ACOUSTIC THERMOAGITATION BASED ON PIEZOELECTRIC

β-PVDF POLYMER FILMS

Potential Evaluation in Lab-on-a-Chip Applications

V. F. Cardoso,

G. Minas

University of Minho, Department of Industrial Electronics, Campus de Azurém, 4800-058, Guimarães, Portugal

P. Martins, J. Serrado Nunes,

L. Rebouta, S. Lanceros-Méndez

University of Minho, Department of Physics, Campus de Gualtar, 4710-057, Braga, Portugal

G. Botelho

University of Minho, Department of Chemistry, Campus de Gualtar, 4710-057, Braga, Portugal

Keywords: Lab-on-a-chip, PVDF, Acoustic thermoagitation.

Abstract: This paper describes a lab-on-a-chip device with acoustic thermoagitation based on a piezoelectric β-PVDF

polymer. The device is used for testing and monitoring biochemical parameters in biological fluids using

optical absorption spectrophotometry. Experimental results regarding the influence of the electrical signal

amplitude and frequency applied for the generation of acoustic thermoagitation is presented. The individual

contribution of the heating and the microagitation provided by the actuation of the piezoelectric film for the

fluids mixture was determined. The paper is completed with a study of the β-PVDF degradation with

transparent conductive electrodes, ITO and AZO, when placed in contact with uric acid fluids. The final

goal of using this technique is the improvement of mixing and reaction time without interfering with

biochemical reactions and analytical measurements.

1 INTRODUCTION

For the development of a lab-on-a-chip device for

fluidic analysis, the microfluidics technologies have

been a vital tool allowing the fabrication of precise

and small structures. The huge interest in these

technologies is inherent to the performance

achieved: reduction on the sample quantity, high

integration and consequently high potential for

fluids automation and control in sub-microliter

volumes, decrease of response time, reduction of

chemical quantities stored and a large reduction in

total costs (Auroux et. al, 2002).

Lab-on-a-chip devices can perform several

analyses simultaneously. In order to get in-loco,

quick and reliable results, they need an automatic

system for microfluids control, which can cover all

the steps of a chemical or biological process.

Usually, a bio(chemical) process needs the

mixture of fluids. For that, devices based in MEMS

(Micro Electro Mechanical Systems) such as

micropumps (Reyes et. al, 2002) and microvalves

(Rife et. al, 2000) are used, but they increase the

device cost, need complex control systems and their

integration is complex. The mixture of the fluids

using just diffusion avoids these disadvantages.

However, when large molecules with small

diffusivities take part in the reaction, it is needed

high transit times of the molecules on the channels

and consequently long channels (Ottino et. al, 2004).

To overcome this high transit times, it is necessary

to develop alternative methods for improving

mixture.

The use of acoustic waves is an interesting

solution and it is one of the main issues of this

present work. The acoustics waves traveling inside

the fluid create differential pressures and induce the

so called acoustic propagation. For occurring the

394

F. Cardoso V., Minas G., Martins P., Serrado Nunes J., Rebouta L., Lanceros-Méndez S. and Botelho G. (2009).

ACOUSTIC THERMOAGITATION BASED ON PIEZOELECTRIC β-PVDF POLYMER FILMS - Potential Evaluation in Lab-on-a-Chip Applications.

In Proceedings of the International Conference on Biomedical Electronics and Devices, pages 394-397

DOI: 10.5220/0001546903940397

Copyright

c

SciTePress

acoustic microagitation of the fluids, the reaction

chamber must be coated with an electroactive

polymer. One example is the β-PVDF (Lanceros-

Mendez et. al, 2006), which the use for fluid

microagitation purposes is the main innovation of

this work. Applying an a.c. voltage to the contacts of

the piezoelectric β-PVDF film, it is produce

mechanical oscillations promoting the movement,

mixture and reaction of the fluids, as well the heat

generated by this technique, the so called acoustic

thermoagitation.

2 DEVICE DESCRIPTION

This paper describes the incorporation and

validation of an acoustic thermoagitator based on a

piezoelectric β-PVDF polymer in a fully-integrated

disposable lab-on-a-chip for point of care testing and

monitoring of biochemical parameters in biological

fluids. This lab-on-a-chip has interesting

characteristics such as portability, low-cost and

disposability. Furthermore, it has a completely

automatic operation and uses optical absorption

spectrophotometry as analytical measurement

technique.

2.1 Biosystem Operation

The lab-on-a-chip is composed by two dies: the

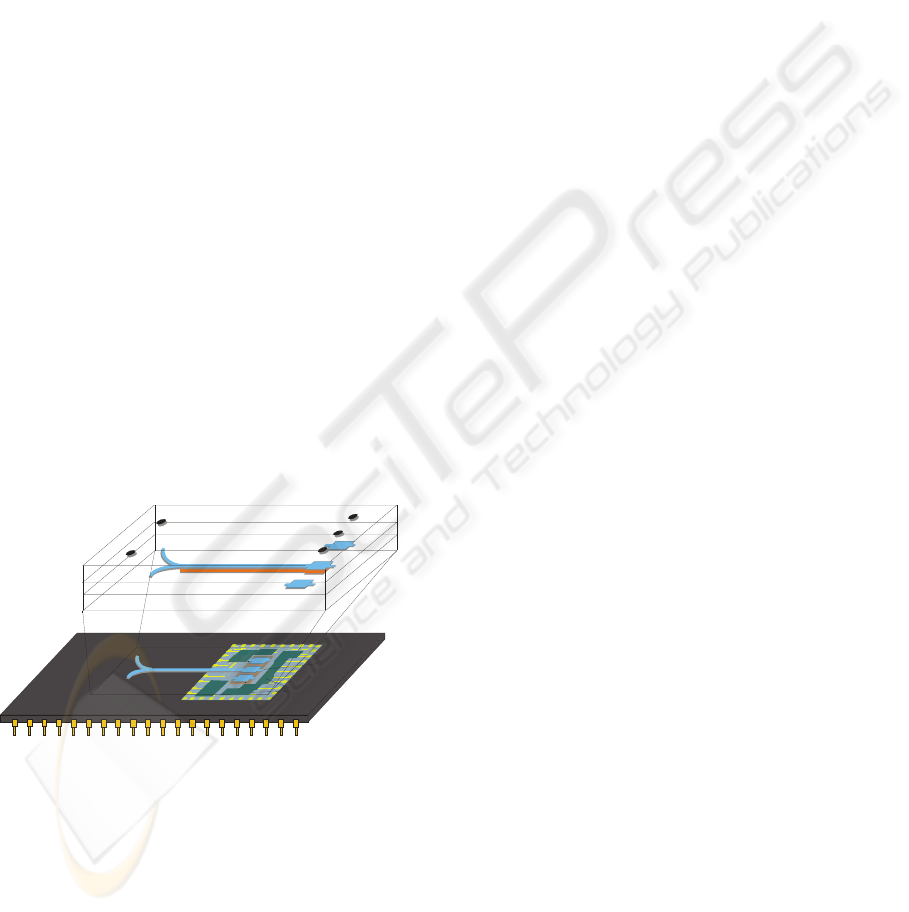

fluidic die and the detection die (Figure 1).

Figure 1: Schematic representation of the lab-on-a-chip

structure with the β-PVDF deposited underneath the

microfluidic structure.

The microfluidic die, fabricated in SU-8,

includes the microchannels and the reaction

chambers. Three reaction chambers are needed for

each analysis. One with a well-known concentration

sample of the biochemical parameter that is being

analysed, is used for the calibration of the device.

Other, for the mixture of the sample and the reagent

is needed, to perform the analysis of the coloured

mixed solution. Finally, a third one is used for the

chemical reagent in order to obtain the baseline

reference. Underneath the reaction chambers was

deposited the piezoelectric β-PVDF polymer with its

corresponding electrodes.

The detection die includes the photodetectors and

the electronic components for signal actuation and

detection, all fabricated in CMOS technology.

Above the photodetectors, there are several high-

selective band-pass optical filters, deposited by Ion

Beam Deposition, that select the wavelength

according to the several biomolecules into analysis.

This optical filtering system allows the use of non-

calibrated external polychromatic light source.

2.2 Analytical Measurement Technique

Among the several analytical techniques available in

laboratories of clinical analysis, the

spectrophotometry is the most used. However, this

technique cannot be used directly since a high

number of biomolecules for clinical analysis do not

have chromophores which absorb the light in the

visible spectra. In order to overcome this limitation,

several specific chemical reactions allow to

transform these biomolecules in colored products

which absorbency is within the visible light spectra -

colorimetric reactions.

In the ideal colorimetric analysis, the mixture

coloration intensity is proportional to the

concentration of the biochemical parameter and can

be quantified measuring the optical absorption of the

mixture (reagent + biomolecule) at a specific

wavelength (Thomas, 1999).

2.3 Acoustic Streaming

The acoustic streaming is a steady flow generated by

the propagation of acoustic waves in a viscous fluid.

It arises from the transfer of momentum and energy

of the acoustic field to the medium, through its

acoustic attenuation.

Acoustic streaming offers several distinct

advantages for application in microfluidic devices

(Frampton et. al, 2004). In this work, the acoustic

streaming is due to the absorption of the acoustic

energy in the fluid itself. This absorption results in a

radiation pressure in the direction of the acoustic

propagation and is termed by quartz wind.

Quartz wind velocity and effective pressure are

limited by the heating and cavitation tolerance. A

small fraction of the incident acoustic energy goes

into kinetic energy of the fluid and the rest is

transformed into heat. In this way, the acoustic

thermoagitation generated by this effect becomes

Chip

Optical filters and

Photodetectors

Electronics

β−PVDF

Reagent

Mixture

Calibrator

Reagent

Sample

Glass

Glass

SU-8

ACOUSTIC THERMOAGITATION BASED ON PIEZOELECTRIC ß-PVDF POLYMER FILMS - Potential Evaluation

in Lab-on-a-Chip Applications

395

advantageous, once in some applications or

reactions, the increase of temperature is beneficial in

order to reduce the mixture time (Rife et. al, 2000).

2.4 Poly(vinylidene fluoride)

Nowadays, with the rapid development of polymer

processing methods and synthetic technology, the

industrial materials used in various manufacturing

fields are being substituted by polymer substances,

which have better properties than those of materials

previously used in many industrial areas. One of the

polymer that has received increased attention is the

poly(vinylidene fluoride), also known as PVDF. It

shows an unusual polymorphism in this class of

materials, showing four different crystalline phases.

From the technology point of view, the β-phase is

the one which shows better properties to be applied

in sensors, actuators and transducers, due to its

higher piezo- piro- and ferroelectric properties.

Moreover, it shows an excellent combination of

processability, chemical agent resistance, lightness,

moldability and low-cost production. While ceramic

materials break easily and have hard and dense

structures, PVDF is flexible, has a low density and

can be easily produced into thin-films (Brown,

1992). This polymer also shows low acoustic and

mechanical impedance (Foster, 2000) crucial for

generating the acoustic waves that produce the

thermoagitation of the fluids, as is the purpose of

this study. Another interesting feature of the PVDF

is its transparency. Indeed, in the case of this

application, the analytical measurement by

spectrophotometry requires that the PVDF and the

corresponding conductive electrodes, deposited in

the reaction chamber, are transparent to visible light.

3 EXPERIMENTAL RESULTS

3.1 Acoustic Thermoagitation

The quantitative evaluation of the mixing process

was carried out using the Far Diagnostic kit and

standards of urine with 5 mg/dl of uric acid

concentration. The reagent reacts with the sample of

urine containing uric acid in a 40:1 ratio with a

maximum absorption at 550 nm.

The acoustic thermoagitation was studied for

various frequencies and amplitudes of the electrical

signal applied to the electrical contacts of a 110 μm

thick β-PVDF film. The system was calibrated and

the reaction was studied up to a maximum time of

20 minutes, which is the time of the complete

mixture without thermoagitation.

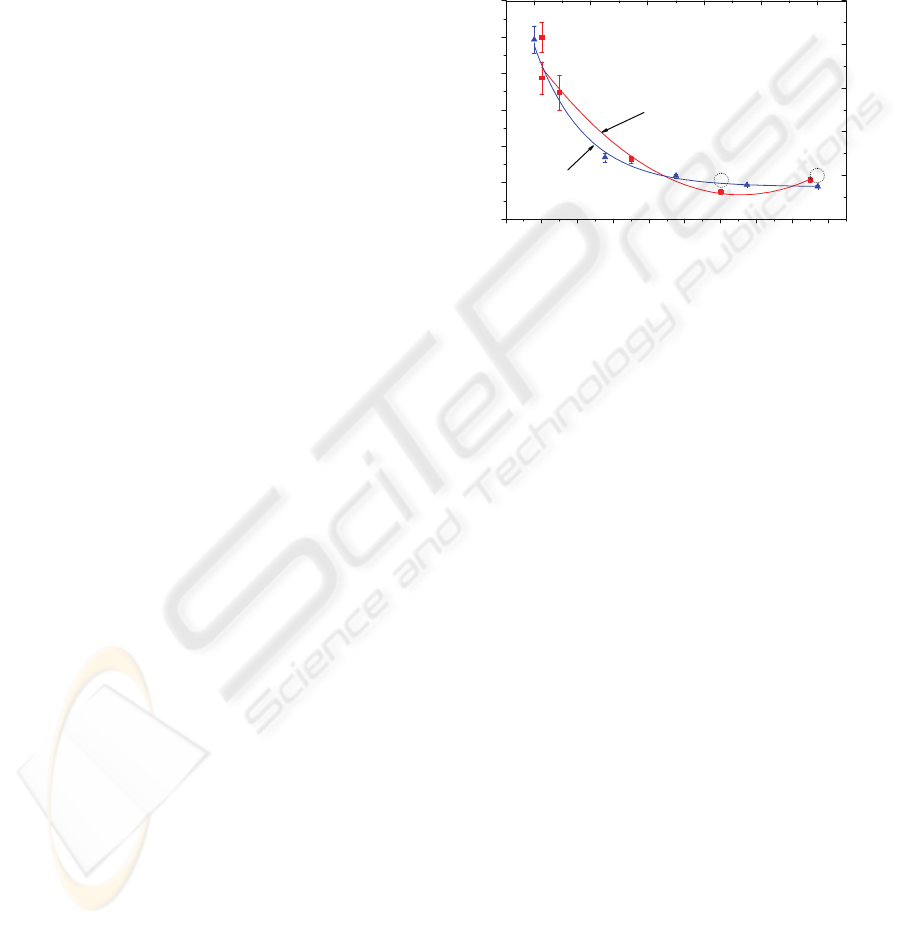

The thermoagitation was performed powering

the β-PVDF, with a sinusoidal signal of 10 V

amplitude at different frequencies. After, a 10 MHz

frequency sinusoidal signal with various amplitudes

was applied. They results were processed to obtain

the results shown in Figure 2.

-2000 0 2000 4000 6000 8000 10000 12000 14000 16000

200

400

600

800

1000

1200

1400

Frequency signal

Mixture Time (s)

Frequency signal (kHz)

0246810

Amplitude signal

Amplitude signal (V)

Figure 2: Mixing time as a function of the frequency and

amplitude of the signal applied to the electrical contacts of

a 110 μm thick β-PVDF film.

It can be observed that with the application of

thermoagitation, the mixing occur in a faster way,

being the time necessary to obtain the complete

mixing, at 10 V amplitude and 10 MHz, only two

sevenths (351 s) of the complete mixing time

without thermoagitation (1200 s). In this way, the

resonance frequency of the used β-PVDF film

(10 MHz) is the most efficient for the generation of

thermoagitation. This result is consistent with the

theory (Eiras, 2007). On the other hand, the mixing

time decreases as the signal amplitude increases.

According to previous results, it was determined

the individual contribution of the agitation and the

heating generated by the use of this acoustic

thermoagitation technique. For that, the temperature

profile of the sample was measured applying an

electrical signal of 10 V amplitude and 10 MHz to

the β-PVDF film. Then, the sample was heated with

the same temperature profile obtained before with

the thermoagitation, using a temperature controller

(SHIMADZU TCC-260). It was observed that, for

the two sevenths in terms of gains achieved by the

application of the acoustic thermoagitation

technique, three-fifths are due to heating and two

fifths to agitation.

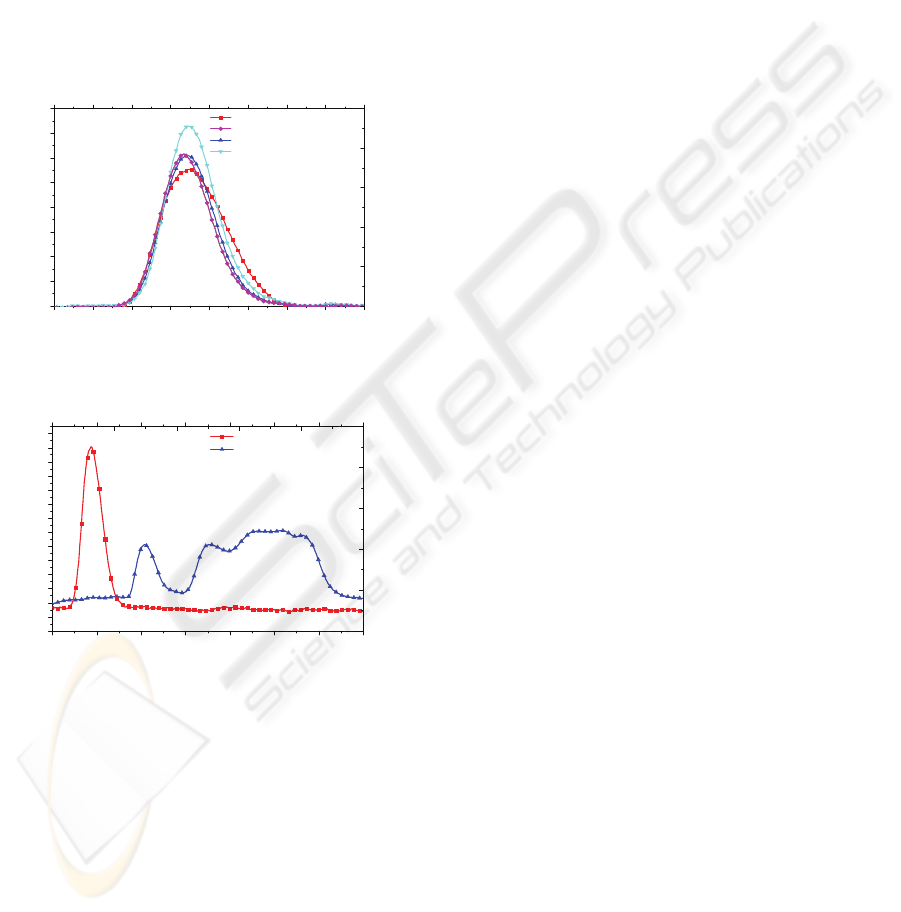

3.2 Transducer Degradation

As the first application of the present lab-on-a- chip

will be for measurement of uric acid concentrations,

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

396

a degradation study (using a high-performance

liquid chromatograph model 875 from Jasco) of the

110 μm β-PVDF film with ITO (Indium Tin Oxide)

and AZO (Aluminium doped Zinc Oxide)

electrodes, when placed in contact with the

biological fluids, was performed. The study was

done with the Far Diagnostic kit of uric acid,

described previously. The chemical reaction was

performed with and without acoustic

thermoagitation during 20 minutes. The

thermoagitation was set using an electrical signal at

10 V amplitude and 10 MHz. The results shown in

Figures 3 and 4 are representative for not degraded

and degraded electrodes, respectively.

2.00 2.05 2.10 2.15 2.20 2.25 2.30 2.35 2.40

0

2

4

6

8

10

12

14

16

Intensity (a.u.)

Time (s)

Allantoin

AZO without thermoagitation

ITO without thermoagitation

ITO with thermoagitation

Figure 3: Chromatogram of the samples that did not

suffered degradation with a reaction time of 20 min.

2.0 2.2 2.4 2.6 2.8 3.0 3.2 3.4

-2

-1

0

1

2

3

4

5

6

7

8

9

10

11

12

Allantoin

AZO with thermoagitation

Intensity (a.u.)

Time

(

s

)

Figure 4: Chromatogram of the samples that suffered

degradation with the reaction time of 20 min.

It can be observed that the β-PVDF films with

ITO electrodes did not influence the analyses results.

The opposite happens when the electrodes of the

β-PVDF film include aluminium, even in small

concentrations, like the transparent conductive AZO.

4 CONCLUSIONS

The application of acoustic thermoagitation through

the β-PVDF piezoelectric polymer is gainful when

fluids need to be mixed in a microfluidic device. It

reduces the mixing time resulting in a fast, complete

and homogeneous reaction of the reactants,

improving the global performance of the analysis

that is being performed.

With the optimization tests, it was proved that

better mixing results were obtained with the

electrical signal for actuation at the resonance

frequency of the film and with an amplitude of 10V.

Moreover, it was demonstrated that the improvement

of the mixture is mainly due to the heating of the

solution.

In the degradation study, it was verified that, for

all electrodes, the ITO is the one which does not

degrade in contact with the uric acid kit.

ACKNOWLEDGEMENTS

Work supported by the Portuguese Science

Foundation (grants PTDC/BIO/70017/2006,

PTDC/CTM/69362/2006).

REFERENCES

Auroux, P., Iossifidis, D., Reyes, D. R., Manz, A., 2002,

Micro Total Analysis Systems: Analytical Standard

Operations and Applications. Anal. Chem., 74, p.

2637-2652.

Reyes, D. R., Iossifidis, D., Auroux, P., Manz, A., 2002,

Micro Total Analysis Systems. 1. Introduction,

Theory, and Technology. Anal. Chem., 74, p. 2623-

2636.

Rife, J. C., et. al., 2000, Miniature Valveless Ultrasonic

Pumps and Mixers. Sensors and Actuators B., 86, p.

135-140.

Ottino, J. M., Wiggins, S., 2004, Introduction: Mixing in

Microfluidics. Phil. Trans. R. Soc. Lond. A. 362, p.

923-935.

Lanceros-Mendez, S., Sencadas, V., Gregorio Filho, R.,

Portuguese patent n.º 103318.

Thomas, M., 1999, Ultraviolet and visible spectroscopy.

Analytical Chemistry by Open Learning, p. 2-47.

Frampton, K. D., Minor, K., Martin, S., 2004, Acoustic

streaming in micro-scale cylindrical channels. Applied

Acoustic, Vol. 65, p. 1121-1129.

Brown, L. F., 1992, Ferroelectric Polymers: current and

future ultrasound applications. In IEEE Ultrason.

Symp. Proc. p. 539-550.

Foster, F. S., 2000, A history of medical and biological

imaging with polyvinylidene fluoride (PVDF

transducers. In IEEE Transactions on Ultrasonics,

Ferroelectrics and Frequency Control. Vol. 47 Nº 6.

Eiras, J. A., 2007, Piezoelectric Materials. Departamento

de Física, Universidade Federal de São Carlos, Brasil.

ACOUSTIC THERMOAGITATION BASED ON PIEZOELECTRIC ß-PVDF POLYMER FILMS - Potential Evaluation

in Lab-on-a-Chip Applications

397