CATECHOL DETETION USING AN OPTICAL MEMS SENSOR

Peter H. Dykstra, Stephan T. Koev, Reza Ghodssi

MEMS Sensors and Actuators Lab, Department of Electrical and Computer Engineering

Institute for Systems Research (ISR), University of Maryland, College Park, MD 20742, U.S.A.

Gregory F. Payne

University of Maryland Biotechnology Institute (UMBI), Rockville, MD 20850, U.S.A.

Liangli Yu

Department of Nutrition and Food Science, University of Maryland, College Park, MD 20742, U.S.A.

Keywords: Catechol, Chitosan, Waveguides, Absorbance.

Abstract: We report the successful fabrication and testing of an optical MEMS sensor for the detection of the toxic

phenol, catechol. Catechol’s presence in food and drinking water posses a health concern due to its harmful

effects on cell respiration. By-products of catechol oxidation have demonstrated increased absorbance

changes in a chitosan film in the UV and near UV range. Our reported sensor takes advantage of this unique

absorbance property to detect catechol by measuring the change in light intensity at 472 nm, thus

eliminating non-specific responses that occur from other oxidized chemicals which do not cause the

absorbance change. Concentrations as low as 1 mM catechol are detected while control experiments

including ascorbic acid display no measurable response.

1 INTRODUCTION

Monitoring the safety of our water supply by using

portable, efficient and inexpensive devices has

become an area of growing interest over the past

decade. The growth of industry has contributed to

the contamination of ground waters with various

potentially dangerous organic chemicals. Catechol is

a synthetic phenol commonly generated in factory

processes and it has been proven to have detrimental

health effects (Starek, 2003). One monitoring

solution is through the use of

microelectromechanical systems (MEMS) to create

on-chip sensors which can give field personnel

accurate and sensitive data on-site regarding the

testing of the water supply.

Recently reported sensors for catechol detection

either use optical or electrochemical measurement

schemes. Optical sensors making use of absorbance

(Abdullah et al., 2006) and fluorescence (Wu et al.,

2004) detection have been reported but the necessity

for bulky, external measuring equipment has

hindered the fabrication of such devices on chip.

Electrochemical sensors typically employ a standard

three electrode system with the working electrode

covered by an immobilization matrix such as

calcium carbonate to entrap oxidizing enzymes

(Shan et al., 2007). Although these devices result in

high sensitivity, the enzyme activity degrades over

time and can be directly affected by certain

conditions such as the pH of the solution making

these sensors difficult to calibrate.

Our reported device utilizes an optical

absorbance technique in a sealed microfluidic

channel for the detection of catechol. In order to

amplify the effect of the detected absorbance by

catechol oxidation, the aminopolysaccharide

chitosan is deposited in the microfluidic channel,

thus intersecting the pathway of the light through the

device. The proposed detection scheme does not

require the use of enzymes yet still remains selective

to phenolic compounds vs other chemical agents.

104

Dykstra P., Koev S., Ghodssi R., Payne G. and Yu L. (2009).

CATECHOL DETETION USING AN OPTICAL MEMS SENSOR.

In Proceedings of the International Conference on Biomedical Electronics and Devices, pages 104-108

DOI: 10.5220/0001552001040108

Copyright

c

SciTePress

2 MATERIALS AND THEORY

2.1 Catechol

Catechol is a benzenediol, which is a subset of the

phenol class of organic compounds. The chemical

formula of Catechol is C

6

H

4

(OH)

2

.

Following

oxidation, catechol loses its hydrogen atoms from

the hydroxyl groups and becomes an

orthobenzoquinone, more commonly referred to as

an o-quinone. The oxidation of catechol in the cell

creates free radicals which cause damage to vital cell

components such as lipids, proteins and DNA (Sies,

1997).

2.2 Chitosan

Chitosan is a unique material that is well suited for

biological micro-devices due to its ability to be

selectivity deposited and its high density of amine

groups, which provide active bonding sites. The

selective deposition occurs due to chitosan’s

insolubility above a pH of 6.5. At low pH, chitosan

is protonated and soluble in water. As the pH rises

above 6.5, the amines lose their net positive charge

and the chitosan becomes insoluble. By taking

advantage of this property, one can deposit a film of

chitosan onto a cathode during an electrochemical

reaction. The pH rises with increasing proximity to

the cathode due to the reduction of the hydrogen

ions. The chitosan forms as a thin film or hydrogel

over the cathode surface depending on the amplitude

of the applied current density.

Chitosan has an added advantage over other

polysaccharides because it contains nucleophilic

primary amine (NH

2

) groups at nearly every

repeating sugar residue in its structure. The o-

quinones, which are formed from the oxidized

catechol molecules, bind to the amine groups and

impart physical changes to the film, such as a

change in the optical absorbance (Wu et al., 2005).

2.3 Optics

Understanding the operating principle of the device

requires a more detailed understanding of light

propagation and absorption through a medium. The

absorbance can be related to the concentration of

absorbing species present as demonstrated by the

Beer-Lambert Law:

lc

I

I

A

ε

=−= )(log

0

1

10

(1)

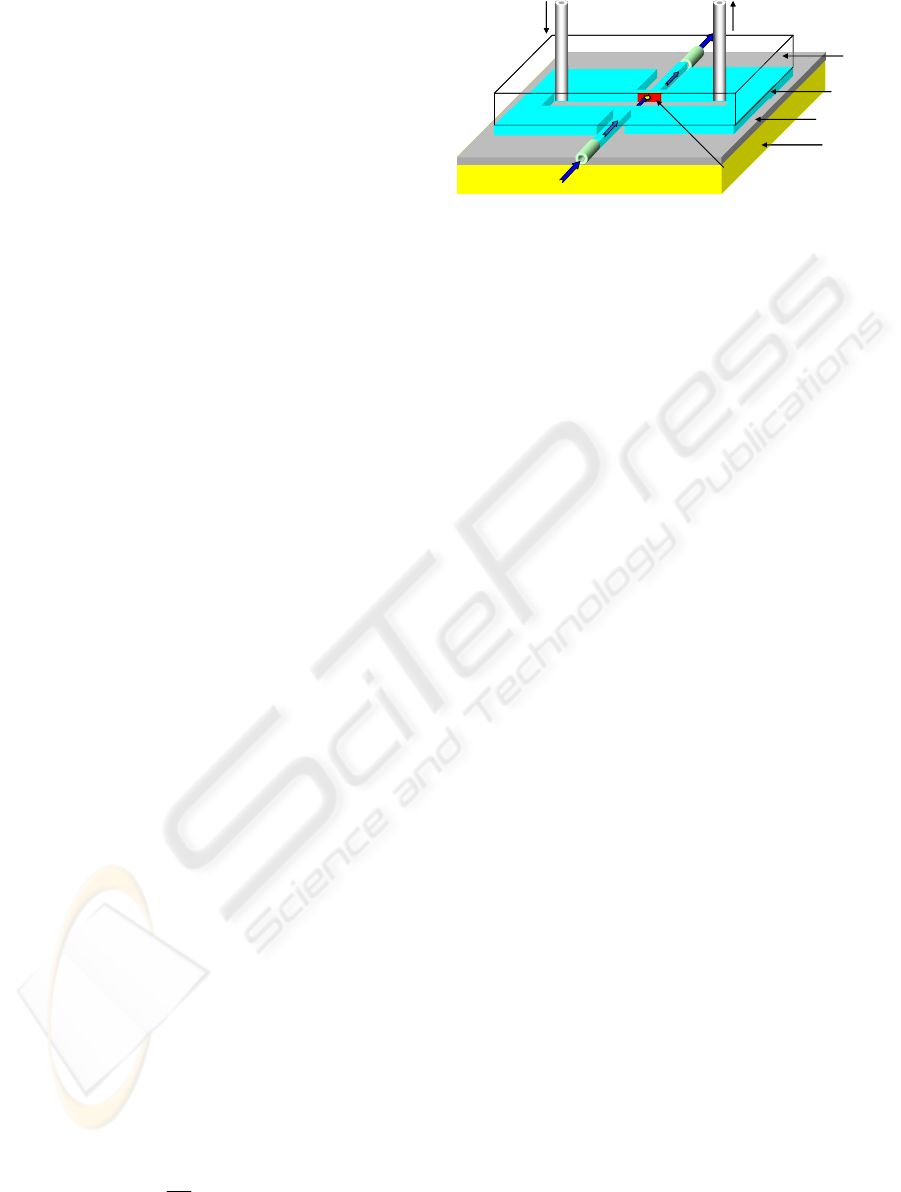

Fluid In

Fluid Out

Light In

Light Out

SU-8

Oxide

Deposited Chitosan Film

Silicon

PDMS

Fluid In

Fluid Out

Light In

Light Out

SU-8

Oxide

Deposited Chitosan Film

Silicon

PDMS

Figure 1: 3-d Schematic of the packaged device. The

device dimensions are 3.2 x 2.4 x 0.24 cm.

Where ε is the molar absorptivity, l is the path length

the light takes as it propagates through the absorbing

layer and c is the concentration. In our experiments,

the path length, l, is defined as the thickness of the

deposited chitosan film. O-quinones have been

reported to show a strong absorbance in the UV and

near UV range of the electromagnetic spectrum (Wu

et al., 2005). For this reason, a blue laser source at

472 nm was chosen for the optical measurements

taken with the MEMS sensor.

In our device, on-chip waveguides are patterned

from the polymer SU-8 as shown in the device

schematic (Figure 1). Blue light is coupled in and

out of the waveguides via multimode fibers with a

core diameter of 62.5 μm. The cross sectional area

of the polymer waveguides is 100 μm by 150 μm.

The light propagates through a film of chitosan that

has been deposited onto a transparent, conductive

film of indium tin oxide.

Since the absorbance measurement is purely

related to the optical power being received, it is

important to understand the different optical loss

mechanisms through the device in order to achieve

an acceptable signal to noise ratio. The primary

sources of loss are caused by waveguide losses

which include material absorption and scattering,

divergence of the light crossing the channel, and

roughness associated with the waveguide facets.

Waveguide loss will occur due to the roughness

of the waveguide and any material absorption

through the SU-8. This attenuation was measured to

be 21.15 dB/cm at 472 nm for waveguides with our

dimensions using image processing software. A top-

down digital photograph was taken of fabricated test

waveguides coupled to a blue laser source. The light

intensity down the length of the waveguide was

analyzed to determine the attenuation coefficient.

Divergence of the light as it crosses the

microfluidic channel from one waveguide to the next

is another possible source of loss. The light

capturing efficiency from one waveguide to the next

is found by integrating the surface energy of a beam

CATECHOL DETETION USING AN OPTICAL MEMS SENSOR

105

with a Gaussian profile and is related to the width of

the beam waist as seen in (2).

2

0

2

0

)(

*)(2

wzw

wzw

+

=

η

(2)

Where w

0

and w(z) are the width of the beam

waist before and after it has traversed the channel.

For the dimensions used in our device, the coupling

efficiency of the light as it traverses the channel

from one waveguide to another is near unity (η =

0.99). The high coupling efficiency is a result of

using waveguides with large cross sectional areas.

With these considerations, the most significant

factor that contributes to optical loss in the device is

the roughness of the waveguide facets and sides. The

surface roughness of the waveguides is an inherent

limitation when using lithography and cannot be

completely avoided.

3 DEVICE FABRICATION

3.1 Wafer Level Processes

The MEMS sensor was fabricated using

conventional MEMS patterning techniques. Four

inch silicon wafers (<100> orientation) begin with a

one μm thick thermal SiO

2

to act as a bottom

cladding layer for the waveguides. Layers of chrome

(20 nm) and gold (200 nm) are sputtered onto the

oxide coated wafers and patterned to create the

electrodes inside the microfluidic channels.

SU-8 was applied to the wafer and spun first at

600 RPM for 10 seconds followed by 1150 RPM for

30 seconds to achieve a final thickness of 100 μm.

The pre-bake was performed on a hotplate at 55

o

C

for 2 hours with a temperature ramp of 5 degrees per

minute.

The SU-8 was exposed to UV light at a dose of

2500 mJ/cm

2

using a mask aligner system, and then

placed back on the hotplate to bake at 55

o

C for 90

minutes with a temperature ramp of 5 degrees per

minute. After post-baking, the SU-8 was developed

for 10 minutes.

A film 200 nm thick of indium tin oxide (ITO)

was deposited on the wafer using RF magnetron

sputtering. The sidewall patterning procedure of the

ITO using AZ9245 photoresist has been described

elsewhere (Powers et al., 2005). The wafers are

cleaned using acetone, methanol, isopropyl alcohol

and DI water, then diced into individual dies for

testing.

3.2 Die-level Processes

Medium molecular weight (~200 kDa) chitosan

flakes were purchased from Sigma Aldrich and

prepared using established methods resulting in a

solution with pH of 5.3 and w/v chitosan of 0.5%

(Yi et al., 2005). The chitosan solution was applied

to the active electrode area using a 100 μl syringe

and biased at a current of 0.35 μA, which

corresponds to a current density of 4 A/m

2

. This

procedure results in complete chitosan coverage of

the sidewall interface. The current was applied for

10 minutes, after which the device was rinsed

extensively with DI water and blown dry with

nitrogen.

The deposited chitosan films were measured to

be between 5 and 10 microns thick by measuring the

distance the chitosan extends from the sidewall

using an optical microscope. Following deposition

and rinsing, the chips are immersed in a 1 M

solution of NaOH for 5 minutes to neutralize the

chitosan film.

The fluidic channel was sealed using a thick (1

mm) flexible polymer, PDMS. PDMS curing agent

and polymer were purchased from Sigma Aldrich

and mixed in a 1:10 ratio. The solution was cured at

80

o

C for 25 minutes in a box furnace, and then cut

into smaller pieces to fit over the device. To position

the PDMS layer, methanol is applied to one side and

the PDMS is slid into place over the device.

Metal capillaries with OD 400 μm and ID 200

μm were inserted through the PDMS to create liquid

inlet and outlet ports. Multimode optical fibers were

aligned to the on-chip waveguides through the use of

patterned grooves in the SU-8 resist. Once aligned

by hand under a stereomicroscope, an adhesive was

used to secure the fiber. The final packaged device is

shown in figure 2.

Figure 2: Photograph of packaged device.

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

106

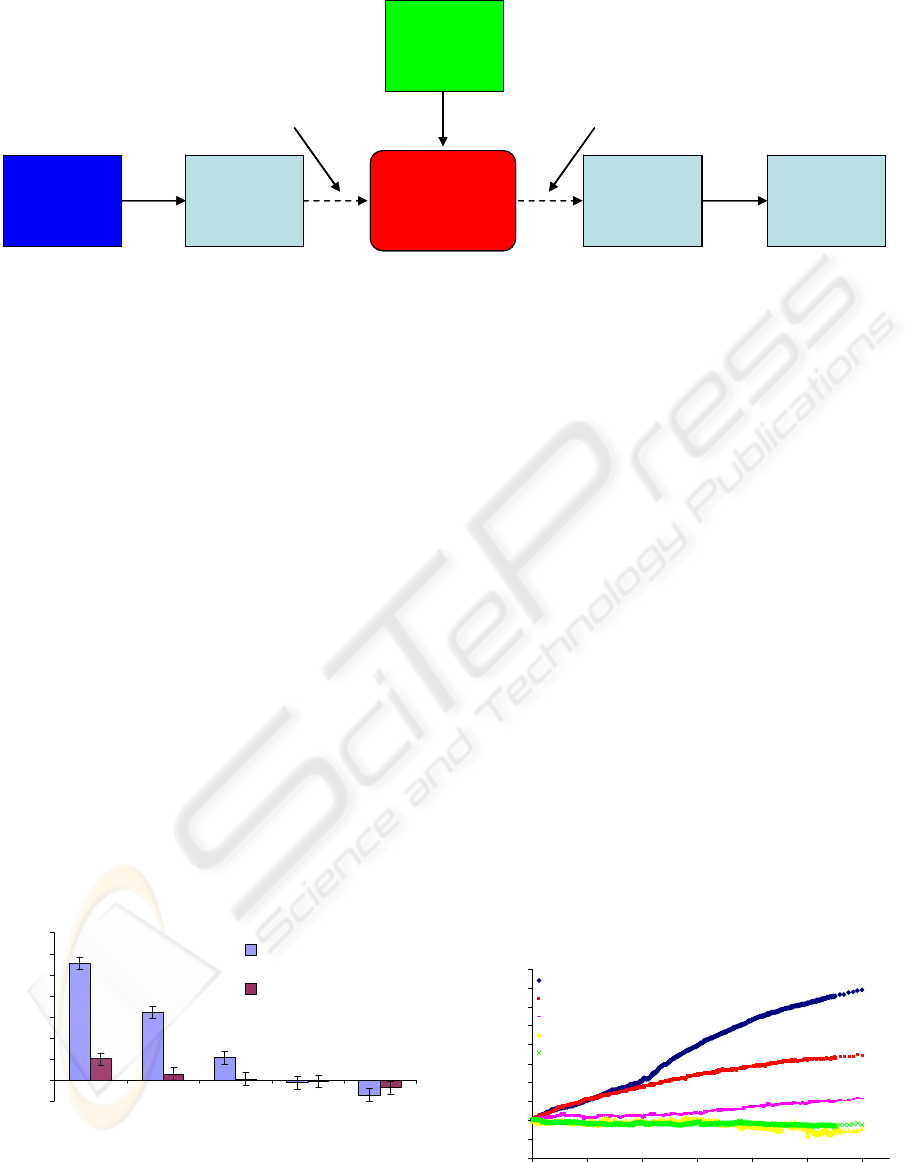

Microsensor

472 nm Blue

Laser

XYZ Fiber

Aligner Stage

Syringe Pump

Photodetector

Computer

Software

Input Fiber Output Fiber

Microsensor

472 nm Blue

Laser

XYZ Fiber

Aligner Stage

Syringe Pump

Photodetector

Computer

Software

Input Fiber Output Fiber

Figure 3: Block Diagram of testing setup for the MEMS sensor.

4 TESTING AND RESULTS

Absorbance measurements from catechol oxidation

were taken using blue light (472 nm) coupled

through the MEMS device. Figure 3 displays a

graphic of the testing setup used. Light was

delivered from a free space blue laser (LaserMate,

Pomona, CA) operating in the continuous wave

mode and focused into a multimode fiber using a

manual alignment stage. Output light was coupled

via the optical fiber to a USB linked

spectrophotometer (Ocean Optics, Dunedin, FL)

which facilitated automated data collection using

software. Catechol flakes were purchased from

Sigma Aldrich and dissolved in a 20 mM phosphate

buffer at a pH of 5.3. Liquid was administered using

a GENIE PLUS syringe pump (Kent Scientific,

Torrington, CT) at a flow rate of 100 μl/hr, which

translates to a linear flow velocity in the channel of

about 1 mm/s. All of the experiments were

performed at room temperature.

Figure 4 displays the change in measured light

intensity for three different catechol concentrations

after they were oxidized for 10 minutes at a current

density of 4A/m

2

. No decrease in intensity was

observed from the oxidation of the buffer solution or

-10

0

10

20

30

40

50

60

70

100 mM

Catechol

10 mM

Catechol

1 mM

Catechol

Buffer

Solution

100 mM

Ascorbic Acid

Decrease in Intensity (%)

with chitosan

without chitosan

Figure 4: Measured decrease in light intensity at 472 nm

after 10 minute oxidation at 4 A/m

2

. A clear signal

increase is displayed for all catechol concentrations when

using chitosan in the device.

the common antioxidant, ascorbic acid. Also shown

are measurements for devices without the chitosan

film. The data clearly demonstrates the necessity of

the chitosan in order to detect smaller concentrations

of catechol. Devices with the chitosan film display a

3x and 7x signal increase vs. those without chitosan

for 100 mM and 10 mM catechol concentrations

respectively. At our lowest measured concentration

of 1 mM, no change in the light intensity is detected

for the device without the chitosan film. The

chitosan film amplifies the signal because it

effectively traps the generated o-quinones at the

sensing area of the device through covalent bonding.

It should be noted that these tests without chitosan

require the liquid flow to be stopped in the channel.

Any applied flow rate will cause the o-quinones to

be swept away from the sensing area, disallowing

any accumulation which would cause a detectable

change in absorbance. Measurement error was

calculated based on the observed fluctuations in the

intensity measurement due to either changes in the

laser power or noise effects in the detector.

The increasing absorbance change over the 10

minute period for each sample is displayed in figure

5. The accumulation of the o-quinones is roughly the

same for each concentration of catechol for the first

minute as the rate is primarily reaction limited. Over

-0.1

-0.05

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

0.4

0 100 200 300 400 500 600

Time (sec)

Absorbance

100 mM Catechol

10 mM Catechol

1 mM Catechol

100 mM Ascorbic Acid

Buffer Solution

Figure 5: Change in absorbance over time for each sample.

CATECHOL DETETION USING AN OPTICAL MEMS SENSOR

107

time, the absorbance rate becomes diffusion limited

as the catechol must traverse through the chitosan

film to reach the electrode.

5 CONCLUSIONS

We report the demonstration of on-chip catechol

detection using optical absorbance measurements.

The device successfully demonstrates selective

detection of phenolic (catechol) vs. non-phenolic

(ascorbic acid) compounds without the need of

enzymes. The device also exhibits good

differentiation for a wide range of catechol

concentrations. Since our device uniquely allows for

the collection of time resolved absorbance data,

calibration curves can be fit to different times in

order to achieve more accurate sensing of the

concentration. The analysis performed in this

research can hopefully help to provide the

groundwork for a device used for the detection of

catechol packaged in a low-cost, portable system.

ACKNOWLEDGEMENTS

The authors would like to thank the National

Science Foundation (NSF-EFRI) and the R. W.

Deutsch Foundation for funding this research.

REFERENCES

Abdullah, J., Ahmad, M., Karuppiah, N., Heng, L. Y. &

Sidek, H. (2006) Immobilization of tyrosinase in

chitosan film for an optical detection of phenol.

Sensors and Actuators B, 114, 604-609.

Powers, M. A., Koev, S. T., Schleunitz, A., Yi, H.,

Hodzic, V., Bentley, W. E., Payne, G. F., Rubloff, G.

W. & Ghodssi, R. (2005) A fabrication platform for

electrically mediated optically active biofunctionalized

sites in BioMEMS. Lab on a Chip, 5, 583-586.

Shan, D., Zhu, M., Han, E., Xue, H. & Cosnier, S. (2007)

Calcium carbonate nanoparticles: A host matrix for the

construction of highly sensitive amperometric phenol

biosensor. Biosensors and Bioelectronics, 23, 648-

654.

Sies, H. (1997) Oxidative stress: oxidants and

antioxidants. Experimental Physiology, 82, 291-295.

Starek, A. (2003) Estrogens and Organochlorine

Xenoestrogens and Breast Cancer Risk. International

Journal of Occupational Medicine and Environmental

Health, 16, 113-124.

Wu, L.-Q., Ghodssi, R., Elabd, Y. A. & Payne, G. F.

(2005) Biomimetic Pattern Transfer. Advanced

Functional Materials, 15, 189-195.

Wu, X. J., Choi, M. M. F. & Wu, X. M. (2004) An

organic-phase optical phenol biosensor coupling

enzymatic oxidation with chemical reduction. The

Analyst, 129, 1143-1149.

Yi, H., Wu, L.-Q., Bentley, W. E., Ghodssi, R., Rubloff,

G. W., Culver, J. N. & Payne, G. F. (2005)

Biofabrication with chitosan. Biomacromolecules, 6,

2881-2894.

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

108