C) = min

α∈A

F(α)

mean Feret diameter:

MEANF(C) =

1

|A|

∑

α∈A

F(α)

variance Feret diameter:

VARFD(C) =

1

|A|

∑

α∈A

F(α) −MEANF(C)

2

area of bounding rectangle:

AREAB(C) = w

BR

h

BR

eccentricity:

ECCEN(C) =

√

a

2

+b

2

a

aspect ratio:

ASPRA(C) =

MAXFD(τ)

MINFD(τ)

extent:

EXTEN(C) =

AREA(C)

AREAB(C)

formfactor:

FORMF(C) =

4 π AREA(C)

PERIM(C)

2

roundness:

ROUND(C) =

4 AREA(C)

π MAXFD(C)

2

compactness:

COMPT(C) =

2

√

AREA(C)

√

π MAXFD(C)

regularity of aspect ratio:

REGAR(C) =

1+ VARFD(C) +MAXFD(C)−MINFD(C)

−1

• 48 local features for a single component (24 for a

black component and 24 for a white component),

• 2 scaling methods (by the proportional size and by

the total number of components), and

• 8 global statistics.

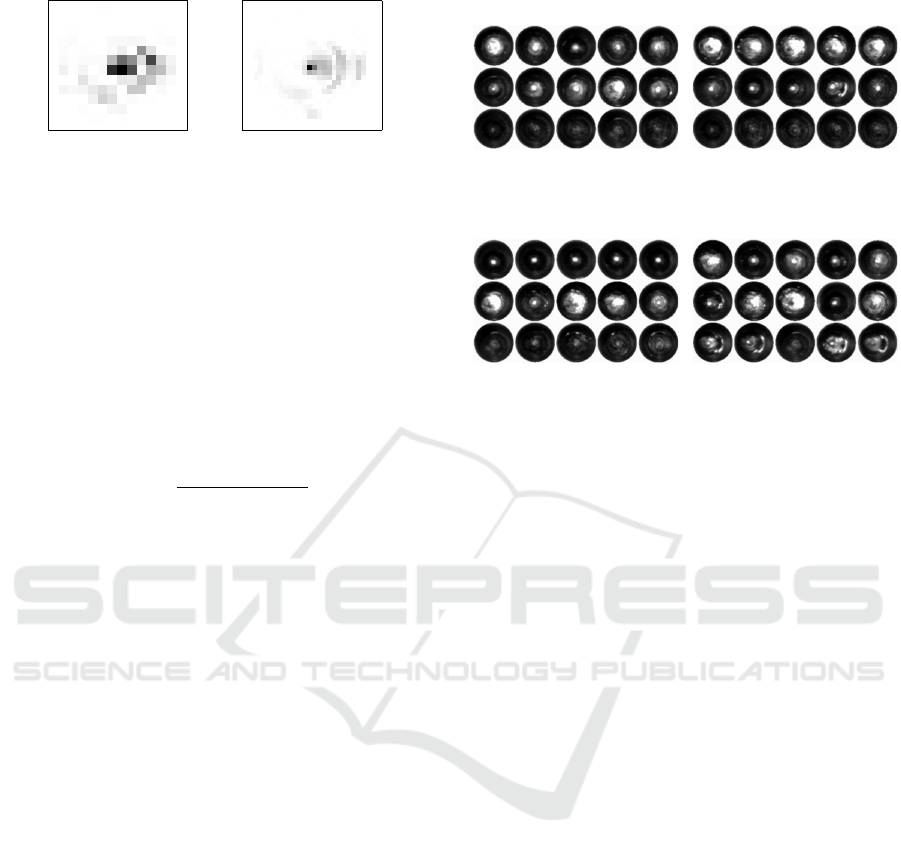

Figure 5: Comparison of a two-class SVM (left) and a

one-class SVM (right). The positive class is depicted by

white squares, the negative class (outlier) is shown by black

circles and the class boundary (separating hyperplane) is

shown in gray.

3.3 Classification

The support vector machine (SVM) has become a

very useful approach for classification and yields best

performances on several benchmark datasets (Cortes

and Vapnik, 1995; Boser et al., 1992; Vapnik, 1995).

Standard two-class SVMs require samples that de-

scribe both classes in a proper way. In our case,

however, there are only a few defective cathodes that

are characterised well. We therefore apply a one-

class support-vector machine. Furthermore, we make

use of a simple incremental training algorithm with

several improvements for fast parameter validation

(Labusch et al., 2008; Timm et al., 2008; Tax and

Duin, 2004; Sch

¨

olkopf et al., 2001). In contrast to

standard two-class SVMs, which separate the input

space into two half-spaces, one-class SVMs learn a

subspace such as to enclose the samples of only the

target class (see Fig. 5). This increases the robustness

against unknown classes of outliers and also extends

the time intervals for retraining when new samples are

available.

4 EXPERIMENTS AND RESULTS

In the following, different sets of features are com-

pared and analysed with respect to their separation

capabilities. These feature sets are:

• raw pixel intensities of scaled images (12 × 12

pxl → 144 features),

• raw pixel intensities of scaled images (24 × 24

pxl → 576 features),

• SGFs (48 features), and

• preselected SPECs (48 features).

Since the performance of the SGFs can vary depend-

ing on the grey level depth of the images we used

different depths ranging from 2bit to 8bit (Walker

VISAPP 2009 - International Conference on Computer Vision Theory and Applications

150

(a) 12×12 (b) 24×24

Figure 6: Relevant pixel positions in the image. Dark val-

ues indicate high relevance. Pixels in the image centre have

large values and are therefore relevant. This confirms the

description of non-defective weldings which have a white

reflection at this position.

and Jackway, 1996) and two different sizes (12×12,

24×24). The raw pixel intensities are only used as a

baseline. We selected the 48 most important features

from the SPECs to evaluate the performance with the

same number of features as the SGFs. The preselec-

tion of these 48 features was done by computing the

discriminant value d of each feature i:

d(i) = 2

(µ

+

(i) −µ

−

(i))

2

σ

2

+

(i) + σ

2

−

(i)

, (6)

where µ

+

(i), µ

−

(i) are the means of the positive and

negative class concerning feature i, and σ

2

+

(i), σ

2

−

(i)

are the class specific variances (Fukunaga, 1972). The

48 features with the highest discriminant values are

then chosen as input features for the one-class SVM.

This very simple ranking method is not optimal in the

sense that it identifies the best subset of features, but

it is computationally efficient and yields good results.

For the SVM we chose a Gaussian kernel and

evaluated the best parameters by 10-fold cross vali-

dation (Stone, 1974). To avoid numerical problems

we scaled the input features to [−1, +1]. Each con-

stant feature, e.g. the minimum over certain local fea-

tures, was removed before training to speed up the

algorithm and to save memory. For a comparison of

the different feature extraction methods we applied a

Wilcoxon signed rank test to the test errors.

Since no benchmark datasets of solder joint im-

ages are available, we only applied the feature extrac-

tion methods to images of laser-weldings.

4.1 Results of Feature Ranking

Relevant features of the raw pixel intensities are

mostly located in the centre (see Fig. 6). This cor-

responds to the description in Sec. 2 where white re-

flections (regions) in the centre of the image indicate

good weldings. The ring structure, i.e. the neck of

the socket, can also be detected, which is relevant

for defective weldings (see Fig. 6 (left), Fig. 1 (lower

(a) sample std of white irreg-

ularity

(b) sample std of white aver-

aged clump area

(c) median of white extent

(d) entropy of white form-

factor

Figure 7: Example images with large values of the indicated

features (top row), medium (middle row) and small (bottom

row).

right)). Obviously, this depends neither on the size of

the images nor on their quantisation.

The most relevant features among the SGFs are:

• sample std. of white irregularity (see Fig. 7a),

• sample std. of white averaged clump area (see

Fig. 7b),

• mean of white displacements,

• mean of white irregularity, and

• mean of number of white components.

Not only the positions of white components are

important but also their size and irregularity. Com-

pared to the raw pixel intensities the SGFs can

also cover shape properties of local components (see

Fig. 6, 7a, 7b).

The most relevant SPECs are:

• median of the white extent (scaled by the number

of components (NOC), see Fig. 7c),

• median of the white compactness (scaled by

NOC),

• median of the white minimum distance from the

image centre (scaled by NOC),

• entropy of the white formfactor (scaled by NOC,

see Fig. 7d), and

• mean of white eccentricity (scaled by NOC).

Compared to the SGFs, more complex features be-

come significant, such as the extent or the form factor,

which can describe, for example, small white reflec-

tions in the image centre and holes in the socket of

defective cathodes simultaneously (seeFig. 7c, 7d).

WELDING INSPECTION USING NOVEL SPECULARITY FEATURES AND A ONE-CLASS SVM

151

Table 4: Frequency of the different local and global features

for the 48 most relevant features when combining SGFs and

SPECs.

name occurrence

scale by number of comp. 37

scale by relative area 11

white properties 48

black properties 0

local SPECs 47

local SGFs 1

global SPECs 22

global SGFs 16

When combining SGFs and SPECs only one SGF

is present in the 48 most relevant features which indi-

cates the quality of the SPECs (see Tab. 4). Further-

more, scaling by the number of components is more

important than scaling by their relative size. Hence,

small white regions are also responsible for defective

weldings, e.g. if they are located at the neck of the

socket (see Fig. 7(d) bottom row). Altogether, the

large number of extended shape properties (47) and

new global statistics (16) shows that the SPEC fea-

tures describe the relevant image properties of welded

cathodes more accurately than the SGFs.

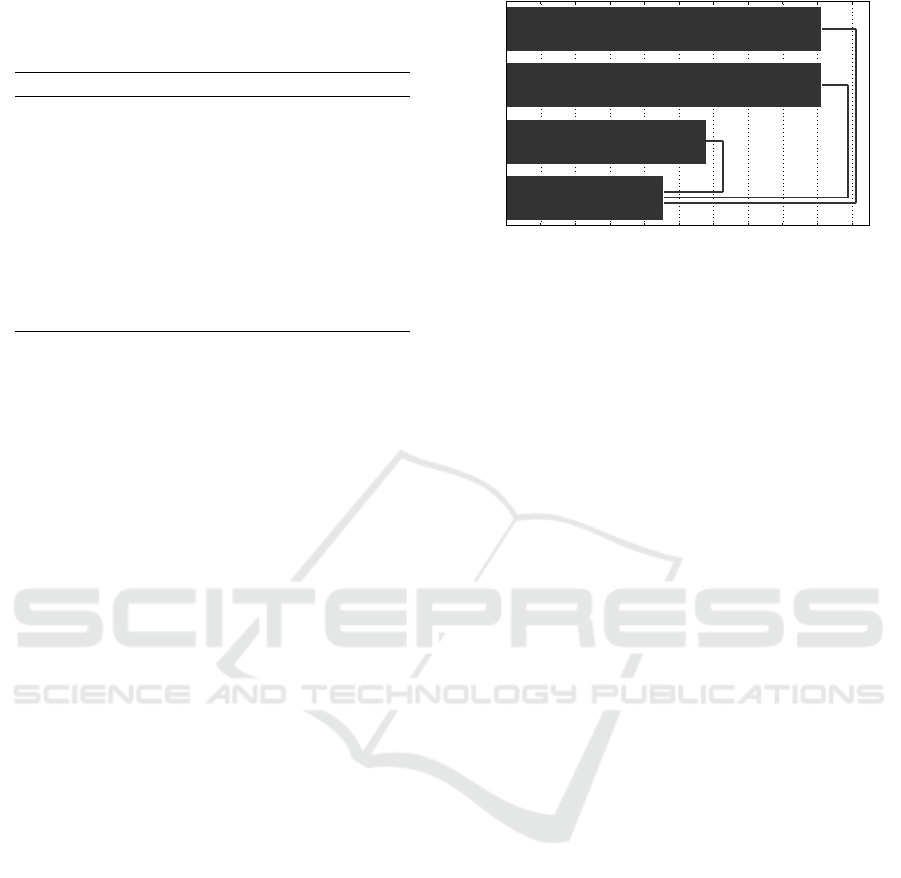

4.2 Results of Classification

The results for the different feature extraction meth-

ods applied to images of welded cathodes show sev-

eral aspects.

First, features of images of higher grey level depth

(6 – 8 bit) yield significantly lower error rates than

features of lower depth (see Fig. 9). This is inde-

pendent of the feature extraction method and confirms

the complexity of specular reflections in terms of grey

values.

Second, no significant difference between the two

image sizes could be observed, i.e. grey level reso-

lution is more important than spatial resolution (see

Fig. 9, 8). If the image size is lower than 12 ×12,

however, the higher relevance of the grey level depth

compared to image size does not hold, since the struc-

tures of the welded pin and the socket are merged,

e.g. holes and rings (see Fig. 3 bottom left) cannot

be detected. Also, SGFs and SPECs of images with

a higher grey value resolution perform significantly

better (see Fig. 9b, c).

Third, the SPECs (6 bit) have the lowest error

rate of 9.2% and perform significantly better than the

SGFs (7 bit, error rate 11.5%, p = 0.029, see Fig. 8).

Hence, SPECs describe the specular reflections of

SPEC (48 features)

SGF (48 features)

raw features 12×12 (144 fe atures)

raw features 24×24 (576 fe atures)

median of test errors

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18

0.2

Figure 8: Comparison of the methods. Some of the signifi-

cant differences (p < 0.05) are indicated by black lines.

welded cathodes more precisely than SGFs and yield

a more accurate classification.

Fourth, the SPECs (6 bit) significantly outperform

the raw pixel intensities (error rate 18%, image depth

of 7 bit, see Fig. 8). Hence, the raw pixel intensi-

ties can only cover very simple image properties, e.g.

white reflections in the centre of the image, and they

are not able to describe holes or dependencies be-

tween reflections accurately.

5 CONCLUSIONS

We introduced a novel set of specularity features

(SPECs) for welding seam inspection and showed that

these features significantly outperform the statistical

geometric features as well as raw pixel intensities.

We extracted the relevant features of the SPECs and

found white regions in the centre of the image and

their shape to be of high importance for the classifi-

cation. The SPECs can cover several complex shape

properties and their dependencies and are, neverthe-

less, intuitive and computed efficiently. Hence, they

are well appropriate for the automatic inspection of

welding seams and can even be applied to a wider

range of machine vision problems concerning com-

plex specular reflections, such as surface inspection

or defect detection of specular objects.

The labelling of the datasets of solder joints or

other weldings is usually based on experts viewing

images and not on the actual functional test. Hence,

these labels are very subjective and do not necessar-

ily correspond to the physical and electrical properties

of the weldings. Therefore, additional information

about the welding, e.g. the conductivity, rigidity or

weld strength, has to be collected and combined with

a machine-vision based approach in order to improve

the results.

The results may further be improved using other

feature selection methods. However, the error rates

VISAPP 2009 - International Conference on Computer Vision Theory and Applications

152

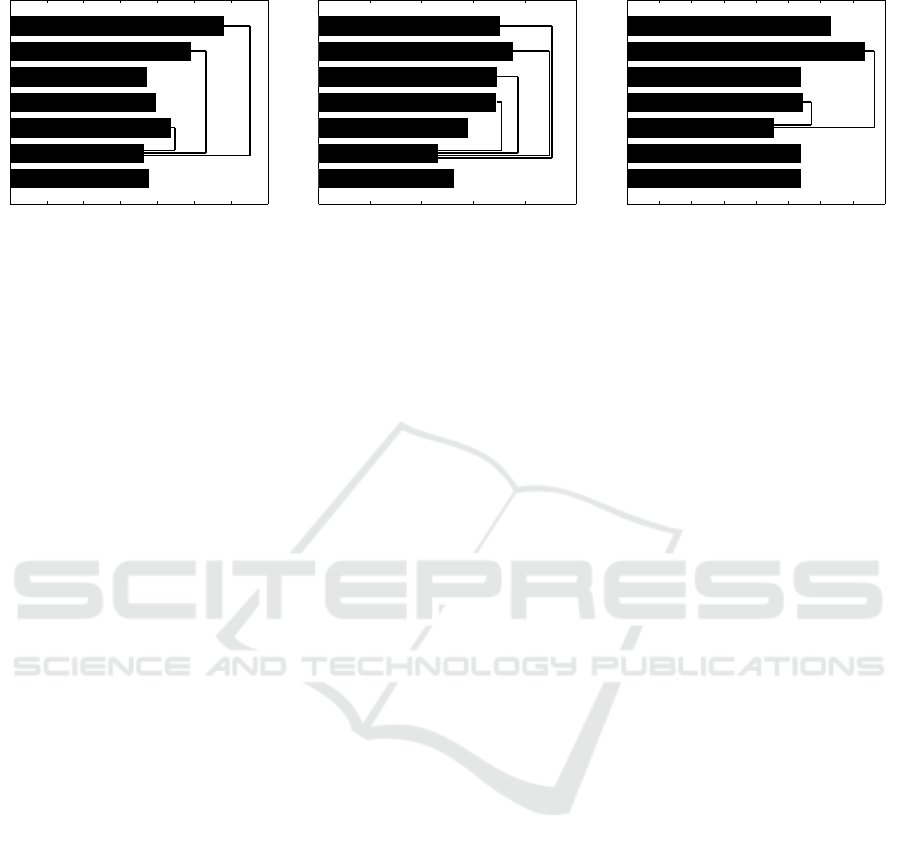

(a) raw pixel intensities (12×12).

8bit

7bit

6bit

5bit

4bit

3bit

2bit

median of test errors

0 0.05 0.1 0.15 0.2 0.25 0.3

0.35

(b) SGFs.

8bit

7bit

6bit

5bit

4bit

3bit

2bit

median of test errors

0 0.05 0.1 0.15 0.2

0.25

(c) SPECs.

8bit

7bit

6bit

5bit

4bit

3bit

2bit

median of test errors

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14

0.16

Figure 9: Medians of test errors. Black lines indicate a significant difference (p < 0.05) between two methods. Only significant

differences of the best depth level to all others are considered in the plot.

of the novel SPEC features are comparable to those

obtained by manual inspection.

REFERENCES

Boser, B., Guyon, I., and Vapnik, V. (1992). A training al-

gorithm for optimal margin classifiers. In Haussler,

D., editor, Proc. of the 5th Annual ACM Workshop

on Computational Learning Theory, pages 144–152.

ACM Press.

Chen, Y. Q., Nixon, M. S., and Thomas, D. W. (1995). Sta-

tistical geometrical features for texture classification.

Pattern Recognition, 28(4):537–552.

Chiu, S. and Perng, M. (2007). Reflection-area-based fea-

ture descriptor for solder joint inspection. Machine

Vision and Applications, 18(2):95–106.

Cortes, C. and Vapnik, V. (1995). Support-vector networks.

Machine Learning, 20(3):273–297.

Driels, M. and Lee, C. (1988). Feature selection for auto-

matic visual inspection of solder joints. The Int. Jour-

nal of Advanced Manufacturing Technology, 3:3–32.

Fukunaga, K. (1972). Introduction to Statistical Pattern

Recognition. Academic Press.

Kim, J. and Cho, H. (1995). Neural network-based inspec-

tion of solder joints using a circular illumination. Im-

age and Vision Computing, 13(6):479–490.

Ko, K. and Cho, H. (2000). Solder joints inspection using

a neural network and fuzzy rule-based classification

method. IEEE Transactions on Electronics Packaging

Manufacturing, 23(2):93–103.

Labusch, K., Timm, F., and Martinetz, T. (2008). Sim-

ple incremental one-class support vector classifica-

tion. In Rigoll, G., editor, Proc. of the 30th German

Pattern Recognition Symposium DAGM, volume 5096

of Lecture Notes in Computer Science, pages 21–30.

Springer.

Ong, T., Samad, Z., and Ratnam, M. (2008). Solder joint

inspection with multi-angle imaging and an artificial

neural network. The Int. Journal of Advanced Manu-

facturing Technology, 38(5–6):455–462.

Poechmueller, W., Glesner, M., Listl, L., and Mengel, P.

(1991). Automatic classification of solder joint im-

ages. In Proc. of the Int. Joint Conf. on Neural Net-

works, volume 2, pages 933–940. IEEE Computer So-

ciety Press.

Russ, J. C. (2007). The Image Processing Handbook. CRC

Press.

Sch

¨

olkopf, B., Platt, J. C., Shawe-Taylor, J., Smola, A. J.,

and Williamson, R. C. (2001). Estimating the support

of a high-dimensional distribution. Neural Computa-

tion, 13(7):1443–1471.

Stone, M. (1974). Cross-validatory choice and assessment

of statistical predictions. Journal of the Royal Statis-

tics Society, 36:111–147.

Tax, D. M. J. and Duin, R. P. W. (2004). Support vector data

description. Machine Learning, 54(1):45–66.

Timm, F., Klement, S., and Martinetz, T. (2008). Fast model

selection for maxminover-based training of support

vector machines. In Proc. of the 19th Int. Conf. on

Pattern Recognition, Florida, USA. IEEE Computer

Society Press. to appear.

Vapnik, V. (1995). The Nature of Statistical Learning The-

ory. Springer Verlag, New York.

Walker, R. and Jackway, P. T. (1996). Statistical geometric

features: Extensions for cytological texture analysis.

In Proc. of the 13th Int. Conf. on Pattern Recognition,

pages 790–794. IEEE Computer Society Press.

WELDING INSPECTION USING NOVEL SPECULARITY FEATURES AND A ONE-CLASS SVM

153