IN-SITU, REAL-TIME BIOREACTOR MONITORING BY FIBER

OPTICS SENSORS

R. G. Silva

1

, J. S. Silva

1

, A. A. Vicente

1

, J. A. Teixeira

1

and R. C. Martins

2∗

1

IBB - Institute for Biotechnology and BioEngineering, Universidade do Minho

Campus de Gualtar, 4710-057 Braga, Portugal

2

BioInformatics - Molecular and Environmental Biology Research Center, Universidade do Minho

Campus de Gualtar, 4710-057 Braga, Portugal

Keywords:

UV-VIS-SWNIR spectroscopy, Real-time monitoring, Multivariate calibrarion.

Abstract:

One of the most studied bioprocesses is fermentation by yeasts. Although this is true, there is still the lack

of real-time instrumentation that is capable of providing detailed information on metabolic state of fermen-

tations. In this research we explore the possibility of using UV-VIS-SWNIR spectroscopy as a high-output,

non-destructive and multivariate methodology of monitoring beer fermentation. We herein report the imple-

mentation of the a fibber optics sensor and the capacity for detecting key parameters by partial least squares

regression for biomass, extract, pH and total sugars. Results show that UV-VIS-SWNIR is a robust technique

for monitoring beer fermentations, being able to provide detailed information spectroscopic fingerprinting of

the process. Calibrations were possible to obtain for all the studied parameters with R2 of 0.85 to 0.94 in

the UV-VIS region and 0.95 to 0.97 in the VIS-SWNIR region. This preliminary study allowed to conclude

that further improvements in experimental methodology and signal processing may turn this technique into a

valuable instrument for detailed metabolic studies in biotechnology.

1 INTRODUCTION

The most common bioprocess in bioengineering is

fermentation. Fermentation is the result of plant

physiology, yeast physiology, metabolomics and

quimiomics, and as well as of physical phenomena,

such as fluid flow, heat and mass transfer. Because

this complex system is auto-organized inside a biore-

actor during fermentation, fermentations have been

controlled using only macroscopic variables, such

as, temperature, pH and CO

2

pressure. Neverthe-

less, these provide low discrimination and informa-

tion on how to control the metabolic transformations,

especially because fermented products differ not in

macroscopic chemical composition, but rather in mi-

cro quantities which are especially relevant, such as

key odorants in beer or wine, or in the production of

pharmaceutical highly valued drugs.

The metabolome has been mostly studied by tar-

geted approaches in analytical chemistry techniques.

These are not capable to obtain in real time the

metabolomics inside bioreactors and are usually de-

structive methodologies. Therefore, various on-line

∗

Corresponding author: rui.martins@bio.uminho.pt

analytical methods, such as flow injection analysis

(FIA), liquid chromatography(HPLC), infrared spec-

troscopy (IR), gas chromatography (GC) and mass

spectrometry (MS), become more and more popu-

lar in metabolic studies (Schugerl, 2001). Although

these are highly accurate methods for metabolic stud-

ies, these are difficult to be implemented in-line, not

only due to their high price, but because they need

special and highly controlled conditions to operate.

Spectroscopy is a powerful multivariate method-

ology that have great potential for the metabolomics

study in biological systems. It provides a conve-

nient method for analysis of liquids, solutions, pastes,

powders, films, fibres, gases and surfaces, and mak-

ing possible to characterize proteins, peptides, lipids,

membranes, carbohydrates in pharmaceuticals, foods,

plants or animal tissues. It can also provide detailed

information about the structure and mechanism of

action of molecules (Stuart, 1997). Over the past

decade, interest in bioprocess monitoring using non-

invasive infrared spectroscopic sensors has increased.

This is mainly due to their rapid simultaneous multi-

variate determination ability, in situ sterilizability, and

low need for maintenance during operation. Among

the various spectral regions, near-infrared(NIR) spec-

327

G. Silva R., S. Silva J., A. Vicente A., A. Teixeira J. and C. Martins R. (2009).

IN-SITU, REAL-TIME BIOREACTOR MONITORING BY FIBER OPTICS SENSORS.

In Proceedings of the International Conference on Bio-inspired Systems and Signal Processing, pages 327-336

DOI: 10.5220/0001549503270336

Copyright

c

SciTePress

troscopy has been used widely due to ease of sam-

pling using fiber optics, and inexpensive and robust

instrumentation (Cooper et al., 1997; Yano et al.,

1997; Majara et al., 1998; Yeung et al., 1999; Alison

et al., 2000; Rhiel et al., 2002).

UV-VIS spectroscopy has not been used in bio-

process engineering, where the use of near infrared

(NIR) has been preferred due to the association to

specific vibrations of molecular groups (Workman,

1993). It has been widely accepted that vibrational

spectroscopy is more adequate for organic chemistry

measurement than transitional spectroscopy (Faust,

1992). However, NIR spectroscopy has as high in-

convenience the high absorbance of water in this re-

gion, which greatly decreases the sensitivity, being

more difficult to detect metabolites in lower concen-

trations. Furthermore, NIR and MIR equipments are

more expensive, and today’s cheap miniaturized spec-

trometers are capable to detect with high precision in

the UV-VIS-SWNIR region.

UV-VIS-SWNIR has not been used for a fer-

mentation monitoring. This is perhaps attributed to

the fact that UV-VIS spectroscopy records transmi-

tions between electron energy levels from molecu-

lar orbitals, instead of vibrational or structural os-

cillation of molecular groups as in the infrared re-

gion. Electronic transitions in the UV-VIS region

depend upon the energy involved. For any molecu-

lar bound (sharing a pair of electrons), orbitals are

a mixture of two contributing orbitals σ and π, with

corresponding anti-bounding orbitals σ

∗

and π

∗

, re-

spectively (Bruice, 2006). Many organic molecules

present conjugated unsaturatedand carbonylsbounds,

such as aminoacids, phospholipids, free fatty acids,

phenols and flavonoids, peroxides, peptides and pro-

teins, sugars and their polymers absorbance in these

bands. Furthermore, many biological molecules

present chromophore groups, which increase the ab-

sorption in the UV-VIS region, such as: nitro, ni-

troso, azo, azo-amino, azoxy, carbonyl and thiocar-

bonyl, which can be used to characterize the different

metabolomic stages that occur on a bioprocess. Fur-

thermore, UV-VIS-SWNIR registers many features

such as fluorescence and vibrational resonances due

to energy decay of exited electrons, which may pro-

vide highly accurate fingerprinting of metabolites and

metabolic state of the fermentation.

In this research we explore the use of fiber op-

tics sensors for monitoring the yeast metabolic ac-

tivity during beer fermentation. Beer its the final re-

sult of wort fermentation with selected yeast. As the

metabolism is dependent on several internal and ex-

ternal variables the main objectives of this work were:

i) implement a fibber optics sensor capable of re-

producibility and immunity to processing conditions;

ii) determine the capacities of UV-VIS-SWNIR spec-

troscopy in capturing detailed metabolic features dur-

ing fermentation; and iii) determine the capacity for

detecting key metabolites by partial least squares re-

gression of the signal (biomass, extract, pH and sug-

ars).

2 MATERIALS AND METHODS

2.1 Fermentation

Two complete fermentations were monitored in this

exploratory study. The conical cylinder fermentor,

with maximum volume 1.9 L and a work volume of

1.4 L in Figure 1 (a) was used. To maintain a con-

stant temperature of 18

o

C a refrigeration serpentine

involves the cylindrical part of the bioreactor, being

possible to achieve a complete fermentation in 5 days.

The fermentation starts by adding the inoculum to the

malt wort (13.4

o

Brix) previously put inside the biore-

actor. The inoculum is composed of Saccharomyces

pastorianus (carsbergensis) (brewing yeast) with a

concentration of 12 to 16x10

6

cells / ml of wort. An

inoculum stock was stored in a freezer at −80

o

C in

order to obtain reproducibility between batches. In-

oculum was prepared in the following fashion: the

microorganisms were incubated in wort (previously

aired) under anaerobic conditions on a rotary shaker

(120 rpm) at 27

o

C for 72h. After this period of time

the yeast were collected from the wort by centrifu-

gation (5000 rpm for 10 minutes) in Sigma 4K15

(Sigma, 2008), and then diluted in NaCl (0,9% v/v)

in the reason of 4 ml/g of yeast, to form a paste.

Once obtained this paste it’s necessary determine, by

direct counting in the microscope of the yeast, the

correct volume of inoculum, to ensure the necessary

initial concentration of yeast on the fermentor (12 to

16x10

6

cells / ml). After this, the required volume

of inoculum is calculated and added to the wort to

begin fermentation. Monitorization was performed

at-line by removing 15 ml samples with a frequency

of three samples per day during the consecutive five

days of fermentation. These samples were thereafter

subjected to both spectroscopy and physical-chemical

measurements.

2.2 Spectroscopy

UV-VIS-SWNIR spectroscopy measurements

were performed using the fiber optic spec-

trometer AvaSpec-2048-4-DT (2048 pixel, 200-

1100nm)(Avantes, 2005). Standard Transmition

BIOSIGNALS 2009 - International Conference on Bio-inspired Systems and Signal Processing

328

(a)

5 cm

5 cm

(c) (d)

(b)

Figure 1: Experimental setup: (a) Fermentor; (b) Equipment for spectroscopy analysis (Spectrometer, Light source, Com-

puter with spectroscopy software, Transmition dip probe and Probe holder); (c) Probe holder, side view and corresponding

dimensions and (d) Probe holder, up view and corresponding dimensions).

dip probes T300 - RT-5mm UV-VIS and VIS-

NIR (200-1100 nm) for UV-VIS and VIS-SWNIR

(Ocean-Optics, 2008) were adapted to a special probe

container designed to isolate the environmental light

and maintain the probe at the horizontally to prevent

the deposition of debris in the mirrored surface,

as presented in Figures 1 (b) to 1 (d). A balanced

deuterium tungsten Light Source - DH2000-Bal was

used for UV-VIS and VIS-SWNIR transmission

measurements (Ocean-Optics, 2008); and recorded

using AvaSoft 7.0 software (Avantes, 2007). All

measurements were performed at the room temper-

ature of 18±2

o

C. The deuterium lamp (UV-VIS)

was let to stabilize during 20 min; and the tungsten

lamp (VIS-SWNIR) was let to stabilize during 15

min. The dark spectra was recorded and the spectra

measurements were taken with linear and electric

dark correction. Both light spectra were monitored by

statistically assessing the reproducibility of the light

source with measurements of light during the several

days of the experiment. The spectra were acquired

three times a day to follow the different stages of the

fermentation. Ten spectra replicates were recorded

of UV-VIS and VIS-SWNIR measurement for each

sample of the fermentation to study scattering effects.

2.3 Physic-chemical Analysis

Cell Concentration: Samples were centrifuged

(5000 rpm for 5 minutes) to remove the yeast from

beer; To determine the concentration of yeast cells.

The yeast removedby centrifugationwas resuspended

in 15 ml of NaCl (0.9% v/v), and after performing

the appropriate dilution, cell concentrations were de-

termined with a Neubauer improved counting cham-

ber at the microscope. pH determination: 2 ml

of each centrifuged beer were analyzed in triplicate

in a Metrohm 691 pH meter following the instruc-

tions from (Metrohm, 2008); Total sugars: sugar

weight percentage in solution was obtained through

refractometry, by placing 1 ml of sample in the

AR12 SCHMIDT+HAENSCH ABBE refractometer

(Schemidt-haensch, 2008); Dry extract: three sam-

ples of 1 ml each were placed in the oven at 105

o

C

for 24 h and the dry weight of this samples was calcu-

lated matching the dissolved solids concentration in

the original samples .

2.4 Analysis and Multivariate

Calibration

2.4.1 Spectra Pre-processing

The large biochemical transformations of fermenta-

tion makes impossible use the same integration time

for all the fermentation sampling times. Under these

circumstances, all the collected spectra were trans-

formed into intensity (I) to remove this effect (I =

Raw Signal/Integration Time) and smoothed by us-

ing the Stavisky-Golay filter (length = 15, Order=

2) (Stavitzky and Golay, 1964). Afterwards, spectra

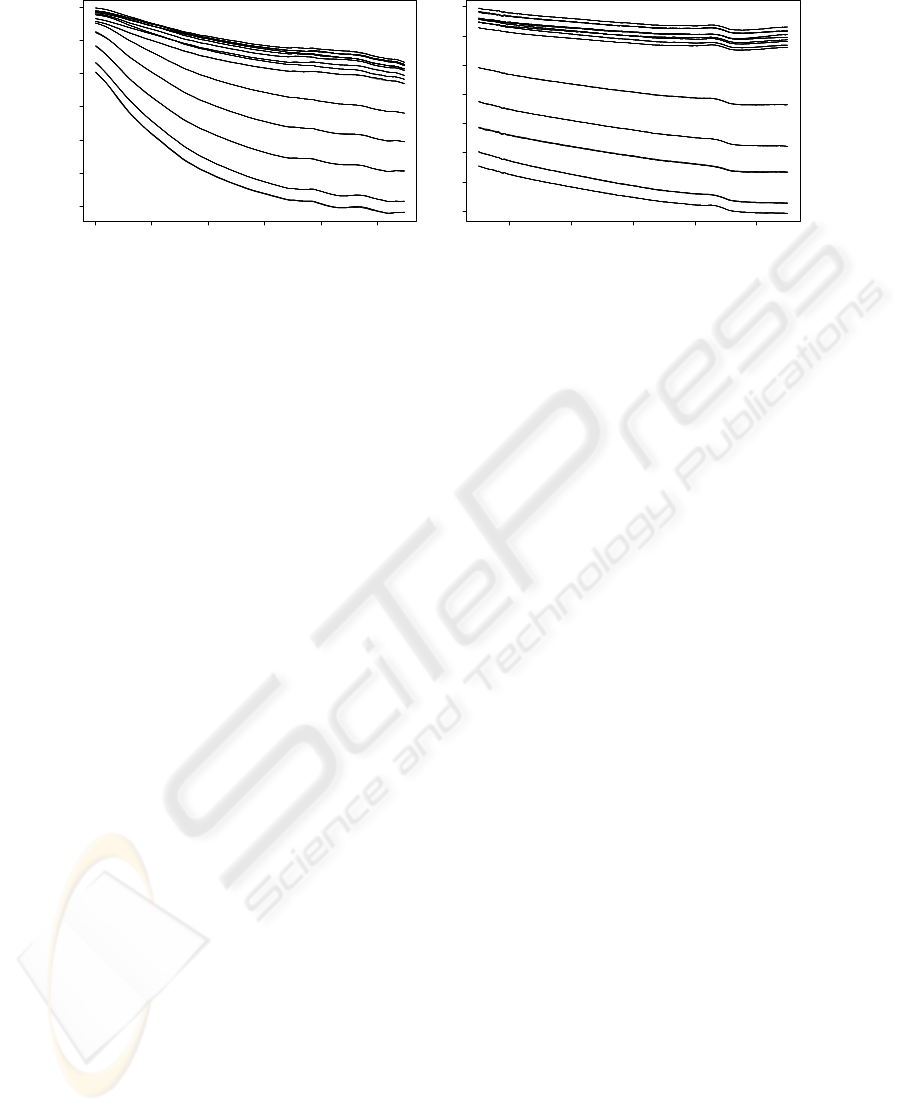

was transformed into absorbance (Figure 2): Abs

i

=

log

I

0

I

i

; where Abs

i

is the absorbance spectra for the

IN-SITU, REAL-TIME BIOREACTOR MONITORING BY FIBER OPTICS SENSORS

329

360 380 400 420 440 460

2.5 3.0 3.5 4.0 4.5 5.0 5.5

(a)

Wavelength (nm)

Absorbance

600 700 800 900 1000

1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5

(b)

Wavelength (nm)

Absorbance

Figure 2: Absorbance spectra: (a) UV-VIS; (b) VIS-SWNIR.

different samples, I

0

is the light spectra and I

i

sam-

ple spectra intensities, respectively. Furthermore,

small scattering artifacts were corrected using a mod-

ified robust multiplicative scatter correction algorithm

(RMSC) (Martens and Stark, 1991; Martens et al.,

2003; Gallager et al., 2005): x

corr

= xb+ a = x

ref

.

The a and b are computed by minimizing the follow-

ing error: e

j

= bx

j

+ a − x

ref

; where the x

j

is the j

sample spectrum and x

ref

is a reference spectrum.

2.4.2 Qualitative Spectral Analysis

It is well known that beer fermentation has: i) initial

lag phase where the yeast initiates its metabolism for

budding; ii) exponential phase, where the yeast repro-

duces at high rates increasing biomass and metabo-

lites such as alcohol and CO

2

; and iii) floculation -

when the yeast forms colonies that are became denser

than the wort and start to flocculate; and iv) decrease

in metabolic activity. As the physical-chemical com-

position was followed, it is possible to performa qual-

itative spectral analysis to these important steps, iden-

tifying important spectral zones which correspond

to characteristic absorbance bands. Such allows to

comment on qualitative increases and decreases on

groups of compounds which are formed or degraded

during fermentation, providing information about the

wavelengths and the corresponding compounds that

are suffering transformations over the process time

(Ozaki et al., 2001).

2.4.3 Multivariate Regression Methods

Partial least squares regression (PLSR) is a multivari-

ate regression method, which is used to relate multi-

variate data set X to a reference value y (Wold et al.,

1983; Geladi and Kowalsky, 1986; Martens and Naes,

1989):

y = X· b+ e (1)

where, b represents the regression coefficient and

e the error. Typically, X is a low-cost and high-output

multivariate method, such as UV-VIS-SWNIR mea-

surements, whereas y are often time-consuming and

expensive reference methods, such as metabolomic

data. The overall purpose of PLSR is to interpret the

relationship between the two data sets, and being able

to predict y in order to use spectroscopy as a soft-

ware sensor. Partial least squares regression (PLSR)

is a well established regression methodology apply-

ing least squares regression on a small number of or-

thogonalfactors (the scores or latent variables) if both

dependent (Y) and independent (X) variables. PLSR

algorithms maximize the covariance between Y and

X (cov(Y,X)) (Denham, 1995; Denham, 1997; Jong,

2003). PLSR can cope with the non-linear features

of spectra, because regression is performed in the la-

tent variables obtained by orthogonal decomposition

of both dependent and independent data sets (Geladi

and Kowalsky, 1988).

In order to avoid over-fitting, the number of se-

lected PLS factors was performed by using cross val-

idation on the n-1 blocks (90% of data), and tested

on the remaining block (10% of total data) the to cal-

culate the predicted sum of squares criteria (PRESS).

PRESS is obtained by

∑

n

i=1

Y

j

−

ˆ

Y

j

2

; where Y

j

is

the data left-over from the original dataset after sub-

tracting validation sample i, and

ˆ

Y

j

the model predic-

tion for the j sample, so that it is possible to derive

for each model the PRESS criteria statistical distribu-

tion and select the minimum number of PLS factors.

By performing The PLSR confidence intervals were

thereafter determined according to Denham (1997),

and the limit of quantification was assumed ten times

the regression standard error (SE). All statistical com-

puting analysis were performed using R (R-Project,

2008)

BIOSIGNALS 2009 - International Conference on Bio-inspired Systems and Signal Processing

330

3 RESULTS AND DISCUSSION

3.1 Qualitative Analysis

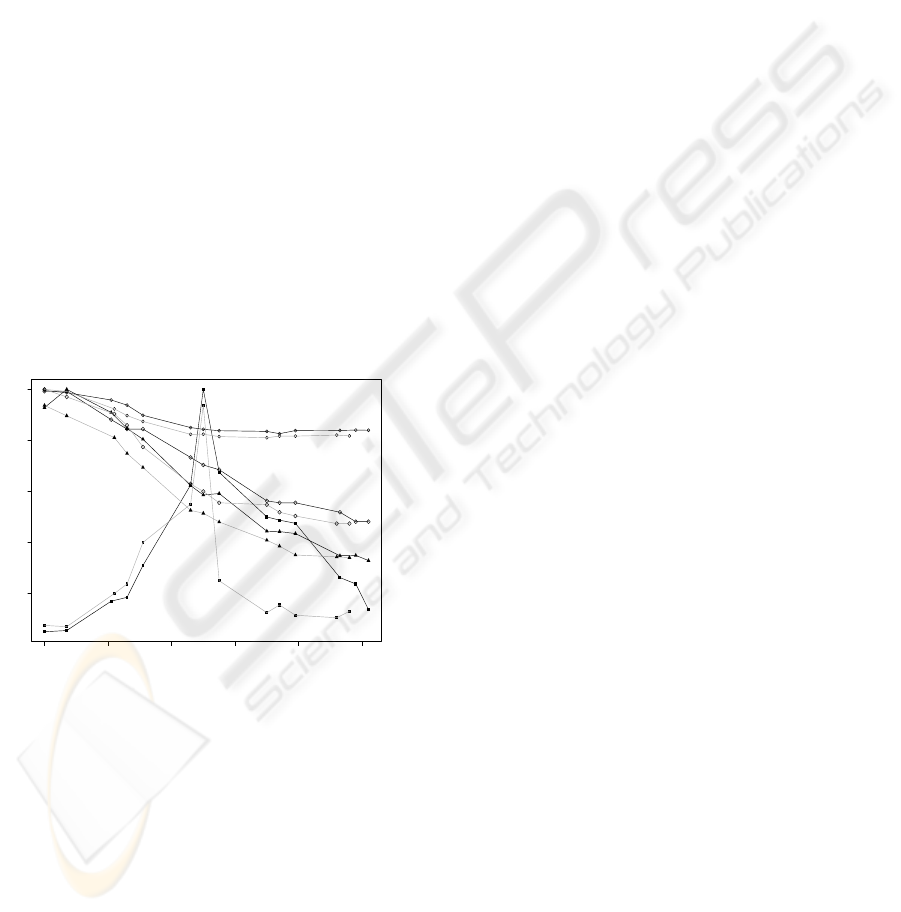

For each fermentation sample it were determined: i)

number of yeast cells; ii) Extract; iii) Sugar weight

percentage in solution; and iv) pH. This results are

shown on Figure 3. In the first 7h, after yeast addi-

tion, the lag phase occurs and a rapid absorption of

the oxygen contained in the wort occurs. Therefore,

a significant decrease in pH and absorption of free

amino nitrogen, indicating the adjustment of the yeast

to the nutrient medium. Followed by an exponential

growth phase with rapid decrease in medium density,

abundant consumption of wort sugars and consequent

abundant production of alcohol,marked fall in pH and

nitrogen absorption of the wort. After 50h yeast floc-

culation occurs, greatly decreasing the ethanol pro-

duction as the nitrogen source also begins to scare.

This phase continues until the end of the fermenta-

tion, whereby sugar consumption begins to decrease

until it stabilizes at the 3rdday of fermentation. At the

end of fermentation pH is about 3.7, the sugar weight

percentagefalls 50% to (from 13.4% to 6.5%) and dry

extract the value of 0.05g/ml.

0 20 40 60 80 100

0.2 0.4 0.6 0.8 1.0

Time (h)

Normalized Concentration

Figure 3: Normalized chemical data over the fermentation

time ( Biomass x 2x10

8

cells/ml of wort; N Extract x

0.1382 g/ml of wort, ◦ pH; and ♦ sugar weight percentage

in the wort x 13.5). Black lines represents Fermentation 1;

and grey lines represents Fermentation 2.

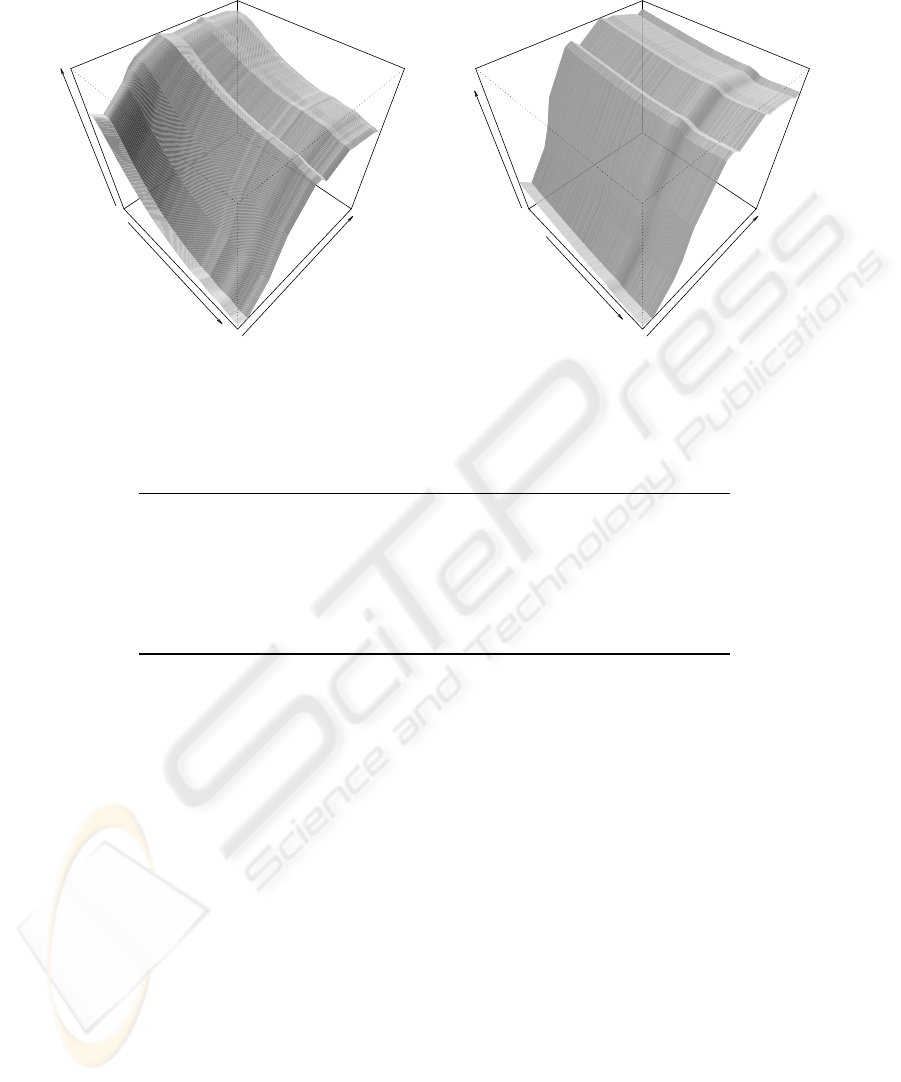

The construction of a three-dimension graph of

UV-VIS and VIS-SWNIR spectra (Figure 4) allows

to observe that the previous phases described on the

chemical results is discriminated in the spectra. We

observed that there is high similarity between the

VIS-NIR and UV-VIS surfaces in both fermentations,

which is an indication of good process reproducibil-

ity. In each graph of Figure 4 we flagged the spec-

tra with letters from “a” to “n” as being the different

sampling times for better qualitative spectra interpre-

tation.

The confrontation of Figure 4 information with

the data contained on Figure 3 makes possible observe

that: “a” corresponds to the fermentation start; from

“a” to “b” there is a stabilization in both absorbance

spectra indicating that lag phase is taking place; “b”

to “g” corresponds to the exponential growth of the

yeast, in this phase organic acids are produced and

buffering compounds (basic amino acids and primary

phosphates) are consumed, this phenomenon is ob-

served in Figure 4 by an increase of the spectra ab-

sorbance; “g” point corresponds to the maximum

number of yeast cells and to a peak in all 3D graphs;

from point “g” to “n” the number of yeast cells de-

crease, which leads to a decrease of number of reac-

tions, leading to a metabolic modification in the pro-

cess, this is perfectly identified in both 3D graphs of

Figure 4.

Although the different stages of beer process be-

ing well identified in both spectra regions, the UV-

VIS and the VIS-SWNIR regions are quite different

on its behavior. On the lag phase (points “a”-“b”) the

UV-VIS spectra have a slope in the absorbance, in UV

wavelengths the absorbance is more high than VIS re-

gion; while VIS-SWNIR spectra its all on its mini-

mum absorbance. Once started the exponential phase

(from point “b” to “g”) the absorbance increases in

different proportions until achieve a similar level in

all wavelengths; In the same phase the VIS-SWNIR

spectra suffer a large increase in all wavelengths un-

til its maximum spectra (point “g”) where the fer-

mentation reaches the flocculation point; The follow-

ing spectra (“h”) suffers a decrease in the absorbance

for both spectra regions (UV-VIS and VIS-SWNIR).

Then the spectra absorbanceincrease againuntil point

“i” reaching the absorbance peak, after this the ab-

sorbance stabilizes in the next four points (“j”, “k”,

“l” and “m”) for the entire region under study (UV-

VIS and VIS-SWNIR); The end of the fermentation

is identified in both spectra by a decrease in the last

point (“n”) absorbance. This analysis show that UV

region can be a very important region for the charac-

terization of the compounds that are changing along

the fermentation, once that is the region where the

absorbance have more difference between the wave-

lengths over the time.

3.2 Multivariate Calibrations

Beer wort is highly dispersive and scattering artifacts

are significant. The undesired scattering occurs be-

cause of the particles in wort and accumulation of

solids in the dip probe. Light scattering does not

IN-SITU, REAL-TIME BIOREACTOR MONITORING BY FIBER OPTICS SENSORS

331

Wavenumber

Time

Absorbance

a

b

c

d

e

f

g

h

i

j

k

l

m

n

(a)

Wavenumber

Time

Absorbance

a

b

c

d

e

f

g

h

i

j

k

l

m

n

(b)

Figure 4: Spectra evolution during fermentation: (a) UV-VIS and (b) VIS-SWNIR; where: a - 0 hrs; b - 7 hrs; c - 21 hrs; d -

26 hrs; e - 31 hrs; f - 46 hrs; g - 50 hrs; h - 55 hrs; i - 70 hrs; j - 74 hrs; k - 79 hrs; l - 93 hrs; m - 98 hrs; and m 102 hrs.

Table 1: Partial least squares regression model estimates for both fermentations UV-VIS spectra.

PLS-1 Model Data Variance (%) PRESS R

2

Err

Number of yeast cells X-block 89.34 3.7478x10

16

0.9471 1.1782x10

7

(nPC=15) Y-block 98.47

Extract X-block 79.24 3.4708x10

−2

0.8632 1.3380x10

−2

(nPC=10) Y-block 92.31

pH X-block 72.58 3.2430 0.8539 0.1095

(nPC=10) Y-block 92.62

Sugars weight percentage X-block 79.52 235.4118 0.8565 0.9337

(nPC=10) Y-block 92.27

(a)

Limit of quantification = 10 x Err (10:1 Signal to noise ratio)

affect the the chemical information contained in the

spectra. Neverthenless, if not corrected, it influences

the interpretation of the SVD and microorganisms

classification. Scattering is mostly of multiplicative

matter (Gallager et al., 2005), and the robust mean

scattering correction (RMSC) was able to minimize

this effect. Direct comparison of the corrected spectra

(figure not shown) leads to the conclusion that scat-

tering is obtained in both light sources evenly spread

over all wavelengths. As the absorbance has an ex-

tremely high variation when compared to the scatter-

ing effect, it expected that scattering even if not cor-

rected totally, will not significantly influence most of

PLS regressions. Such observation gives a good indi-

cation for fiber optics sensors robustness, which may

work in very difficult conditionsof bioprocesses, such

as in this case with high particle densities and cellular

concentrations.

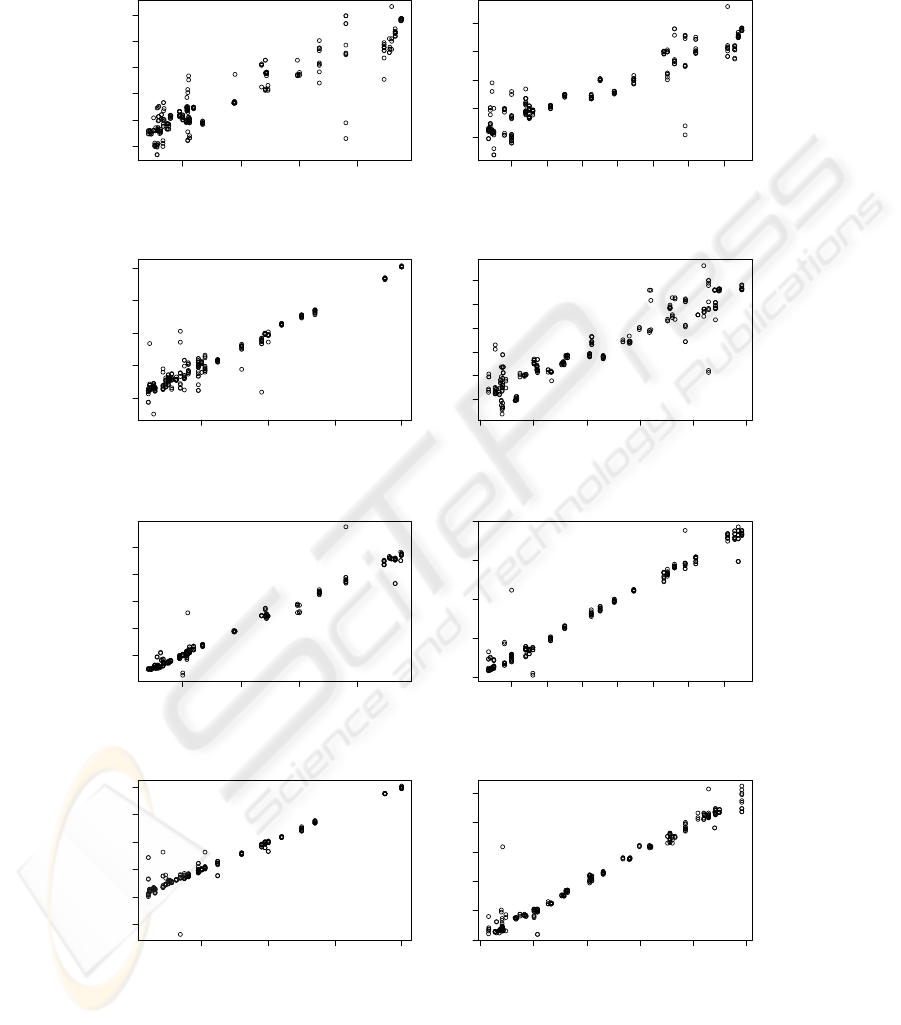

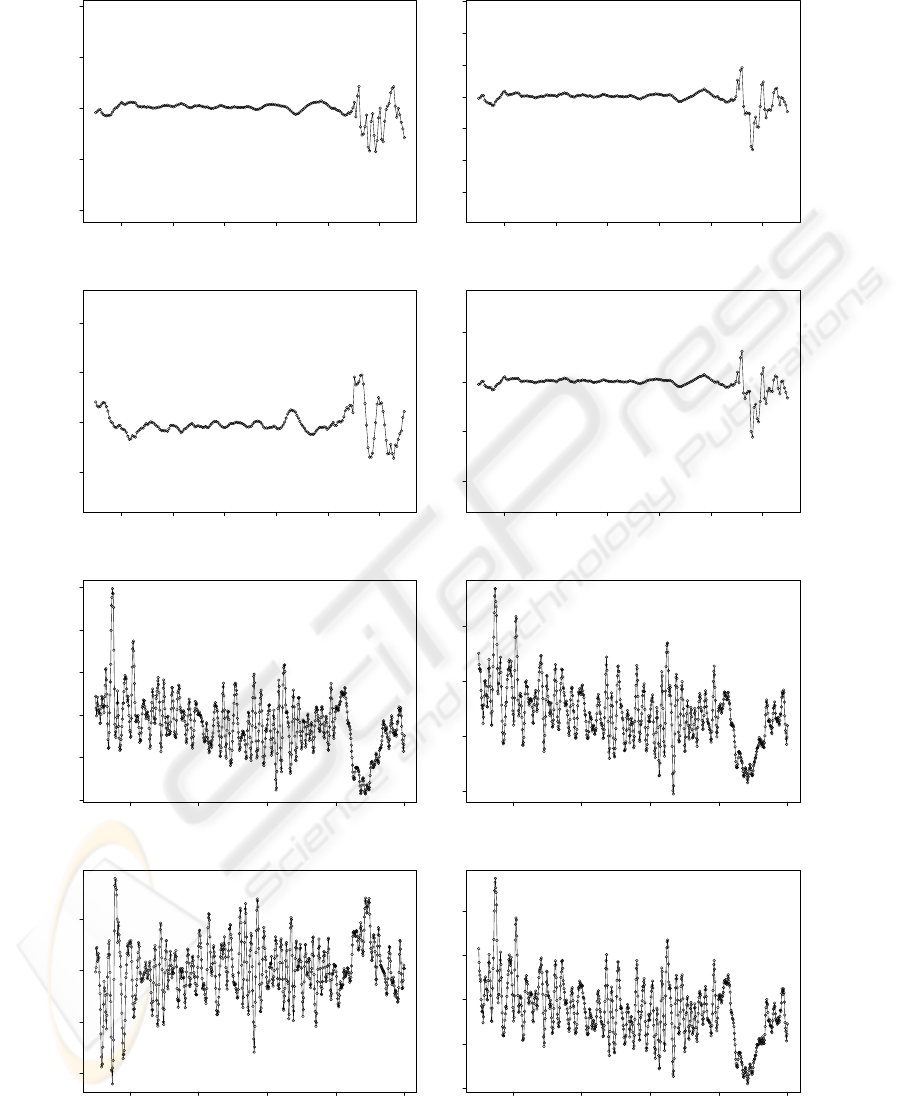

PLS regression results are presented in Tables 1

and 2 and calibrations are presented in Figure 5. Cal-

ibrations were obtained using the 2nd derivate which

allows the direct background and baseline correction.

A direct comparison of the R

2

allows to conclude that

VIS-NIR calibrations are better than the calibrations

in UV-VIS spectra; all VIS-NIR calibrations have R

2

≥ 0.95 and only need ≃ 58% of X-block variance

to explain 99% of Y-block variance; while all UV-

VIS calibrations have R

2

≤ 0.95 and need at least

79% of X-block variance to explain 92% of Y-block

variance. Furthermore, VIS-SWNIR have lower de-

tection limits for the studied parameters than with

the UV-VIS wavelengths, especially for dry extract,

pH and total sugars. Nevertheless, interesting detec-

tion limits are observed for all the studied parame-

ters: i) cell density: UV-VIS (1.1782x10

8

cells/ml)

and VIS-SWNIR (1.0259x10

8

cells/ml); ii) dry ex-

tract: UV-VIS (1.3380x10

−1

g/ml) and VIS-SWNIR

(4.8024x10

−2

g/ml); iii) pH: UV-VIS (1.095) and

VIS-SWNIR (0.416); and iv) total sugars UV-VIS

(9.337 % w/w) and VIS-SWNIR (3.565 % w/w).

Furthermore, VIS-SWNIR wavelengths allowed

to obtain robust calibrations with less numberof spec-

tral decompositions. In all UV-VIS PLS regressions

were obtained with 10 to 15 factors, where as, VIS-

BIOSIGNALS 2009 - International Conference on Bio-inspired Systems and Signal Processing

332

3.8 4.0 4.2 4.4

3.6 3.8 4.0 4.2 4.4 4.6

(a)

measured

predicted

7 8 9 10 11 12 13

6 8 10 12 14

(b)

measured

predicted

5.0e+07 1.0e+08 1.5e+08 2.0e+08

0.0e+00 1.0e+08 2.0e+08

(c)

measured

predicted

0.04 0.06 0.08 0.10 0.12 0.14

0.04 0.08 0.12

(d)

measured

predicted

3.8 4.0 4.2 4.4

3.8 4.0 4.2 4.4 4.6

(e)

measured

predicted

7 8 9 10 11 12 13

6 8 10 12 14

(f)

measured

predicted

5.0e+07 1.0e+08 1.5e+08 2.0e+08

−5.0e+07 5.0e+07 1.5e+08

(g)

measured

predicted

0.04 0.06 0.08 0.10 0.12 0.14

0.04 0.06 0.08 0.10 0.12 0.14

(h)

measured

predicted

Figure 5: PLS-R Calibrations for UV-VIS: (a) pH; (b) sugar weight percentage; (c) Biomass; (d) extract; and for VIS-SWNIR:

(e) pH; (f) sugar weight percentage; (g) Biomass; (h) extract.

IN-SITU, REAL-TIME BIOREACTOR MONITORING BY FIBER OPTICS SENSORS

333

360 380 400 420 440 460

−400 −200 0 200 400

(a)

Wavelenghts (nm)

Coefficients

360 380 400 420 440 460

−3000 −2000 −1000 0 1000 2000 3000

(b)

Wavelenghts (nm)

Coefficients

360 380 400 420 440 460

−2e+10 0e+00 2e+10 4e+10

(c)

Wavelenghts (nm)

Coefficients

360 380 400 420 440 460

−40 −20 0 20

(d)

Wavelenghts (nm)

Coefficients

600 700 800 900 1000

0.0 0.5 1.0 1.5 2.0 2.5

(e)

Wavelenghts (nm)

Coefficients

600 700 800 900 1000

0 5 10 15

(f)

Wavelenghts (nm)

Coefficients

600 700 800 900 1000

−3e+08 −2e+08 −1e+08 0e+00

(g)

Wavelenghts (nm)

Coefficients

600 700 800 900 1000

0.00 0.05 0.10 0.15 0.20

(h)

Wavelenghts (nm)

Coefficients

Figure 6: PLS-R Coefficients for UV-VIS: (a) pH; (b) Sugar weight percentage; (c) Number of yeast cells; (d) Extract; and

for VIS-SWNIR: (e) pH; (f) Weight sugar percentage; (g) Number of yeast cells; (h) Extract.

BIOSIGNALS 2009 - International Conference on Bio-inspired Systems and Signal Processing

334

Table 2: Partial least squares regression model estimates for both fermentations VIS-SWNIR spectra.

PLS-1 Model Data Variance (%) PRESS R

2

Err

Number of yeast cells X-block 58.63 2.8417x10

16

0.9599 1.0259x10

7

(nPC=8) Y-block 99.51

Extract X-block 58.46 6.2269x10

−3

0.9755 4.8024x10

−3

(nPC=8) Y-block 99.48

pH X-block 58.43 0.4675 0.9789 0.0416

(nPC=8) Y-block 99.63

Sugars weight percentage X-block 58.49 34.3200 0.9790 0.3565

(nPC=8) Y-block 99.61

(a)

Limit of quantification = 10 x Err (10:1 Signal to noise ratio)

SWNIR region were obtained with 8. Such discrep-

ancy is not yet fully explainable, being only possi-

ble to affirm so far that perhaps the UV-VIS region

may contain less information correlated to the stud-

ied parameters. This is not an indication that this re-

gion has less information than the VIS-SWNIR re-

gion, because absorbance in this region may be more

well correlated with other chemical and biochemical

compounds. Figure 6 presents the coefficients in the

1st spectral decomposition during PLSR. It is observ-

able that the UV-VIS coefficients present higher auto-

correlation than the VIS-SWNIR coefficients. Fur-

thermore, for all the studied parameters the UV-VIS

region presents the highest coefficients in the region

of 420 to 480 nm. Interpretation in this region is how-

ever not straight forward, because coefficients present

high fluctuations, not being possible to interpret a

well defined peak. In the VIS-SWNIR region most of

the coefficients are high for biomass, increasing from

600nm to 1000nm and showing a peak at 900nm. The

contrary is observed for the rest of the studied pa-

rameters, where all the coefficients decrease with the

wavelength, with a lower peak at 900nm. Therefore,

one can conclude that higher absorbancies are gener-

ally correlated with higher biomass, with special rel-

evance in the SWNIR region. High absorbances in

this region is correlated with lower sugar, pH and dry

extract concentrations.

3.3 Conclusions

This exploratory research shows the feasibility of UV-

VIS and VIS-SWNIR spectroscopy for monitoring

bioprocesses. Nevertheless, both experimental and

signal processing techniques can be improved to take

advantage of the high-output information containedin

the UV-VIS-SWNIR spectra.

Improvements on the experimental methodology can

improve the quality of bioreactor monitoring in the

studied region of the spectra. For example, a better

location inside the bioreactor can be found to place

the probe, or the use of an attenuated total reflec-

tion probes can improve the signal quality in high-

density wort or high number of yeast cells. Further-

more, the measurementof moredetailed chemical and

biochemical composition of the wort during fermen-

tation, may help in the future the development of pre-

cision fermentation monitoring and control systems.

The data pre-treatment successfully remove the small

noise and scattering artifacts present in the spectra;

being possible to achieve high-quality and resolution

in the final spectra before signal treatment. Improve-

ments also should be performed in order to better un-

derstand the relationship between the chemical com-

position and the information contained in the spectra.

Methods such as the combination of the two spec-

tral regions using with n-way and multiblock PLS-R

(e.g. UV-VIS + VIS-SWNIR spectra) as well as using

wavelets or Fourier transformate for compressing and

modelling the spectra may provide better interpreta-

tion of spectra variance during bioprocesses.

In the near future, these improvements on both

experimental and data treatment may turn UV-

VIS-SWNIR a feasible technique for high-output

metabolomic studies and monitoring of Bioprocesses.

ACKNOWLEDGEMENTS

Part of this work was supported by the project Open-

MicroBio (PTDC/BIO/69310/2006) - ’A Framework

for Computational Simulation of Cellular Commu-

nities during BioProcess Engineering’; and partially

supported by CBMA, IBB/CEB and ISR/IST pluri-

anual funds through the POS-Conhecimento Program

that includes FEDER funds.

REFERENCES

Alison, A., John, C., Seetharaman, V., Liliana, M., and

Pankaj, M. (2000). At-line monitoring of a submerged

filamentous bacterial cultivation using near-infrared

spectroscopy. volume 27. Enzyme and microbial tech-

nology.

IN-SITU, REAL-TIME BIOREACTOR MONITORING BY FIBER OPTICS SENSORS

335

Avantes (2005). Avaspec-2048-4-dt/-rm.

http://www.avantes.com.

Avantes (2007). Avasoft 7.0. http://www.avantes.com.

Bruice, P. Y. (2006). Organic Chemestry: Study Guide and

Solutions Manual. Prentice Hall, 5 edition.

Cooper, J., Wise, K., Welch, W., Sumner, M., Wilt, B., and

Bledsoe, R. (1997). Comparison of near-ir, raman, and

mid-ir spectroscopies for the determination of btex in

petroleum fuels. volume 51. Applied Spectroscopy.

Denham, M. (1995). Implementing partial least squares.

5:191–202.

Denham, M. (1997). Prediction intervals in partial least

squares. 11:39–52.

Faust, C. (1992). Near-infrared spectroscopy for bioprocess

monitoring and control. Royal Society of Chemistry.

Gallager, N. B., Blake, T., and Gassman, P. (2005). Ap-

plication of extended inverse scattering correction to

mid-infrared reflectance of soil. 19:271–281.

Geladi, P. and Kowalsky, B. (1986). Partial least-squares

regression a tutorial. volume 185. Analytica Chimica

Acta.

Geladi, P. and Kowalsky, B. (1988). Partial least squares

regression: a tuturial. 185:1–17.

Jong, S. (2003). Simpls: an alternative approach to partial

least squares regression. volume 18. Chemometrics

and Intelligent Laboratory Systems.

Majara, M., Mochaba, F. M., O’connor-cox, E. S. C., Ax-

cell, B. C., and Alexander, A. (1998). Yeast pro-

tein measurement using near infrared reflectance spec-

troscopy. volume 104, 143-146. Journal of the Insti-

tute of Brewing.

Martens, H. and Naes, T. (1989). Multivariate calibration.

Wiley.

Martens, H., Nielsen, J. P., and Engelsen, S. B. (2003).

Light scattering and light absorbance separated by ex-

tended multiplicative signal correction. application to

near-infrared transmission analysis of powder mix-

tures. In Analytical Chemistry 75(9): 394-404. Amer-

ican Chemical Society.

Martens, H. and Stark, E. (1991). Extended multiplicative

signal correction and spectral interference subtraction:

new preprocessing methods for near infrared spec-

troscopy. In Journal of Pharmaceutical and Biomedi-

cal Analysis 9: 625-635. American Chemical Society.

Metrohm (2008). Metrohm 691 ph meter.

http://www.metrohm.com/.

Ocean-Optics (2008). Ocean optics catalog.

http://www.oceanoptics.com.

Ozaki, Y., Sasic, S., and Jiang, J. (2001). How can we

unravel complicated near infrared spectra? - recent

progress in spectral analysis methods for resolution

enhancement and band assignments in the near in-

frared region. Journal of Infrared Spectroscopy, 9:63–

95.

R-Project (2008). R: A programming environment for data

analysis and graphics. URL: http://www.r-project.org.

Rhiel, M., Cohen, M., Murhammer, D., and Arnold, M.

(2002). Nondestructive near-infrared spectroscopic

measurement of multiple analytes in undiluted sam-

ples of serum-based cell culture media. volume 77.

Biotechnology and Bioengineering.

Schemidt-haensch (2008). Ar12 schmidt+haensch

abbe refractometer. http://www.schmidt-

haensch.com/products.html?L=1.

Schugerl, K. (2001). Progress in monitoring, modeling and

control of bioprocesses during the last 20 years. vol-

ume 85, 149-173. Journal of Biotechnology.

Sigma (2008). Sigma 4k15 centrifuge. http://www.sigma-

zentrifugen.de.

Stavitzky, A. and Golay, M. J. E. (1964). Smoothing

and differentiation of data by simplified least squares

procuderes. Analytical Chemistry 36(8): 1627-1639.

Stuart, B. (1997). Biological applications of infrared spec-

troscopy. University of Greenwich, UK. John Wiley

& Sons, Ltd.

Wold, S., Martens, H., and Wold, H. (1983). The multivari-

ate calibration-problem in chemistry solved by the pls

method. volume 973. Lecture Notes in Mathematics.

Workman, J. (1993). A review of process near infrared spec-

troscopy: 1980-1994. pages 221–225. Journal Near

Infrared Spectroscopy.

Yano, T., Aimi, T., Nakano, Y., and Tamai, P. (1997). Pre-

diction of the concentrations of ethanol and acetic acid

in the culture broth of a rice vinegar fermentation us-

ing near-infrared spectroscopy. volume 84. Journal of

Fermentation and Bioengineering.

Yeung, K., Hoare, M., Thornhill, N., Williams, T., and

Vaghjiani, J. (1999). Near-infrared spectroscopy

for bioprocess monitoring and control. volume 63.

Biotechnology and Bioengineering.

BIOSIGNALS 2009 - International Conference on Bio-inspired Systems and Signal Processing

336